Test method and device for automatically adjusting Redriver

A technology of automatic adjustment and test method, applied in the direction of faulty hardware test method, error detection/correction, and detection of faulty computer hardware, etc., to improve test efficiency, save test time and manpower, and ensure accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

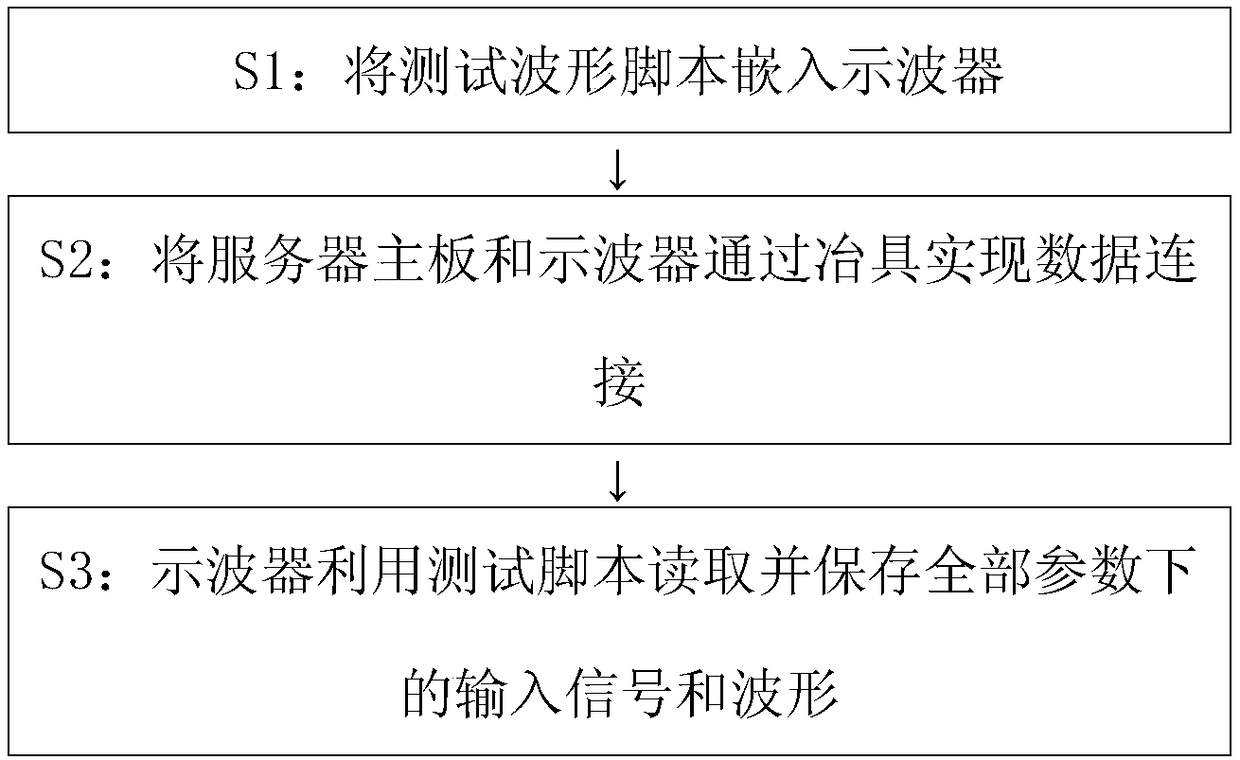

[0036] Such as figure 1 As shown, embodiment 1 of the present invention provides a kind of testing method that automatically adjusts Redriver, and described method comprises:

[0037] S1: Embed the test waveform script into the oscilloscope. The main function of the test waveform script is to automatically test the signal transmitted through the fixture and save the waveform in the oscilloscope by receiving the enable signal each time. During the test, the time of the test signal waveform is fixed.

