Patents

Literature

86 results about "Product lifetime" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Product lifetime or product lifespan is the time interval from when a product is sold to when it is discarded. It is slightly different from service life because the latter consider only the effective time the product is used.

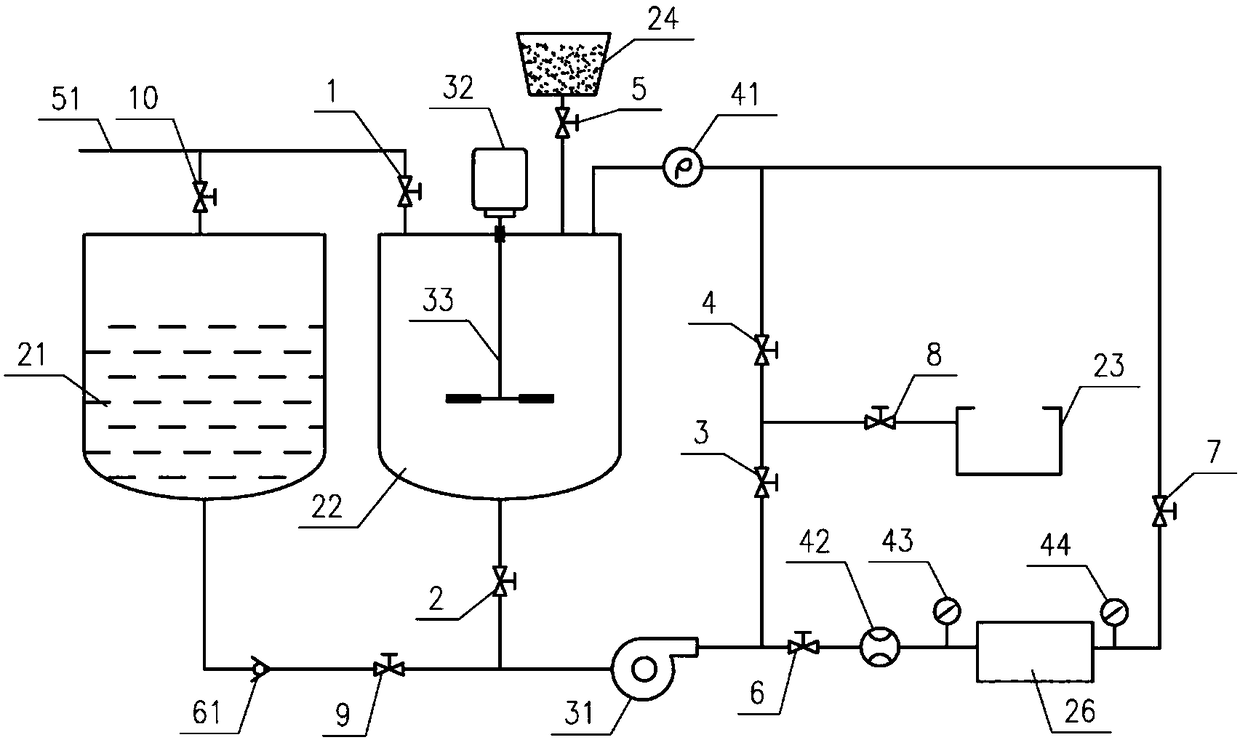

Fluid product service life testing device and testing method

PendingCN108254276AImprove work efficiencyPrevent sinkingInvestigating abrasion/wear resistanceProduct testingBiomedical engineering

The invention provides a fluid product service life testing device. The fluid product service life testing device comprises a fluid generation device, a fluid product testing region and a washing device, wherein a fluid circulating pipeline is formed between the fluid generation device and the fluid product testing region; fluid flows into the fluid product testing region from the fluid generationdevice and then continually flows back into the fluid generation device; the washing device is communicated with the fluid circulating pipeline; the washing device is communicated with the fluid product testing region and then is communicated with the fluid generation device through the fluid circulating pipeline; the fluid generation device is connected with a sediment recycling device. The fluid product service life testing device can be used for testing the service life of a product through simulating fluid flowing of production conditions.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

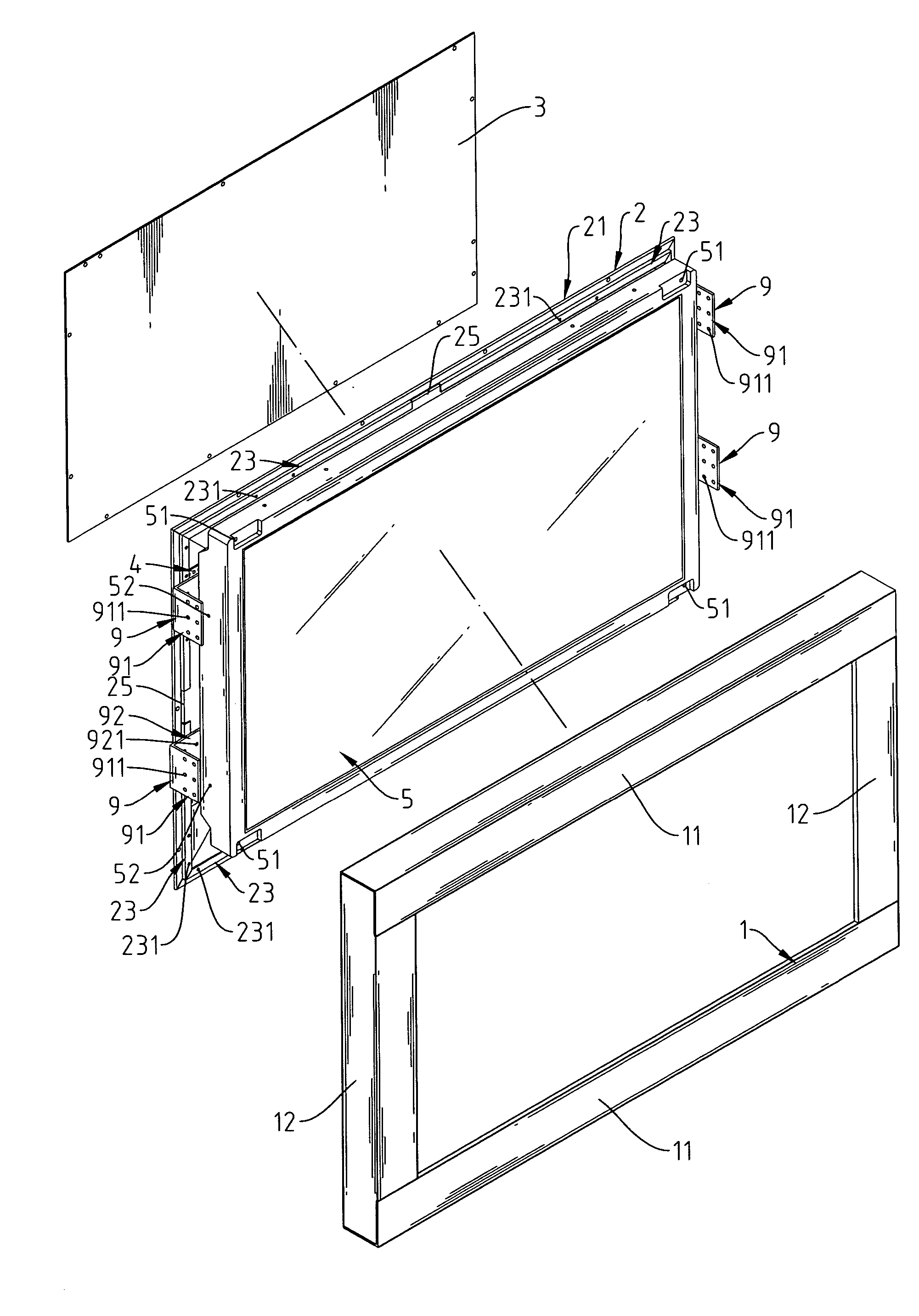

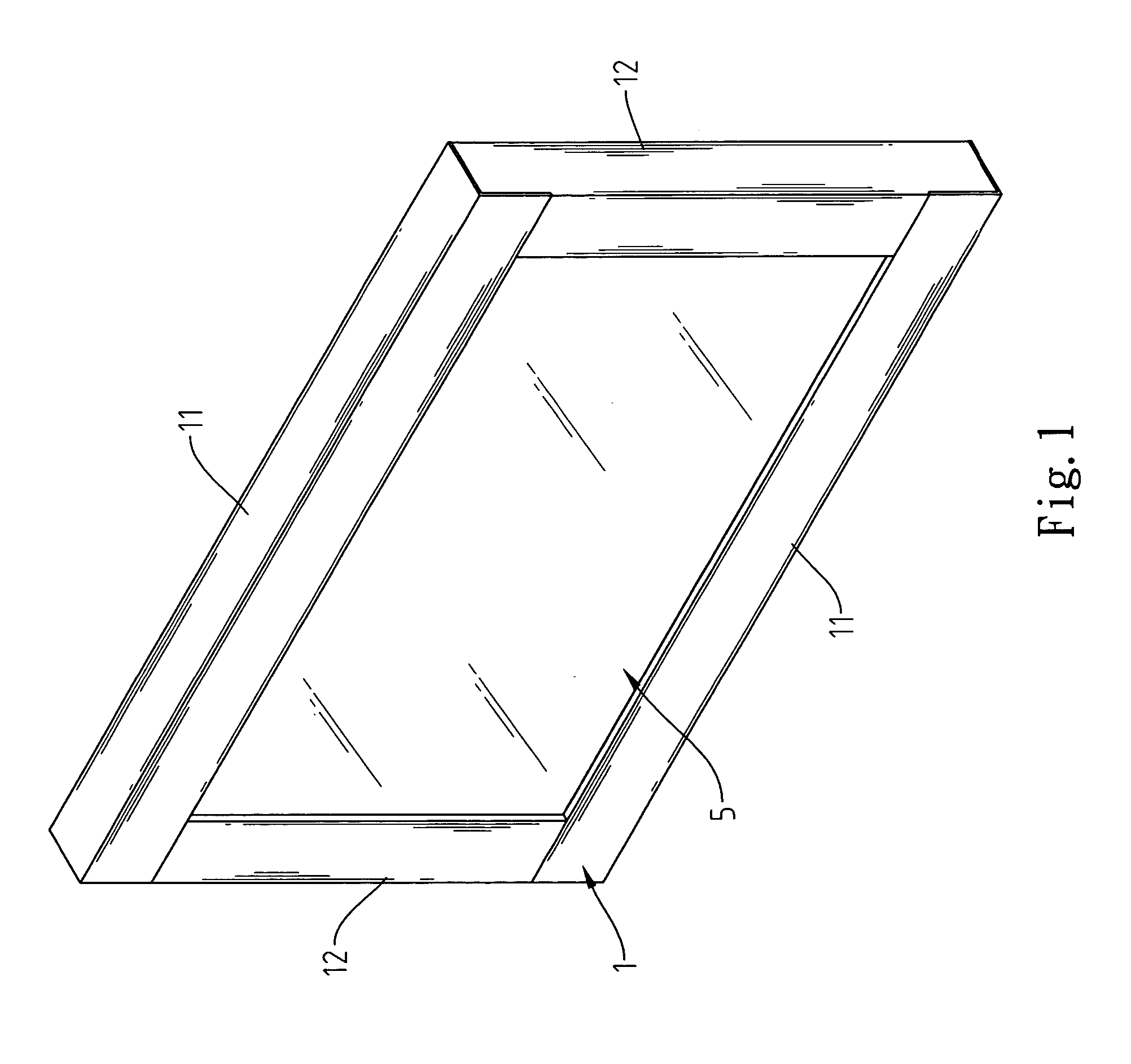

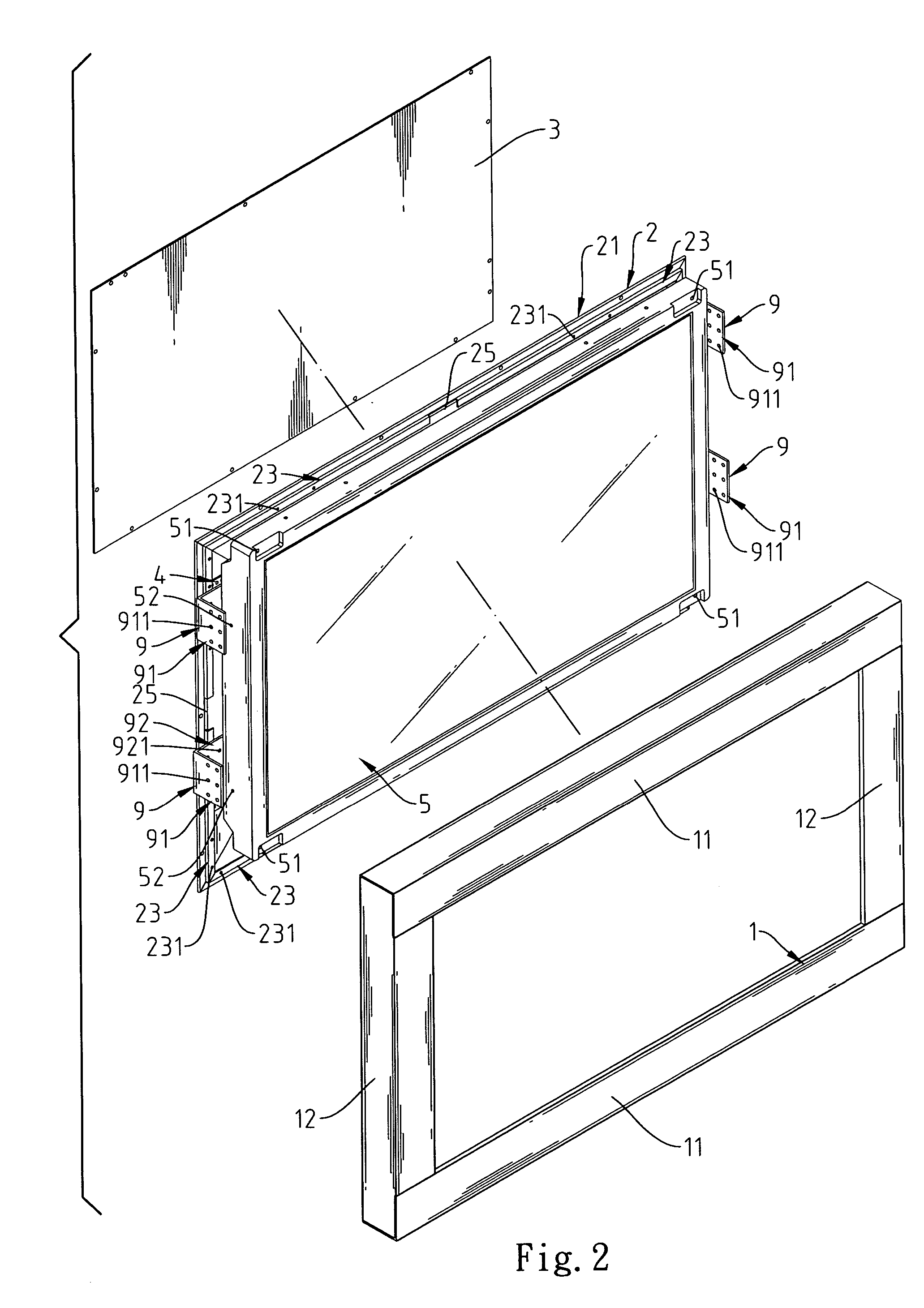

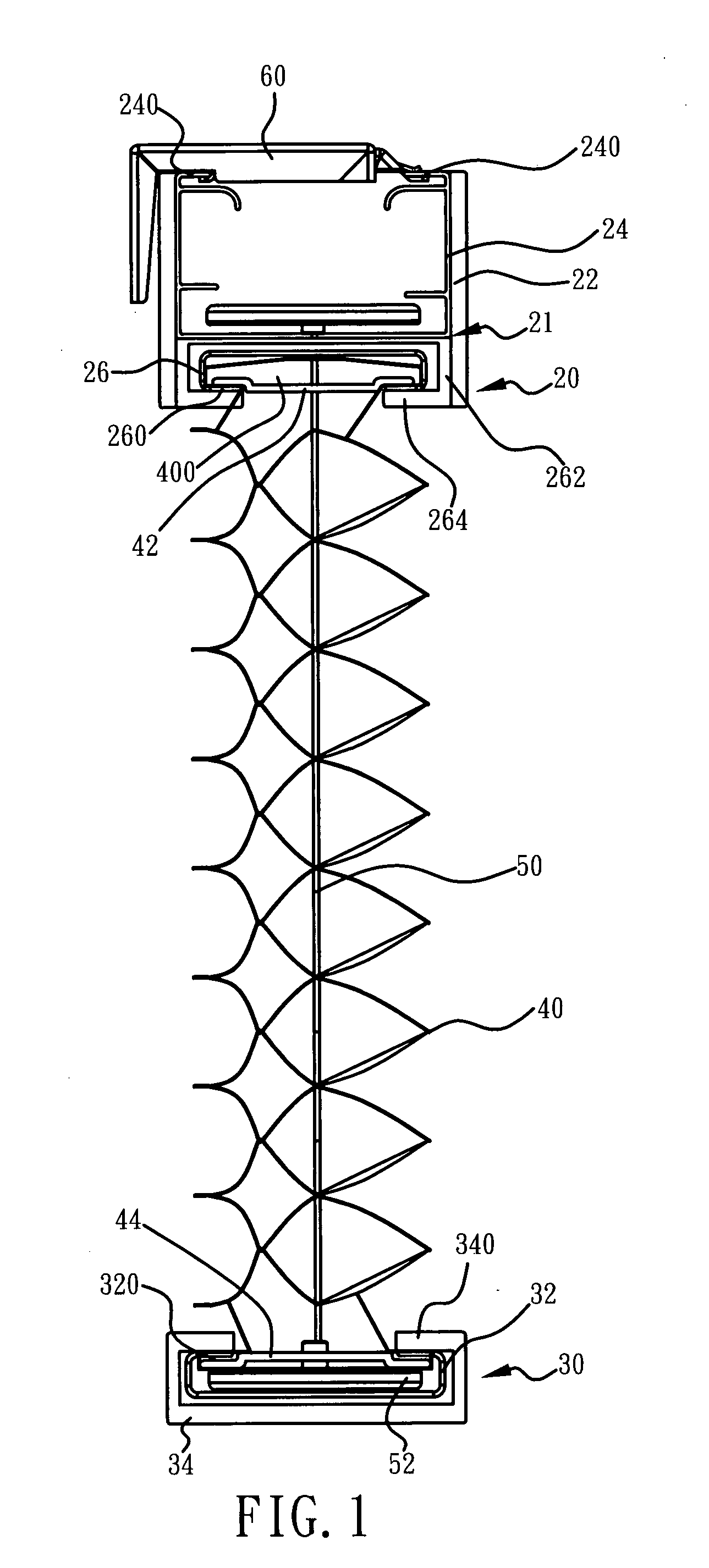

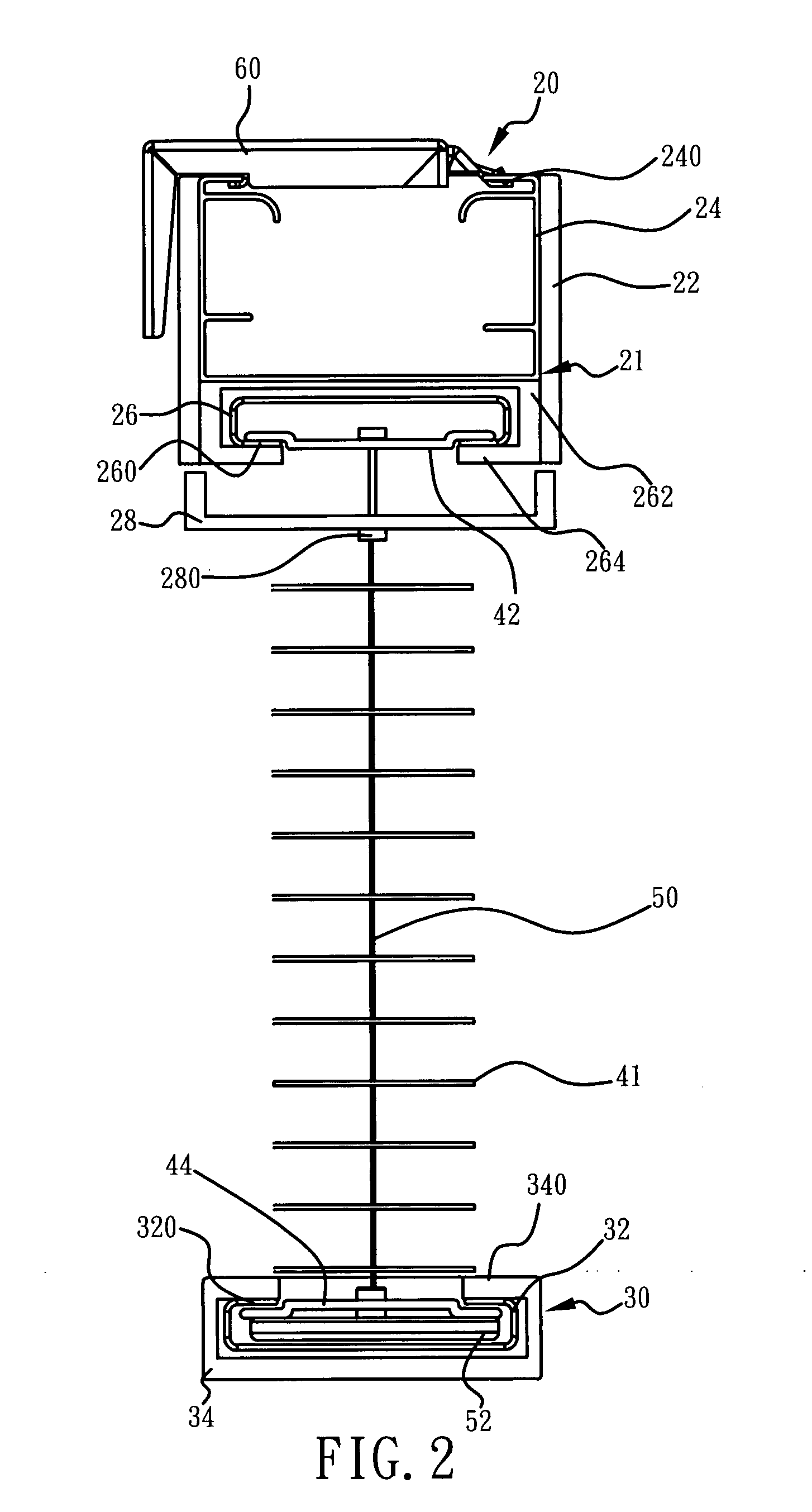

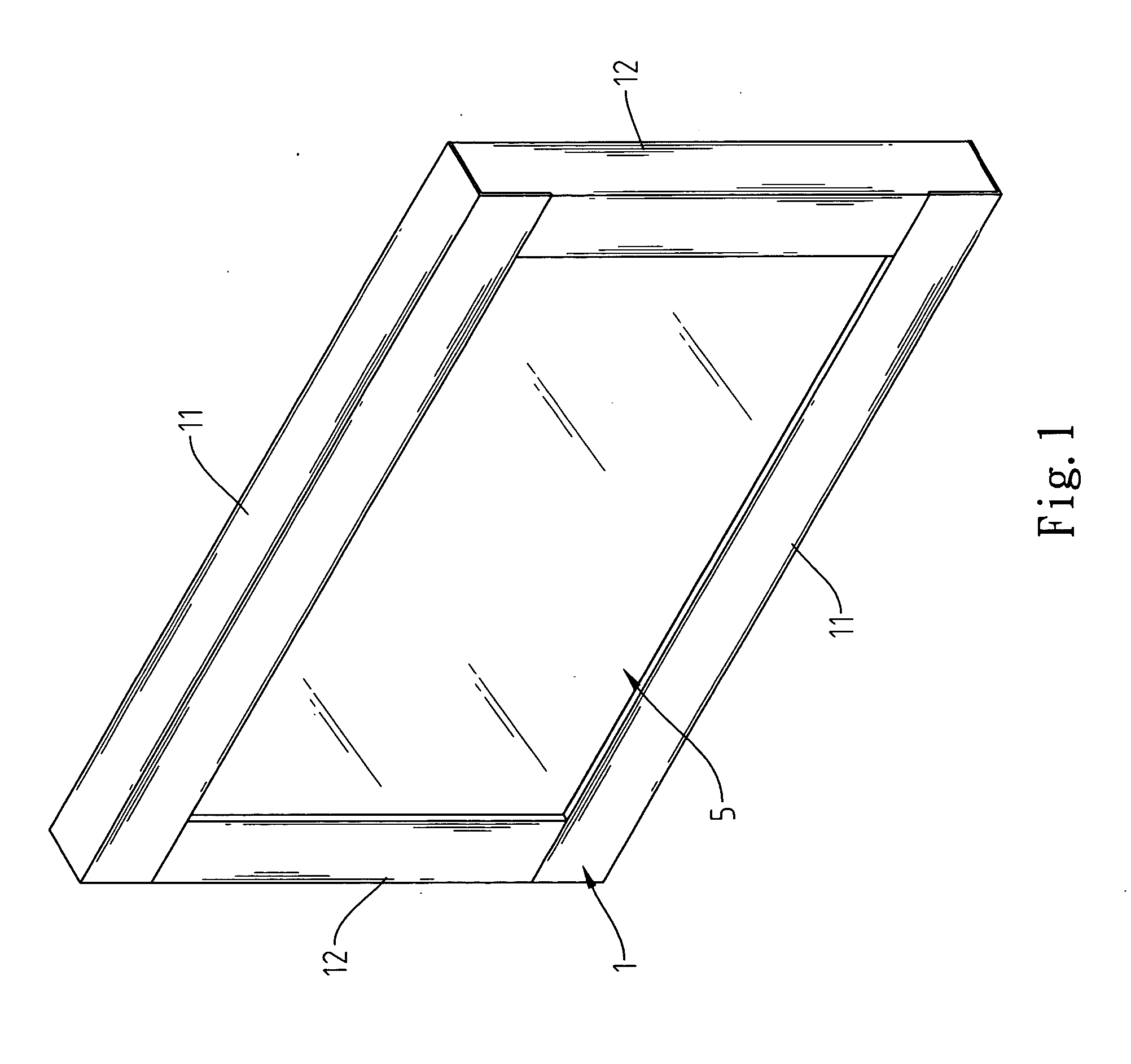

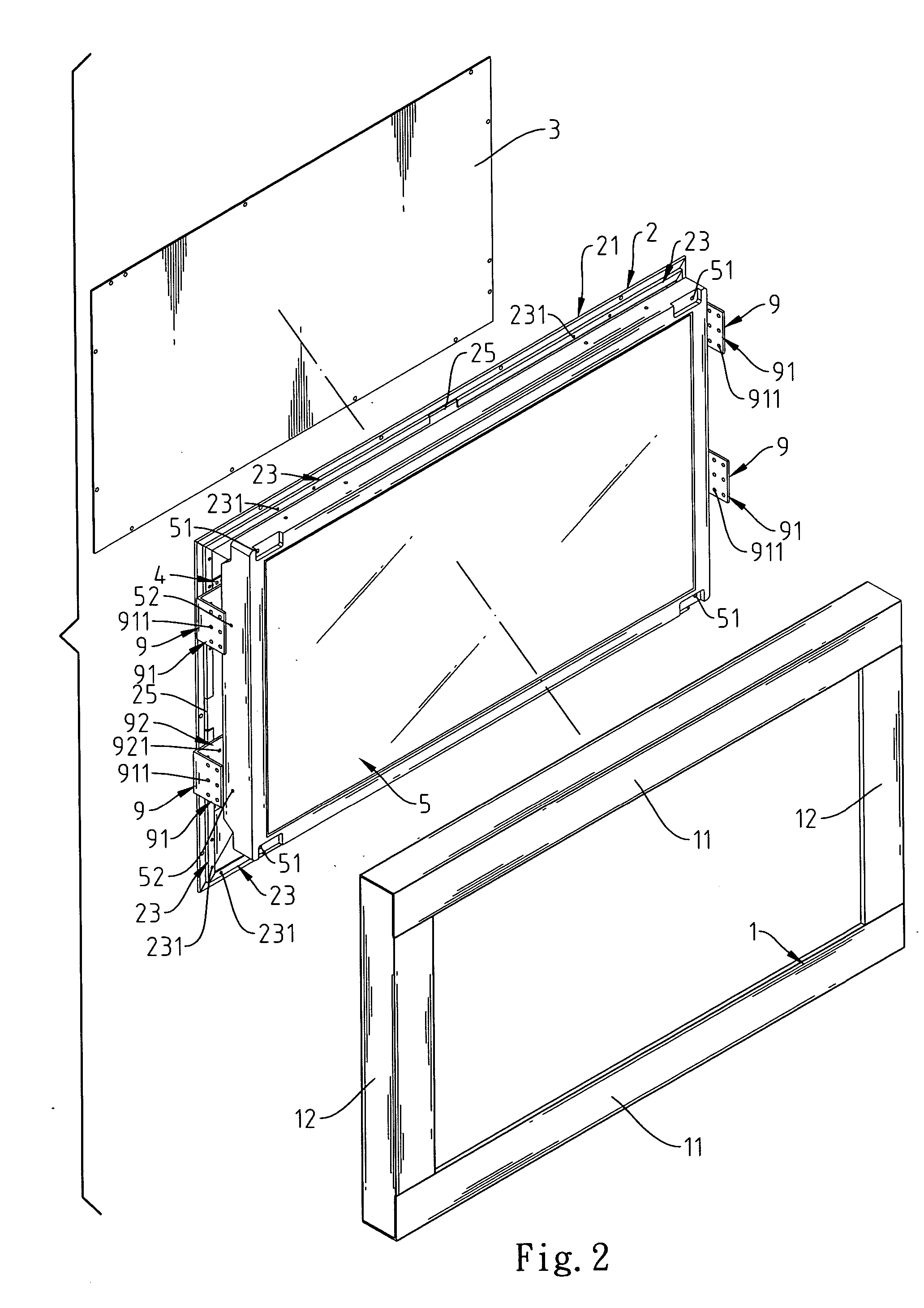

Composite structure of aluminum extrusion external framework of LCD monitor

InactiveUS7319499B2Digital data processing detailsElectrical apparatus contructional detailsLiquid-crystal displayEngineering

An aluminum extrusion external framework of LCD monitor primarily comprises a front frame cap, a back frame cap, and a sheathing, which are assembled with one another. Several movable laminas are mounted on the inside of the back frame cap, wherein the locking positions of the movable laminas are adjustable. The aluminum extrusion external framework of the LCD monitor is made of aluminum for lightening its weight and conforming to the recycle-based environmental protection so as to facilitate the heat sinking, reduce the production cost, and increase the product lifetime. Besides, the movable laminas are applied to the raised slideways around the inside of the back frame cap so as to be universally suitable for the existing LCD panel having various specifications and dimensions.

