Patents

Literature

72results about How to "Timely detection of damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Beam bridge damage assessment early-warning method and early-warning system based on crack development height

InactiveCN103226084ATimely detection of damageMonitoring content is intuitiveMaterial strength using steady bending forcesEarly warning systemConductive coating

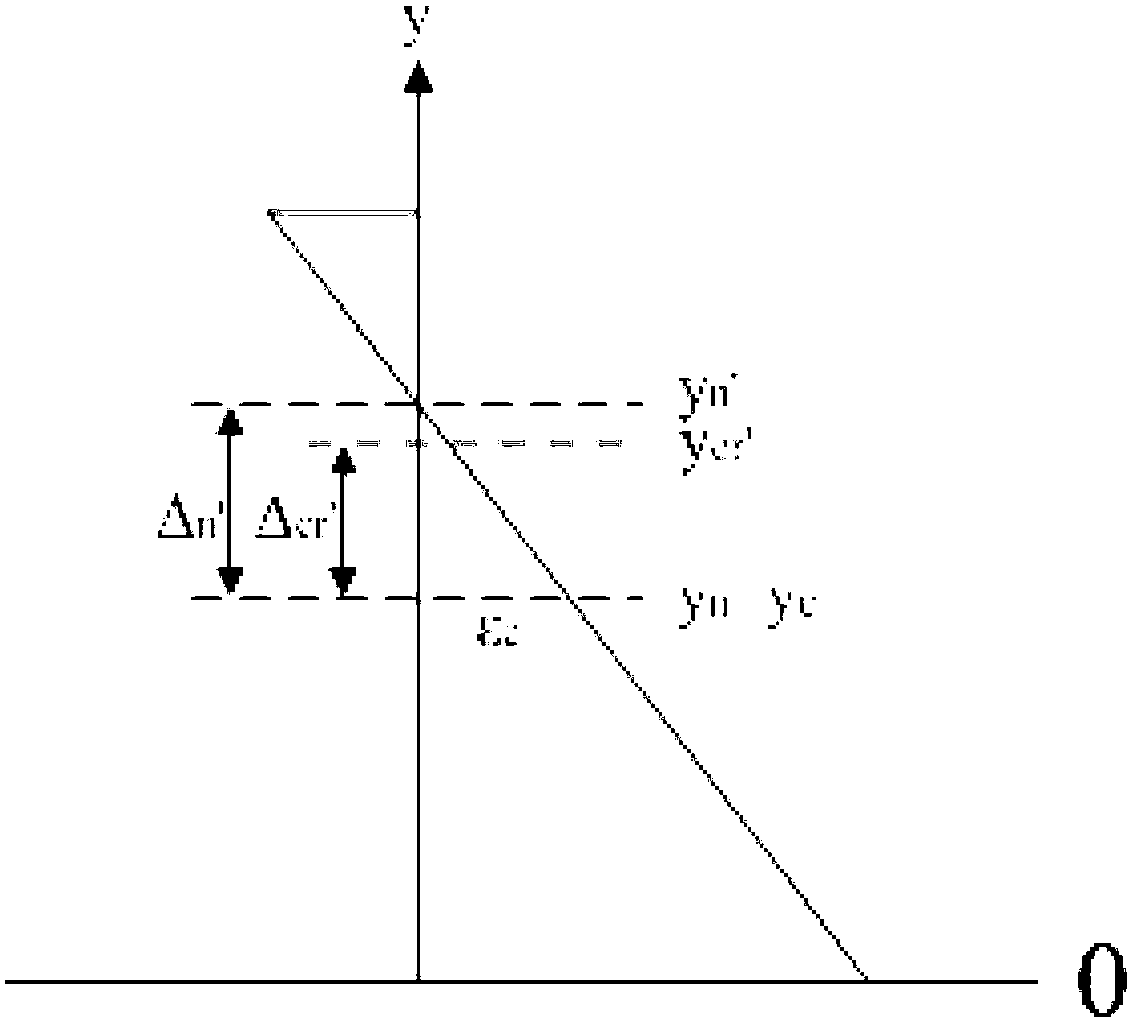

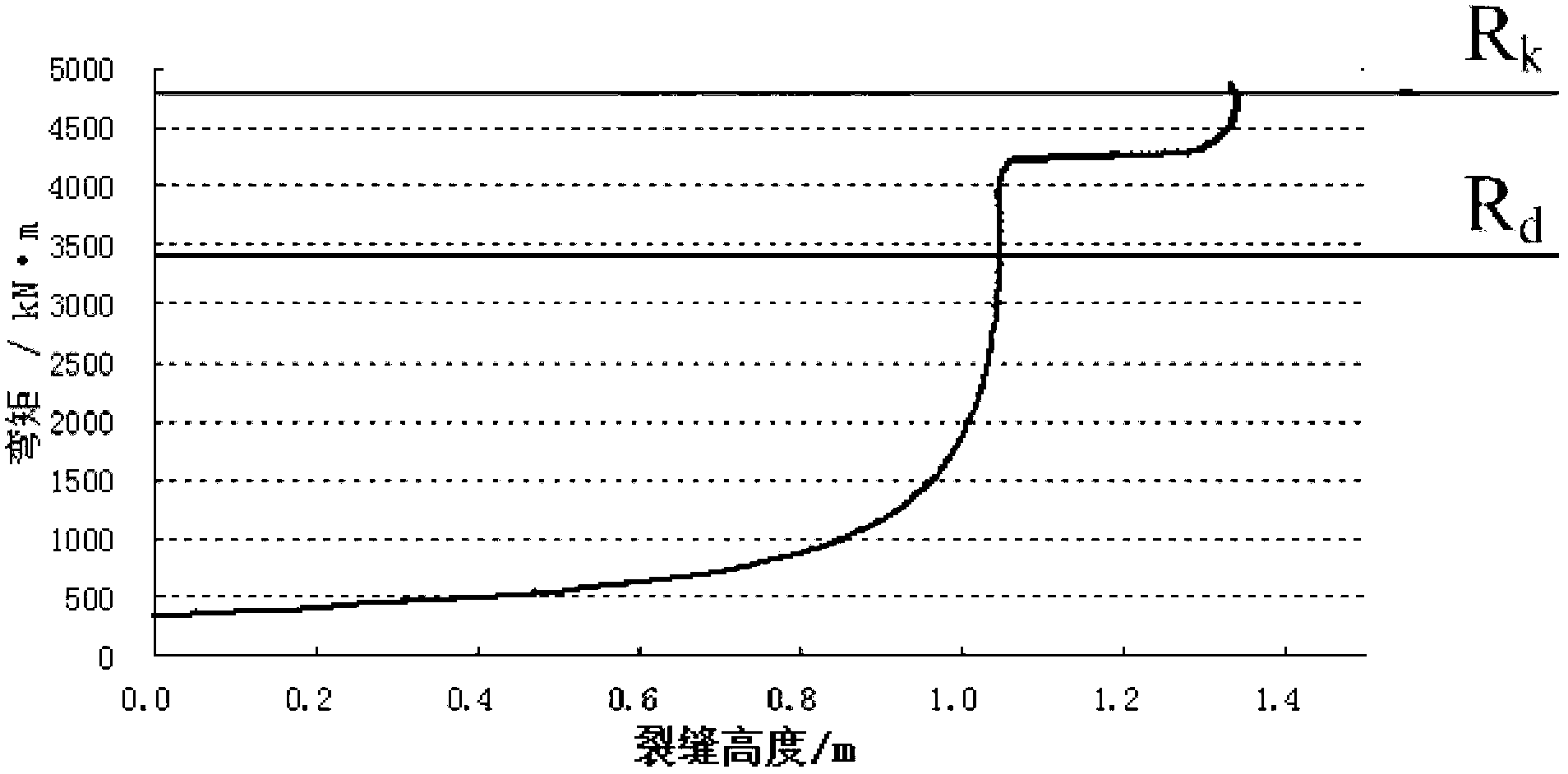

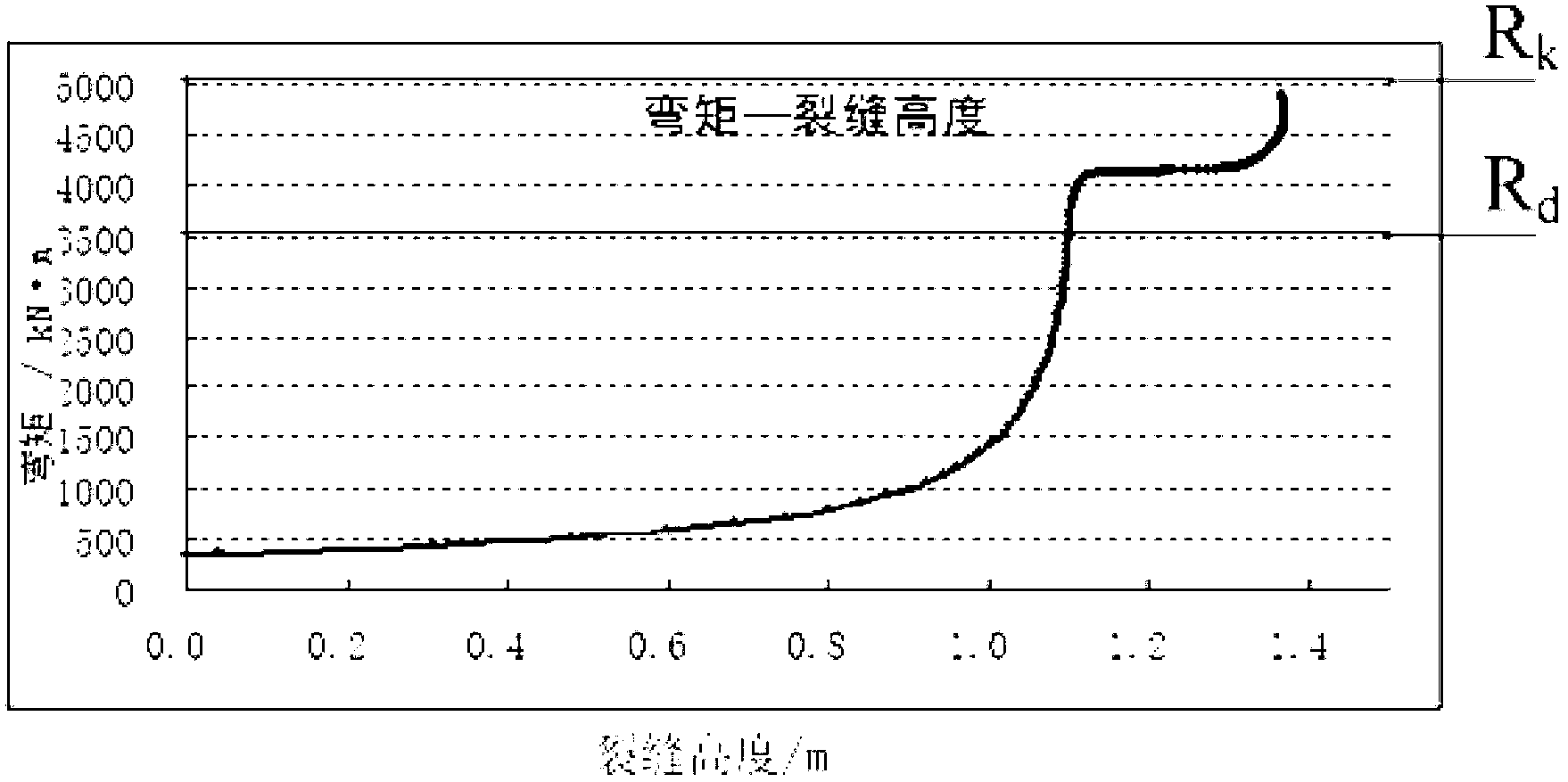

The invention relates to a beam bridge damage assessment early-warning method and an early-warning system based on a crack development height. According to the early-warning method, early warning is carried out when a crack in a main beam of the beam bridge requiring monitoring develops to a dangerous crack height range of a main beam mid-span cross section. The main beam mid-span cross section dangerous crack height range is provided according to a main beam resistance designed value and a main beam resistance standard value, and is determined according to a bending moment-crack height diagram of the main beam mid-span cross section. The bending moment-crack height diagram is obtained according to a cross section non-linear whole process analysis upon the bridge cross section. The early-warning system comprises conductive coatings coated on dangerous crack height ranges of various main beam mid-span cross sections of the beam bridge, and a data processing and early-warning device. The data processing and early-warning device comprises a data acquisition device, a microprocessor, and a GMS short message module. When a crack on the monitored beam bridge main beam develops to a dangerous crack height range, the system carries out early warning with a form of short messages.

Owner:CHANGAN UNIV

GPS/GIS (Global Position System/Geographic Information System)-based engineering machinery electronic controller and control method