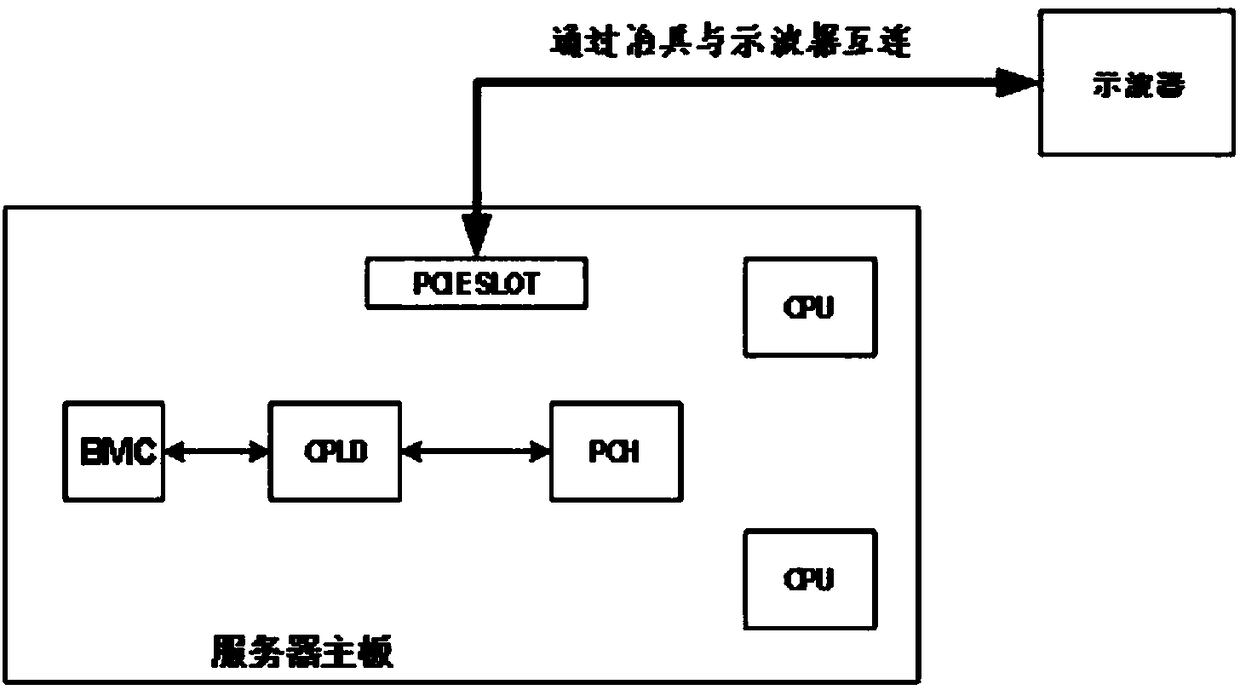

[0038] S2: Connect the server main board and the oscilloscope through the jig for data connection.

[0039] S3: The oscilloscope uses the test script to read and save the input signal and waveform under all parameters.

[0040] The specific implementation process of step S3 is:

[0041] S31: Burn the tested firmware into the BMC by using the burning device and burning software.

[0042] S32: Turn on the server, and the BMC writes the first set of values into the Redriver re...