Owner:PENG CHING LUNG

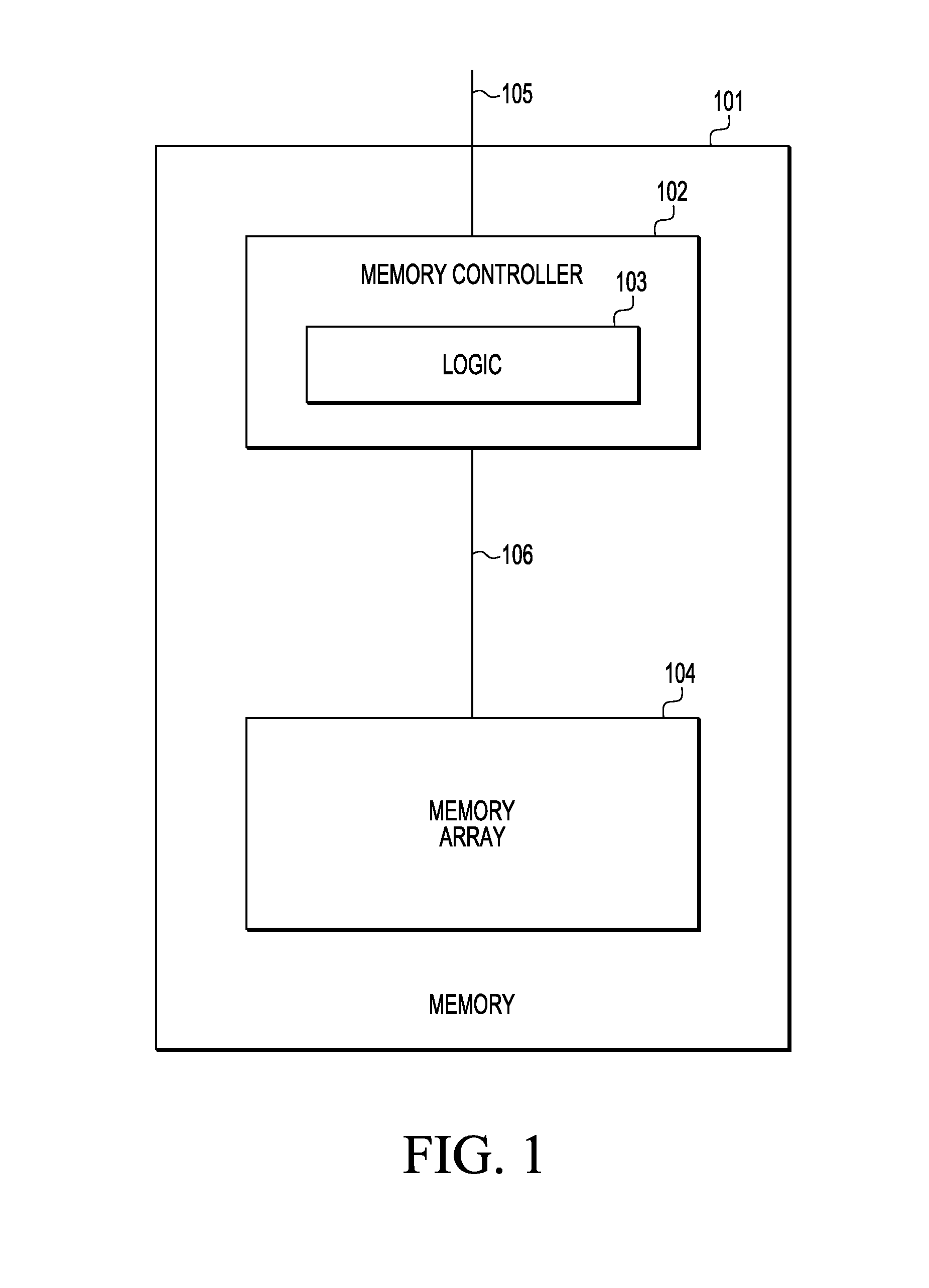

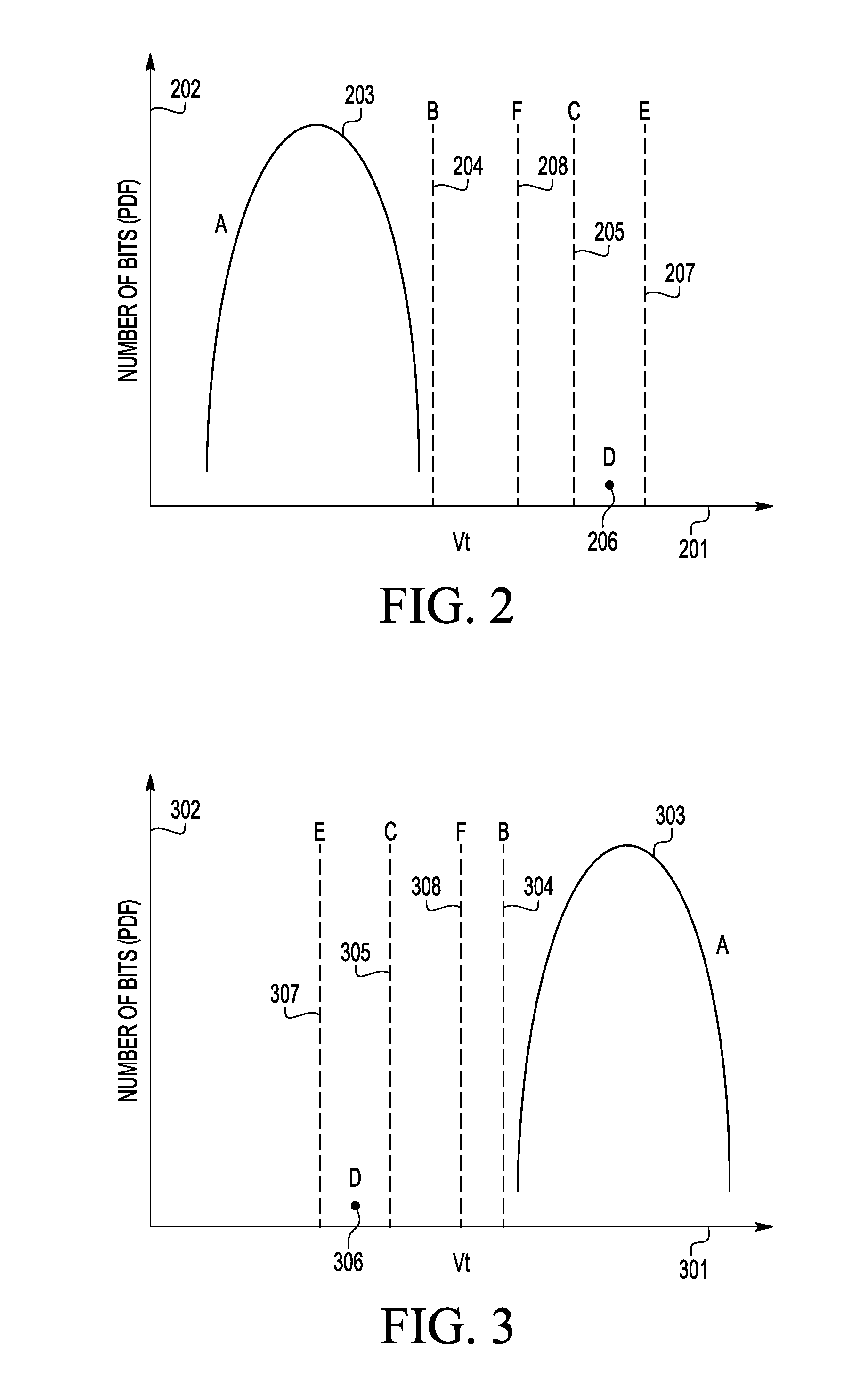

Dynamic read scheme for high reliability high performance flash memory

In accordance with at least one embodiment, a method and apparatus for improving the ability to correct errors in memory devices is described. At least one embodiment provides a way to salvage the part even it has double-bit or multi-bit error from the same ECC section, thus improving product reliability and extending the product lifetime. During a normal read, if a double-bit or multiple-bit error happens, which ECC can detect but cannot fix, the error is corrected by adjusting the read voltage level and reading again to determine the proper read level (and, therefore, the correct value being read). This dynamic read scheme can apply to extrinsic bits from either erase state or program state. It can be also used in a single bit scenario to minimize ECC occurrence and save ECC capacity.

Owner:VLSI TECH LLC

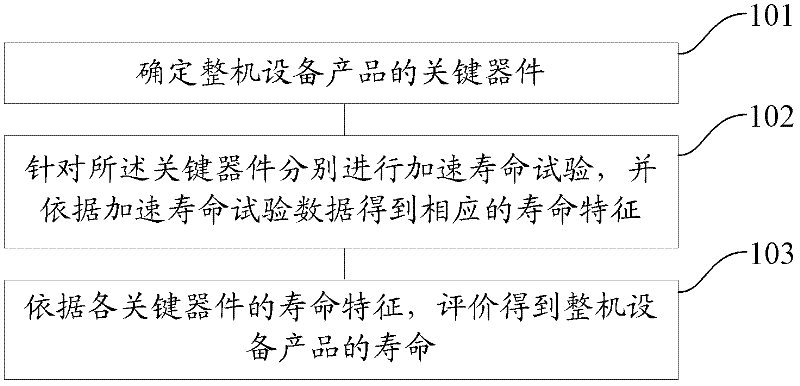

Method and device for evaluating life of product

The invention provides a method and a device for evaluating the life of a product. The method comprises the following steps of: determining key devices of a complete machine equipment product; performing an accelerated life test on each key device, and obtaining the corresponding life characteristic according to accelerated life test data; and evaluating the life of the complete machine equipment product according to the life characteristic of each key device. By the method and the device, time for evaluating the life of the product can be shortened, and the cost of evaluating the life of the product can be reduced.

Owner:DATANG MOBILE COMM EQUIP CO LTD

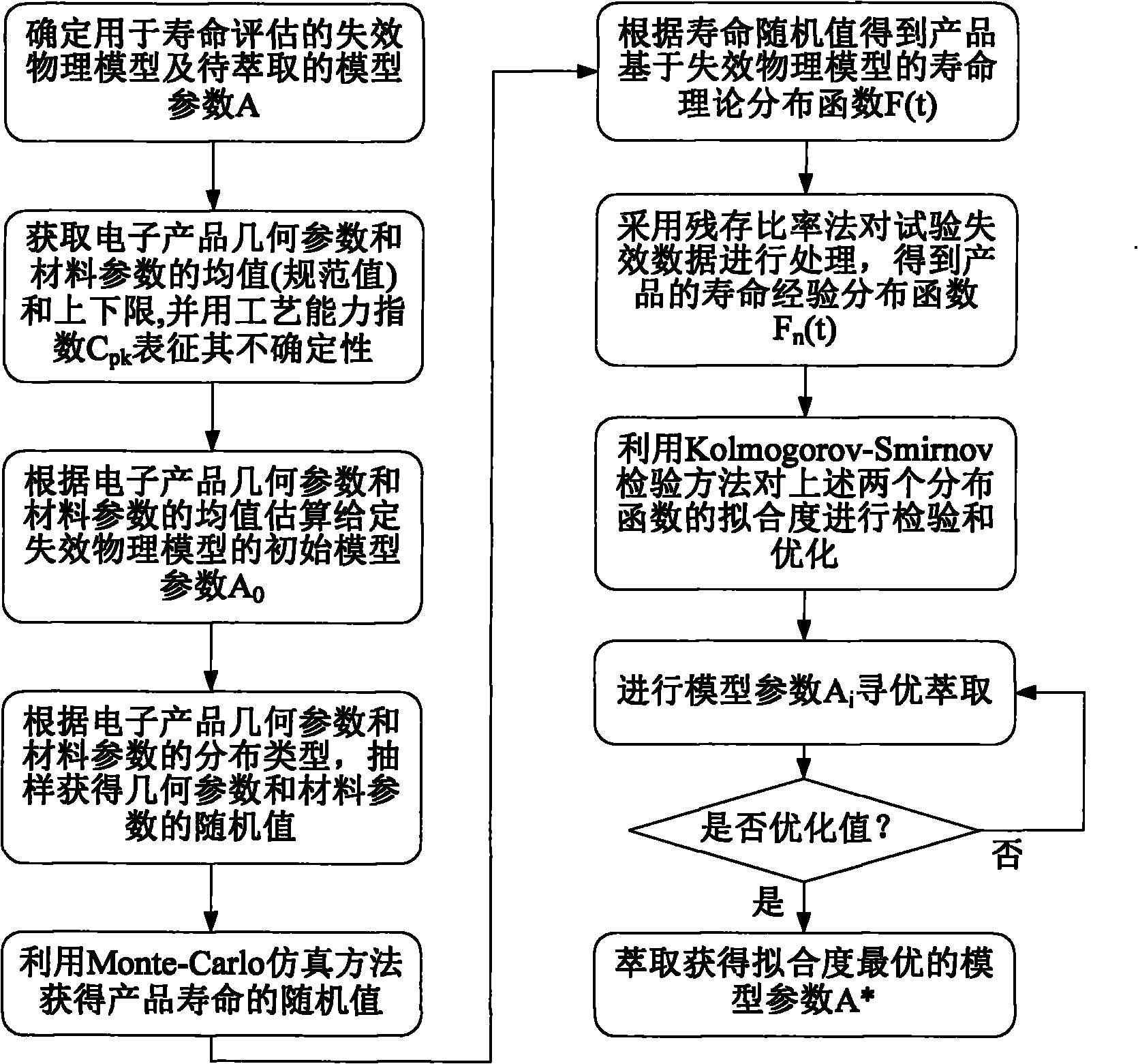

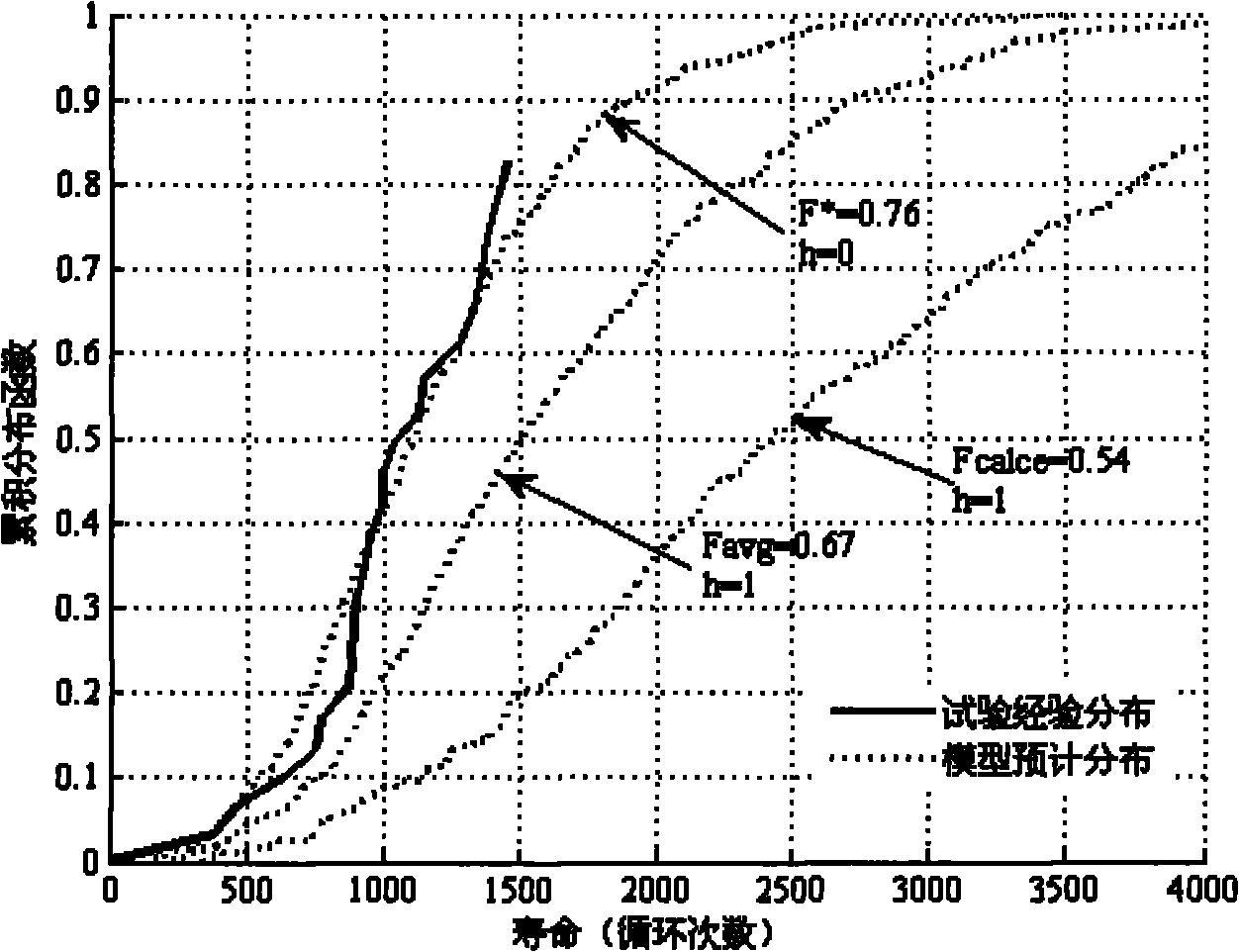

Practical electronic product service life evaluation model parameter high-accuracy extraction method

ActiveCN102103658AGuaranteed accuracyAddress usability bottlenecksSpecial data processing applicationsPhysical modelData mining

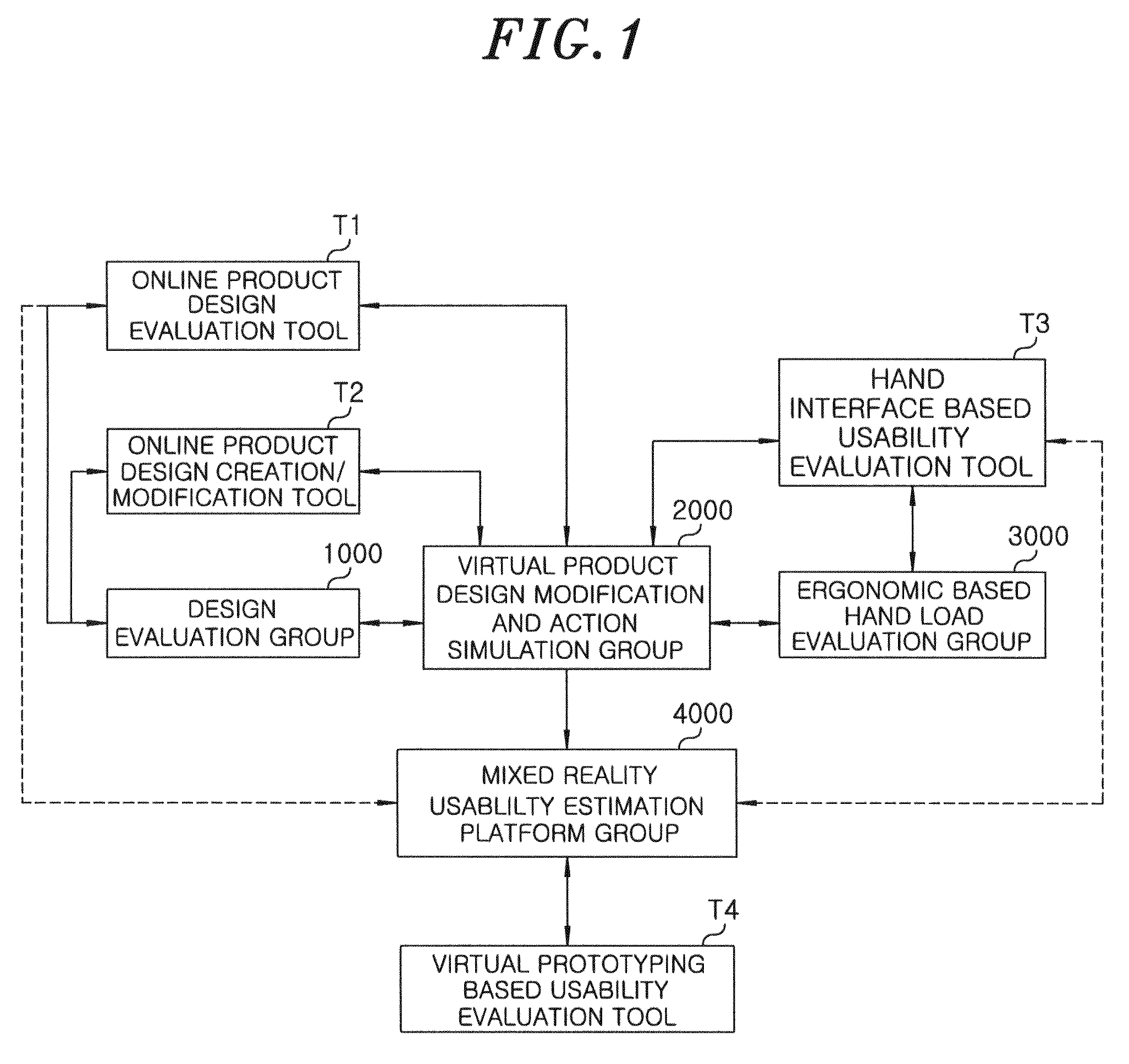

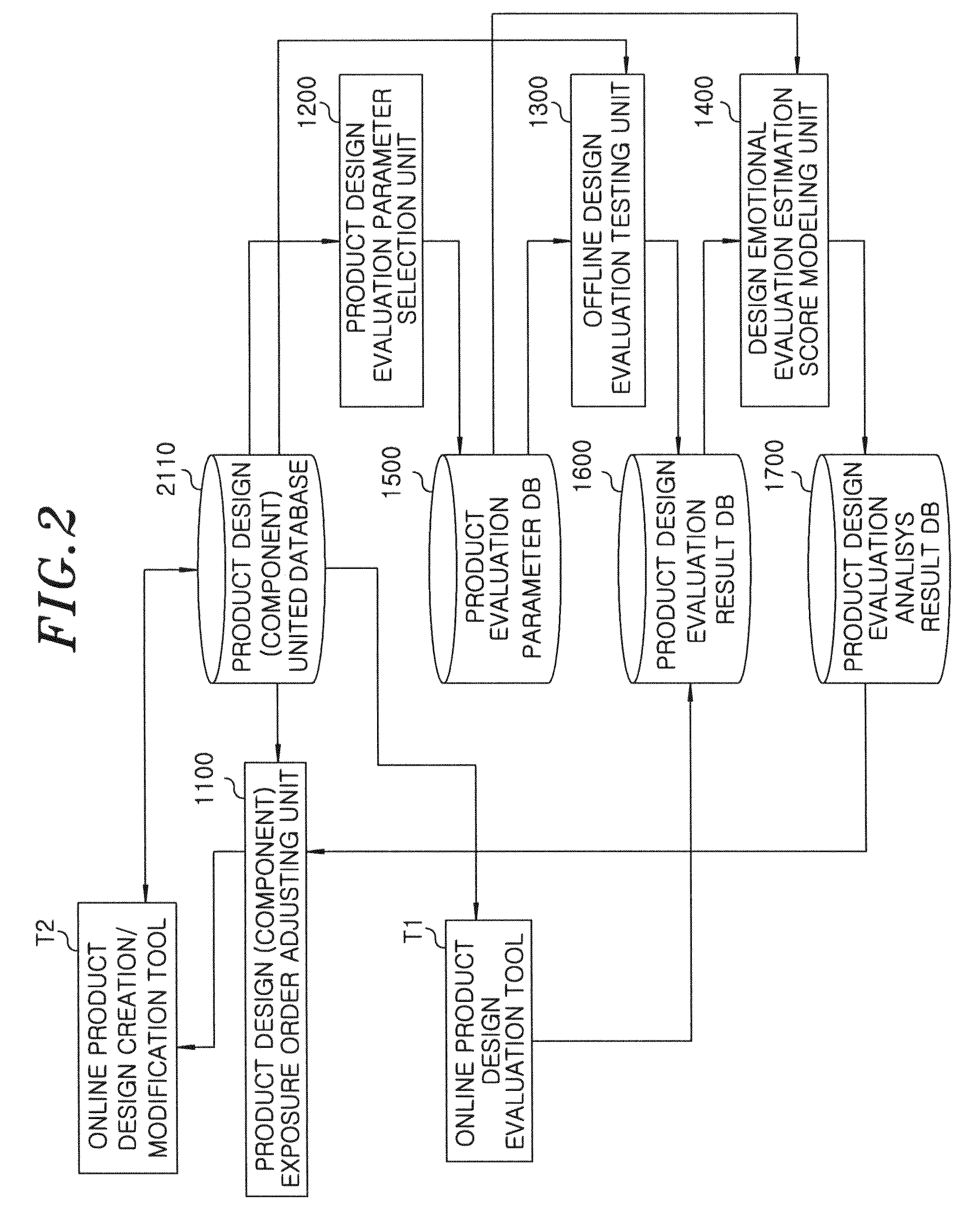

The invention discloses a practical electronic product service life evaluation model parameter high-accuracy extraction method, which comprises the following steps of: (1) determining a failure physical model and model parameters to be extracted; (2) acquiring mean values, upper limits and lower limits of geometric and material parameters of a product, and representing the uncertainty of the parameters by adopting process capability indexes; (3) evaluating initial model parameters of the failure physical model according to the mean values of the geometric and material parameters of the product; (4) performing sampling according to distribution types of the geometric and material parameters to obtain random values of the geometric and material parameters; (5) obtaining the random value of the service life of the product by combining a Monte-Carlo simulation method; (6) obtaining a theoretical distribution function of the service life of the product according to the random value of the service life; (7) processing experimental failure data by adopting a remaining ratio method to obtain an empirical distribution function of the service life of the product; (8) checking a degree of fitting of the two service life distribution function by utilizing a K-S checking method; and (9) performing optimal extraction on the model parameters until the model parameters with an optimal degree of fitting are obtained.

Owner:北京可维创业科技有限公司

Usability evaluation method and system of virtual mobile information appliance

InactiveUS20090157478A1Digitally marking record carriersLink editingDigital dataUsability assessment

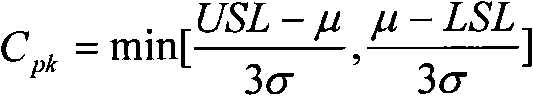

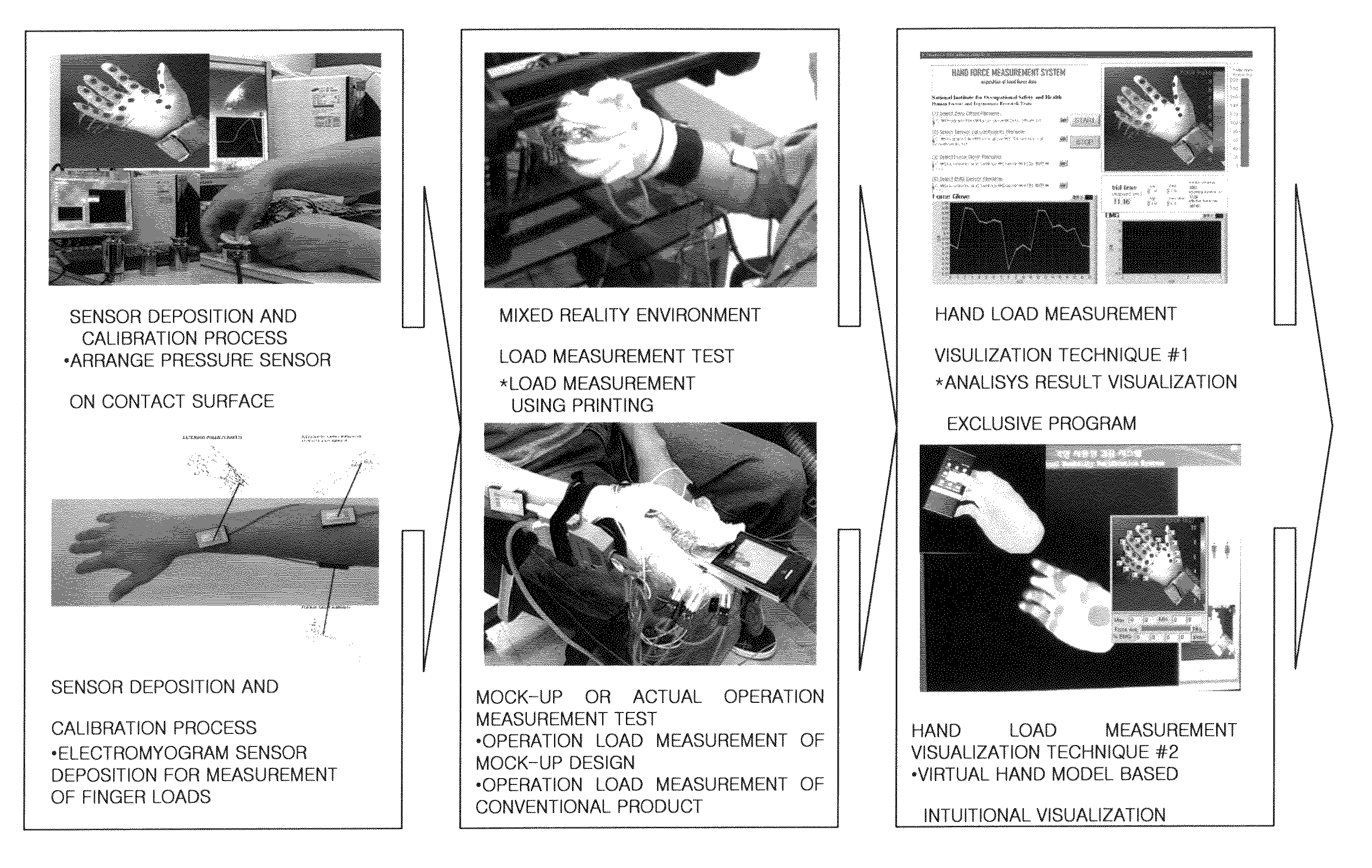

A system for evaluating usability of a virtual mobile information appliance unites a virtual reality technology integrating various digital data created in planning and in designing a product to operate a virtual product and visualizing the virtual product in photo-realistic level, an affective technology organizing a customer's emotional evaluation on a product's design in view of engineering, an ergonomic technology quantatively measuring and analyzing body force activity involved in the operation of a product in a biomechanic manner, and a mixed reality technology supporting both tangible interface capable of directly touching the digital data and a photo-realistic visualization, to thereby finding problems of usability early, obtaining improvements such as a design of the product, improving efficiently an overall quality of the product and managing product-lifetime-cycle in a company manufacturing the product.

Owner:ELECTRONICS & TELECOMM RES INST

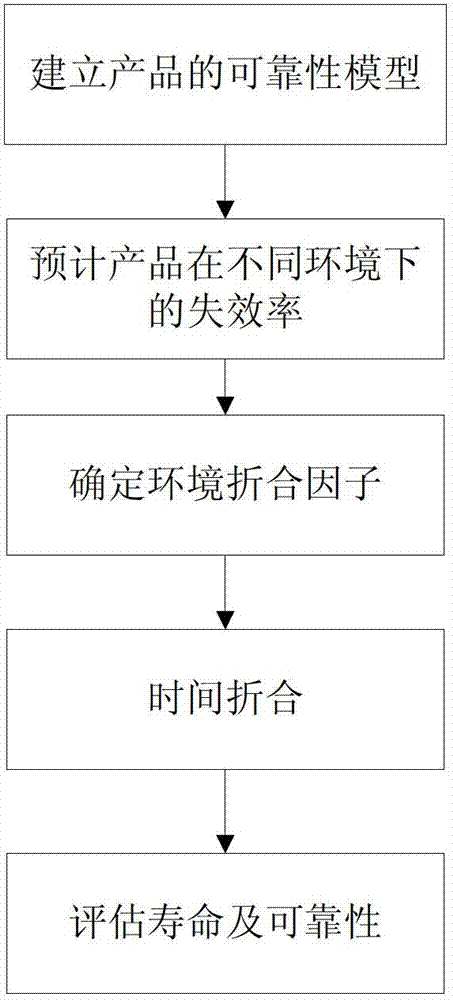

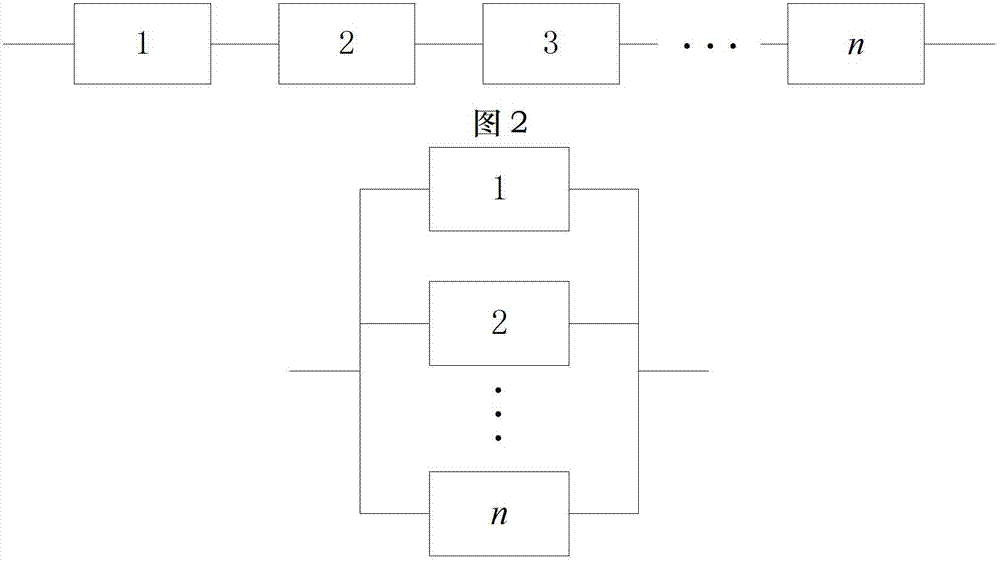

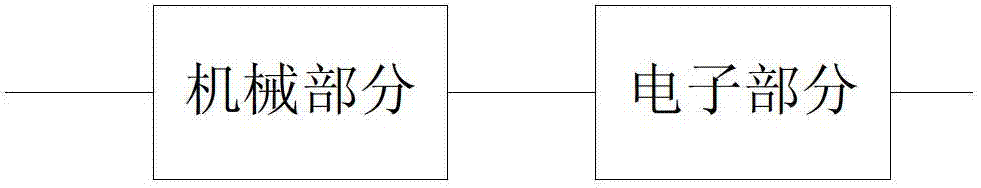

Comprehensive reliability evaluation method based on multi-test information

The invention discloses a comprehensive reliability evaluation method based on multi-test information. The method comprises the following specific steps of: 1, establishing a reliability model of a product; 2, estimating the failure rates of the product under different environments; 3, determining environment reduced factors; 4, performing time reducing and 5, evaluating the service life and reliability of the product. According to the method disclosed by the invention, multi-test information can be integrated, so that the service life and reliability of the product can be evaluated; under the condition that product samples and data are rare, the environment reduced factors under different conditions can be determined, and the evaluation on the service life and reliability of the product can be finished; and the invention provides a method for determining environment reduced factors by utilizing a product reliability estimation result, so that the process of determining the environment reduced factors is simplified, and the method disclosed by the invention can be applied more simply and conveniently.

