Improved method for prolonging product service life based on material ratio and key process parameter

A technology of process parameters and product life, applied in electrical digital data processing, special data processing applications, instruments, etc., to achieve the effect of guiding industrial production, saving sample volume and running time, and increasing life expectancy accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

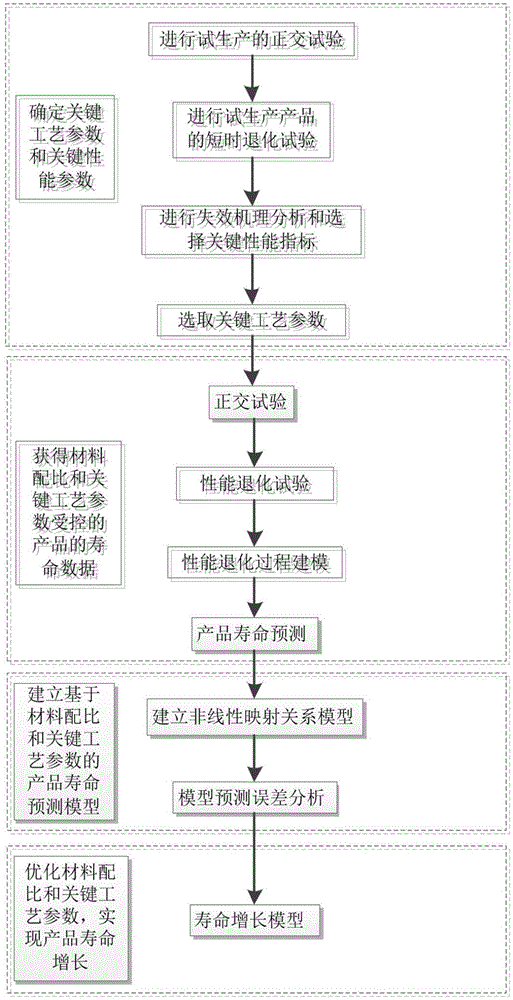

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with specific embodiments.

[0040] Step 1, determining key process parameters and key performance parameters;

[0041] (1) Orthogonal test for trial production

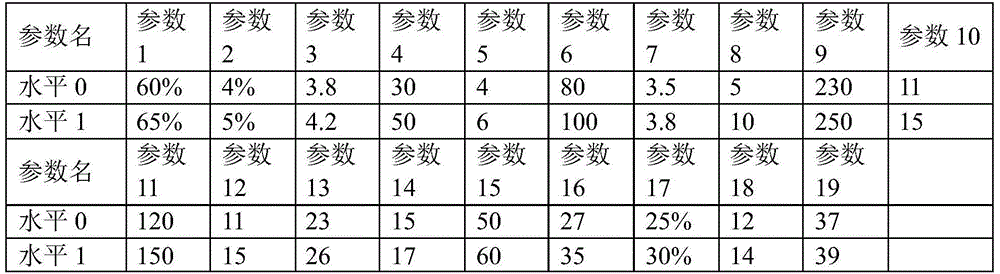

[0042] A case product contains a total of 19 process parameters. In order to reduce the test samples, the level number of each parameter is taken as 2. Through analysis, select the orthogonal test table as L 20 (2 19 ), a total of 20 samples need to be produced. Its factors and factor levels are shown in Table 1:

[0043] Table 1 Factors and factor levels

[0044]

[0045] (2) Short-term degradation test of trial production products

[0046] After obtaining the trial-produced product, it is necessary to conduct a short-term performance degradation test under the same experimental conditions to observe and record the degradation of each performance parameter. Considering that the dimensions of each performance parameter are different...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com