InactiveCN104749982APrevent theftEasy to trackProgramme control in sequence/logic controllersElectric machineryGeographic information system

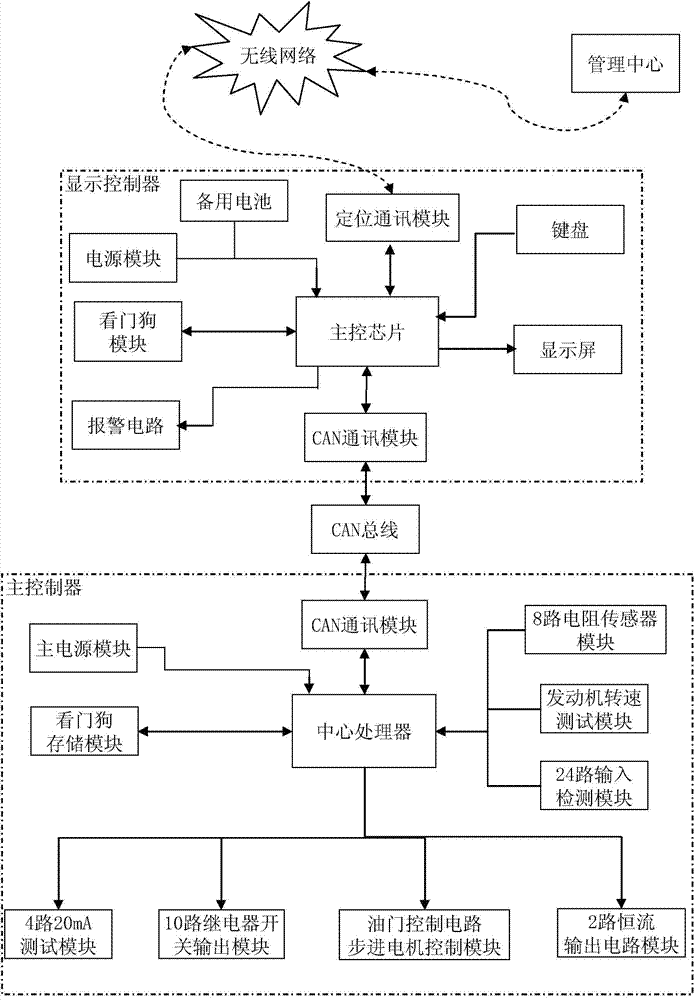

The invention discloses a GPS / GIS (Global Position System / Geographic Information System)-based engineering machinery electronic controller. A CAN bus is connected with a main controller and a display controller, the main controller has all relay on-off output modules and accelerator motor control modules used for receiving operating signals in real time to control equipments to operate, and the display controller has a GPS / GIS wireless communication module and a keyboard display screen. A control method comprises the steps of receiving all working condition parameters by the main controller, and transmitting the GPS / GIS and the working condition parameters to a management center by the display controller; alarming when a positioning communication is abnormal; operating the equipment in time allowance, and relieving alarm after the communication is restored; carrying out the primary locking after exceeding the time limit, and operating an engine in an idling way; restoring the equipment in a locking time limit after contacting with a management center to obtain a password to unlock; carrying out secondary locking after the locking period exceeds, carrying out power failure and fuel cut for an entire vehicle, transmitting the password by a user after the user is in contact with the management center to confirm the equipment is in a good condition, and unlocking the equipment to restore operation. According to the GPS / GIS-based engineering machinery electronic controller provided by the invention, the position and operating condition of the equipment can be timely grasped by the management center, so as to effectively prevent stealing and damaging.