Owner:BEIHANG UNIV

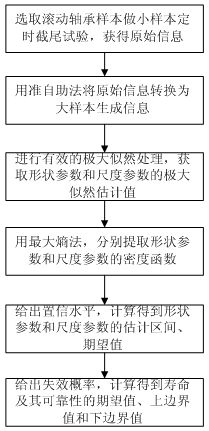

Poor information theory fusion-based product life characteristic information extraction method

InactiveCN102081767AAccurate acquisitionRestore original propertiesInstrumentsPattern recognitionSmall sample

The invention relates to a poor information theory fusion-based product life characteristic information extraction method, which comprises the following steps of: acquiring original information of a small sample; transforming the original information into large-sample generating information by using a right self-service method and performing effective maximum likelihood processing, and acquiring maximum likelihood estimated values of large-sample content of two parameters, namely a Weibull distribution shape parameter and a scale parameter; extracting density functions of the two parameters by using a maximum entropy method; giving a confidence level, and calculating estimation intervals and expected values of the two parameters through the density functions of the shape parameter and the scale parameter respectively; and giving a failure probability, and acquiring the product life characteristic information through Weibull distribution life of the two parameters and reliability calculation thereof. The method has no requirement on completeness of the original information of the small sample, does not need priori information of the shape parameter and the scale parameter, can effectively recover total original characteristics of the product life, disclose nature of the product life information, more accurately acquire the product life characteristic information and reduce the experimental quantity of the product.

Owner:HENAN UNIV OF SCI & TECH

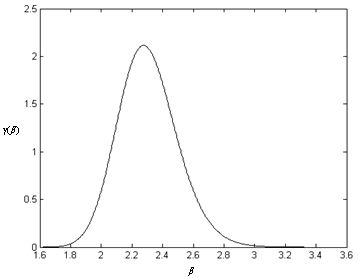

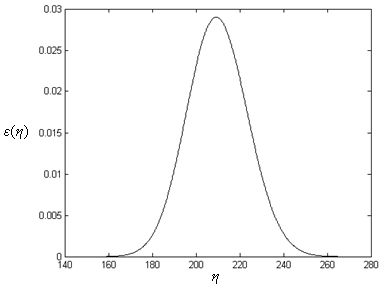

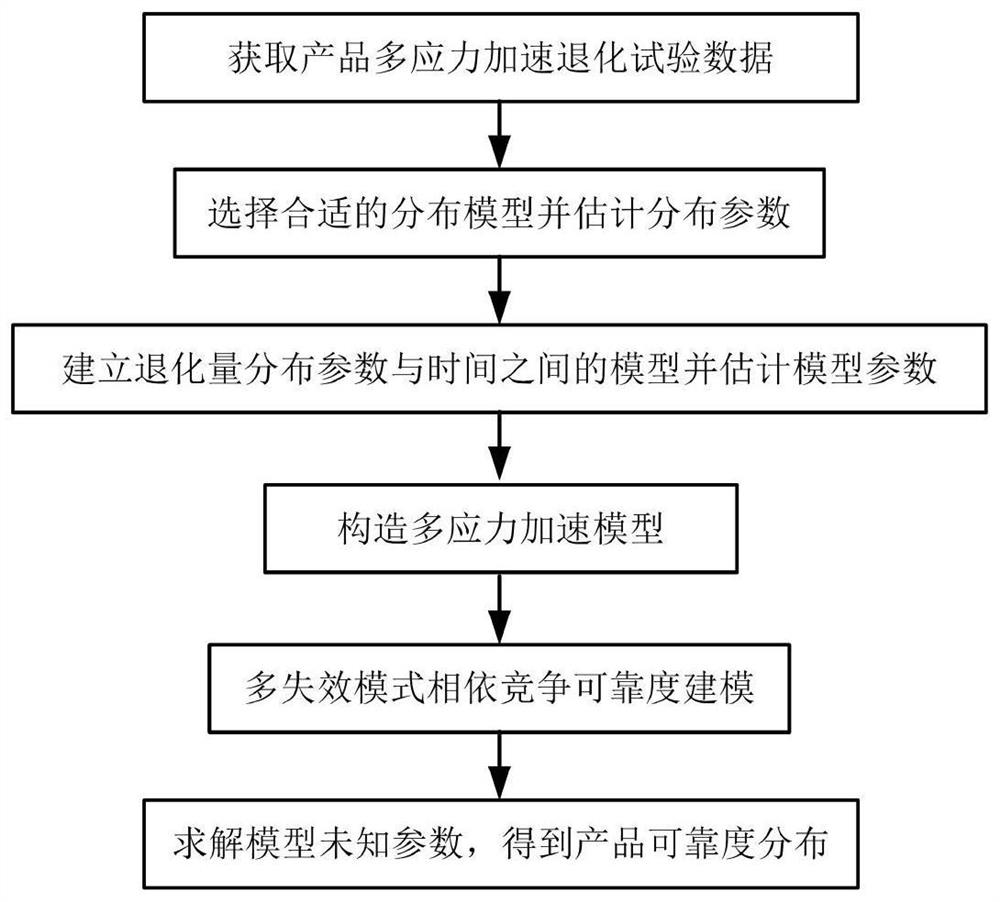

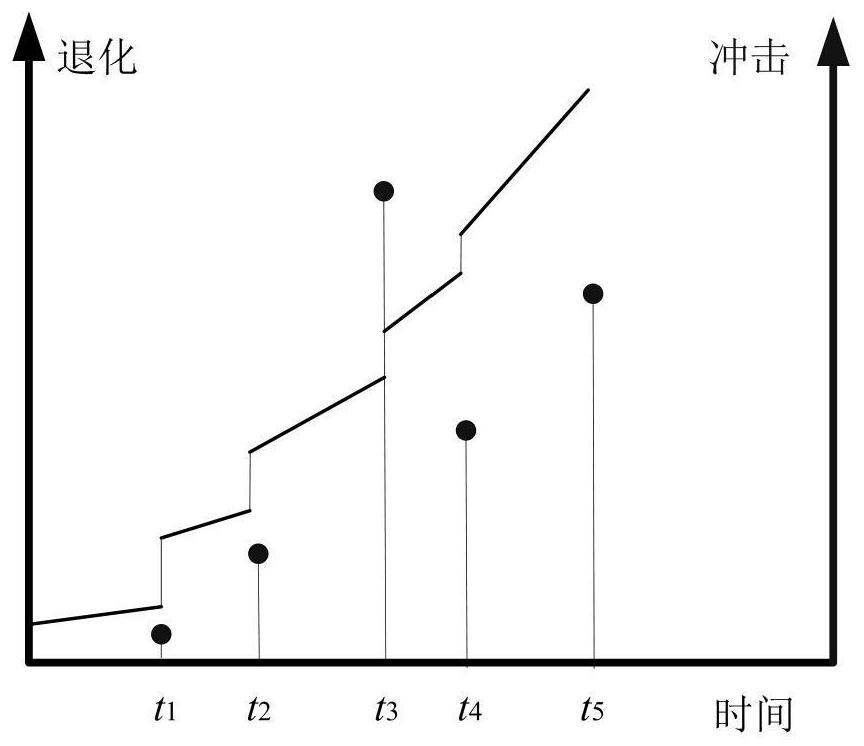

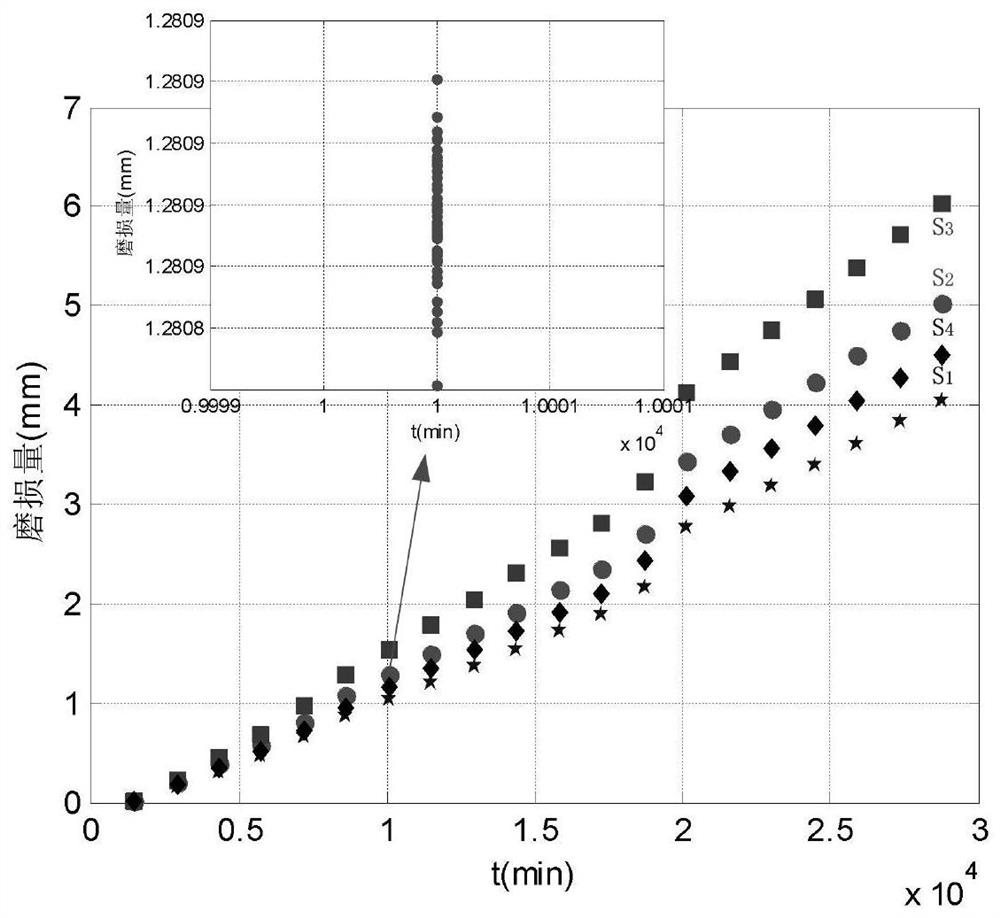

Accelerated degradation test statistical analysis method under multi-stress multi-failure mode dependent competition condition

ActiveCN112069697AIn line with engineering practiceExtend your lifeDesign optimisation/simulationProbabilistic CADAlgorithmStatistical analysis

The invention provides an accelerated degradation test statistical analysis method under a multi-stress multi-failure mode dependent competition condition. The method comprises the following steps: acquiring multi-stress accelerated degradation test data of a product; selecting a proper distribution model and estimating distribution parameters; establishing a model between the degradation amount distribution parameter and time and estimating a model parameter; constructing a multi-stress acceleration model; modelling multi-failure-mode dependent competitive reliability; and solving unknown parameters of the model to obtain product reliability distribution. The coupling influence of multiple stresses on life characteristics and the dependency of a degradation process and a random impact process are considered, a reliability function under the N stress M failure mode dependency competition condition is established, and the gap in the related research field is filled; based on product degradation amount distribution and a multi-stress multi-failure-mode dependent competition reliability model, an analysis method of an N-stress M-failure-mode dependent competition accelerated degradation test is established systematically for the first time, engineering practice is better met, the service life of a product is prolonged, and the accuracy of reliability evaluation is improved.

Owner:NAT UNIV OF DEFENSE TECH

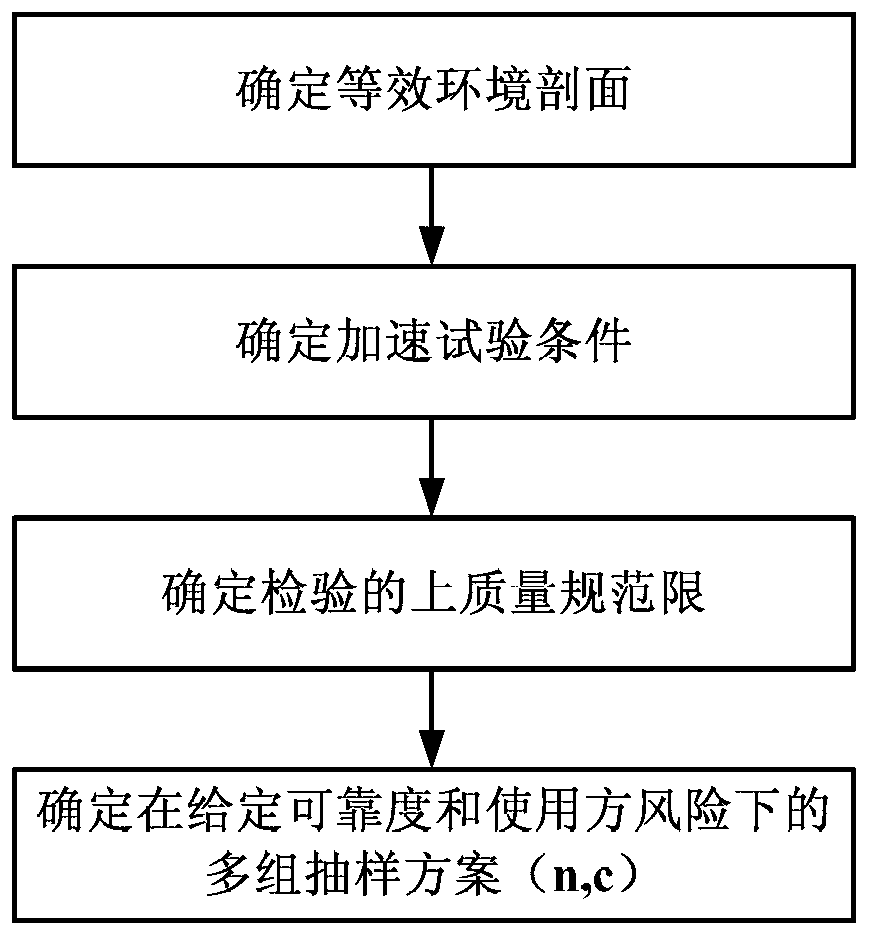

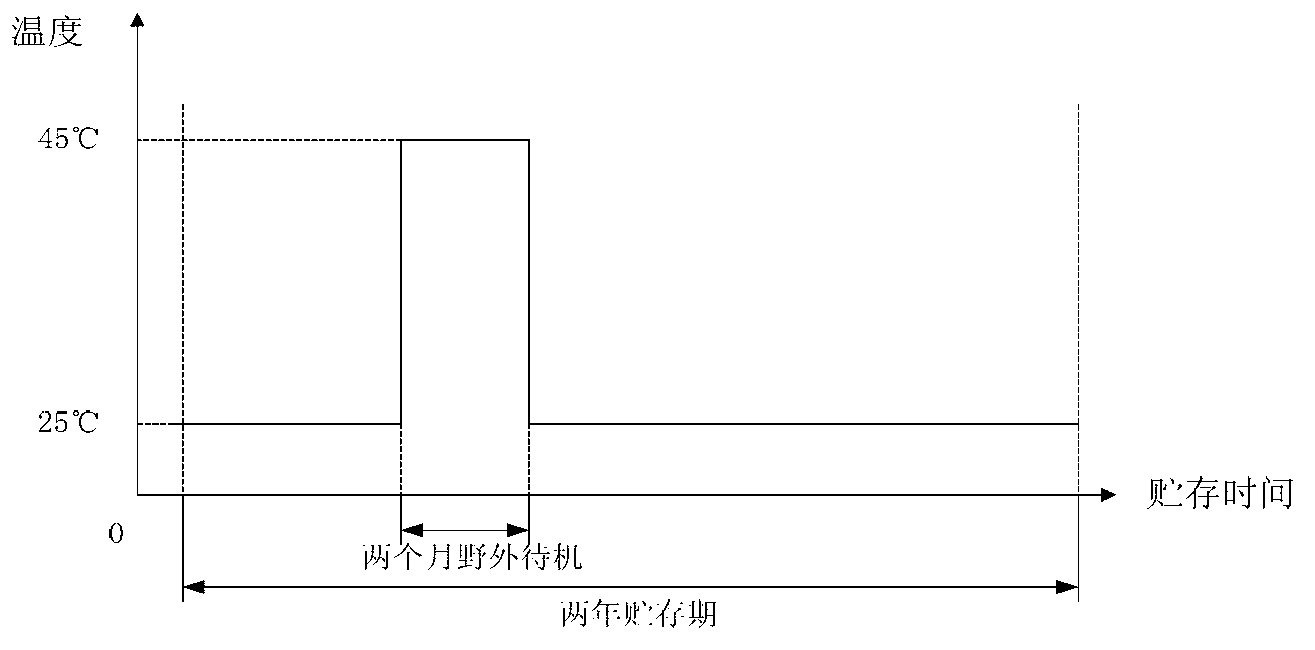

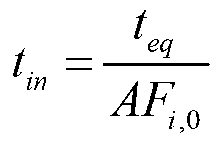

Product service life rapid test method based on physical model

InactiveCN103308723ASave test sample sizeSave test timeStructural/machines measurementTesting/calibration of speed/acceleration/shock measurement devicesTest samplePhysical model

A product service life rapid test method based on a physical model comprises the steps of determining an equivalent environment profile; determining acceleration test conditions; determining an upper quality specification limit of the test; and determining a plurality of groups of sampling plans (n, c) under the given reliability and user risk. According to the method, the degradation physical model and acceleration tests are combined, so that forming of service life rapid test schemes of products of different types can be effectively guided, and whether the batch of products can meet service life index requirements under specified utilization conditions and environment conditions is tested within a short time. The stability rapid test method for product performance parameters is provided through the performance parameter physical model, so that the test sample size and test time can be saved, and research and development costs can be reduced; and by means of the acceleration test method, product batch production test time can be greatly shortened, and test procedures can be simplified.