Embodiment 2

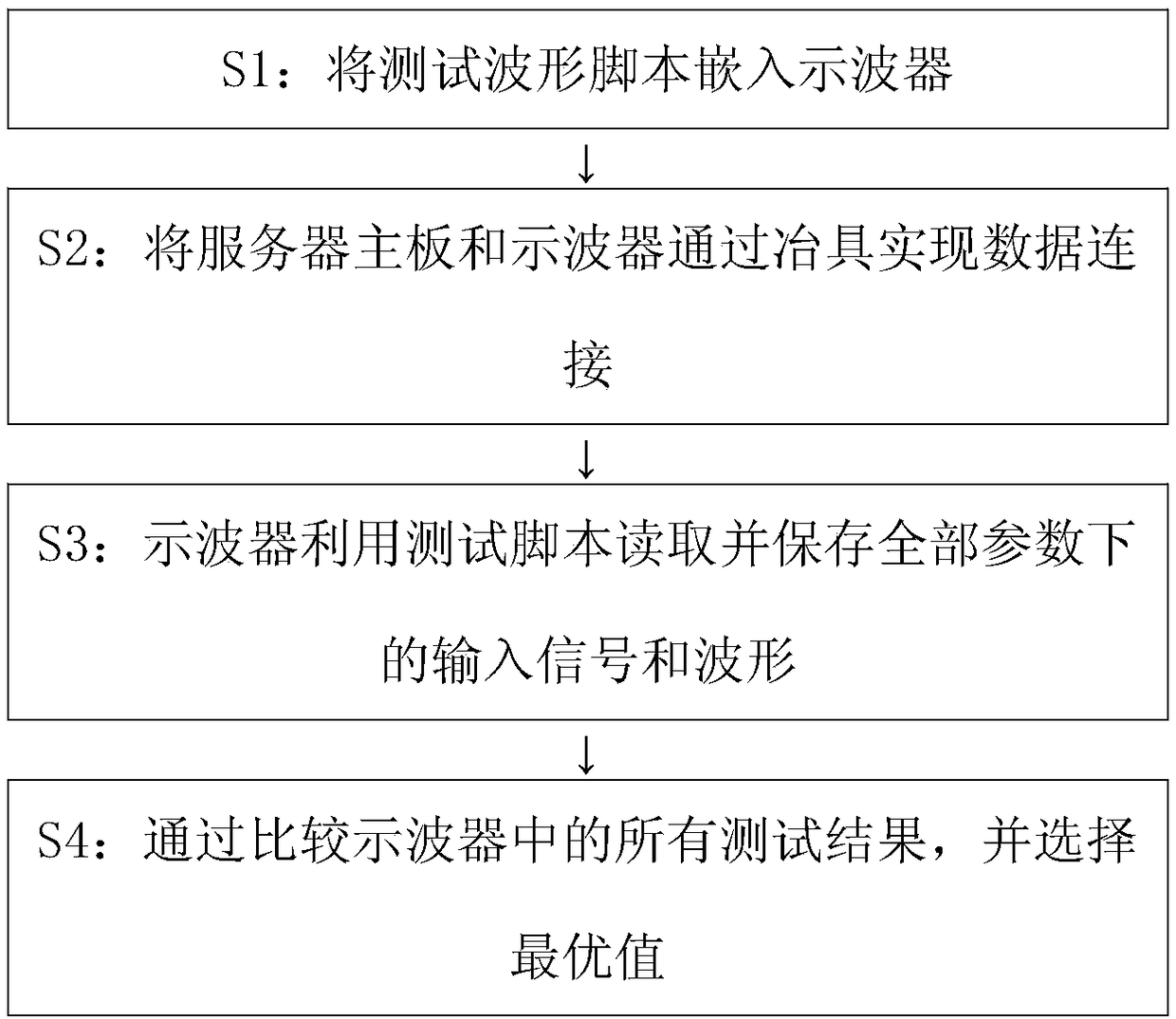

[0047] Such as figure 2 As shown, embodiment 2 of the present invention provides a kind of testing method that automatically adjusts Redriver, and described method comprises:

[0048] S1: Embed the test waveform script into the oscilloscope. The main function of the test waveform script is to automatically test the signal transmitted through the fixture and save the waveform in the oscilloscope by receiving the enable signal each time. During the test, the time of the test signal waveform is fixed.

[0049] S2: Connect the server main board and the oscilloscope through the jig for data connection.

[0050] S3: The oscilloscope uses the test script to read and save the input signal and waveform under all parameters.

[0051] The specific implementation process of step S3 is:

[0052] S31: Burn the tested firmware into the BMC by using the burning device and burning software.

[0053] S32: Turn on the server, and the BMC writes the first set of values into the Redriver r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com