Owner:GUILIN UNIV OF ELECTRONIC TECH

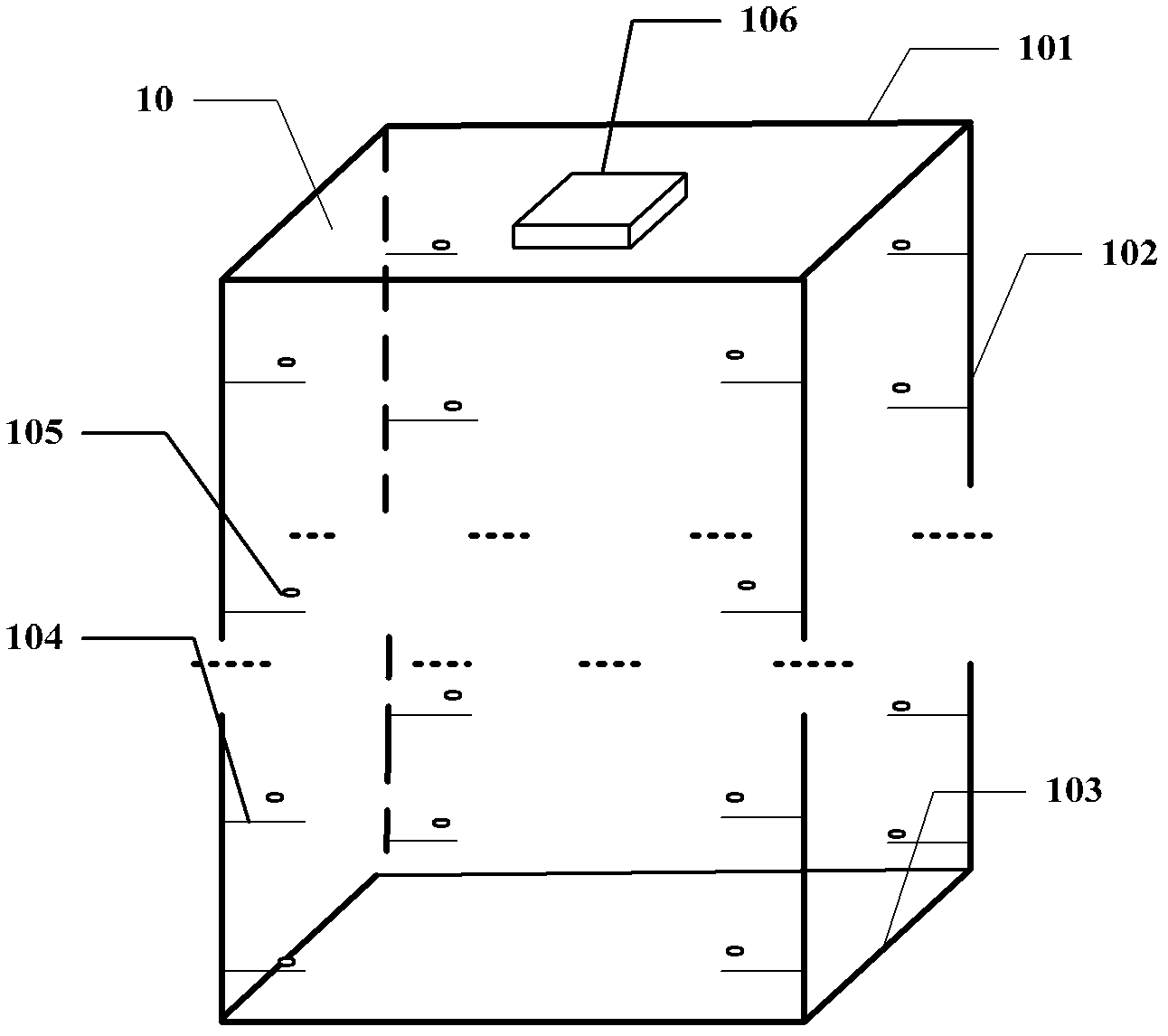

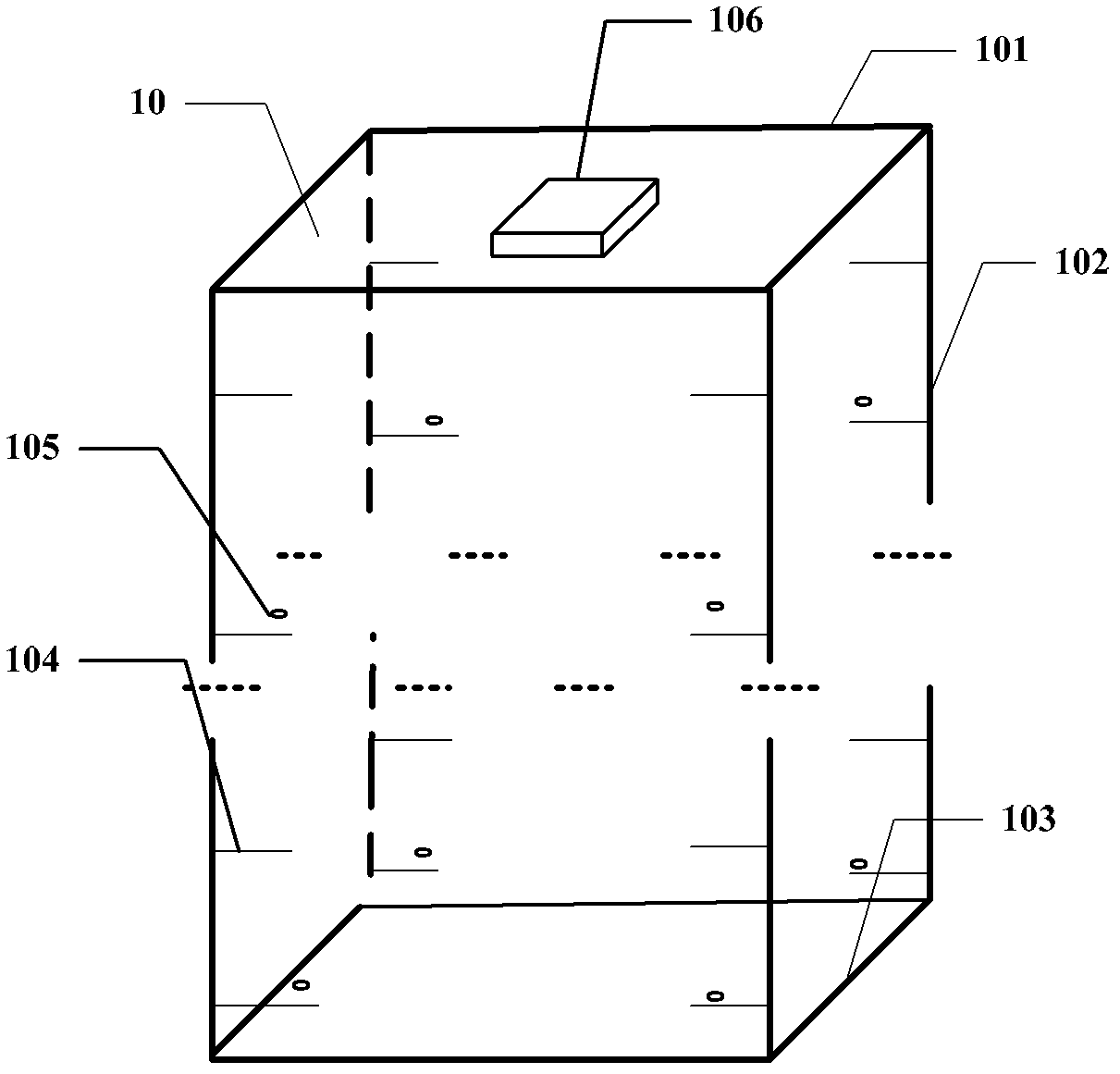

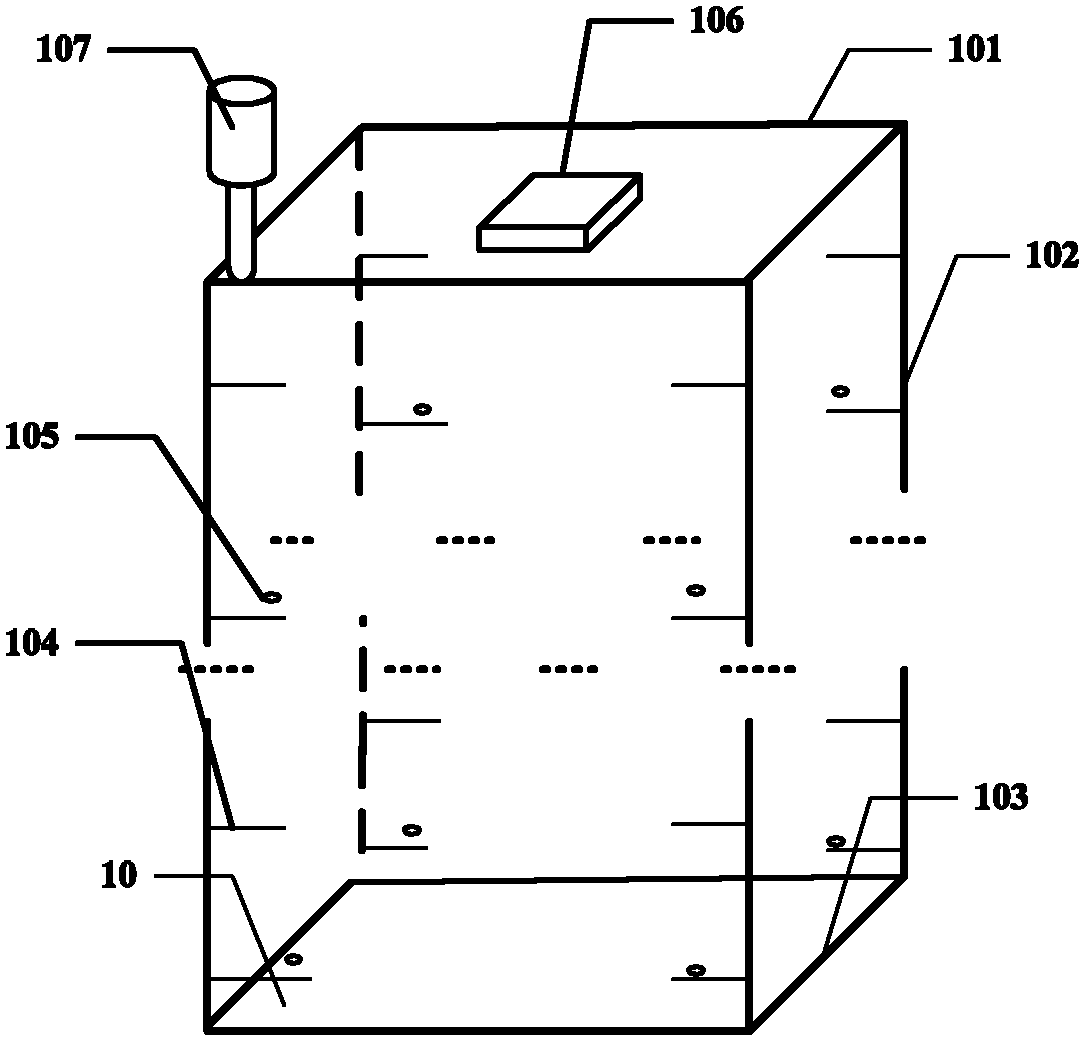

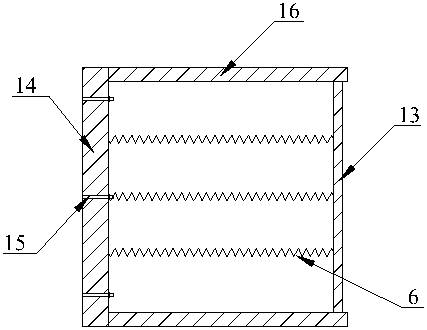

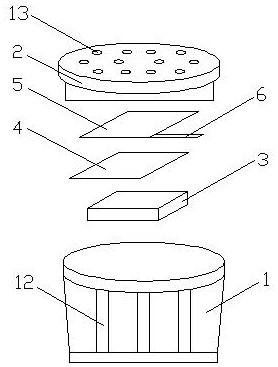

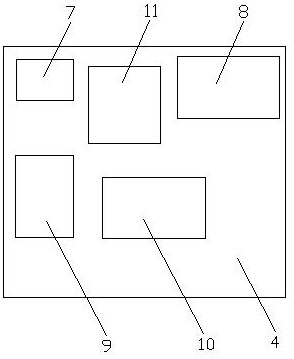

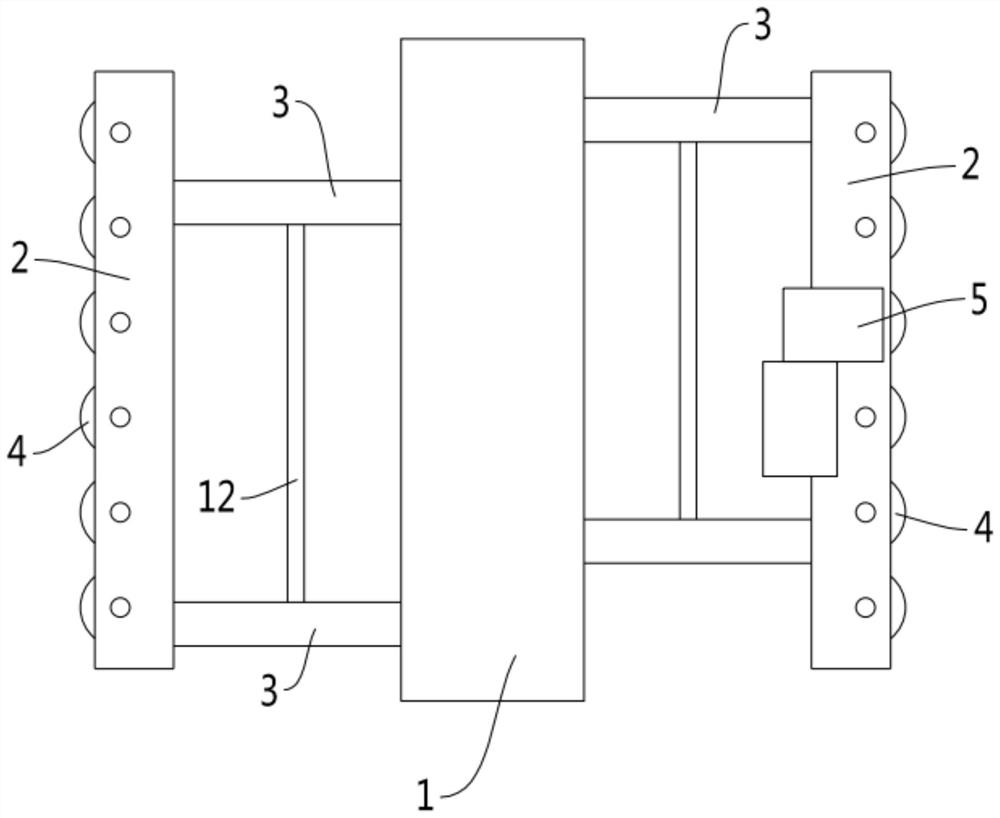

Detection method for detecting substrate damage in placing box and placing box

InactiveCN102651329ATimely detection of damageAvoid continuous damageSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringLiquid crystal

The embodiment of the invention provides a detection method for detecting substrate damage in a placing box and the placing box, and relates to the field of liquid crystal panel manufacture. The detection method can detect if substrates are damaged in the placing box, so that the rate of finished products of the follow-up technique is ensured. The placing box comprises a placing box frame, a top metal plate positioned on the top of the placing box, and a bottom metal plate positioned at the bottom of the placing box frame, wherein multiple layers of substrate placing frames are arranged on the placing box frame, and at least one pressure sensor is arranged on each layer of substrate placing frame of the placing box, or at least one pressure sensor is arranged on every other of the substrate placing frame of the placing box; the pressure sensors are used for acquiring the pressure values of the substrates placed on the substrate placing frame; a data processing unit is connected with the pressure sensors on the substrate placing frames respectively and is used for determining that whether the substrates placed on the substrate placing frames are damaged or not according to the pressure values acquired by the pressure sensors. The embodiment of the invention is used for detecting the substrates in the substrate transporting process.