Owner:BEIHANG UNIV

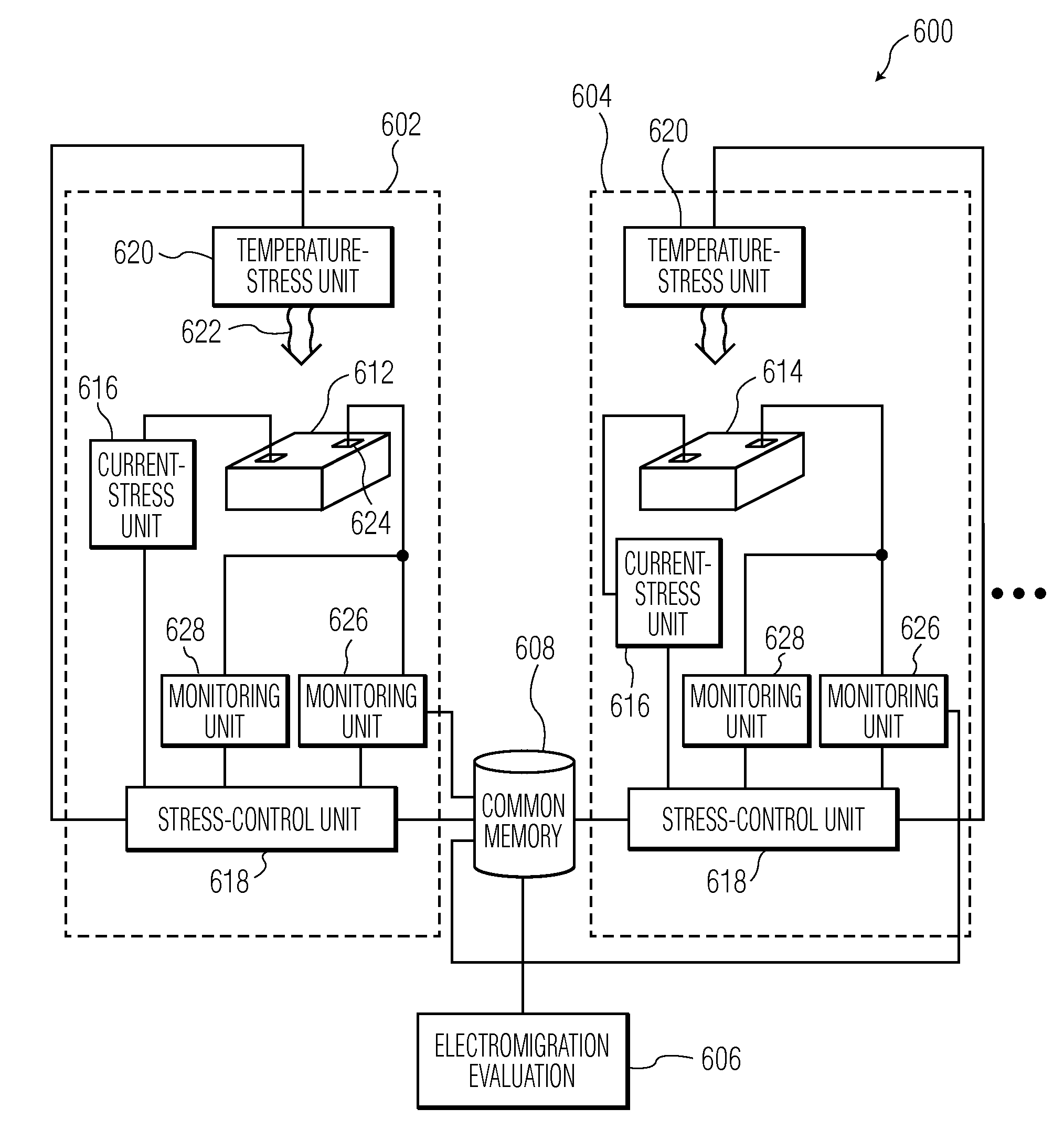

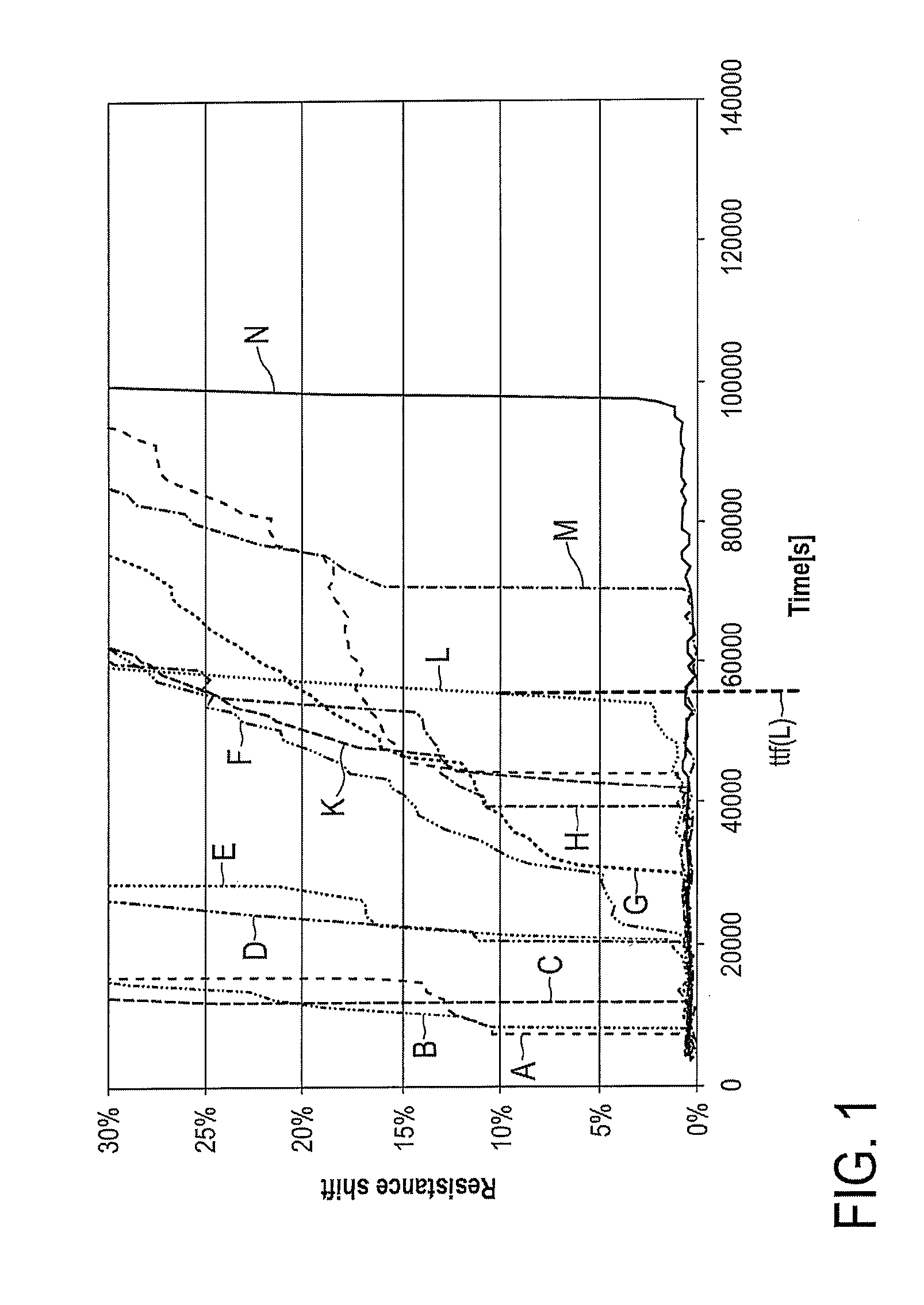

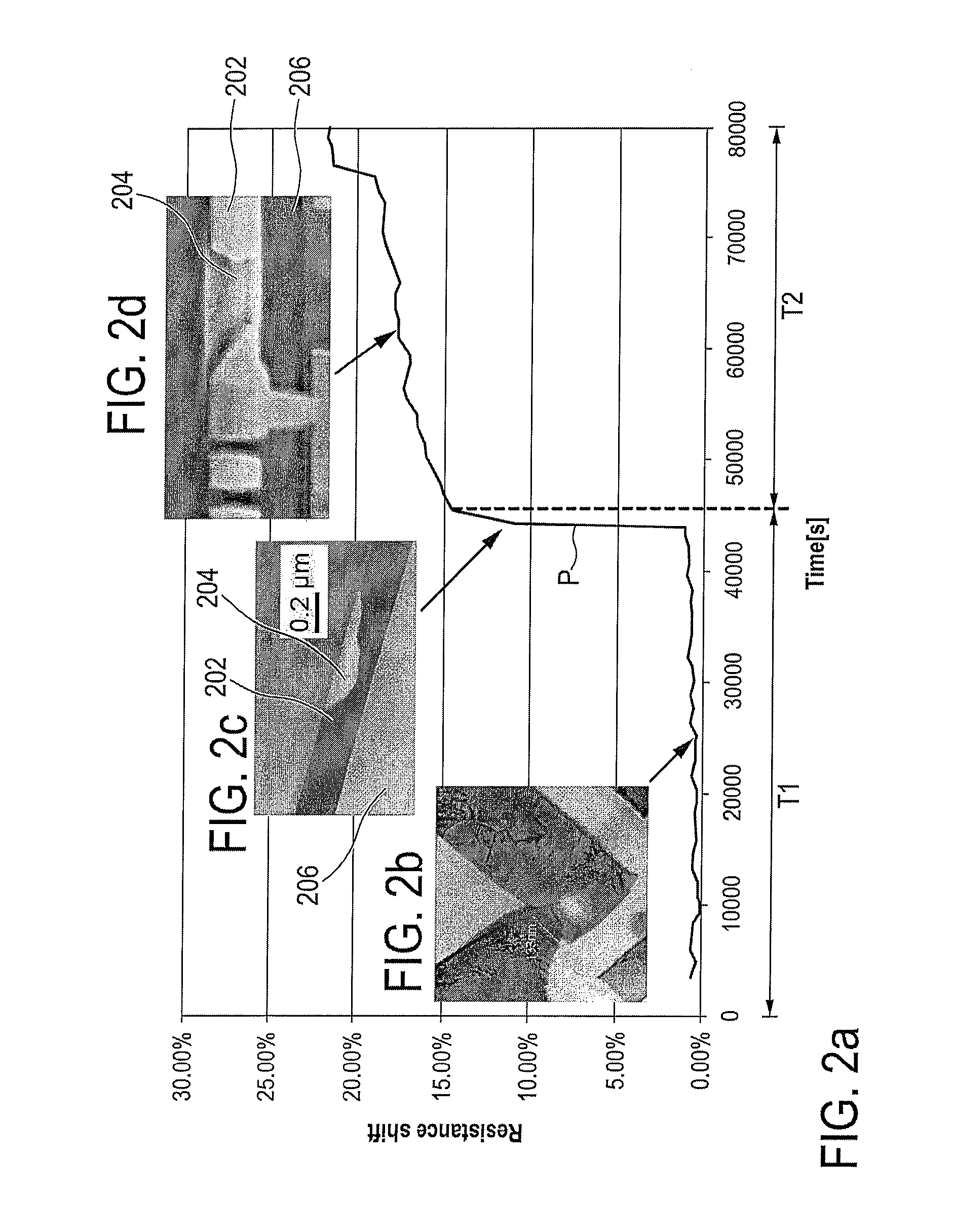

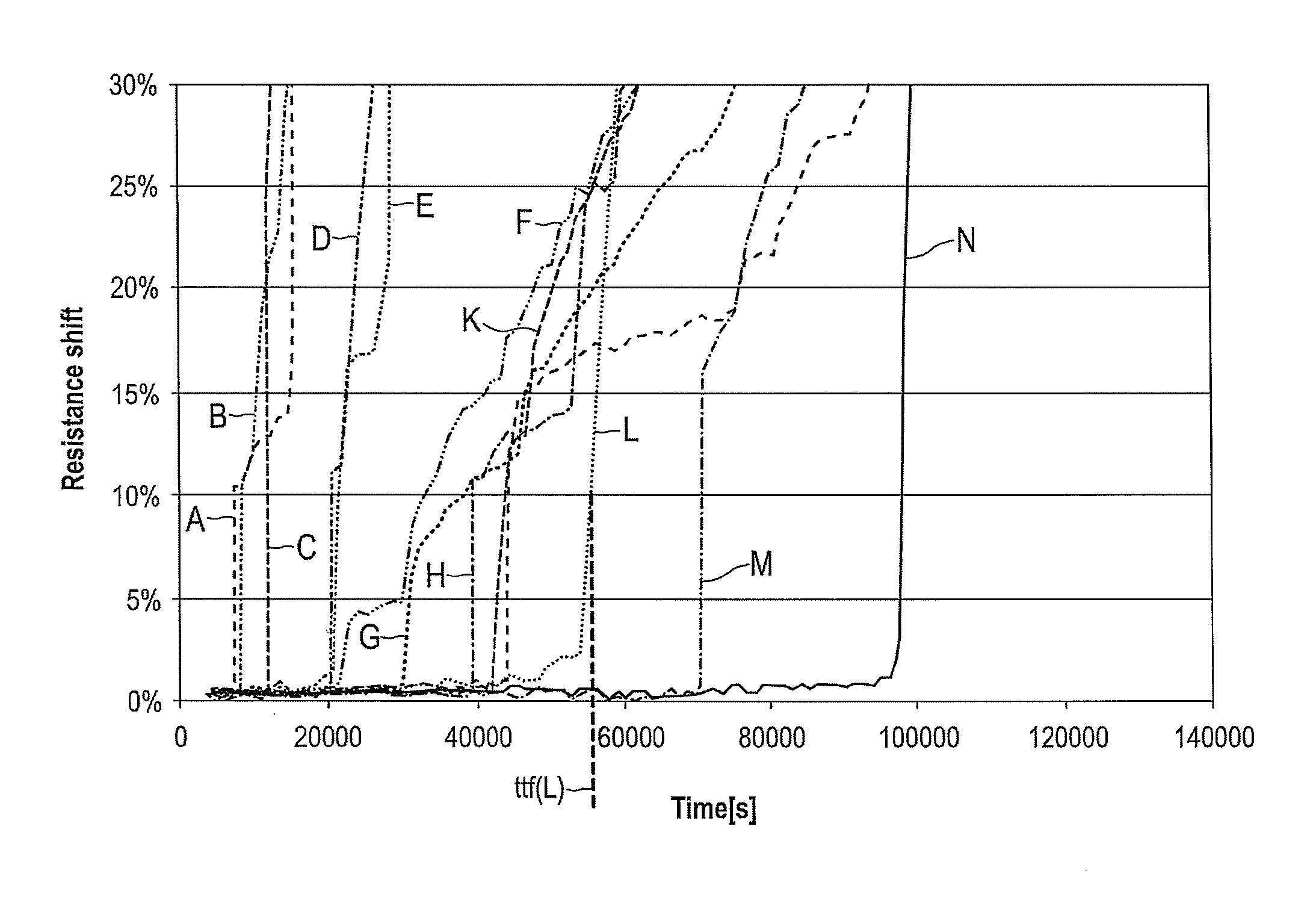

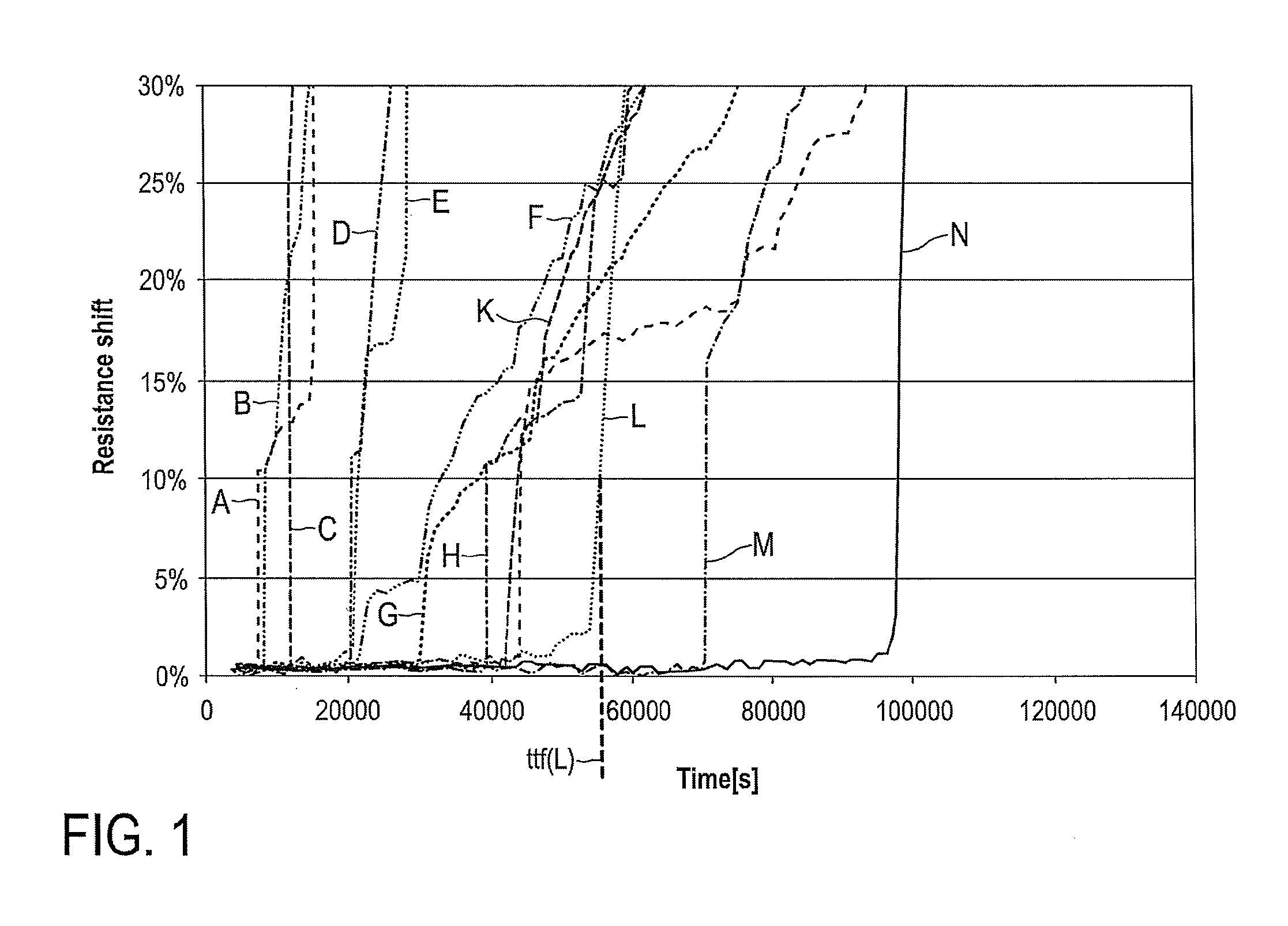

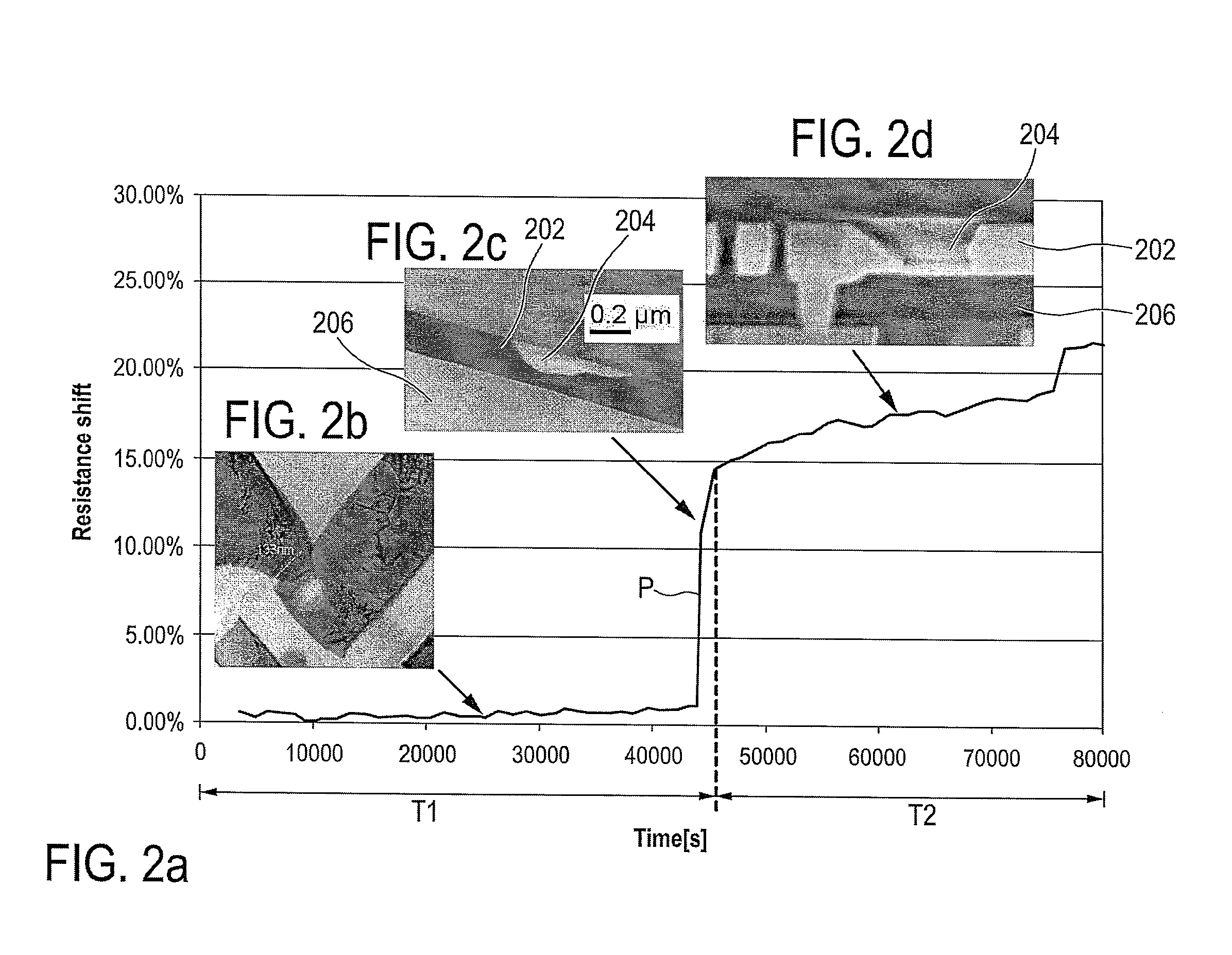

Electromigration testing and evaluation apparatus and methods

ActiveUS8237458B2Produce quicklyEasy to optimizeResistance/reactance/impedenceSemiconductor/solid-state device detailsElectrical resistance and conductanceStress conditions

The present invention relates to electromigration testing and evaluation methods and apparatus for a device under test with an interconnect structure. The method comprises forcing the occurrence of a step resistance-increase of the interconnect structure due to electromigration in the first layer and subsequently subjecting the interconnect structure to at least three respective predetermined stress conditions while concurrently measuring a test quantity indicative of an electrical resistance of the interconnect structure. The method allows performing an electromigration test in much shorter time than known electromigration testing methods, without loss of information or accuracy. It is therefore possible to accelerate the optimization of the interconnect manufacturing process so that the conductor electromigration kinetics remains compatible with a required product lifetime. This allows reducing the time and cost for electromigration testing and thus fabricating integrated-circuit devices with a lower overall cost.

Owner:NXP BV

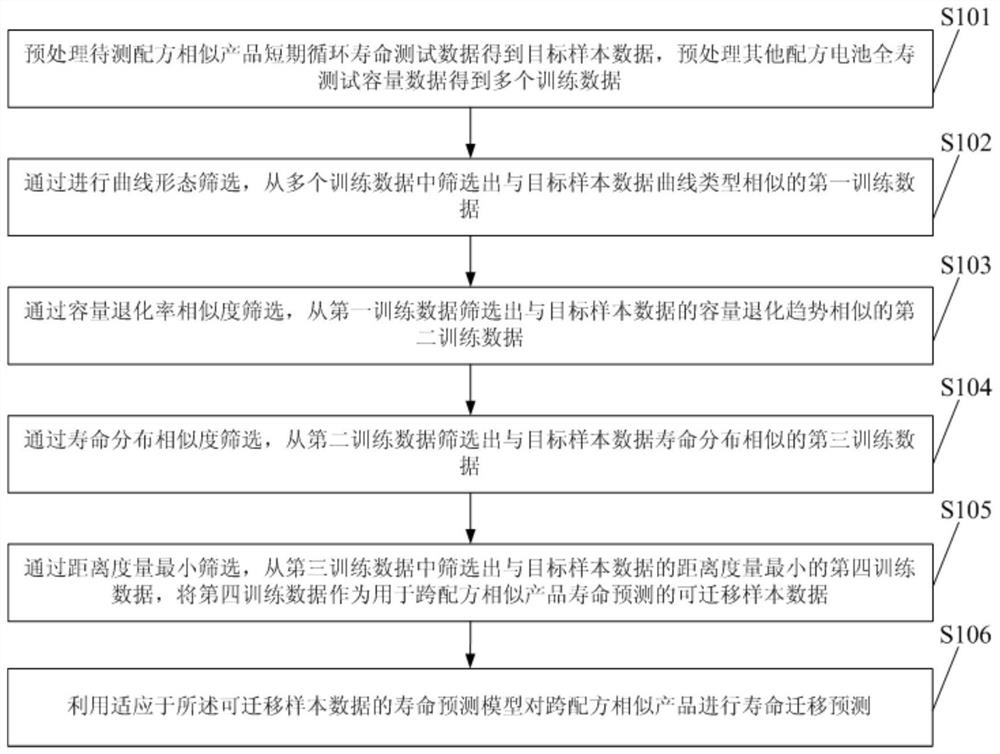

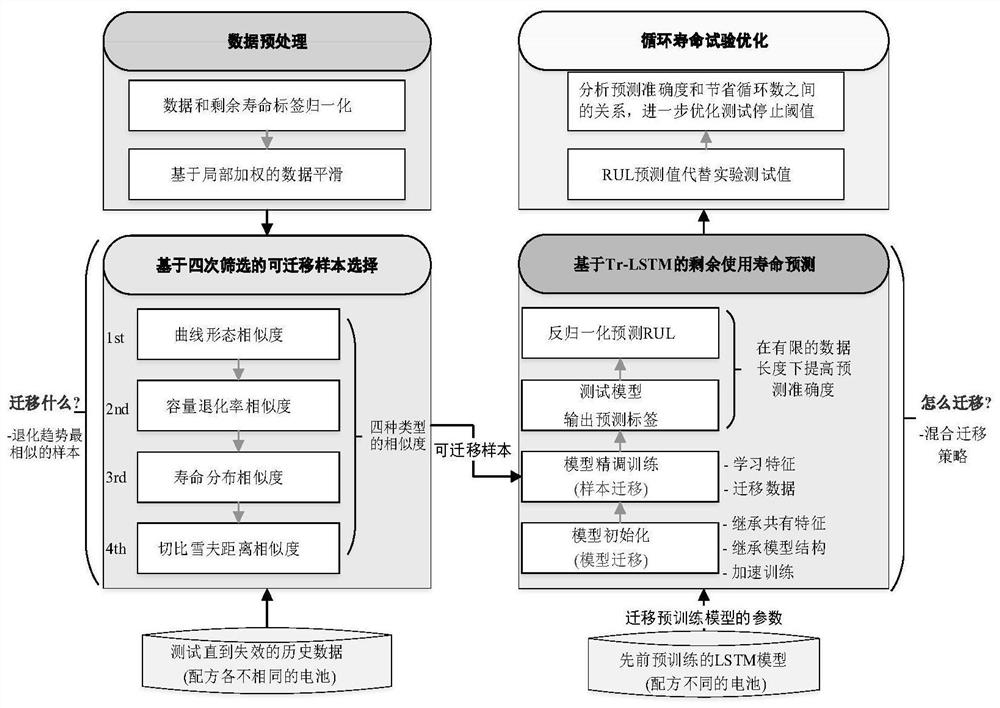

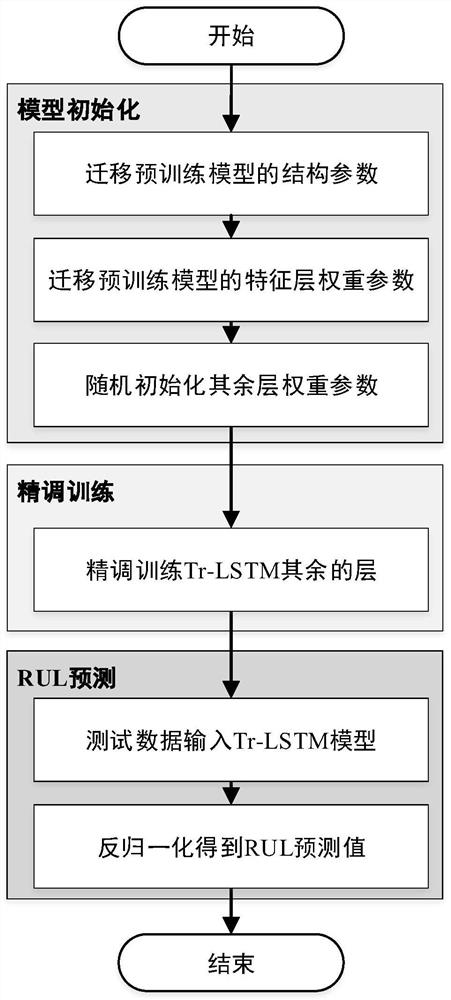

Similar product life migration screening method and system

ActiveCN112036084AAccurate predictionImprove forecast accuracyElectrical testingDesign optimisation/simulationLithium-ion batteryComputer science

The invention discloses a similar product life migration prediction method and system, and relates to the technical field of similar product migration learning, and the method comprises the steps: preprocessing to-be-tested formula similar product short-term cycle life test data and other formula battery full-life test data, and obtaining target sample data and a plurality of pieces of training data; obtaining migratable sample data for predicting the service life of the cross-formula similar product by carrying out minimum screening on curve form, capacity degradation rate similarity, servicelife distribution similarity and distance measurement, carrying out service life migration prediction on the cross-formula similar product by utilizing a service life prediction model adapted to themigratable sample data, and obtaining a life prediction result. According to the invention, the accurate prediction of the cross-formula residual life of the lithium ion battery is realized, the prediction accuracy can reach 99.9% at most, the test time and cost in the design and development process of the lithium battery can be effectively saved, and the method has considerable economic benefitsand application value.

Owner:BEIHANG UNIV

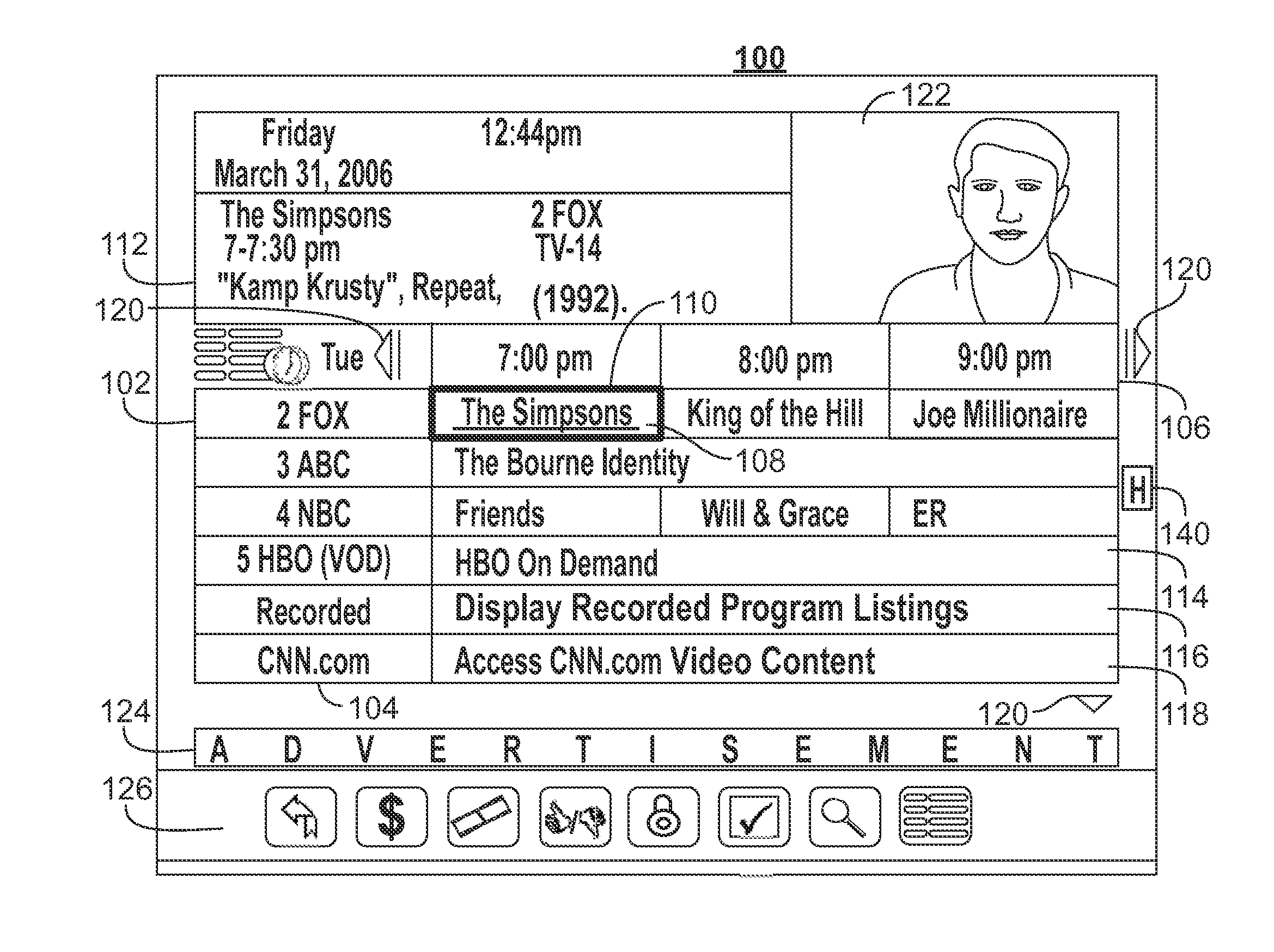

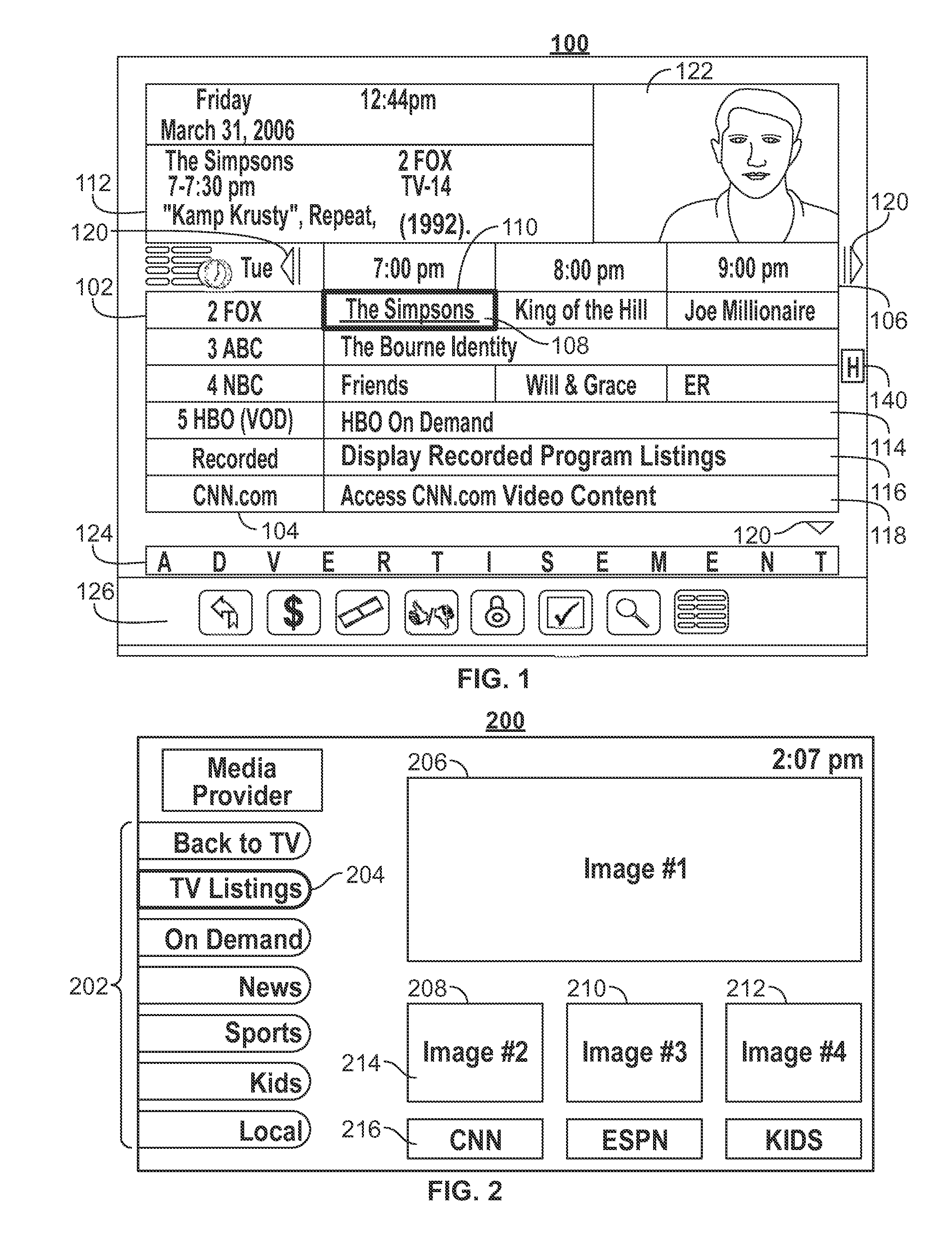

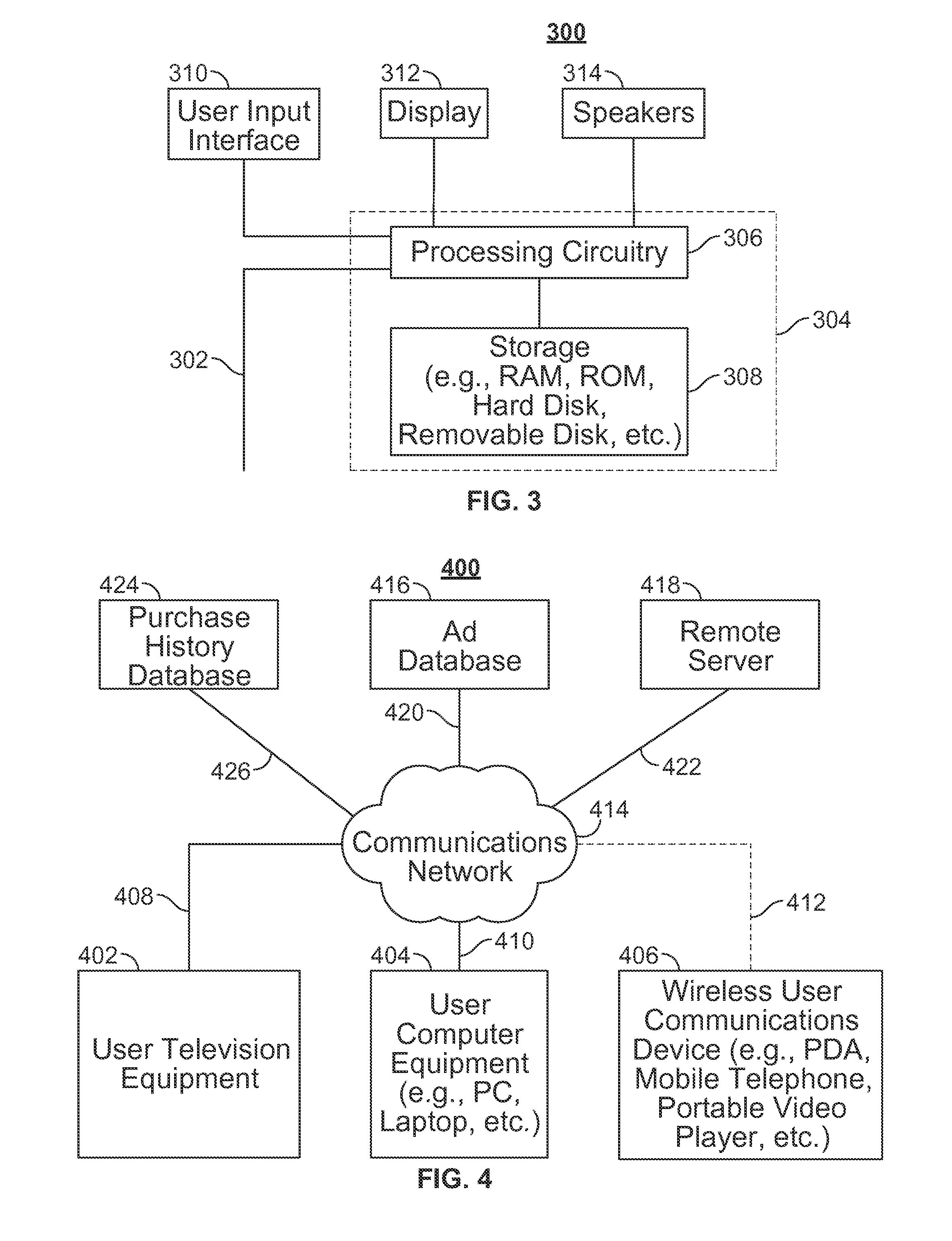

Systems and methods for targeting advertisements based on product lifetimes

Methods and systems for providing improved targeting of advertisements by considering whether or not a particular user is likely to use a particular product, and when the particular user is likely to want or need a product. Two products may be compared to determine if a relationship exists between them, after which a product lifetime is computed for one product. An advertisement for the other product will be shown after the end of the product lifetime for the first product.

