Performance data accompanying product service life and reliability predicting method thereof

A prediction method and technology of product life, applied in prediction, data processing application, calculation, etc., can solve problems such as uncertain product performance life, unknown, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

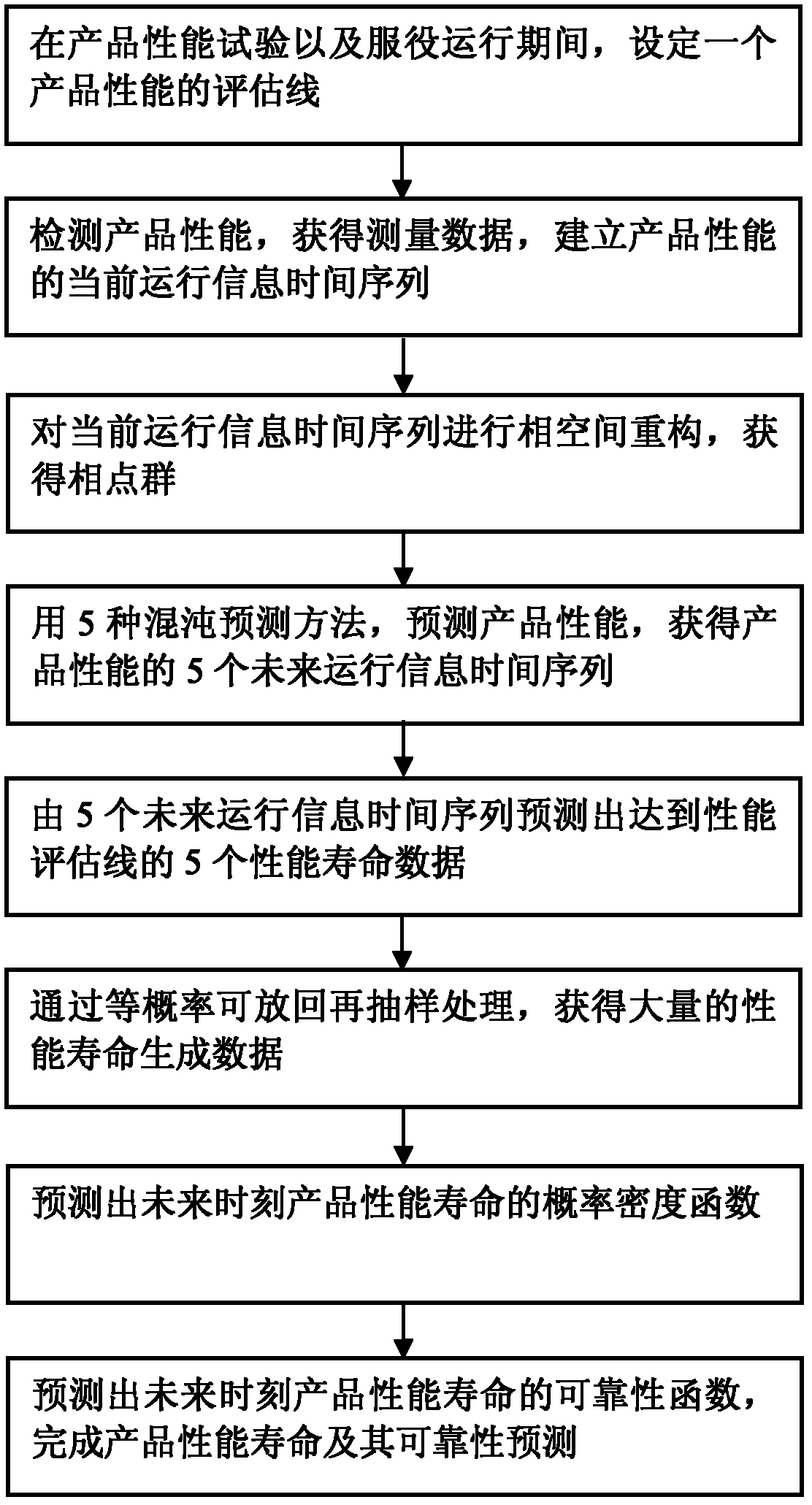

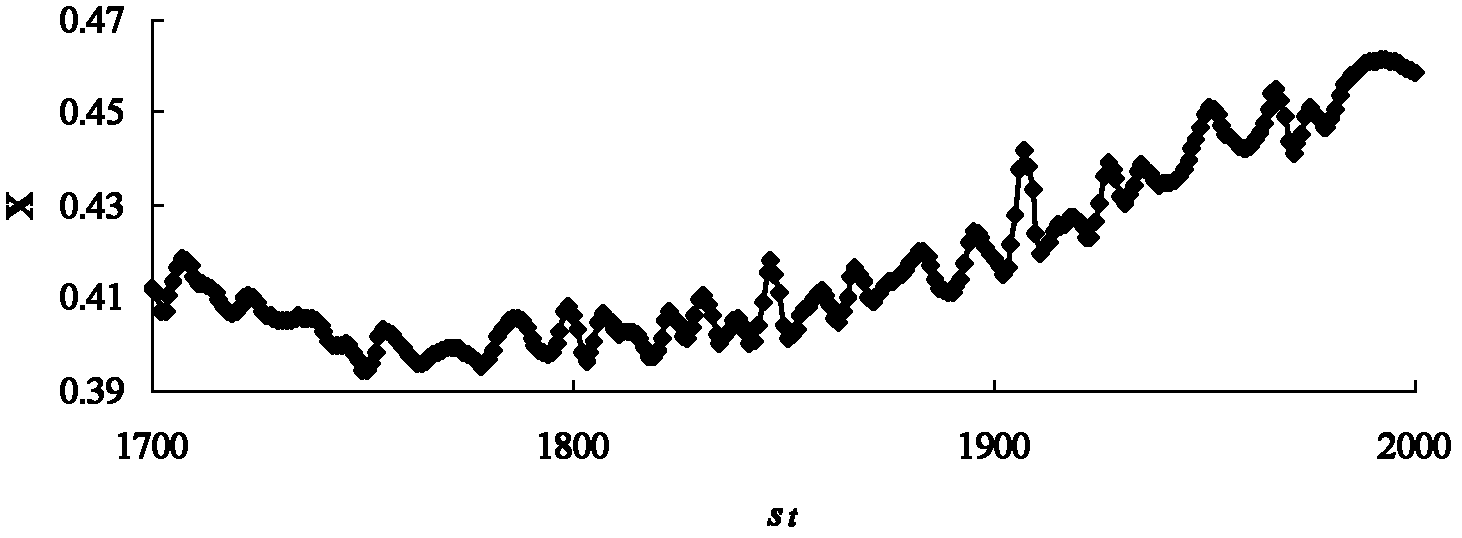

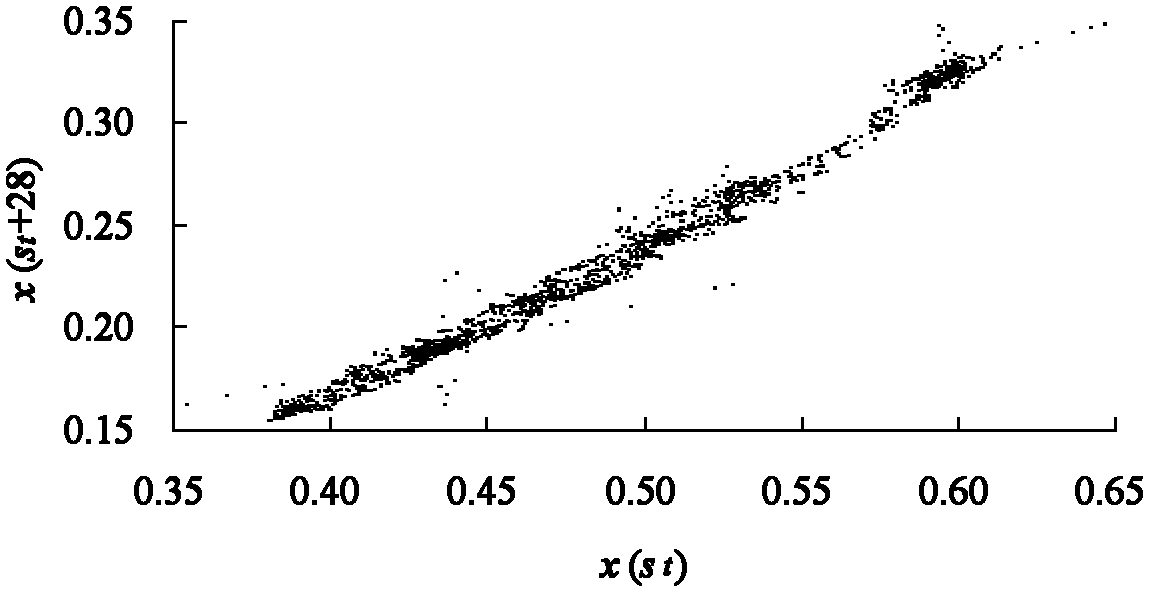

[0070] This is an example of simulating the lifetime and reliability prediction of a rolling bearing with friction torque data. Let the evaluation line X of bearing friction torque be 0 = 0.465m Nm, N = 2000 data of a certain bearing friction torque obtained through experiments, as the current moment t N Time series of current running information of time units. Calculating the Maximum Lyapunov Exponent λ Using Chaotic Time Series Theory 1 =0.032, the effective prediction time interval is T=31 time units. The problem in this implementation case is to predict when the bearing friction torque reaches the evaluation line X 0 = 0.465m Nm before the future operating life time and its reliability. Through this implementation case, the specific operation steps and calculation process of the present invention will also be described, and the flow chart is shown in figure 1 .

[0071] (1) Set product performance evaluation line

[0072] During the bearing friction torque test, let...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com