Product service life rapid test method based on physical model

A physical model and inspection method technology, applied in the testing of machine/structural components, speed/acceleration/shock measurement, and testing/calibration of speed/acceleration/shock measurement equipment, etc., to shorten inspection time, save test sample size, The effect of saving test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

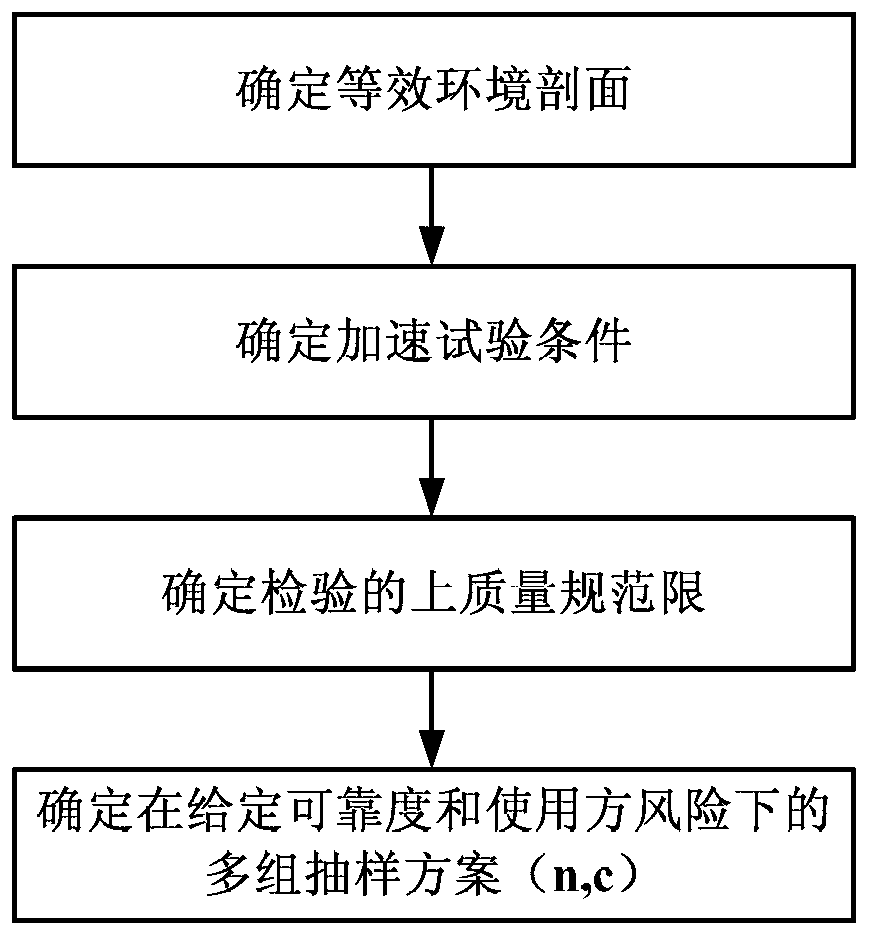

[0048] The following embodiments are based on the quartz flexible accelerometer as the research object figure 1 The flow shown is carried out, and finally a quick inspection scheme for the stability of the performance parameters of the accelerometer is determined. details as follows:

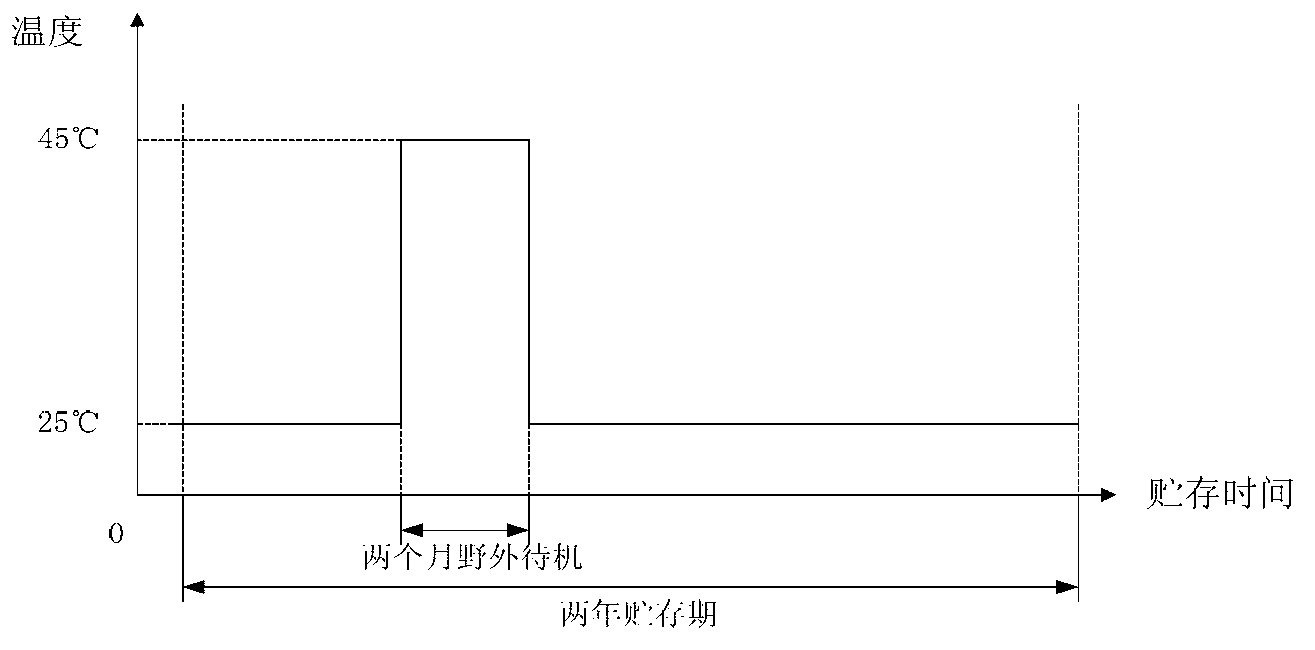

[0049] Step 1: Determine the equivalent environmental profile

[0050] a. Select the degraded physical model of the accelerometer parameters, the degraded physical model characterizes the relationship between the amount of performance parameter degradation and environmental stress and time;

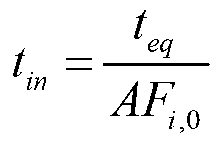

[0051] The physical model of accelerometer performance parameter scaling factor changing with temperature and time is:

[0052] ΔK 1 K 1 = ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com