Owner:ROVI GUIDES INC

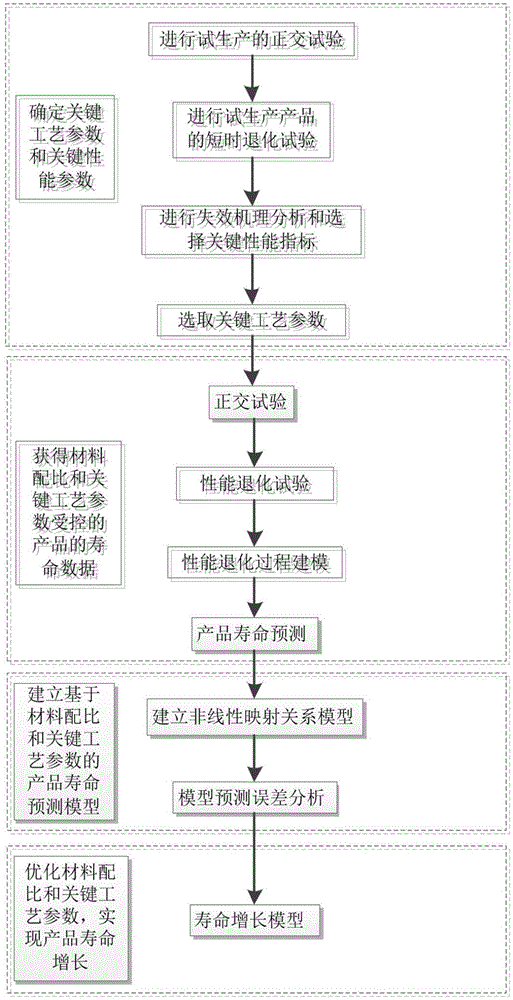

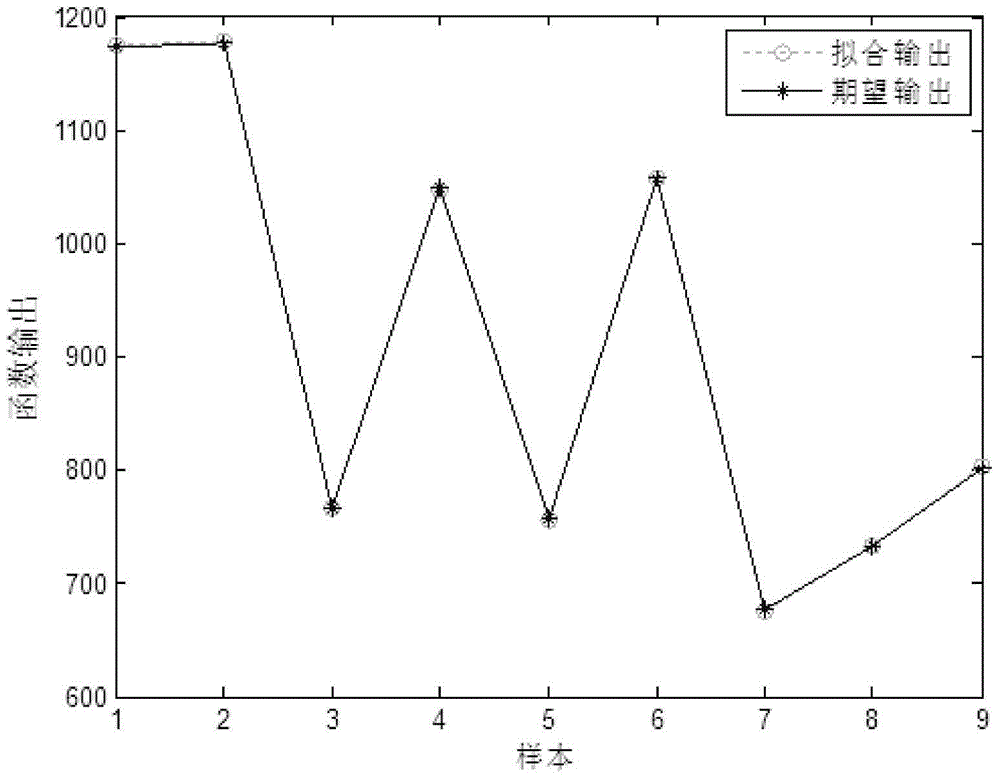

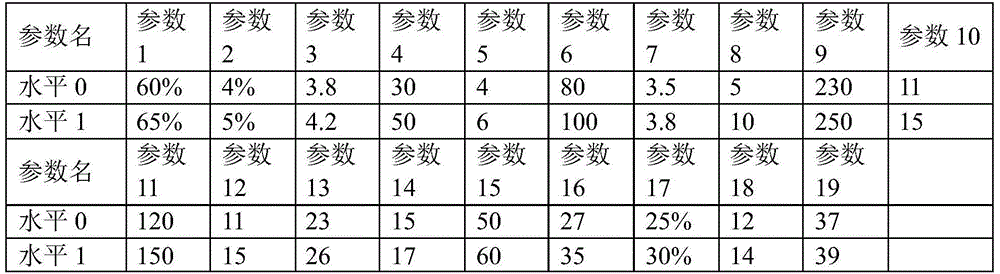

Improved method for prolonging product service life based on material ratio and key process parameter

ActiveCN104834794AConvenient guidanceAccurate lifespan growthSpecial data processing applicationsImproved methodDependability

An improved method for prolonging the product service life based on the material ratio and a key process parameter. The method comprises the following steps: 1, determining the key process parameter and a key performance parameter; 2, obtaining service life data of a product with the material ratio and the key process parameter controlled; 3, establishing a product service life prediction model based on the material ratio and the key process parameter; 4, optimizing the material ratio and the key process parameter to achieve prolonging of the product service life. According to the improved method for prolonging the product service life based on the material ratio and the key process parameter, the reliability and service life of the product are quantitatively adjusted in the view of optimizing the material ratio and the key process parameter, and the non-linear mapping relation model between the material ratio, the key process parameter and the product service life is established for the first time, so that the service life prolonging obtained according to the model is more accurate and more favorable for instructing the industrial production. The complete flow from parameter selection, data obtaining through experiment design and modeling to final prolonging of the service life is given. The method comprises the detailed steps and is easy to implement.

Owner:NAT UNIV OF DEFENSE TECH

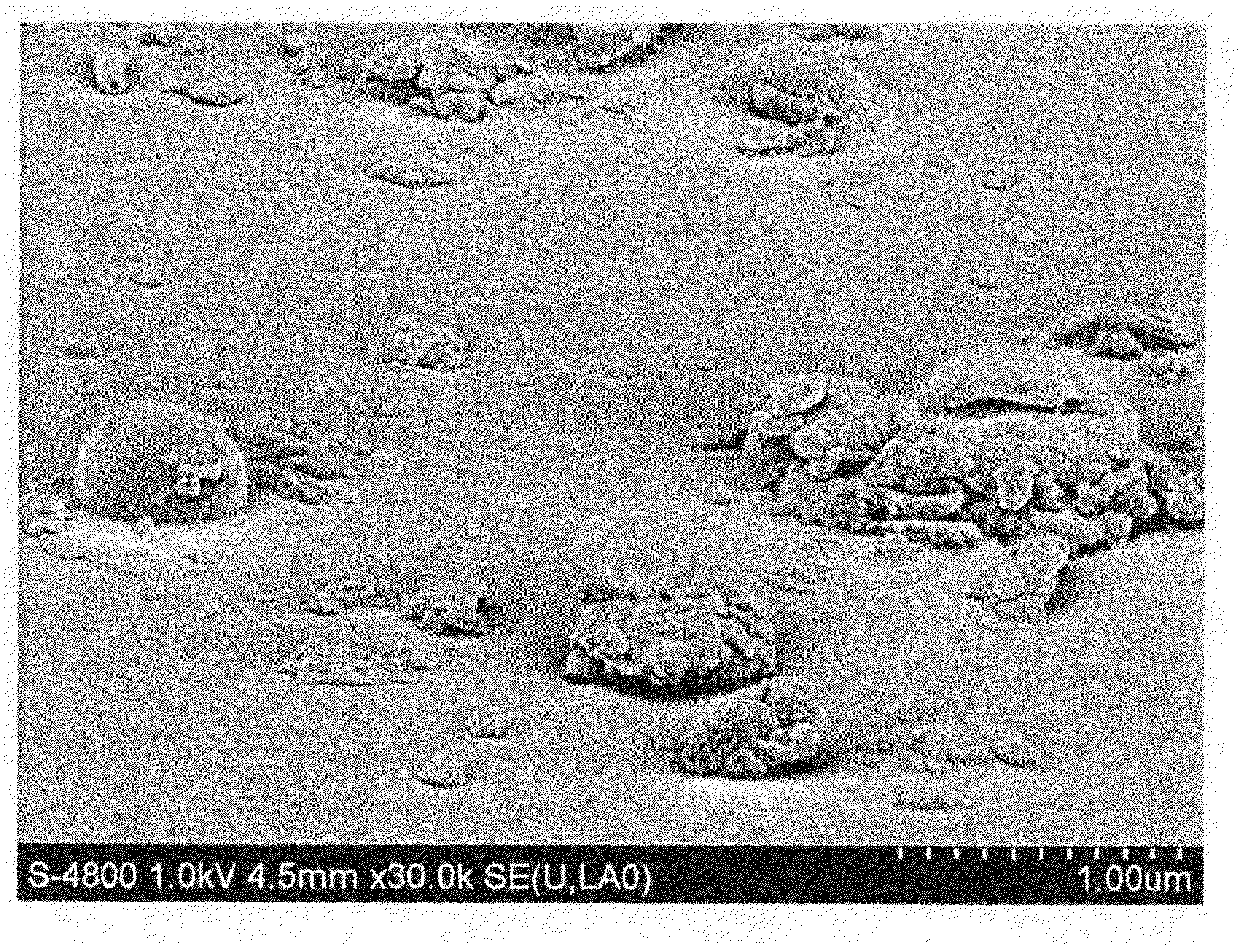

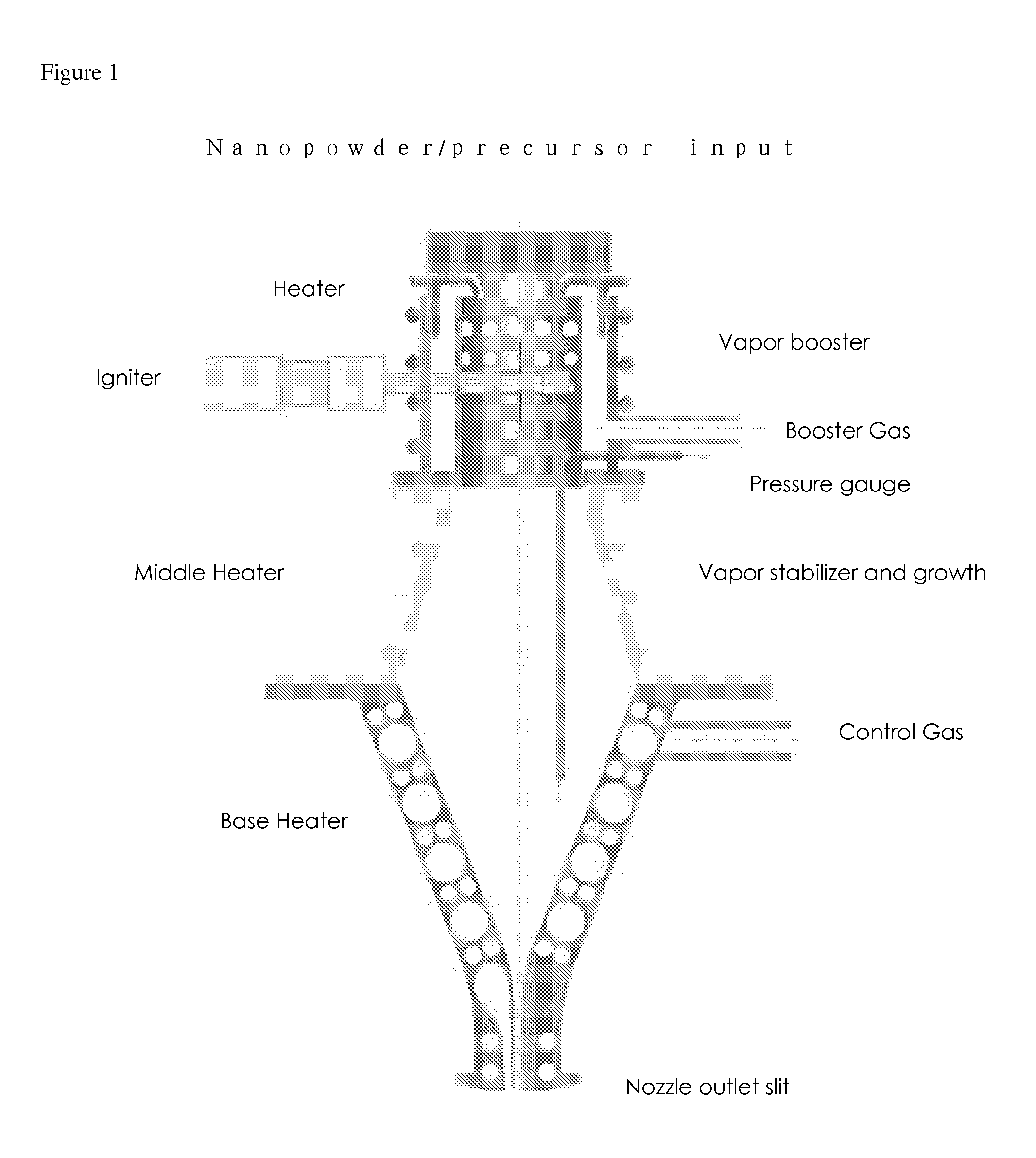

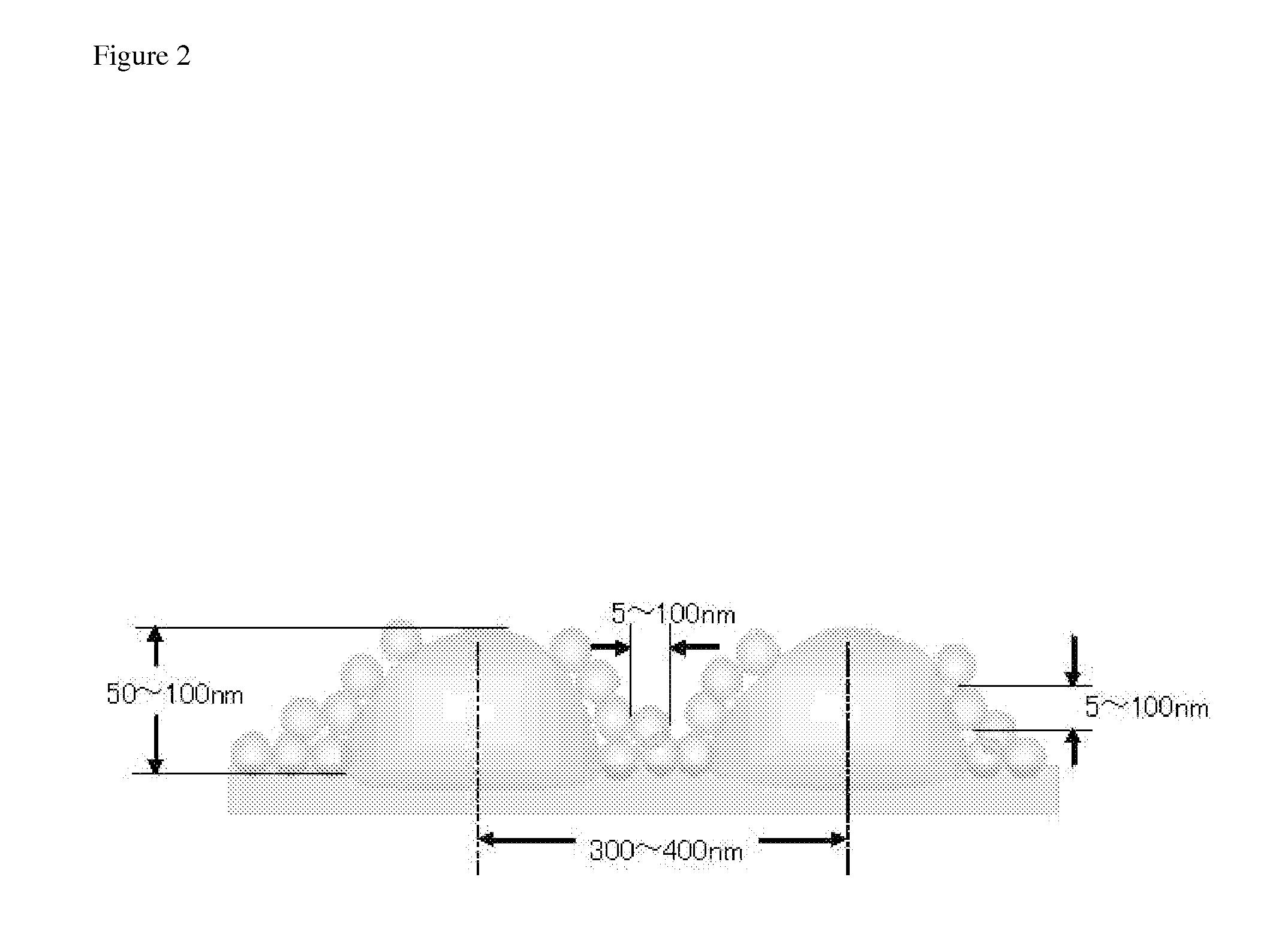

Process for Forming High Surface Area Embedded Coating with High Abrasion Resistance

InactiveUS20110143094A1Reduce frictionLow friction materialMolten spray coatingLayered productsOptical propertyNanostructure

The process of the present invention significantly increases the durability of superhydrophobic surfaces, while retaining similar optical properties to those of the original surface. The process uses velocity and heat to take freshly formed nano- and ultrafine particles and can partially embed and chemically bond them to the substrate, creating a strongly bonded nano-to-submicron textured surface. This nanotextured surface can then be modified to have desirable surface properties; for example, it can be hydrophobic, oliophobic, or hydrophilic. The high points of the coating made with this process protect the remainder of the surface from abrasion, thus greatly increasing product life in many uses. In preferred embodiments, the process is used to coat transportation vehicle windshields.

Owner:ENGI MAT CO

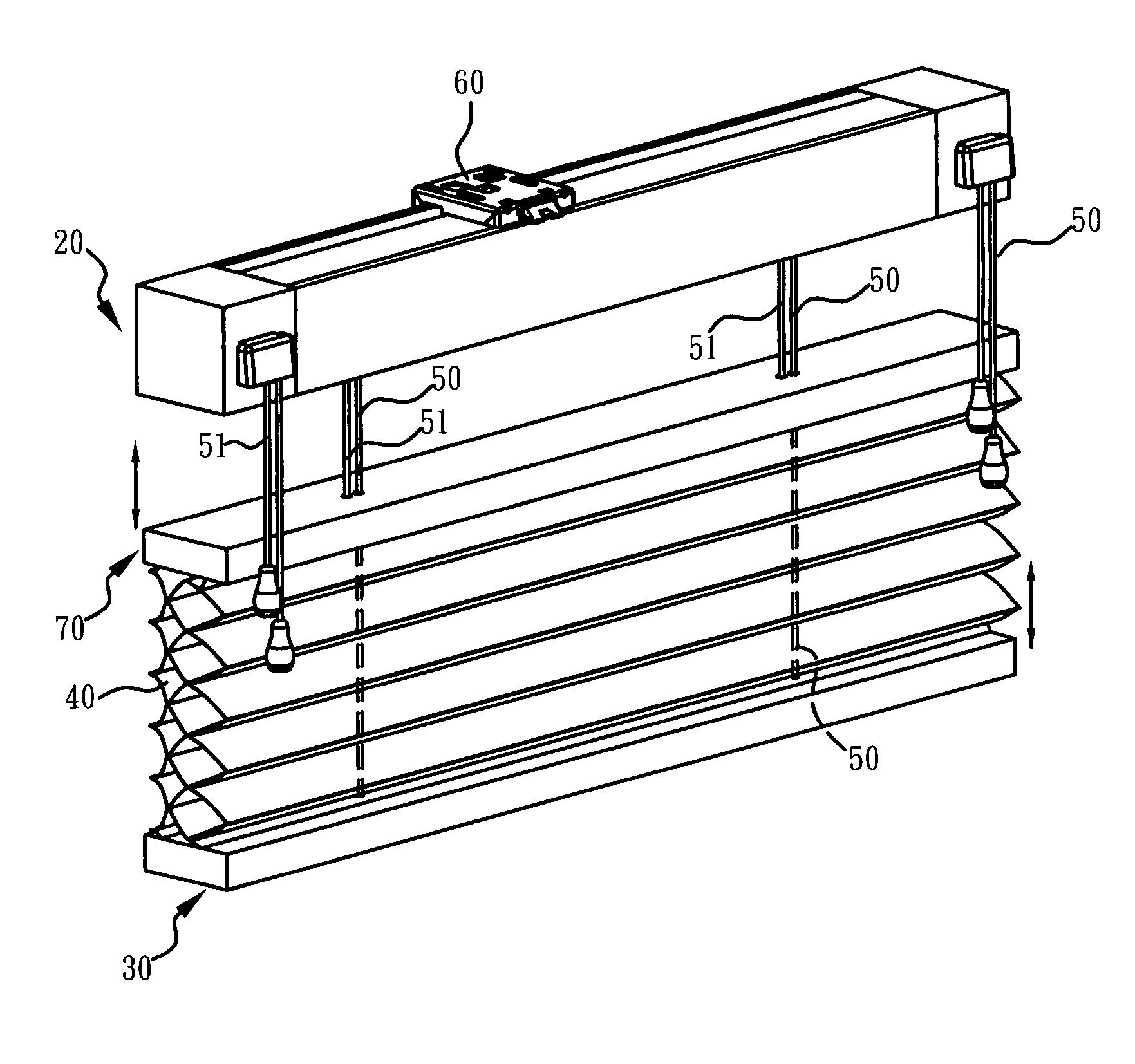

Rail structure for window blinds

InactiveUS20080196843A1Improve aestheticsGood flexibilityLight protection screensWindow shutterFlange

A rail structure for window blinds is provided, which includes a body and at least one connecting member. The body has a pair of first flanges and a pair of second flanges. The first flanges are disposed on tops of two sides of the body, and the second flanges are disposed on bottoms of the two sides of the body. In addition, the connecting member is mounted to an outer surface of one side of the body, has a predetermined shape of constant cross-section profile, a length and a width, Besides, a flange is disposed on a predetermined position of the connecting member and extending to one side of the body. By the connecting members, the headrail appearance can be enhanced. Moreover, as the connecting members do not directly bear the overall or partial weight of the window blind, the rail structure can have an extended product lifetime.