Owner:BOE TECH GRP CO LTD +1

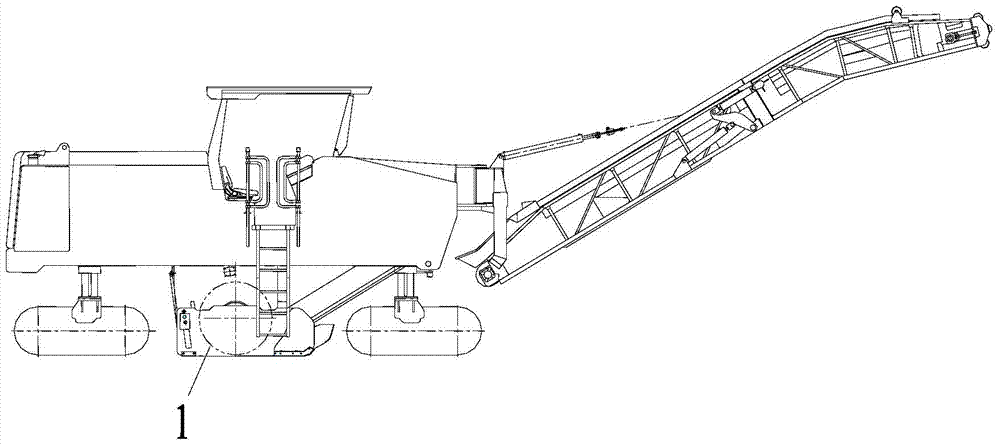

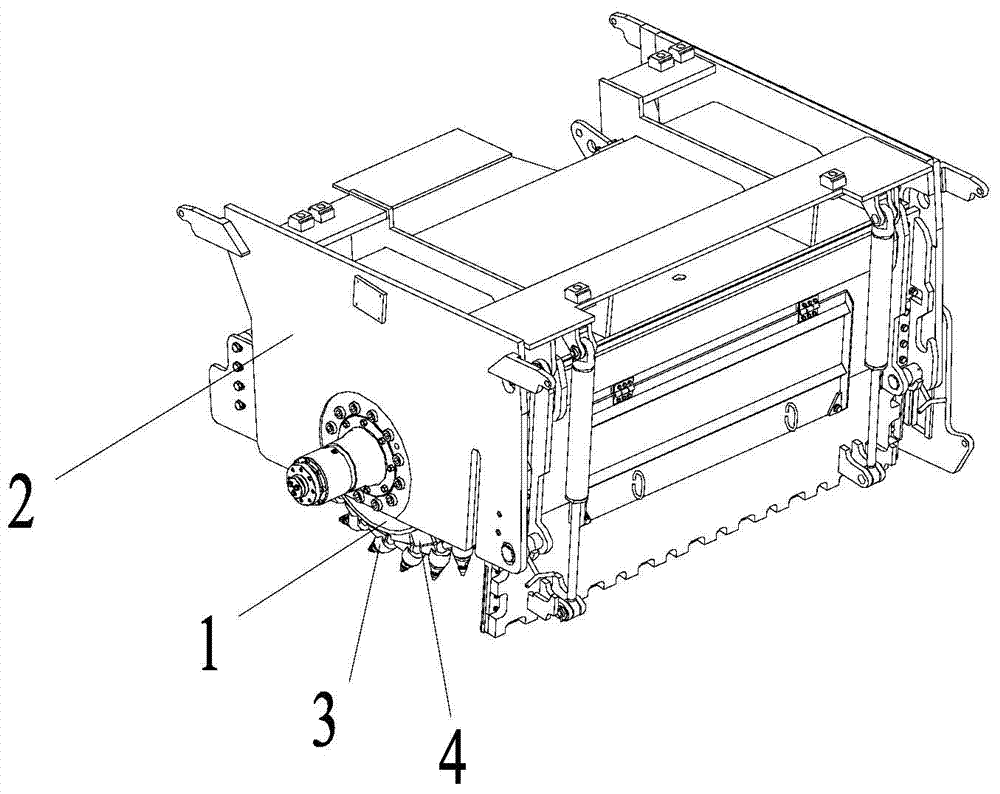

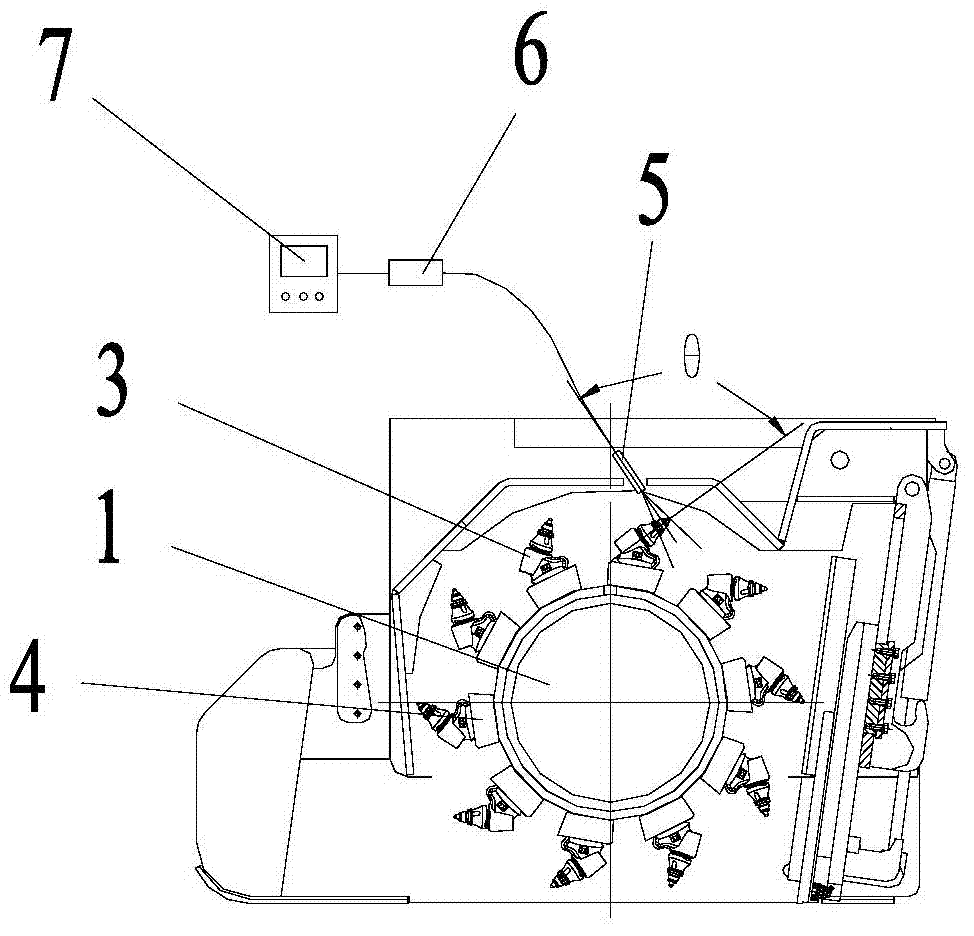

Engineering machinery as well as tool damage detection system and method thereof

InactiveCN103616386AImprove detection efficiencyThe test result is accurateOptically investigating flaws/contaminationIndustrial engineeringDamage detection

The invention discloses a tool damage detection system which comprises a working drum, a working housing, tools and tool aprons, wherein the tools are arranged on the working drum through the tool aprons; the working drum is arranged in the working housing. The tool damage detection system also comprises an infrared videography module, a data processing module and a feedback terminal. According to the tool damage detection system, in a working process of the tools, the temperatures of the tools are obviously higher than that of the surrounding environment; therefore, the infrared videography module arranged on the working housing can be used for recording the shape of a tool; the shape information is processed by the data processing module and then is finally fed to an operator through the feedback terminal, so that the damage condition of the tool can be detected. The tool damage detection system can find defects immediately in a detection process and is high in detection efficiency; a contour image of the tool under high temperature can be acquired through infrared videography, and a detection result is accurate. The invention also discloses a tool damage detection method and engineering machinery provided with the tool damage detection system.

Owner:HUNAN SANY ROAD MACHINERY

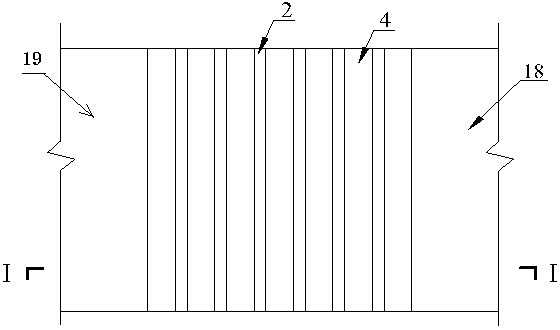

