Significance testing method for rolling bearing performance variation process

A technology for rolling bearings and inspection methods, which is applied in special data processing applications, instruments, electrical digital data processing, etc., and can solve problems such as deterioration of rolling bearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

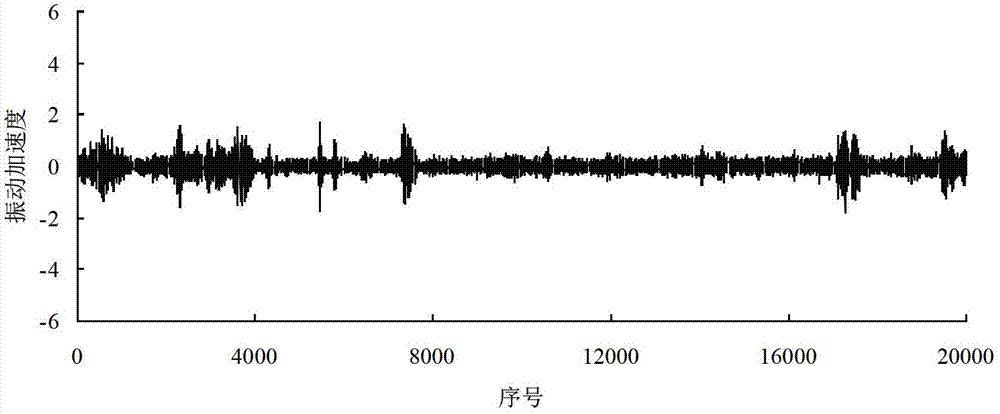

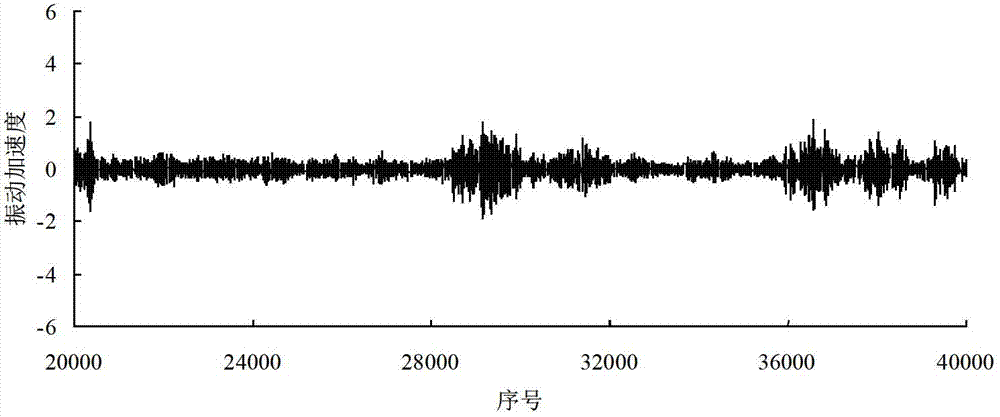

[0107] Take the vibration variation of rolling bearings caused by simulated wear as an implementation case. Experimental data for studying the vibration acceleration of rolling bearings (unit: m / s 2 ), to test the wear process of the bearing, the simulation experiment time was from November 8, 2010 to December 23, 2010. The rolling bearing works continuously for 46 days (the axial load is 49N, the speed is 1000r / min), and 65000 pieces of data are regularly collected from the bearing every day. Starting from November 8, the data is taken every 5 days, and a total of 10 days of data are obtained. The first 4000 data of each day are selected as the research object, so there are 40000 original vibration data in the whole experimental process (a total of 10 time units, each time unit corresponds to a time series, each time series contains 4000 data, a total of 10 time series), such as figure 1 with figure 2 shown.

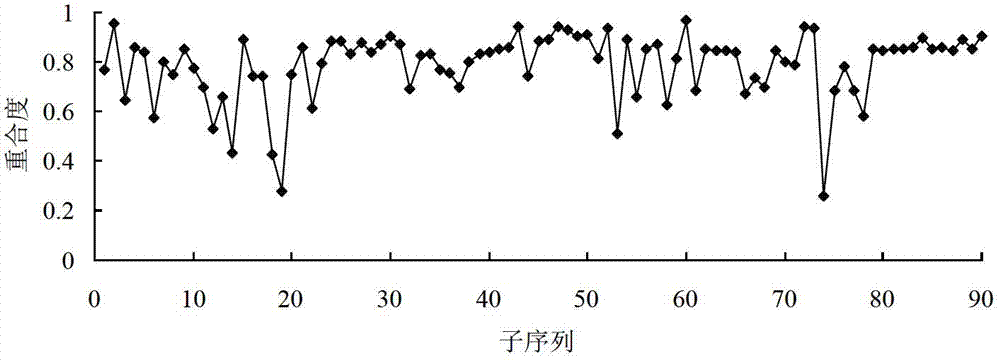

[0108] observe figure 1 with figure 2 , select every 400 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com