Owner:NIEN MADE ENTERPRISE CO LTD

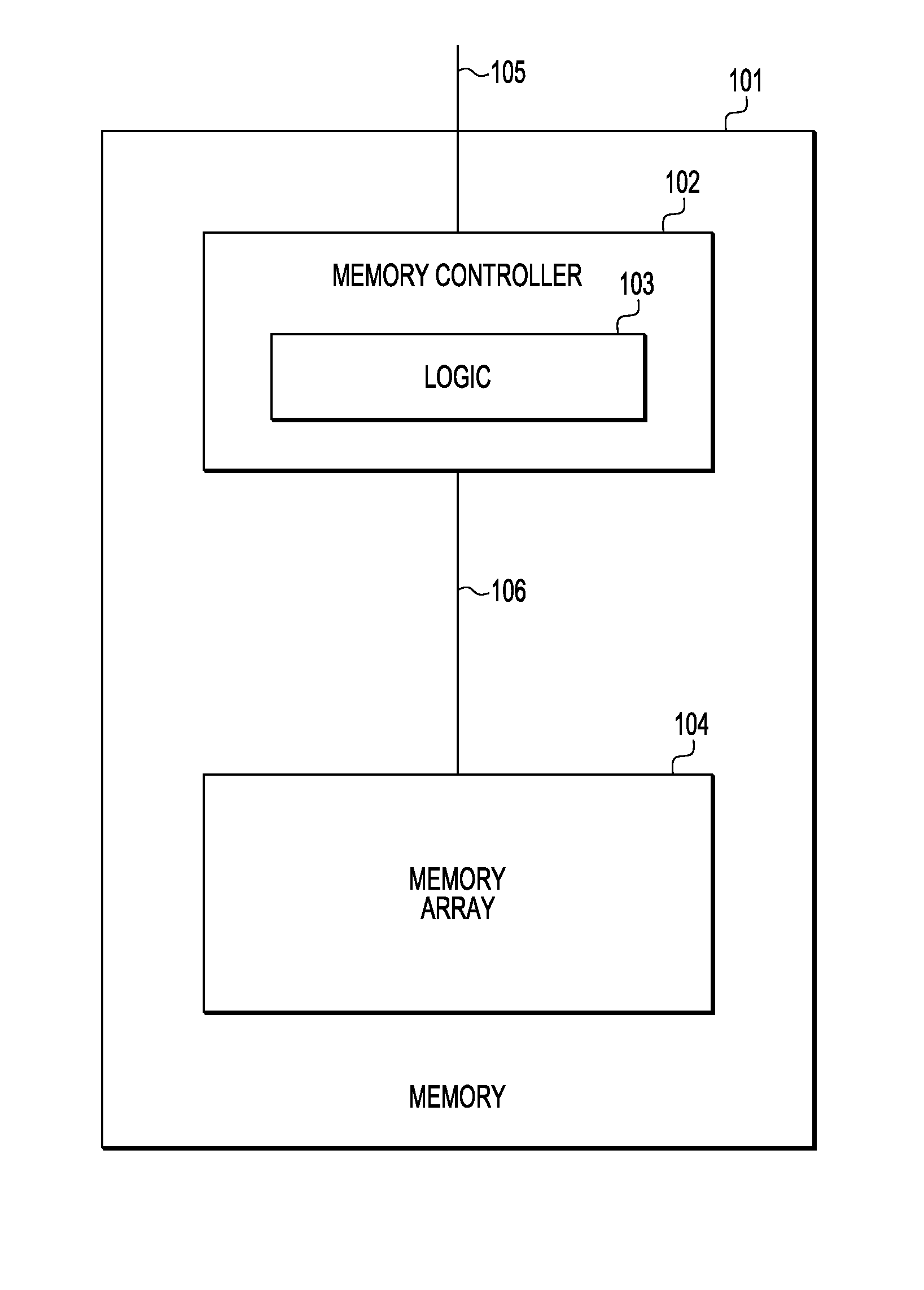

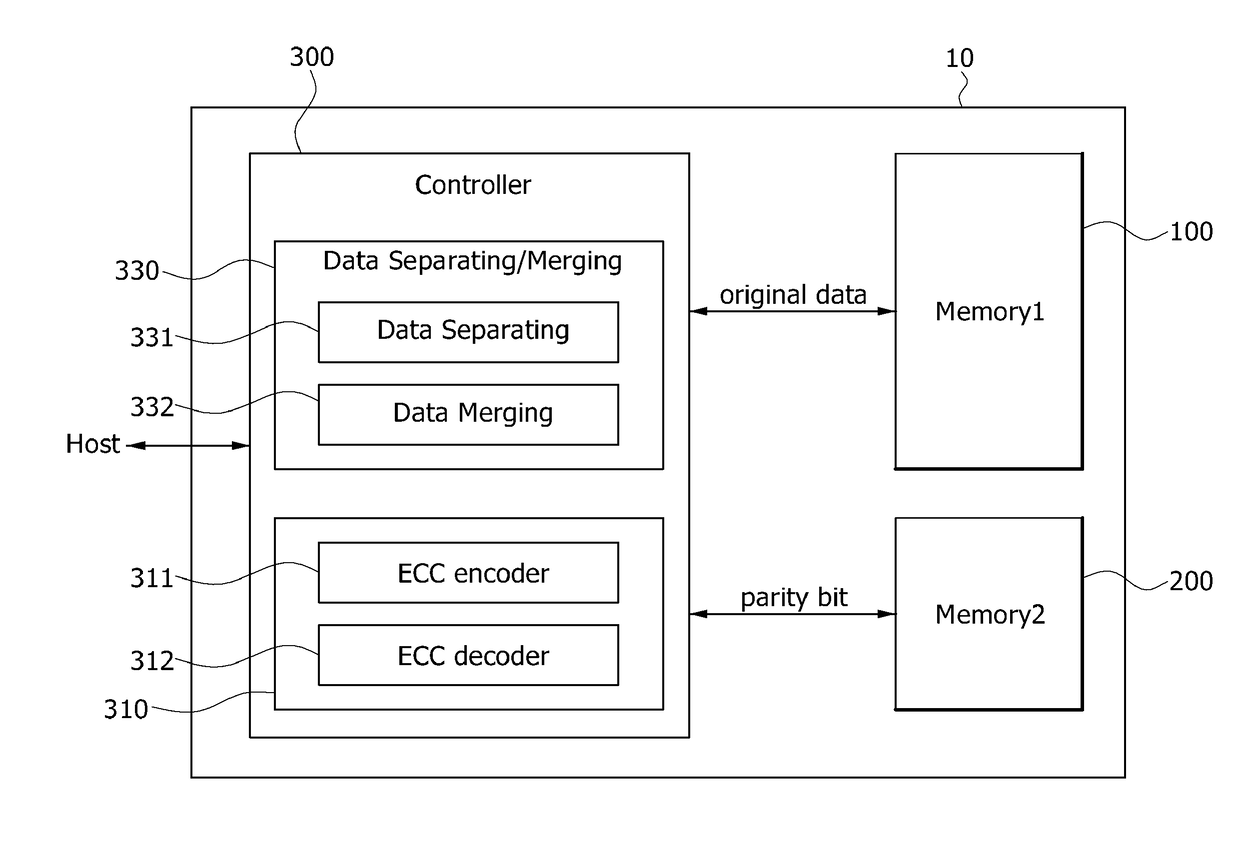

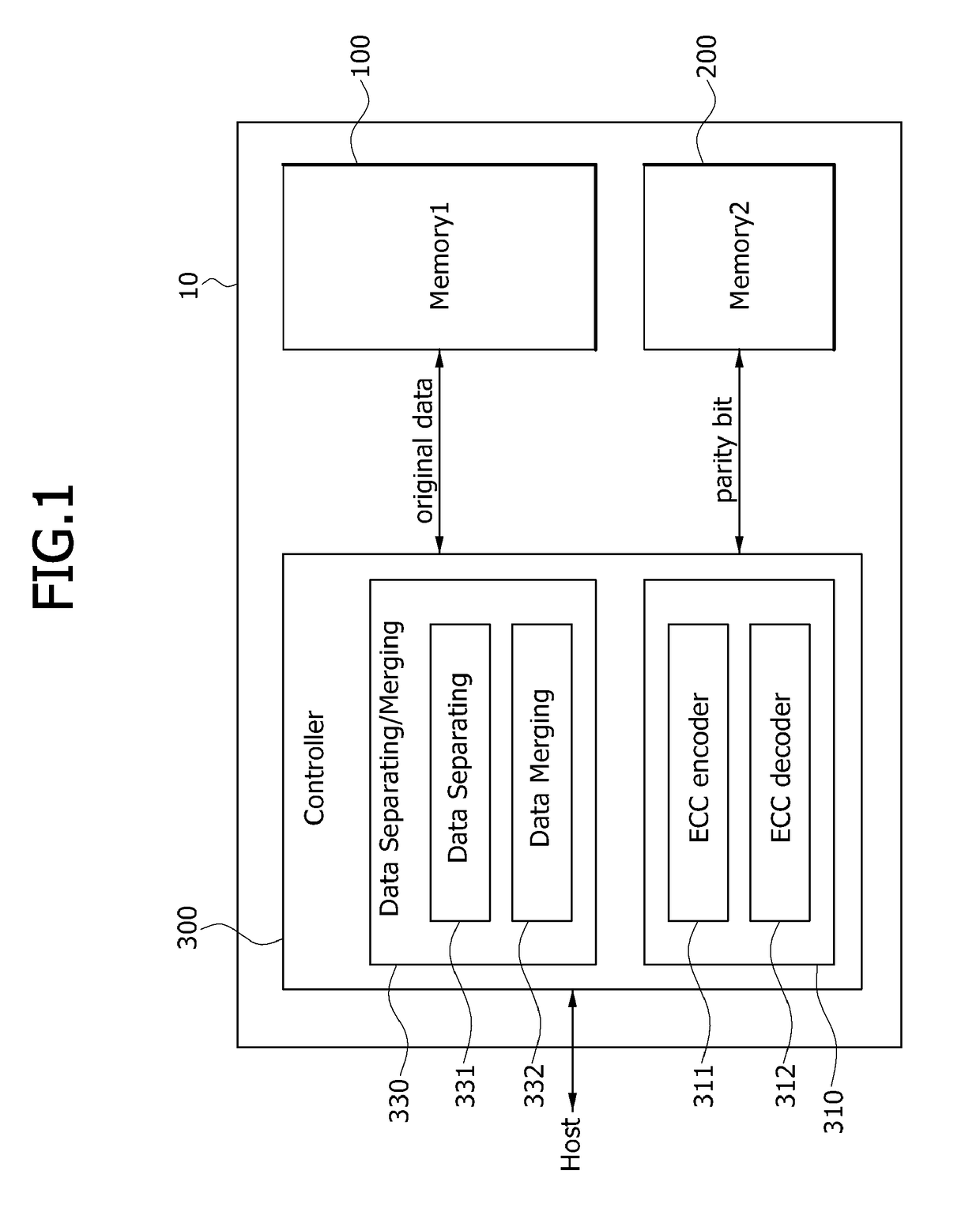

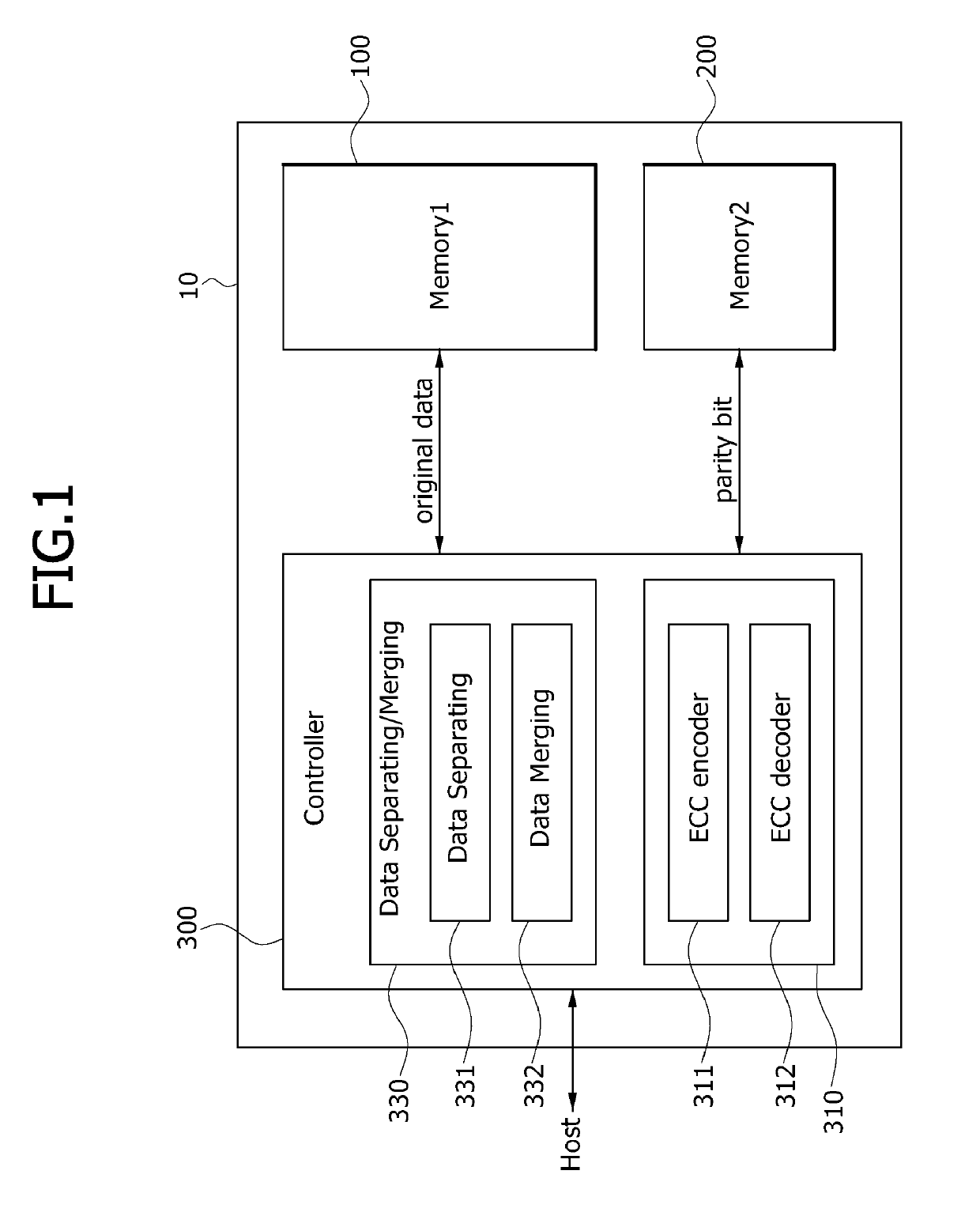

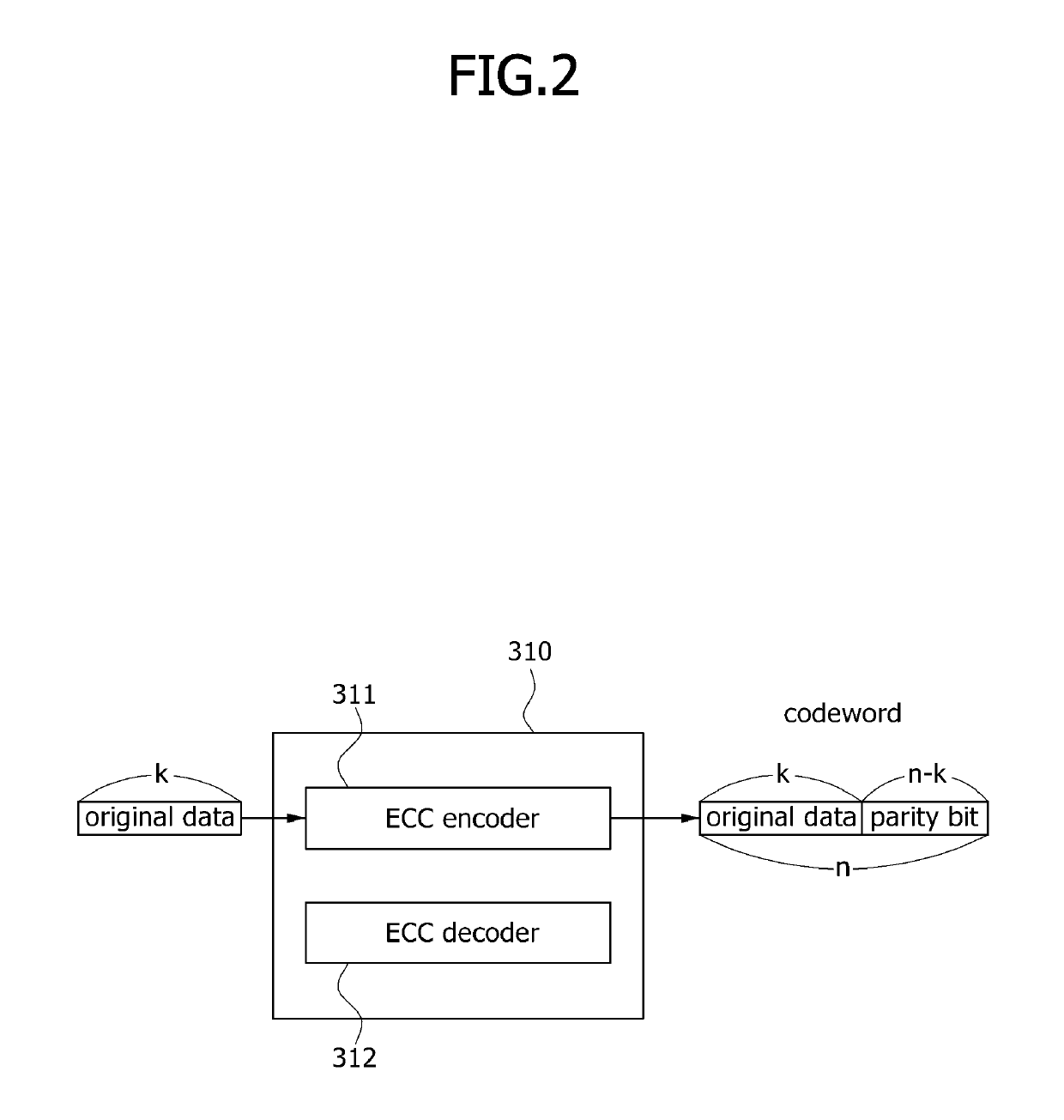

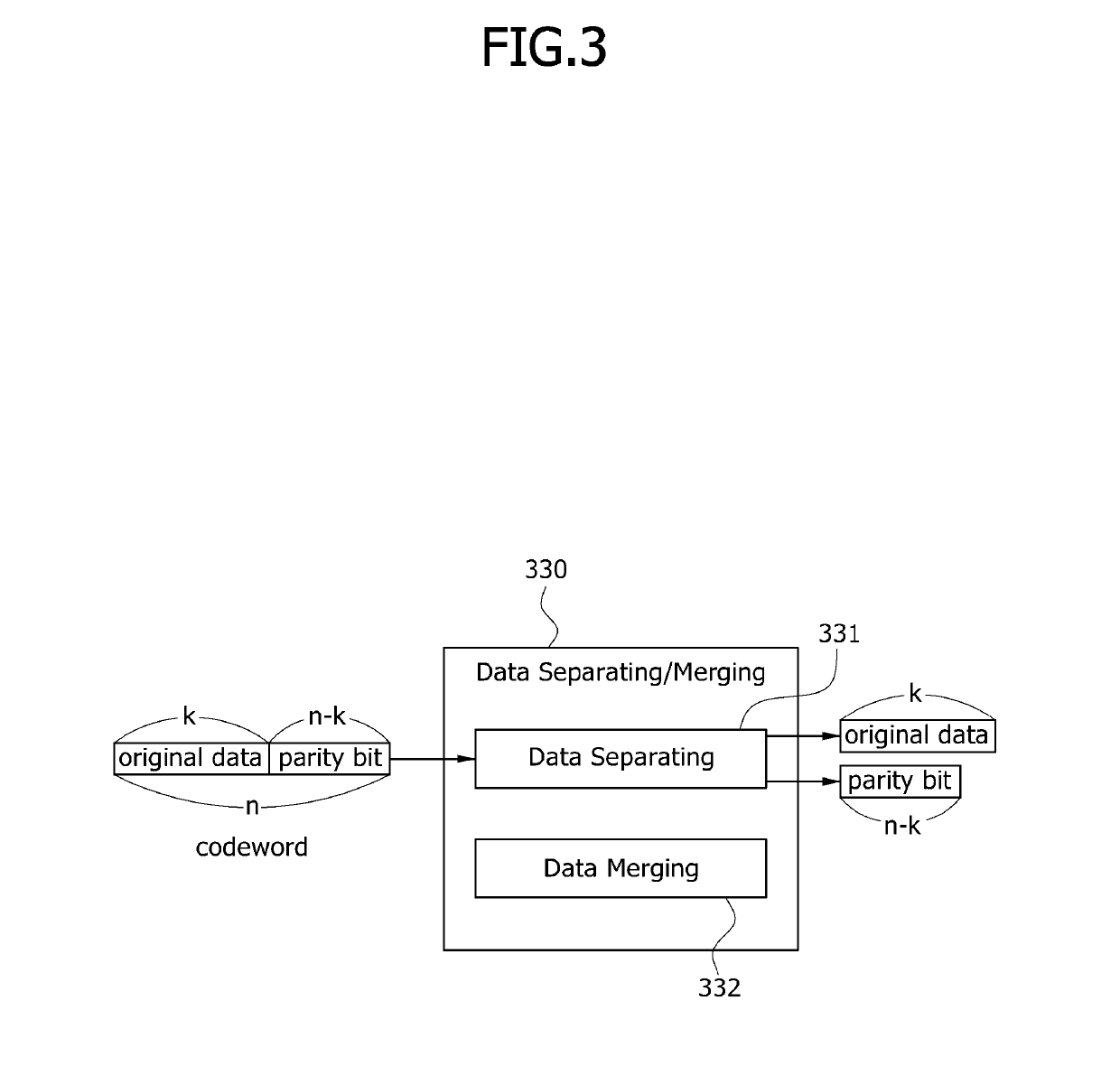

Memory systems having extended product lifetime and methods of operating the same

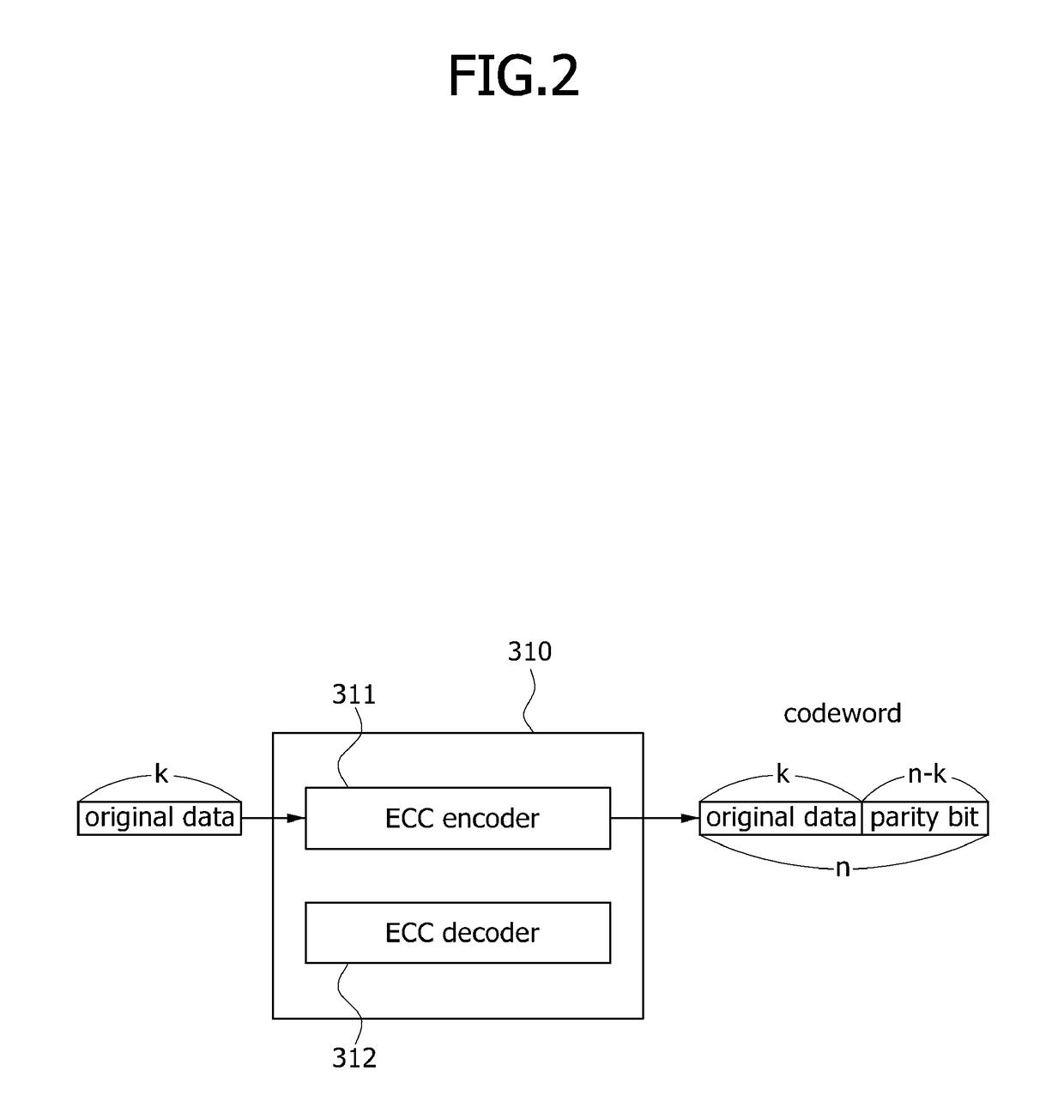

A memory system includes a first memory device, a second memory device, and a controller. The second memory device has a write endurance which is higher than a write endurance of the first memory device. The controller performs an error correction process on original data outputted from a host to generate a codeword including the original data and parity data. The controller separates the codeword into the original data and the parity data to write the separated original data into the first memory device and to write the separated parity data into the second memory device.

Owner:SK HYNIX INC

Electromigration testing and evaluation apparatus and methods

ActiveUS20100127719A1Short test timeReduce evaluation costsResistance/reactance/impedenceSemiconductor/solid-state device detailsElectrical resistance and conductanceElectrical conductor

The present invention relates to electromigration testing and evaluation methods and apparatus for a device under test with an interconnect structure. The method comprises forcing the occurrence of a step resistance-increase of the interconnect structure due to electromigration in the first layer and subsequently subjecting the interconnect structure to at least three respective predetermined stress conditions while concurrently measuring a test quantity indicative of an electrical resistance of the interconnect structure. The method allows performing an electromigration test in much shorter time than known electromigration testing methods, without loss of information or accuracy. It is therefore possible to accelerate the optimization of the interconnect manufacturing process so that the conductor electromigration kinetics remains compatible with a required product lifetime. This allows reducing the time and cost for electromigration testing and thus fabricating integrated-circuit devices with a lower overall cost.

Owner:NXP BV

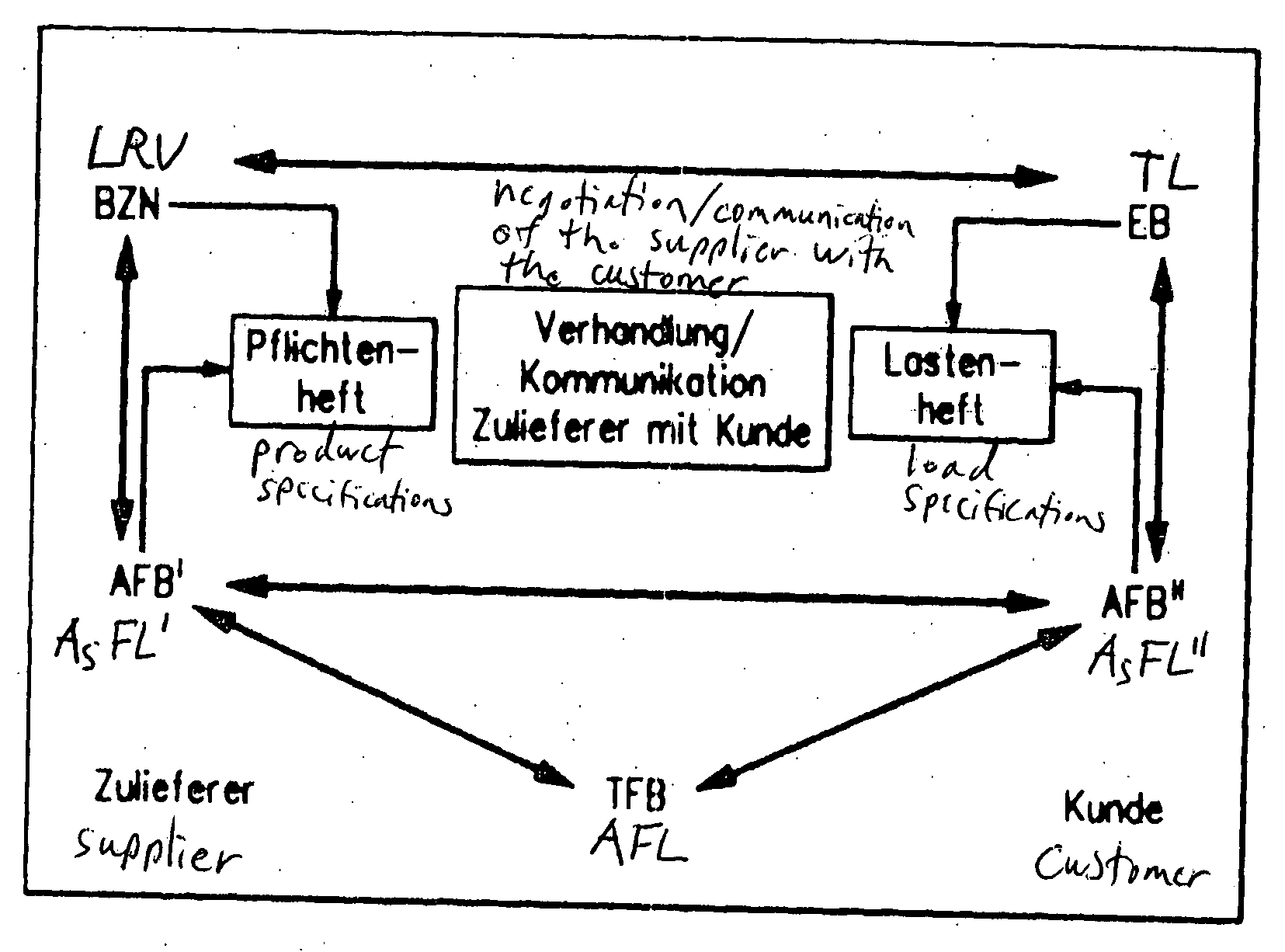

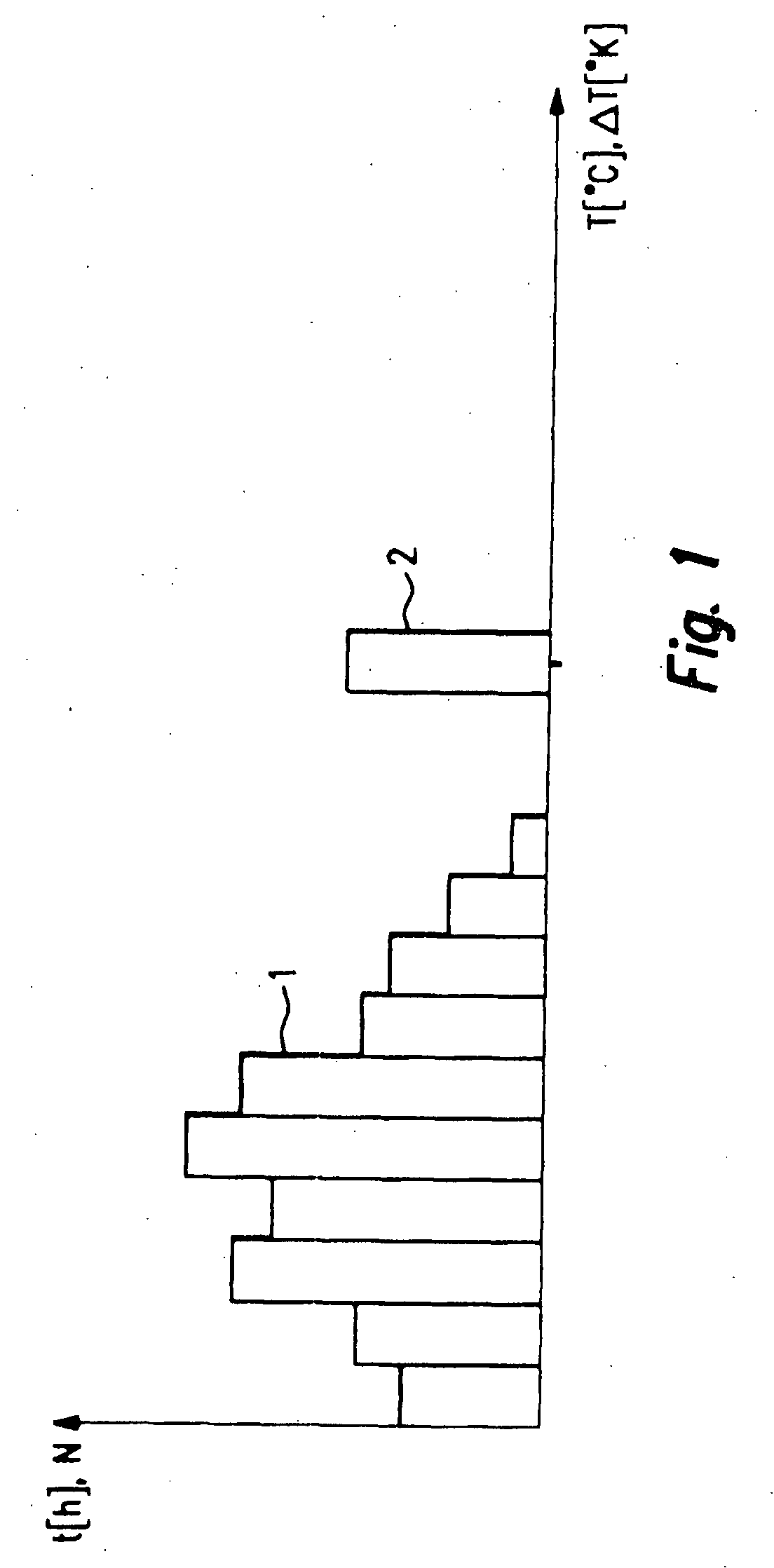

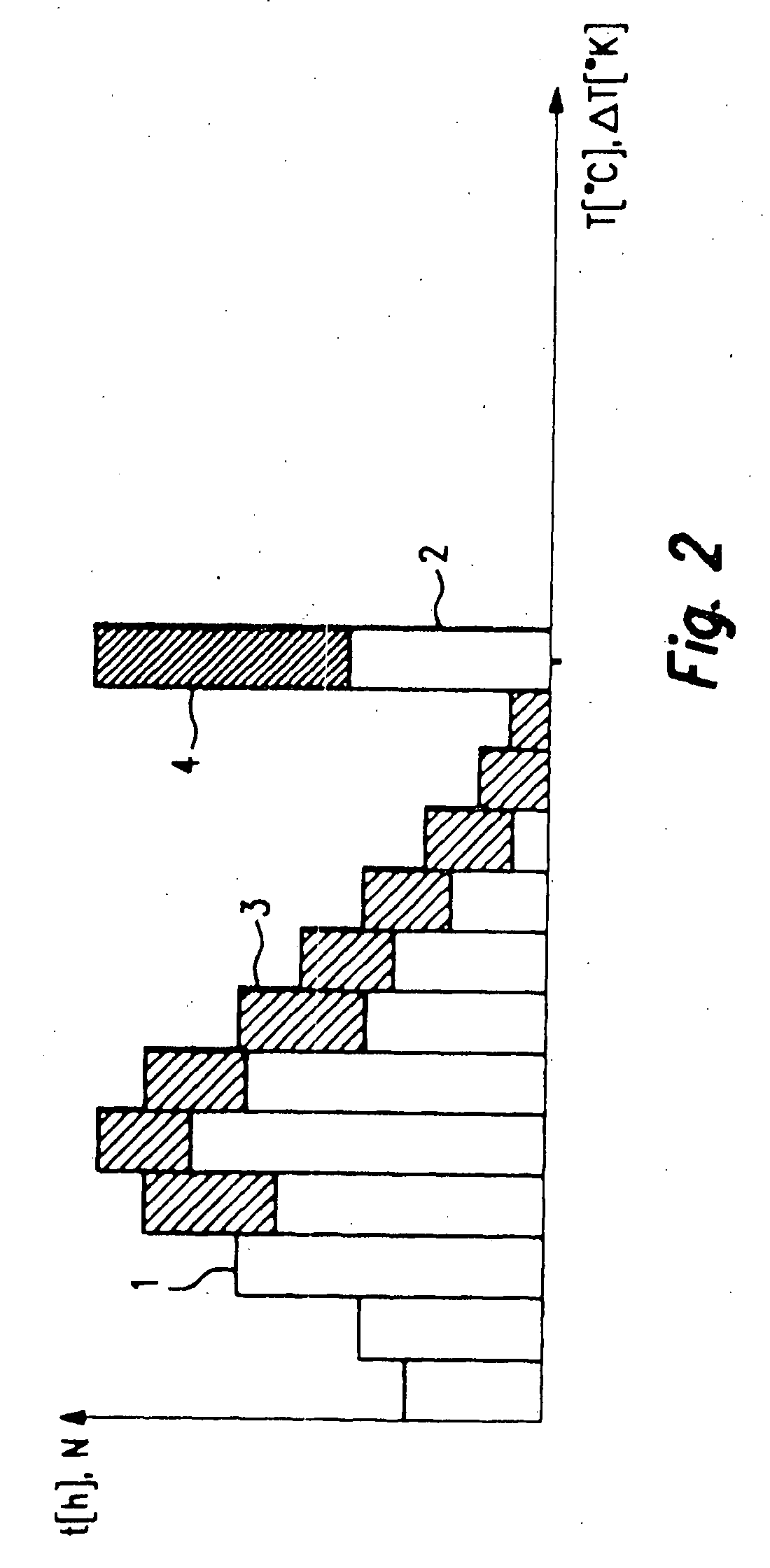

Method and Device for Predicting a Life Expectancy of a Product Containing a Plurality of Components

InactiveUS20090119029A1Meaningful reliability verificationProgramme controlPlug gaugesLife timeLife expectancy

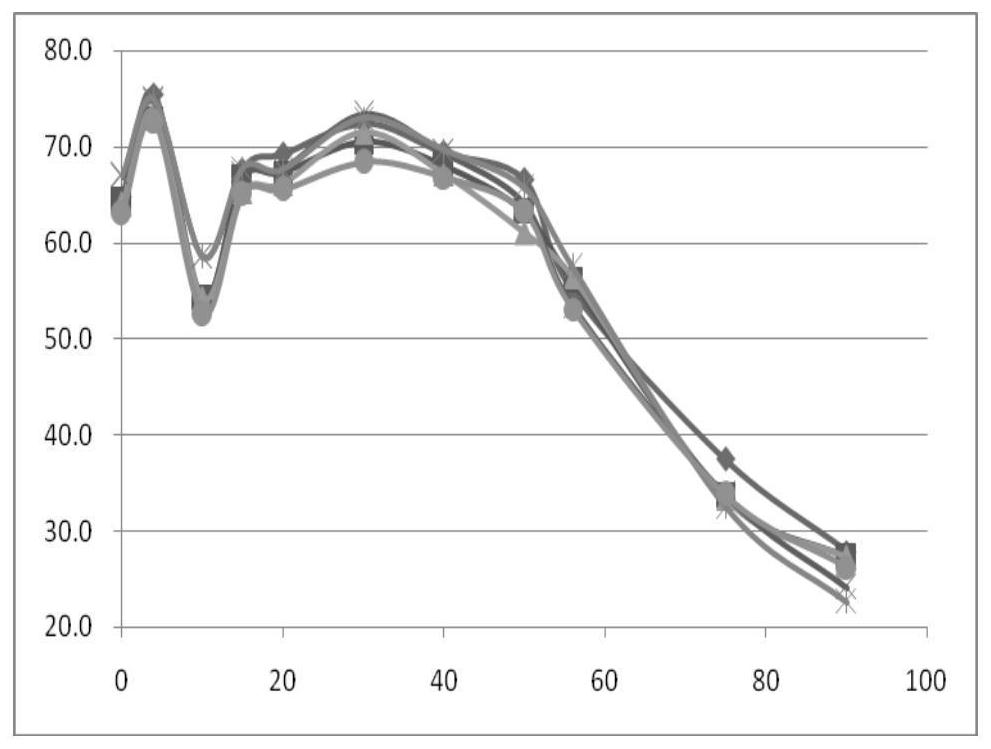

A method and a device are for predicting a life expectancy of a product, which includes at least two components. The life expectancy is ascertained as a function of an assumed field loading of the product. The components of the product are acted upon by different loadings and are operated, in each instance, at the different loadings until they fail. An end-of-life curve of the component is recorded on the basis of the load-dependent failure times of a component. An EOL curve of the product is ascertained such that at the different loadings, it includes the EOL curve of the components which has, in each instance, the shortest failure time at the corresponding loading. The anticipated service life of the product is determined as a functional value of the EOL curve of the product as a function of the predefined loading of the product.

Owner:ROBERT BOSCH GMBH

Memory systems having extended product lifetime and methods of operating the same

A memory system includes a first memory device, a second memory device, and a controller. The second memory device has a write endurance which is higher than a write endurance of the first memory device. The controller performs an error correction process on original data outputted from a host to generate a codeword including the original data and parity data. The controller separates the codeword into the original data and the parity data to write the separated original data into the first memory device and to write the separated parity data into the second memory device.