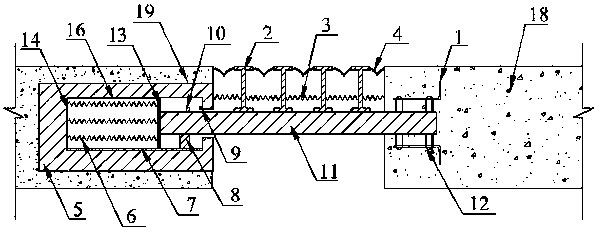

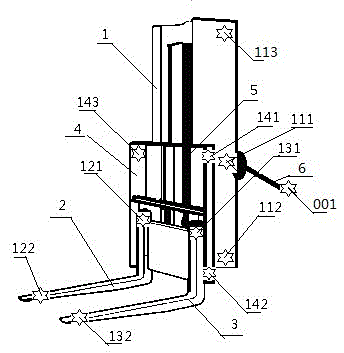

Novel bridge expansion joint device for monitoring displacement of beam end

ActiveCN109235256ASimple structureEasy to installMeasurement devicesBridge structural detailsTension compressionComputer module

The invention discloses a novel bridge expansion joint device for monitoring the displacement of a beam end. The device comprises a beam body 1, a beam body 2, an expansion and contraction system anda distributed displacement measurement system. The invention is connected with the embedded reinforcing bar in the beam body through the C-shaped steel and the U-shaped reinforcing bar on the supporting cross beam. As that beam body at both ends move relative to each other, the supporting beam pushes or stretches the top plate of the distribute displacement measuring system, causing the spring group to produce tension-compression deformation, and the tension-compression sensor can measure the internal force of each spring correspondingly, and convert the displacement of the beam end through awireless data transmission module. The movement of the supporting beam causes the I-shaped middle beam to move on it, and the bird-shaped rubber belt is compressed or stretched to realize the telescopic function. The invention has the advantages of simple structure and convenient installation, and can coordinate and analyze the monitored beam end displacement data with temperature and other data,and serves the bridge health monitoring field, can simultaneously evaluate the service state of the expansion joint, and improves the intelligent level of the bridge expansion joint and the bridge operation management level.