Owner:SK HYNIX INC

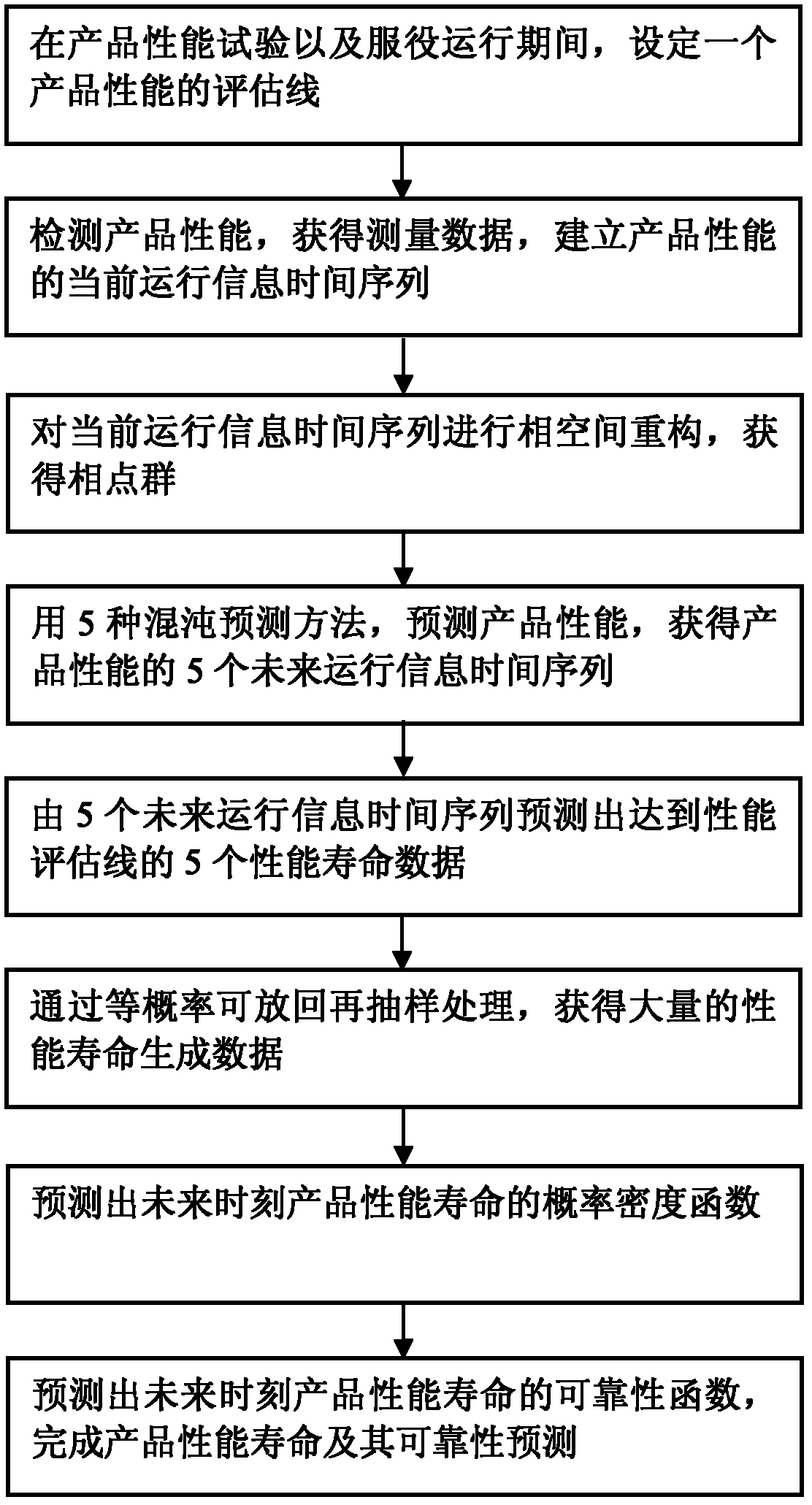

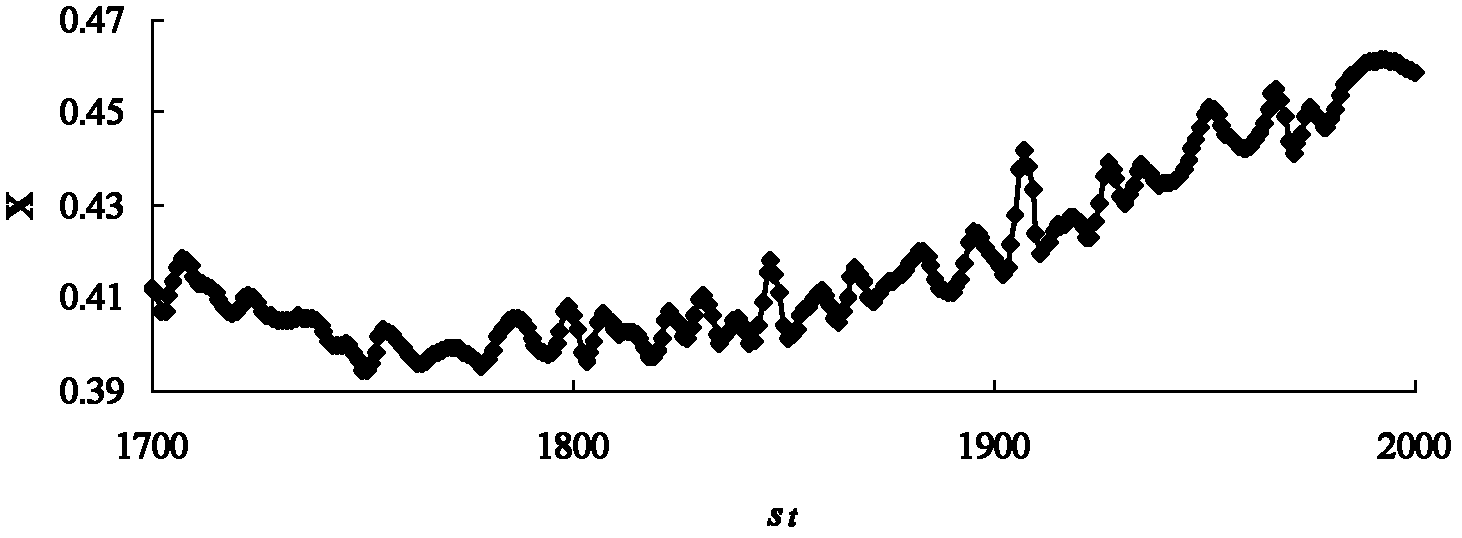

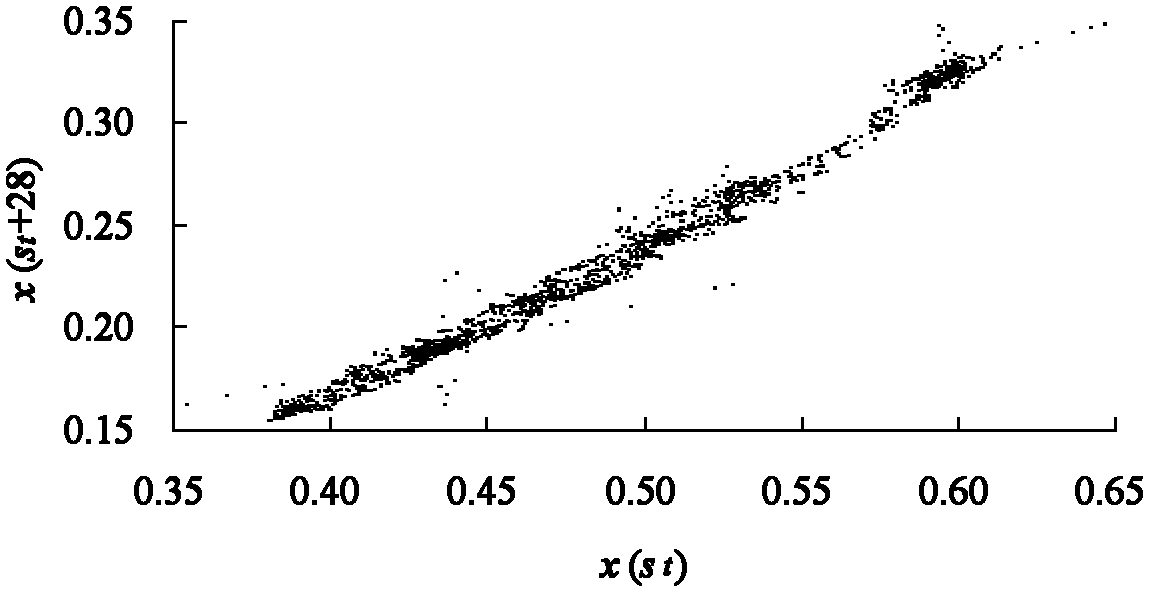

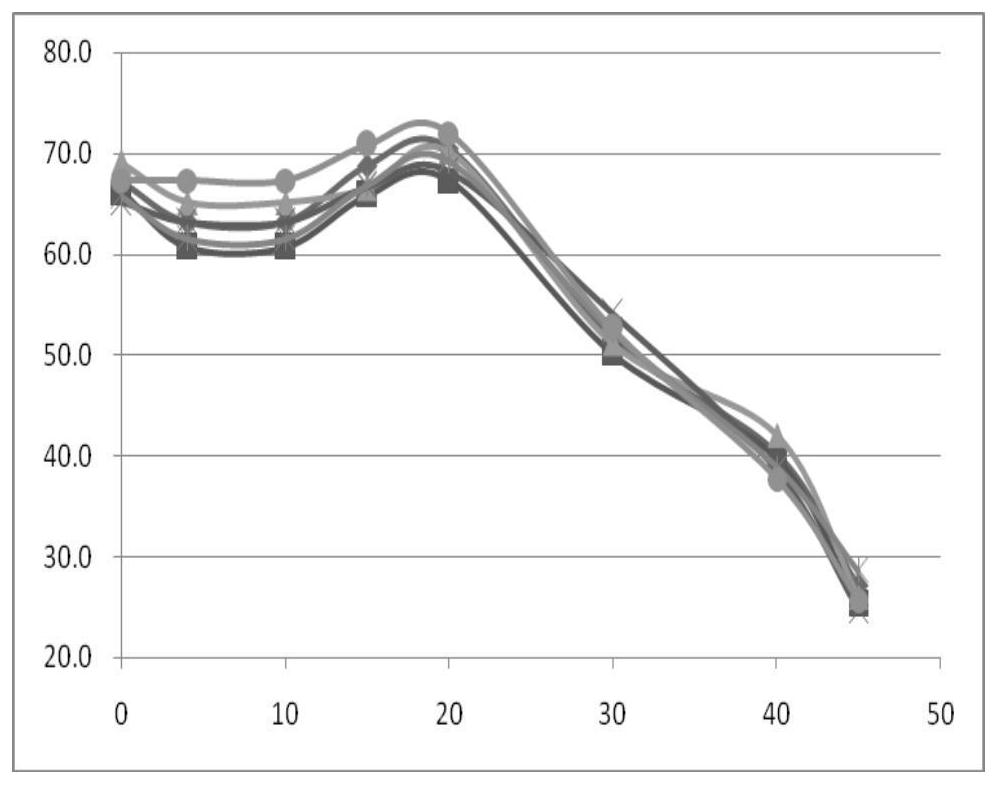

Performance data accompanying product service life and reliability predicting method thereof

The invention relates to a performance data accompanying product service life and a reliability predicting method thereof. The method comprises the following methods that firstly, an evaluation line of the product performance is set, the product performance measuring data is obtained, and the current operation information time sequence is built; the phase space reconstruction is carried out, and a phase point group is obtained; the product performance is predicted, and five future operation information time sequences of the product performance are obtained; five pieces of performance service life data reaching the performance evaluation line are predicted; a large amount of performance service life generation data is obtained; and the probability density function of the future product performance service life is predicted, the reliability function is further predicted, and the performance service life and reliability prediction of the product are completed. The method has the advantages that the probability density function of the future time product performance service life can be obtained according to the current operation information of the product performance, further, the future service life and reliability function of the product are built, the future time performance service life and reliability of the product are favorably predicted in real time, the product performance change / degeneration and failure hidden troubles are found in time, and the occurrence of serious accidents is avoided.

Owner:HENAN UNIV OF SCI & TECH

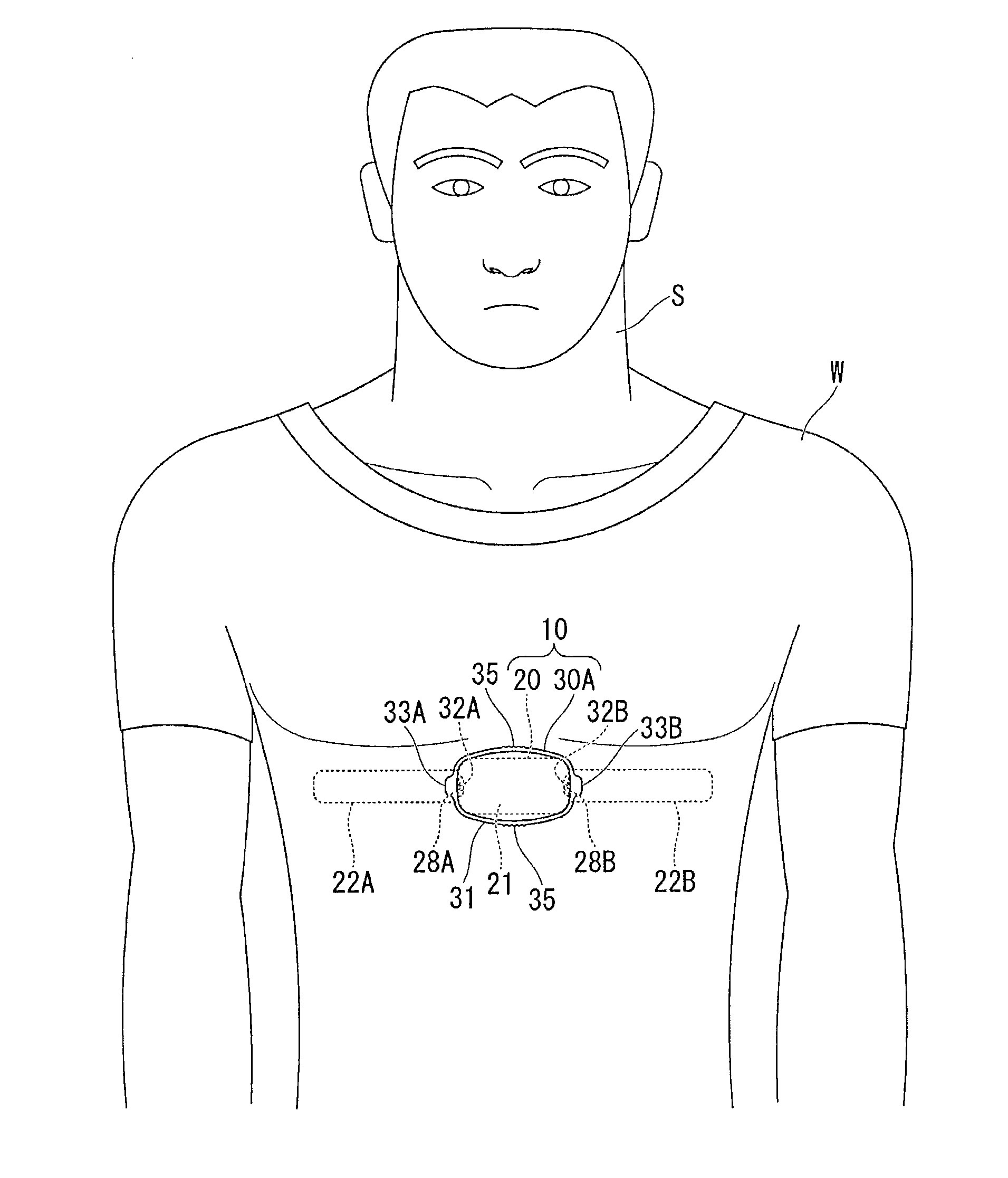

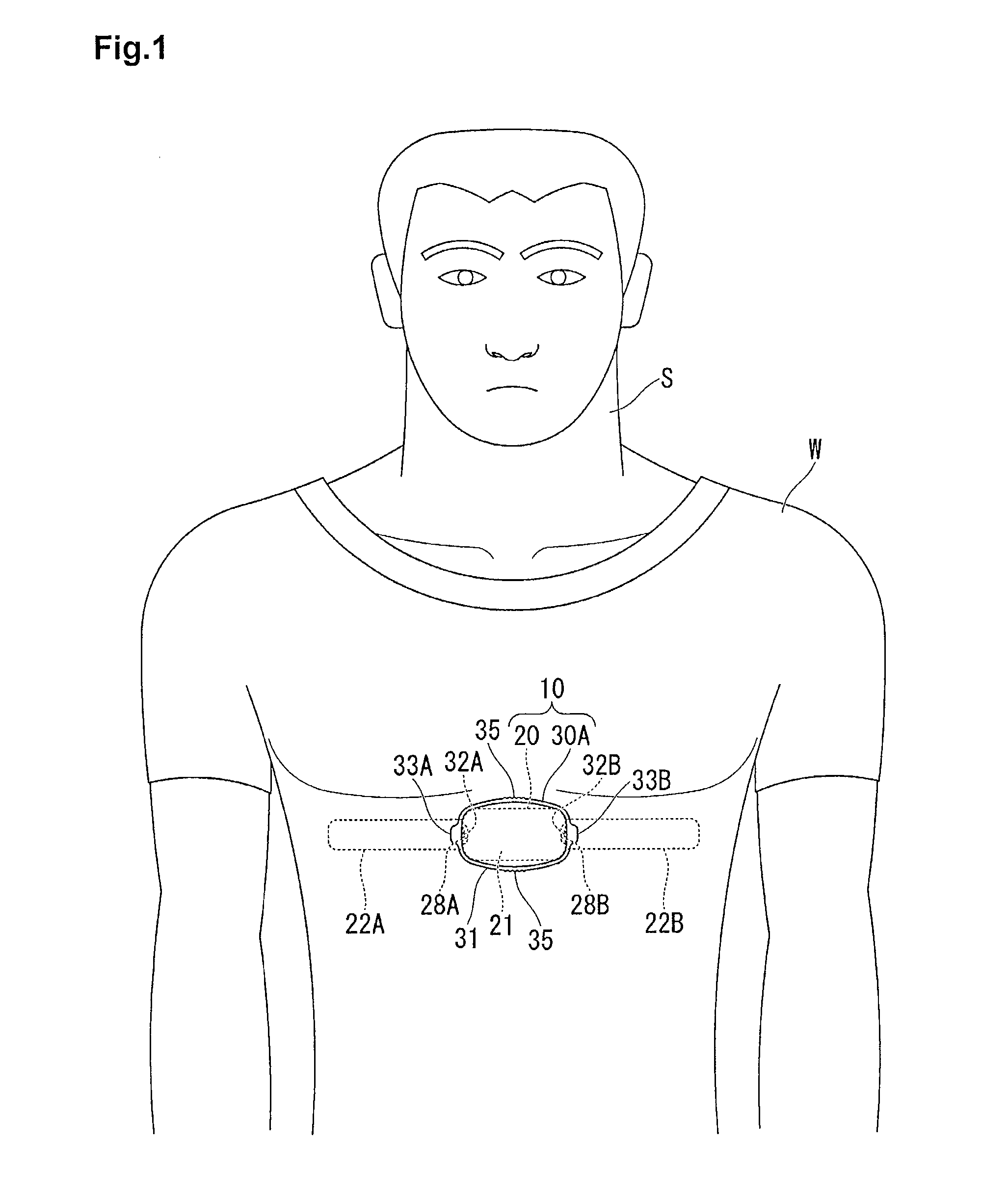

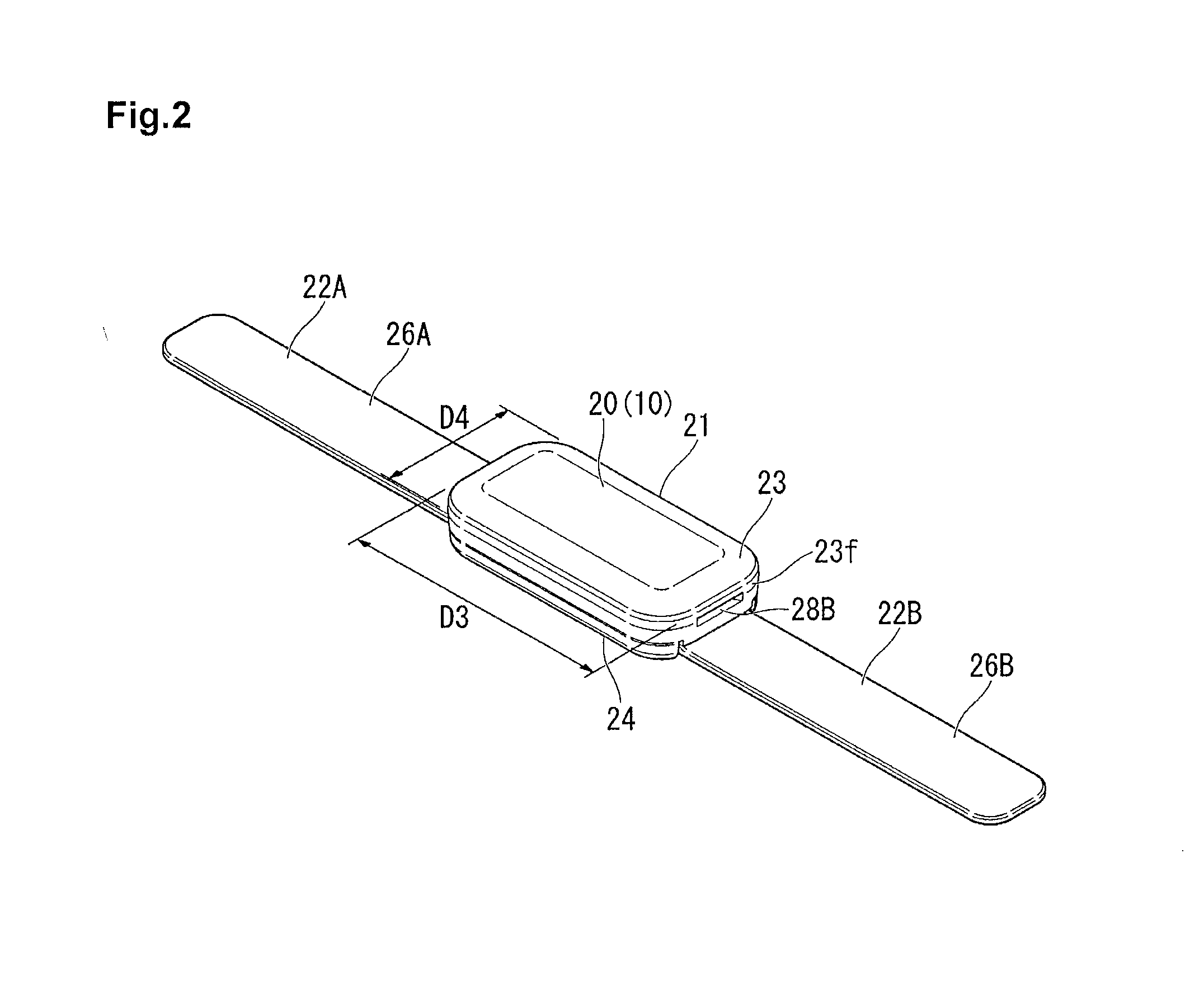

Portable electronic device

ActiveUS20150119676A1Extend product lifeSensorsTelemetric patient monitoringElectronic componentBiomedical engineering

To improve product lifetime as well as to increase wearing feeling, maintainability and productivity, and to suppress manufacturing costs and expenses of the user. A portable electronic device 10 includes a device body 20 arranged inside a garment W and housing an electronic component and a fixing member 30A formed separately from the device body 20 and arranged outside the garment W, which fixes the device body 20 so as to be attached and detached to and from the garment W in a state of sandwiching the garment W between the fixing member 30A and the device bogy 20 from the other side of the garment W. The fixing member 30A is formed so as to be elastically deformed, which is formed in a ring shape surrounding the device body 20. Gaps are provided on both sides of the device body 20 in the radial direction of the fixing member 30A between an inner peripheral surface of the fixing member 30A and the device body 20.

Owner:SEIKO INSTR INC

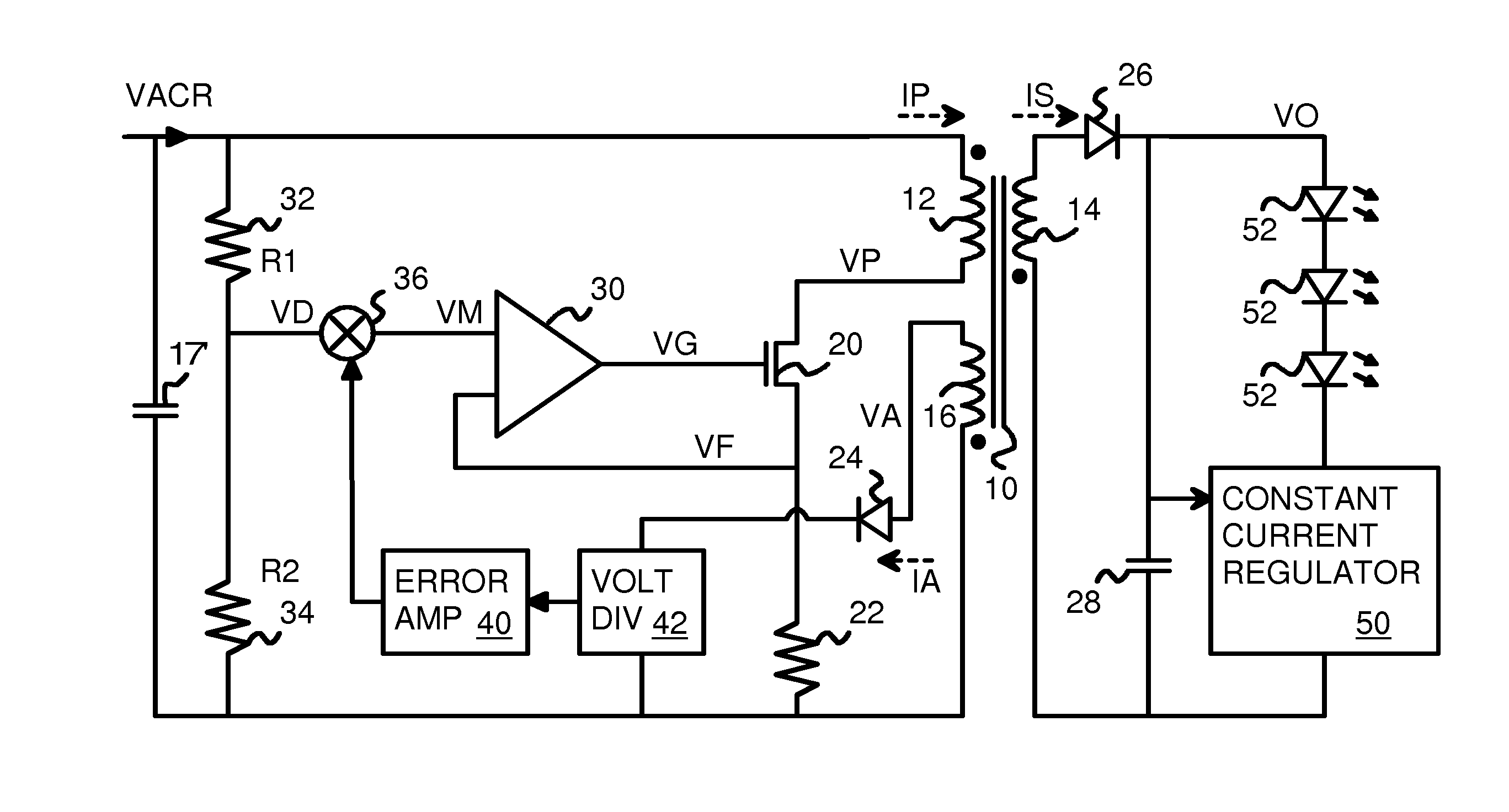

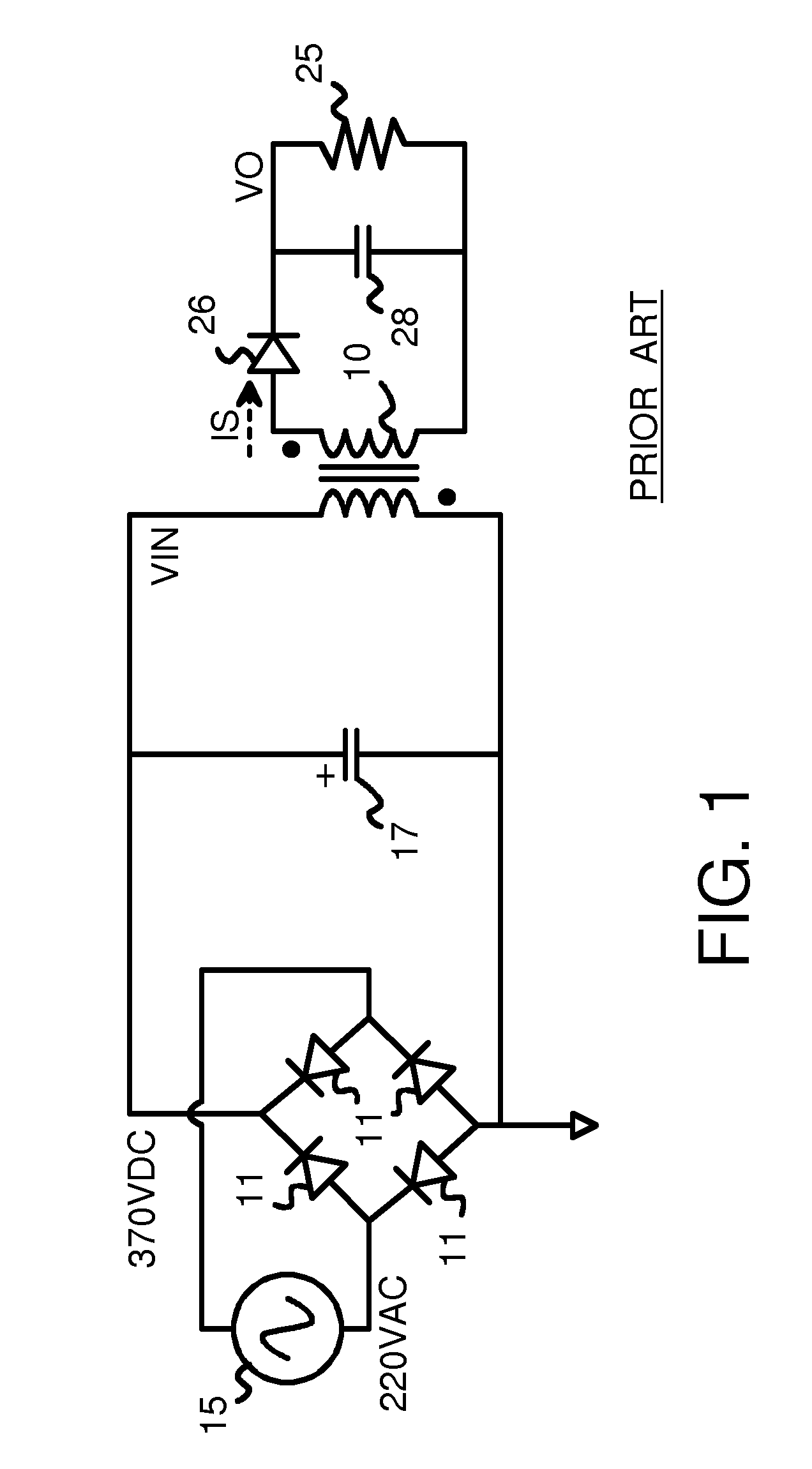

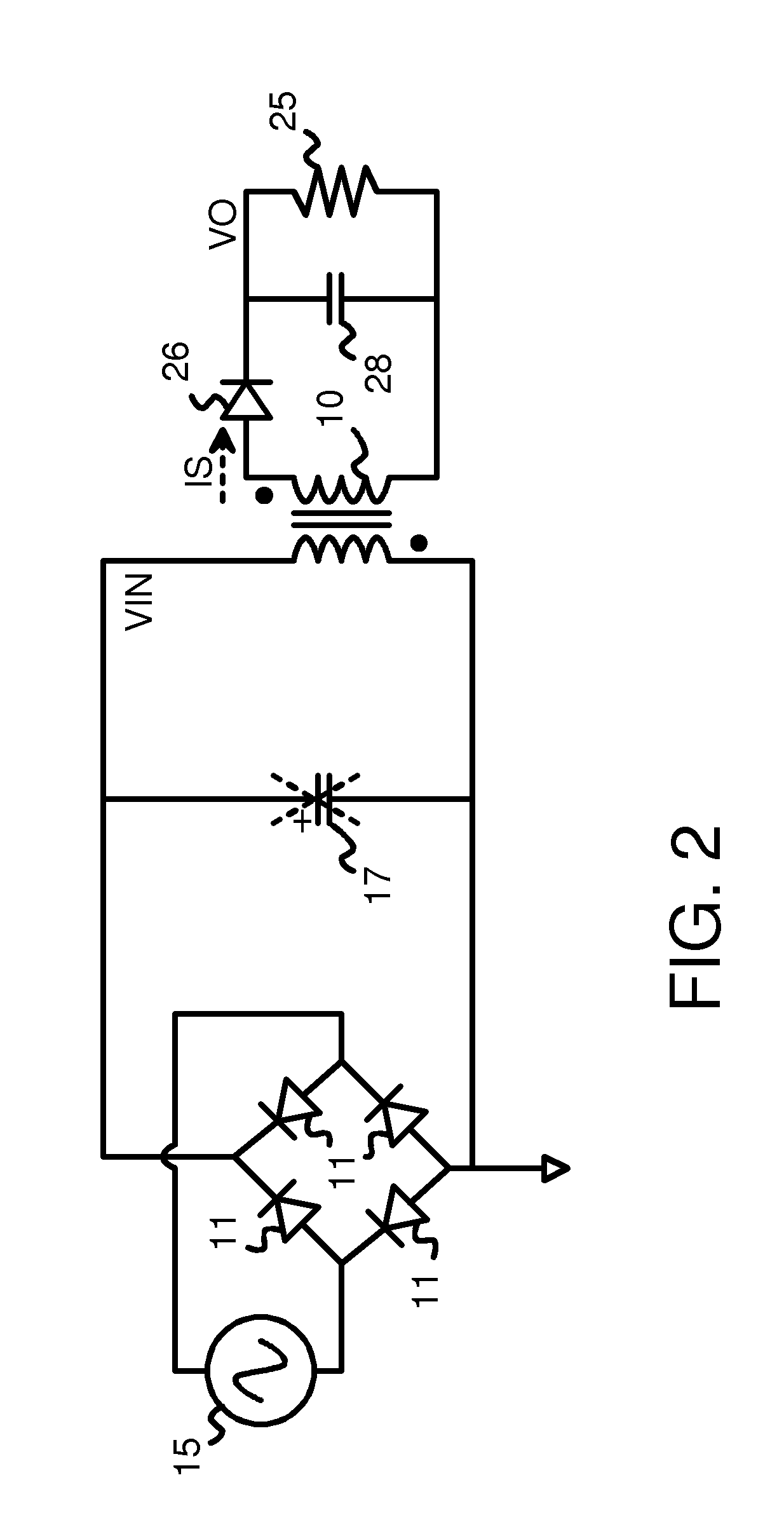

LED Driver with Small Output Ripple Without Requiring a High-Voltage Primary-Side Electrolytic Capacitor

ActiveUS20150381054A1Efficient power electronics conversionElectroluminescent light sourcesCapacitanceEngineering

A power converter reduces output ripple without using an electrolytic primary-side capacitor that can reduce product lifetime. Primary-Side Regulation (PSR) using an auxiliary winding provides a regulated secondary voltage with some low-frequency ripple on a secondary winding of a transformer. A smaller secondary capacitor that is not an electrolytic capacitor filters the output of the secondary side. A bang-bang controller controls the secondary side current to reduce current ripple despite voltage ripple. The bang-bang controller has a series resistor and inductor in series with a load such as an LED. A voltage drop across the series resistor increases when a switch turns on. This increasing voltage drop toggles the switch off once an upper limit voltage is reached. The voltage drop then decreases as inductor current is shunted by a diode, until the voltage drop reaches a lower limit voltage and the switch toggles on again.

Owner:HONG KONG APPLIED SCI & TECH RES INST

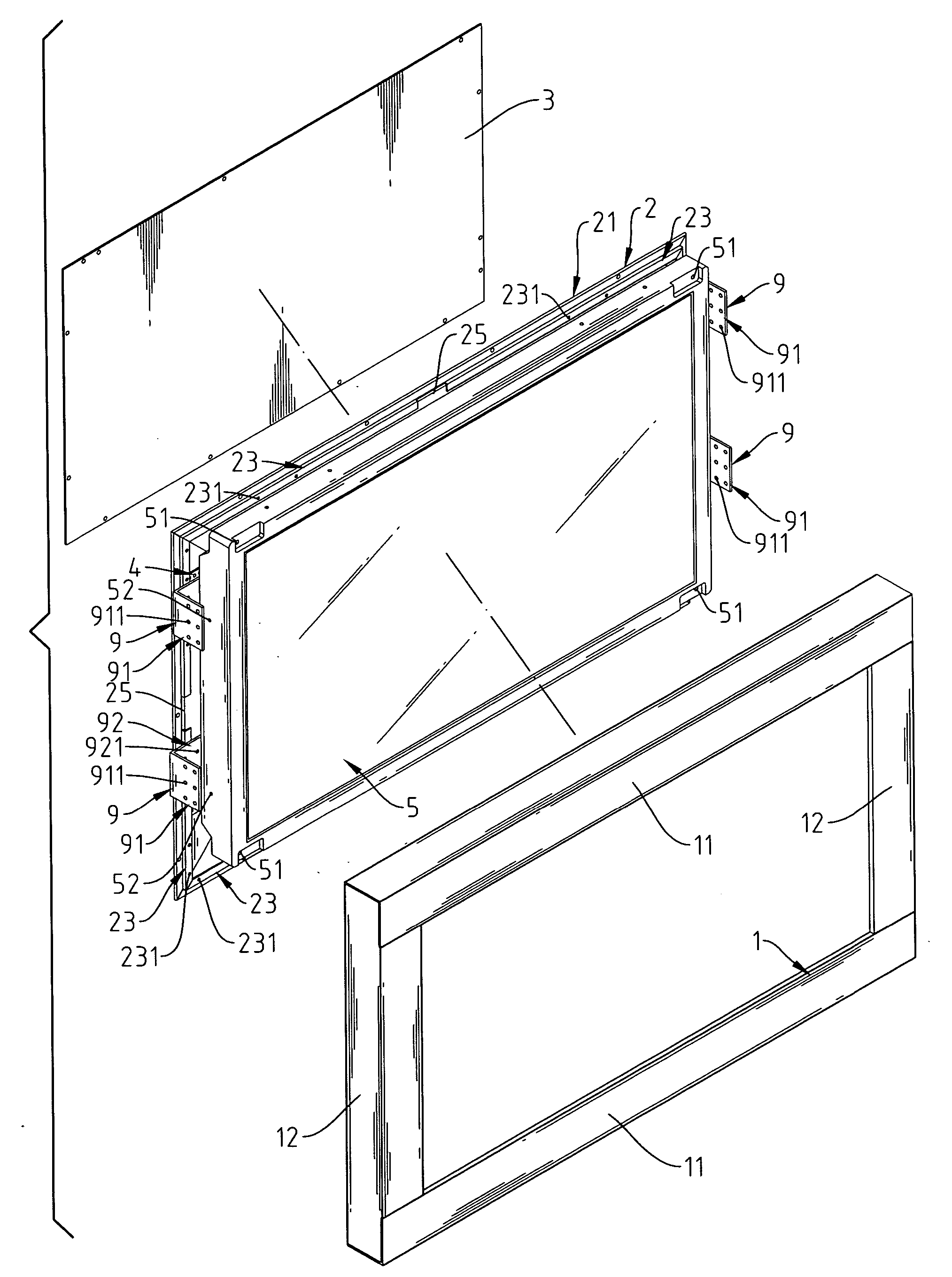

Composite structure of aluminum extrusion external framework of LCD monitor

InactiveUS20060279669A1Improve competitivenessDigital data processing detailsElectrical apparatus contructional detailsLiquid-crystal displayThin slab

An aluminum extrusion external framework of LCD monitor primarily comprises a front frame cap, a back frame cap, and a sheathing, which are assembled with one another. Several movable laminas are mounted on the inside of the back frame cap, wherein the locking positions of the movable laminas are adjustable. The aluminum extrusion external framework of the LCD monitor is made of aluminum for lightening its weight and conforming to the recycle-based environmental protection so as to facilitate the heat sinking, reduce the production cost, and increase the product lifetime. Besides, the movable laminas are applied to the raised slideways around the inside of the back frame cap so as to be universally suitable for the existing LCD panel having various specifications and dimensions.

Owner:PENG CHING LUNG

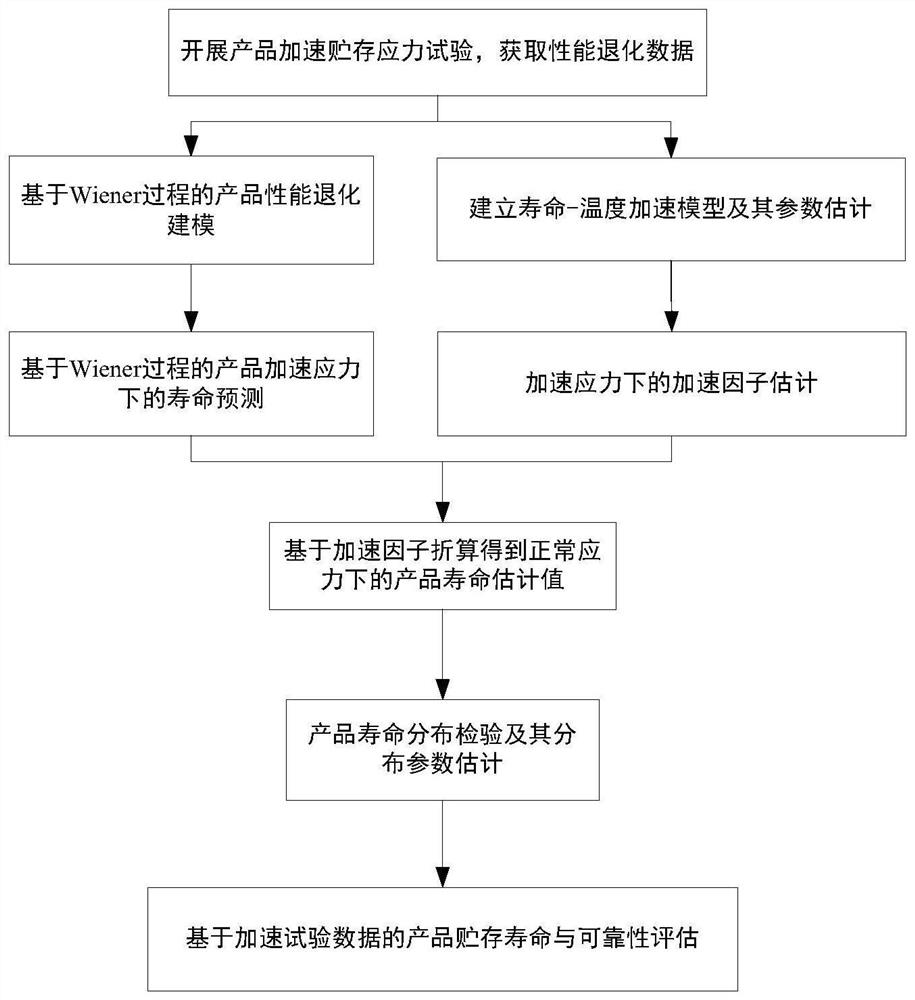

Product storage life and reliability evaluation method

ActiveCN111859658AImproving the Accuracy of Failure Life EstimationIncrease credibilityDesign optimisation/simulationSpecial data processing applicationsEngineeringProcess engineering

The invention relates to a product storage life and reliability evaluation method. The method comprises: A1, carrying out a product accelerated storage stress test to obtain performance degradation data; A2, performing product performance degradation modeling based on a random wiener process; A3, carrying out life prediction under product acceleration stress based on a random Wiener process; A4, establishing a service life-temperature acceleration model, and estimating parameters of the service life-temperature acceleration model; A5, performing acceleration factor estimation under acceleration stress; A6, performing product life estimation value under normal stress based on acceleration factor conversion; A7, performing product life distribution inspection and distribution parameter estimation are carried out; and A8, carrying out storage life and reliability evaluation.

Owner:BEIJING INST OF STRUCTURE & ENVIRONMENT ENG

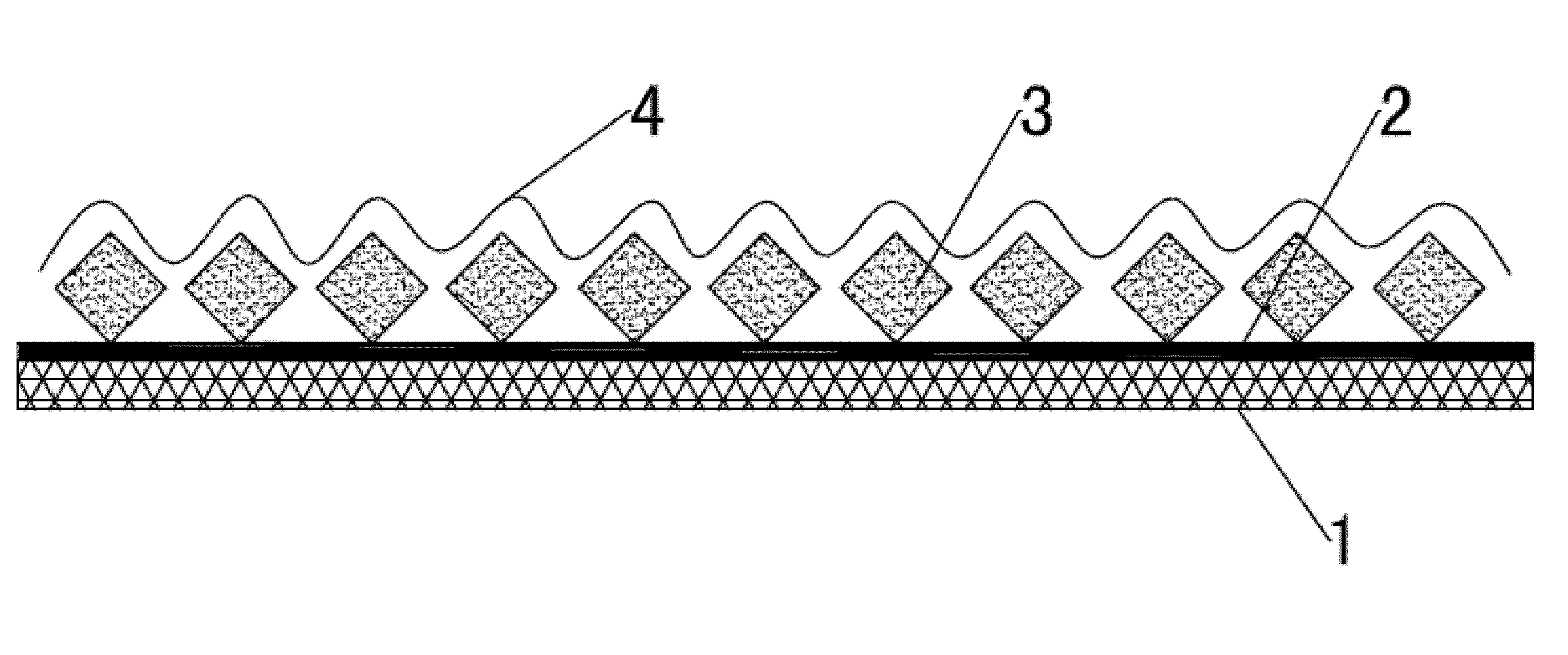

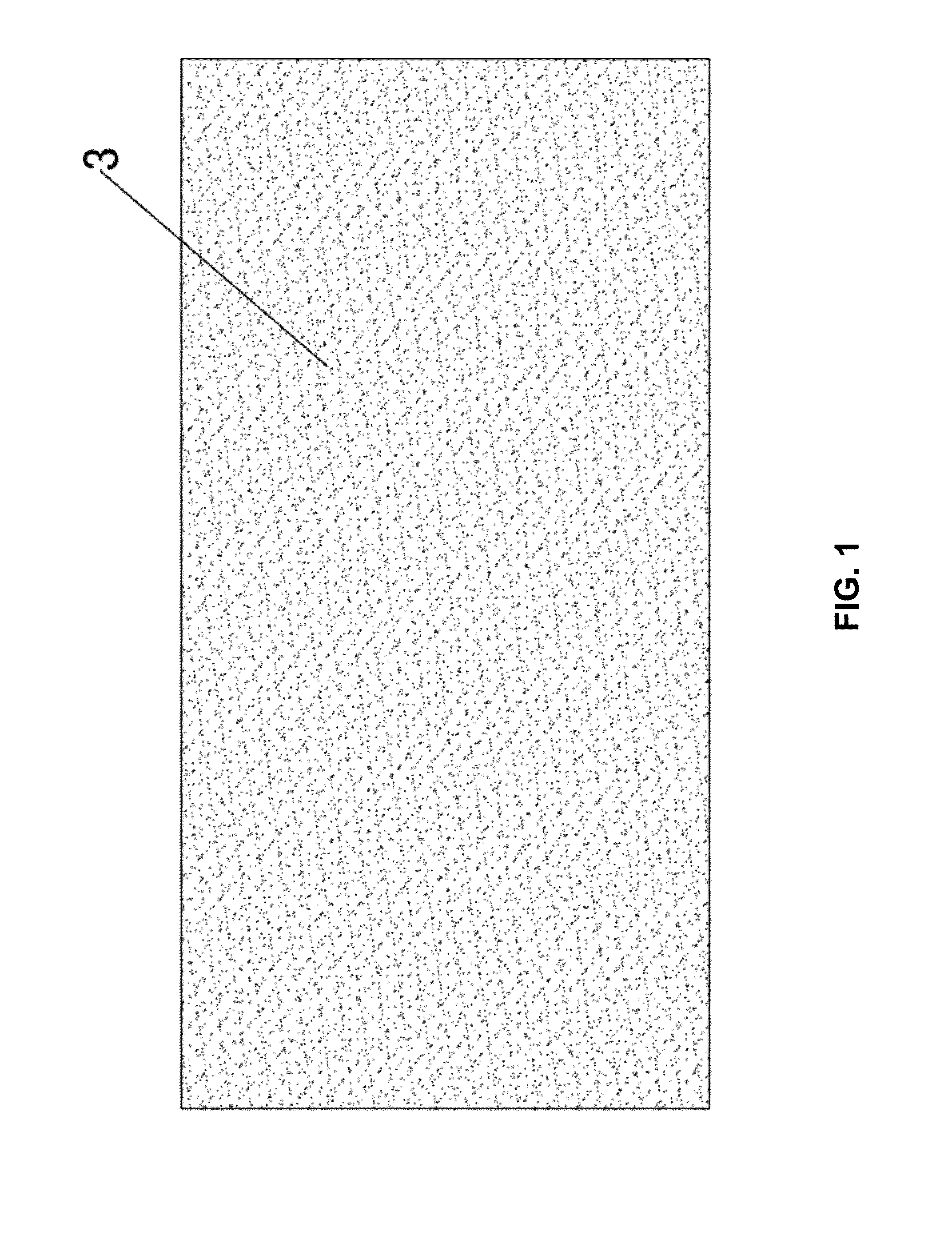

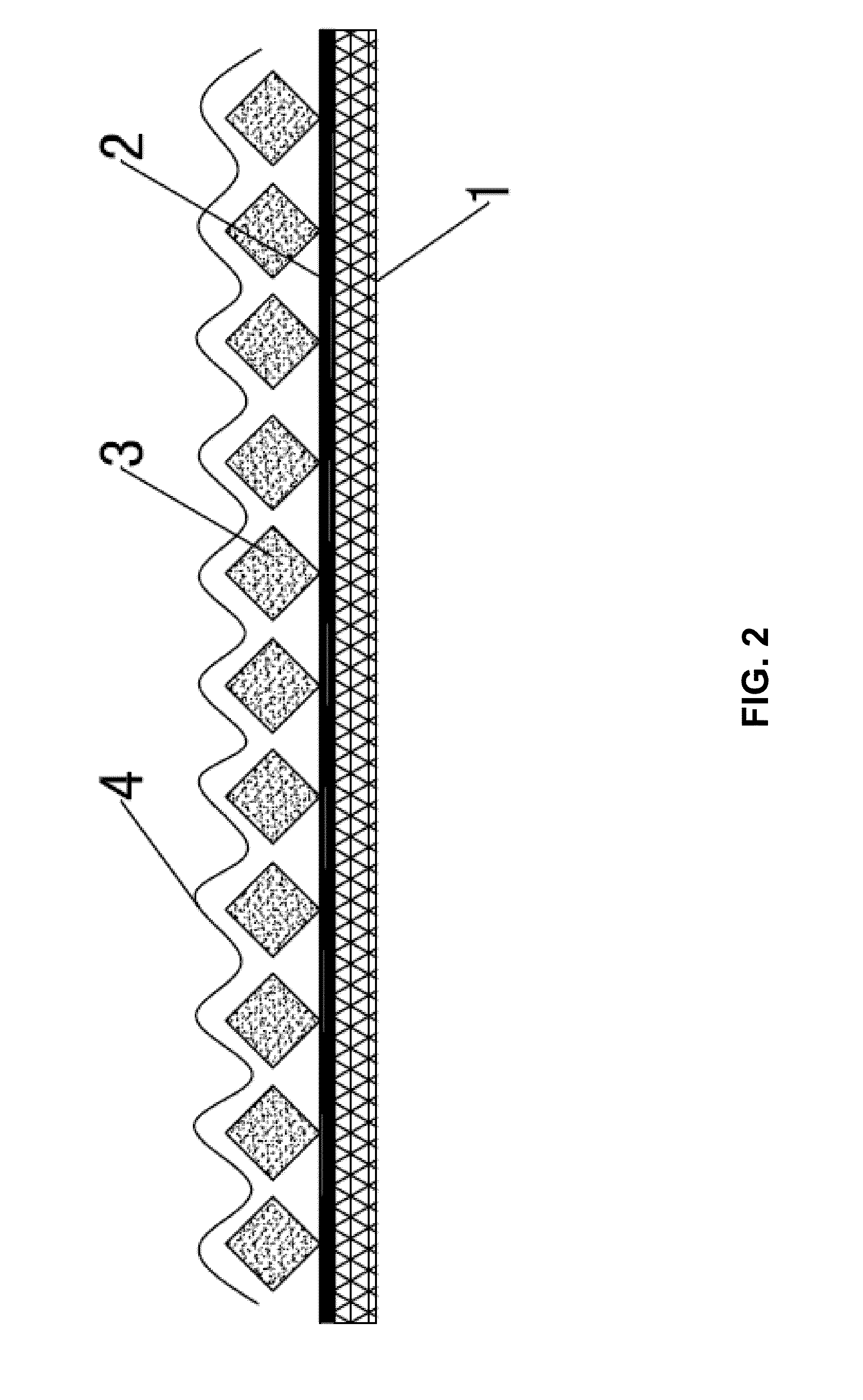

Velcro Abrasive Cloth

The invention is a new Velcro-backed abrasive cloth. It is used in the coated abrasives industry. Its uniqueness is in the construction. It is formed by a cloth with Velcro on one side (1), after the cloth is dipped in resin, the side with no Velcro is coated with a layer of primer (2), and an abrasive layer (3) is then planted on top of the primer. On top of the abrasive layer, a multi-layer adhesive (4) is then planted. There is an anti clogging coating, an anti static coating or a combination of both on the multi-layer adhesive. This new Velcro backed abrasive cloth utilizes a napped fabric as the base material. The abrasives are directly planted onto the resin treated base material thus reducing the manufacturing steps and lowering costs. The unique construction of the base material extends the product lifetime and increases the sanding efficiency.

Owner:ZIBO RIKEN MT COATED ABRASIVES

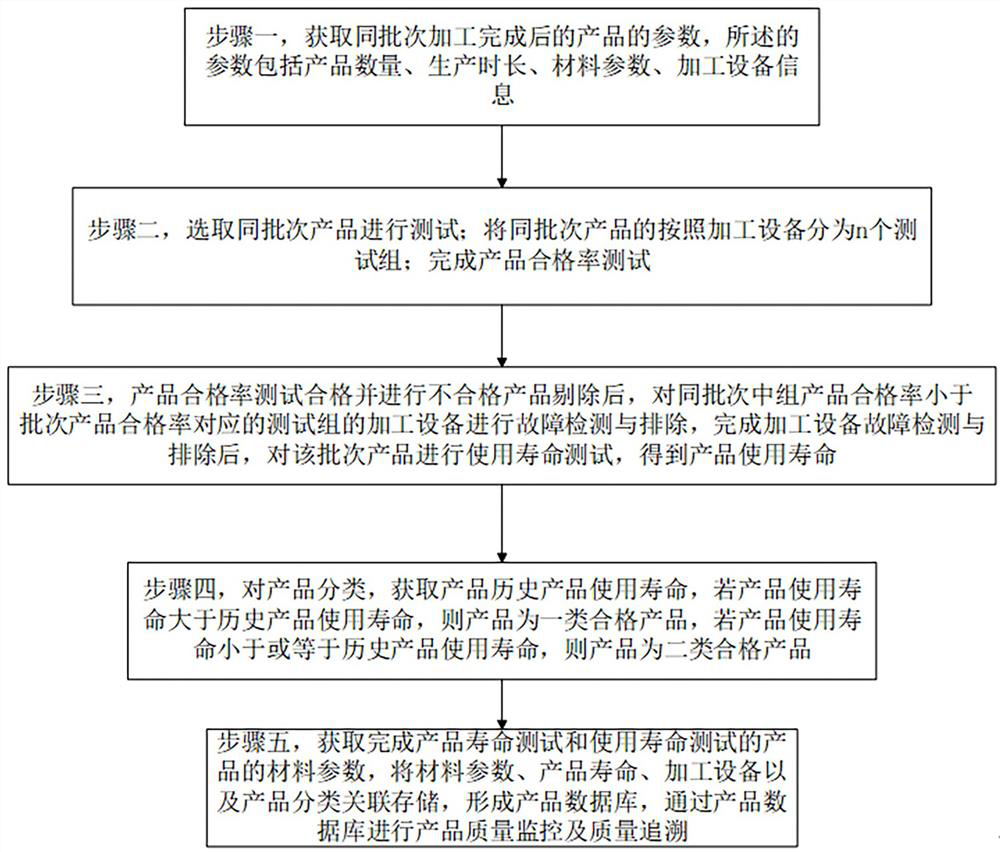

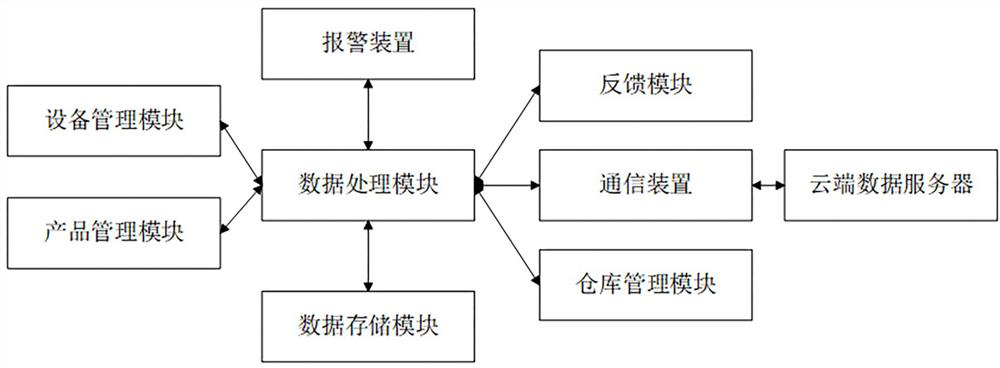

Product processing quality monitoring method and monitoring system

InactiveCN113627833ARapid positioningQuality improvementOther databases indexingResourcesMonitoring systemProcess engineering

The invention discloses a product processing quality monitoring method, comprising the following steps: obtaining parameters of products processed in the same batch, wherein the parameters comprise product quantity, production duration, material parameters and processing equipment information; selecting the same batch of the products for testing; dividing the products of the same batch into n test groups according to processing equipment; after a product qualification rate test is qualified and unqualified products are removed, testing the service life of the batch of products to obtain the service life of the products, classifying the products, obtaining material parameters of the products subjected to the product life test and the service life test, associatively storing the material parameters, the product life, the processing equipment and product classification, forming a product database, and performing product quality monitoring and quality tracing through a product database. According to the invention, not only can the product quality be improved, but also the processing equipment with problems can be quickly positioned.

Owner:JIANGSU NEW HENGJI SPECIAL EQUIP

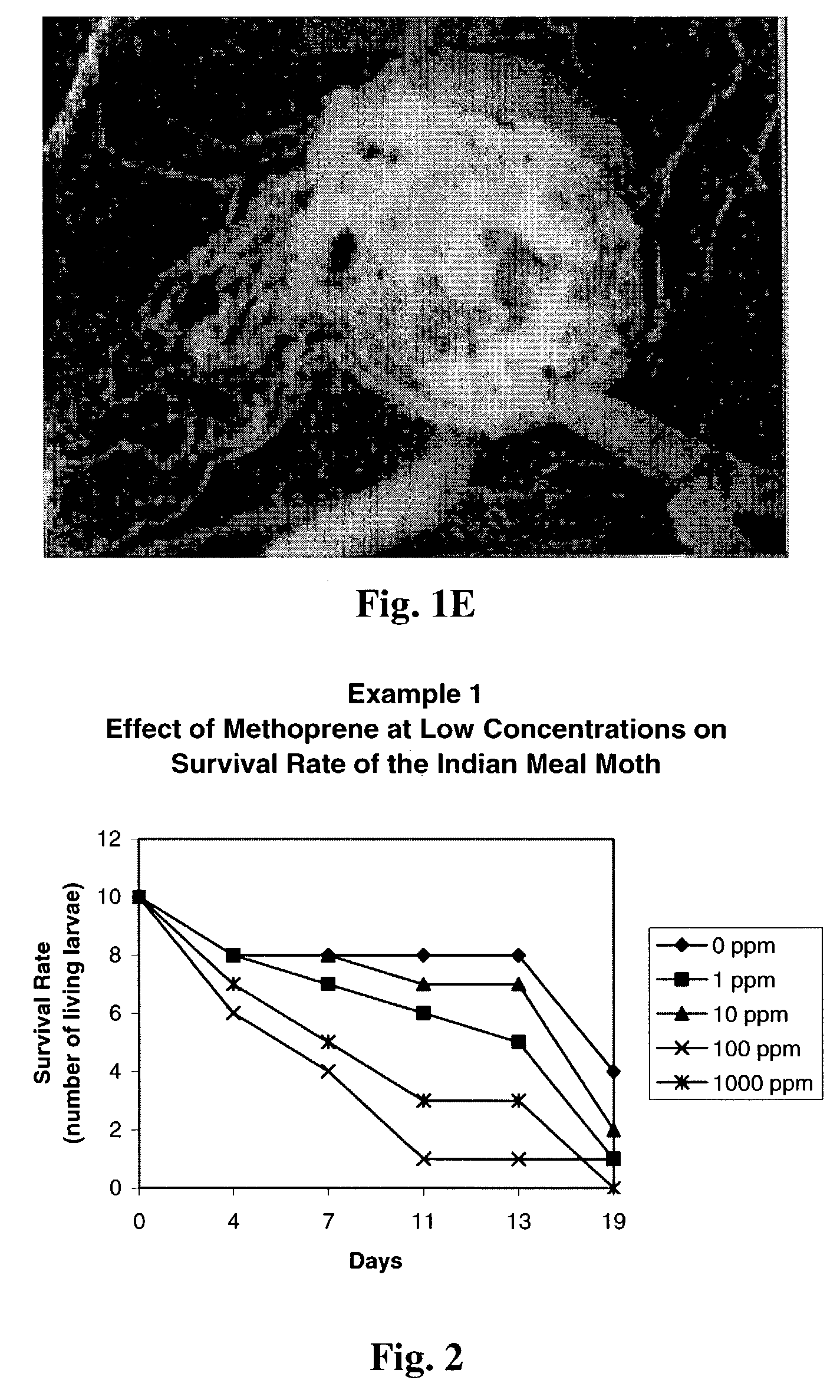

Juvenile hormone compositions and methods for making same

The present invention relates to hormone coating layers having desirable hormone delivery characteristics and product lifetime. In one embodiment, the invention is a hormone composition including a substrate having an external surface, and a coating layer disposed on the external surface. The coating layer preferably includes a polymer web, a UV protectant material, and from about 1 wppm to about 100,000 wppm of a hormone dispersed throughout the polymer web. The invention also relates to methods for making hormone coating materials of the present invention. The coating compositions of the present invention preferably are implemented in human and animal food packaging materials in order to safely and efficiently protect the foodstuffs contained therein from insect infestation.

Owner:PROVISIONGARD HLDG

Lightweight modeling composition

Owner:CHARLIE KAO IND

Long-life valve regulation type sealed lead acid battery life quick detection method

InactiveCN107390134AEasy to detectThe detection data is authentic and credibleElectrical testingEngineeringLife detection

The invention discloses a long-life valve regulation type sealed lead acid battery life quick detection method. The long-life valve regulation type sealed lead acid battery life quick detection method includes the steps: performing random sampling in the same batch of products, equally dividing the samples into two groups, in the same detection environment, applying a circulating charging and discharging detection method to one group, applying a constant current charging detection method to the other group, converting the two groups of detection data into the life of products, and taking the minimum life value as the life of the product. The long-life valve regulation type sealed lead acid battery life quick detection method can accelerate verification of the life of the product by increasing the discharging and charging currents and increasing the discharging depth of a battery. The long-life valve regulation type sealed lead acid battery life quick detection method can greatly reduce the life detection time, thus saving the detection cost of the manufacture party, enabling the demand party to know about the product life as soon as possible, and being convenient for arranging an ordering contract practically.

Owner:SHUANGDENG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com