Owner:SOUTHEAST UNIV

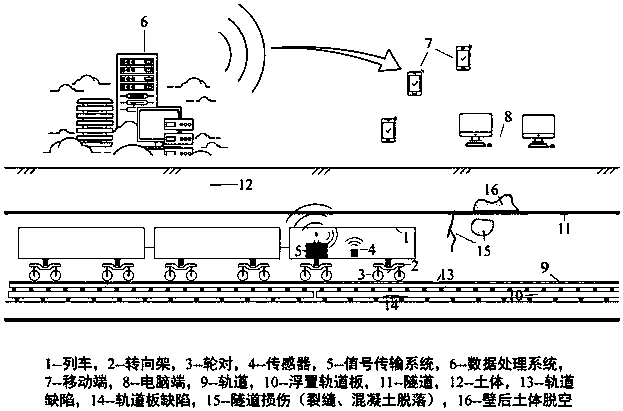

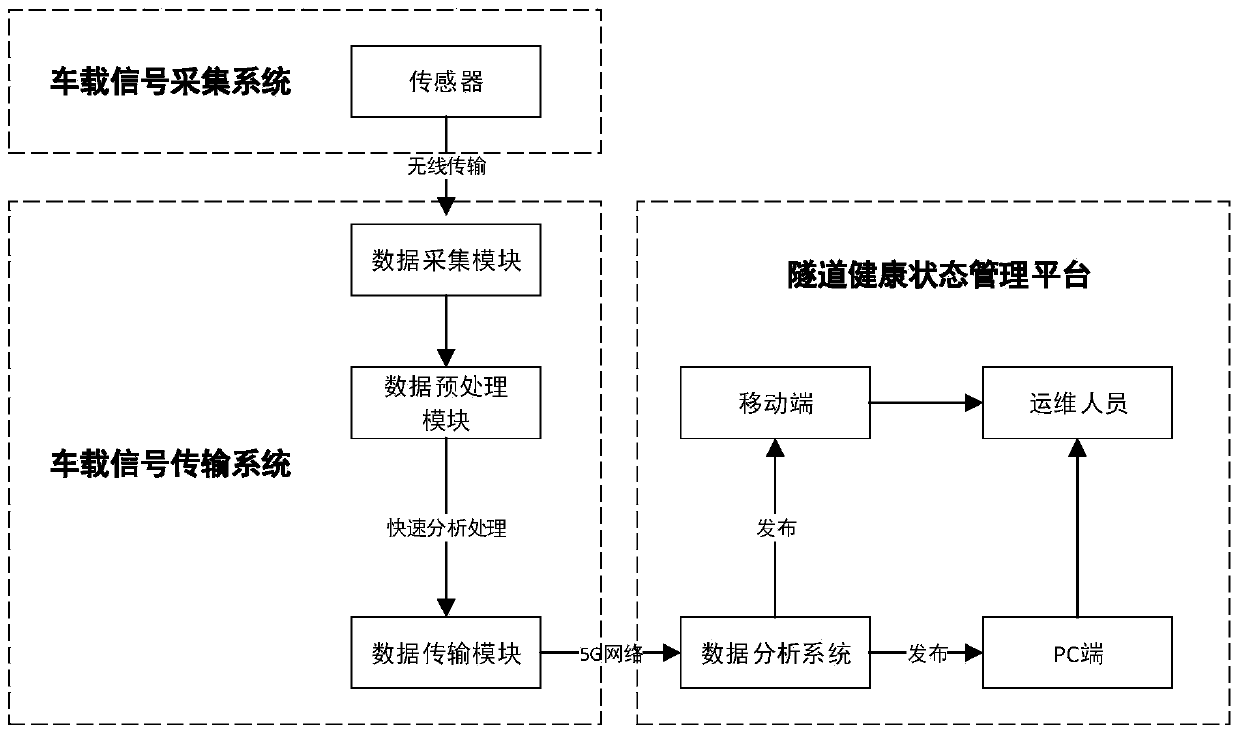

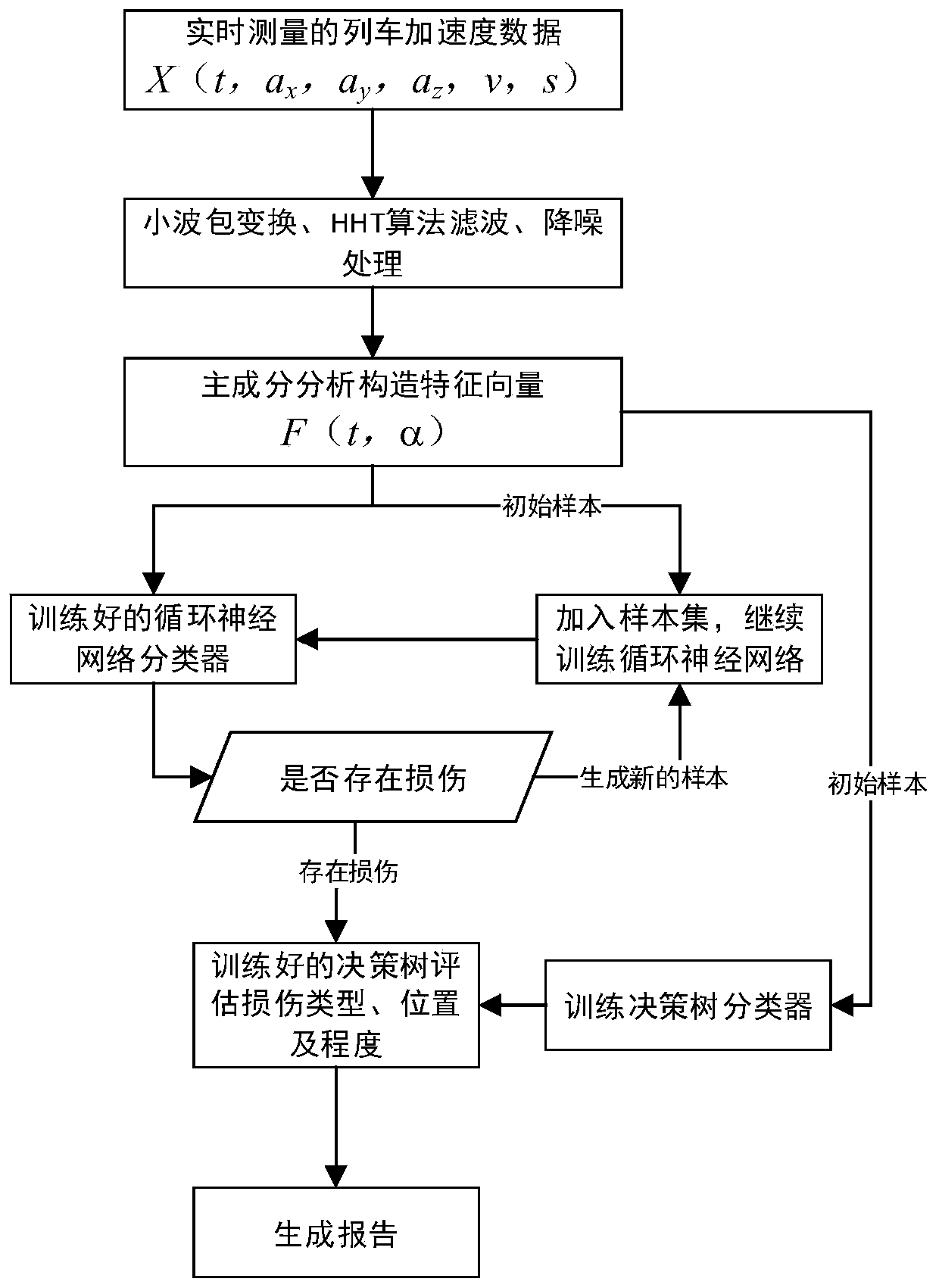

Tunnel damage detection management system based on mobile train vibration signal

ActiveCN111257415ADamage identificationRapid identification of damageMining devicesAnalysing solids using sonic/ultrasonic/infrasonic wavesSimulationAnalysis center

Owner:TONGJI UNIV

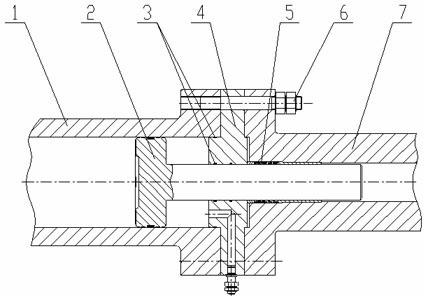

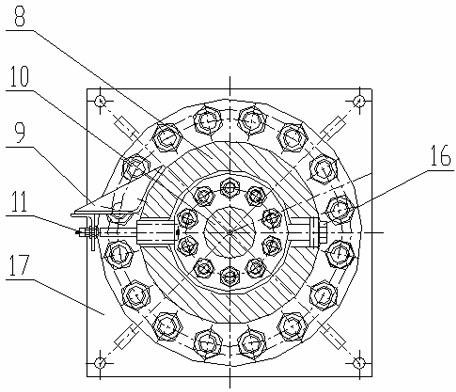

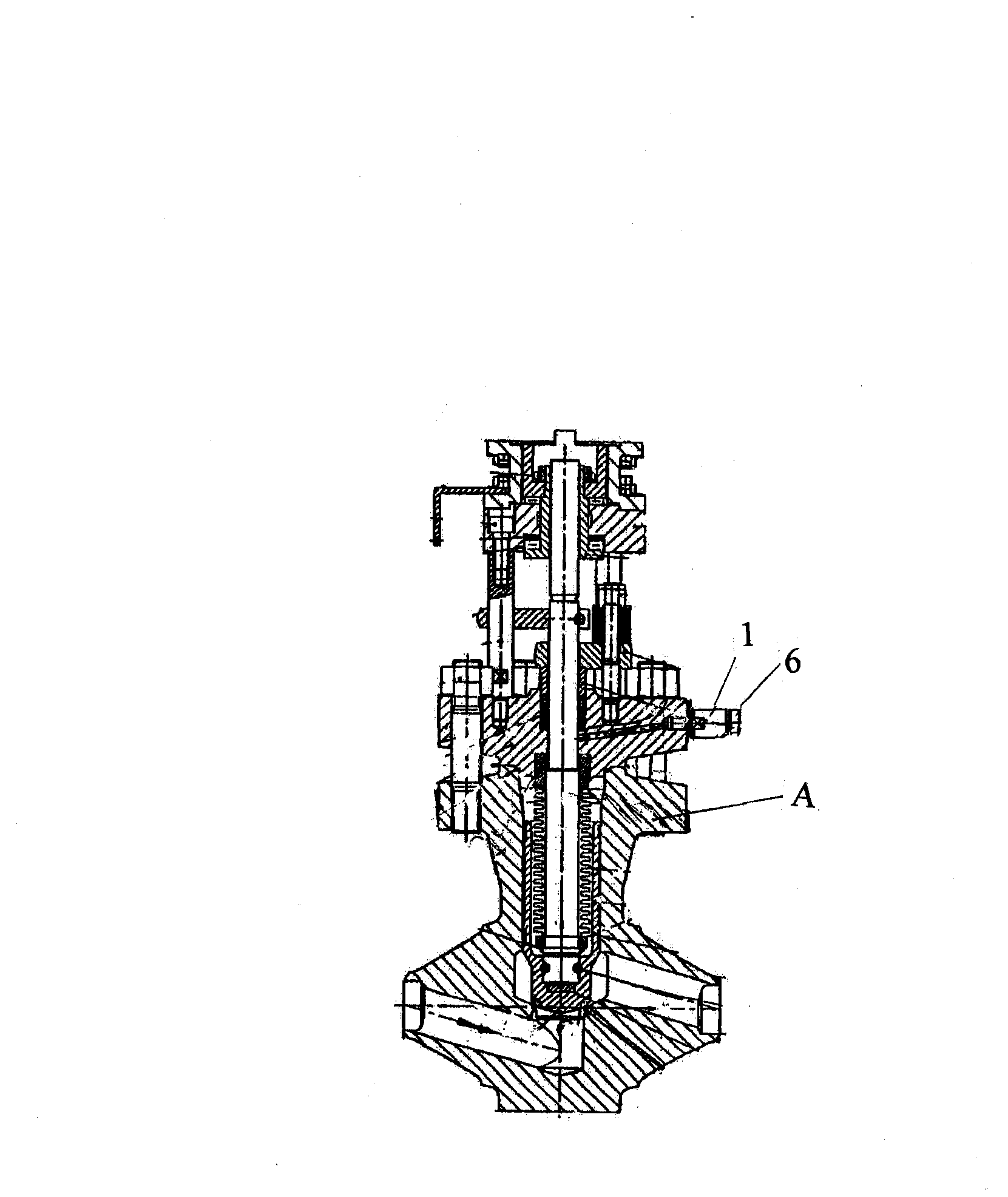

Supercharger applicable to steel pipe water-pressure test system

ActiveCN102352871ATimely detection of damageSimple structureDetection of fluid at leakage pointFluid-pressure convertersPipe waterEngineering

The invention relates to metallurgical equipment, in particular to a supercharger in a steel pipe water-pressure test system. The supercharger is characterized by comprising an oil pressure part, a water pressure part, a detecting part and a fixed bracket, wherein the oil pressure part comprises an oil pressure cylinder body, an oil pressure piston, an oil pressure seal and a pressing ring which are assembled into a piston cylinder; the oil pressure cylinder body is connected with the fixed bracket by a connecting piece; the oil pressure piston is arranged in the oil pressure cylinder body in a matching manner; the pressing ring is arranged between the oil pressure cylinder body and the oil pressure piston in a matching manner; the oil pressure seal is arranged on the pressing ring; the oil pressure cylinder body is provided with a hydraulic oil opening A on the bottom part of the oil pressure cylinder body and a hydraulic oil opening B on the side wall of the oil pressure cylinder body; and the water pressure part consists of an oil pressure piston, a water pressure seal, a water pressure supporting barrel, a water pressure cylinder plunger, a cushion plate, a nut and a pressing plate which are assembled into a plunger cylinder. In the supercharger applicable to the steel pipe water-pressure test system provided by the invention, the structure is simple, the maintenance is convenient, the damage of a sealing piece can be found in time, and whether the oil pressure seal or the water pressure seal is damaged can be accurately judged.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

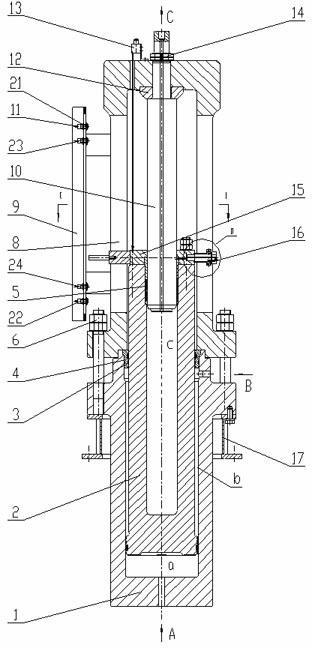

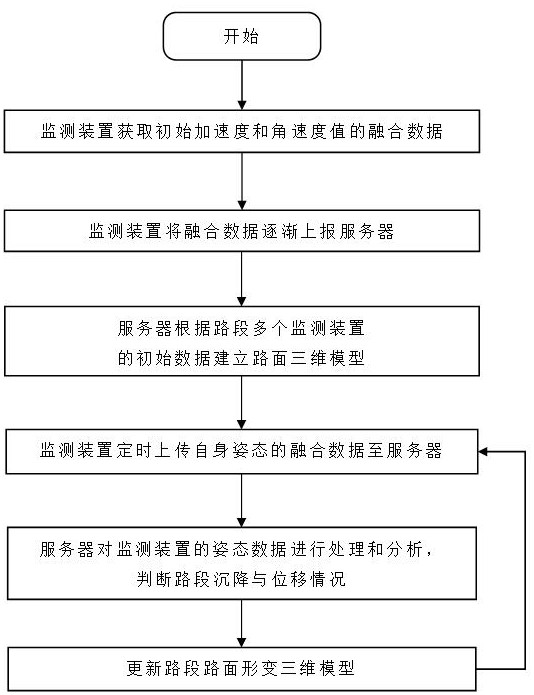

Road surface deformation monitoring method

PendingCN112964219AMonitor settlementMonitoring situationBatteries circuit arrangementsTransmission systemsSimulationTrunking

The invention discloses a road surface deformation monitoring method, which belongs to the technical field of intelligent transportation. The road surface deformation monitoring method is characterized by comprising the following steps of: a, determining a reference value according to an initial condition, and performing information interaction between monitoring devices and a server through a relay and a gateway; B, detecting pavement settlement and deformation through angle changes of attitude sensors in the monitoring devices; C, enabling the gateway to obtain a network relation mapping graph from the server, issuing the network relation mapping graph step by step according to a jurisdiction relation, completing relation mapping, and uploading posture data collected in real time to the server through the relay and the gateway through a Bluetooth network by utilizing the monitoring devices; and D, comparing attitude data acquired by the plurality of groups of monitoring devices with a reference value and historical data respectively by using the server, and acquiring a damage type and a damage range of the road section through model establishment and data analysis. According to the road surface deformation monitoring method, monitoring data can be uploaded in real time, pavement state monitoring and early warning are carried out through modeling and data analysis, and pavement settlement and displacement conditions are effectively monitored.

Owner:四川九通智路科技有限公司

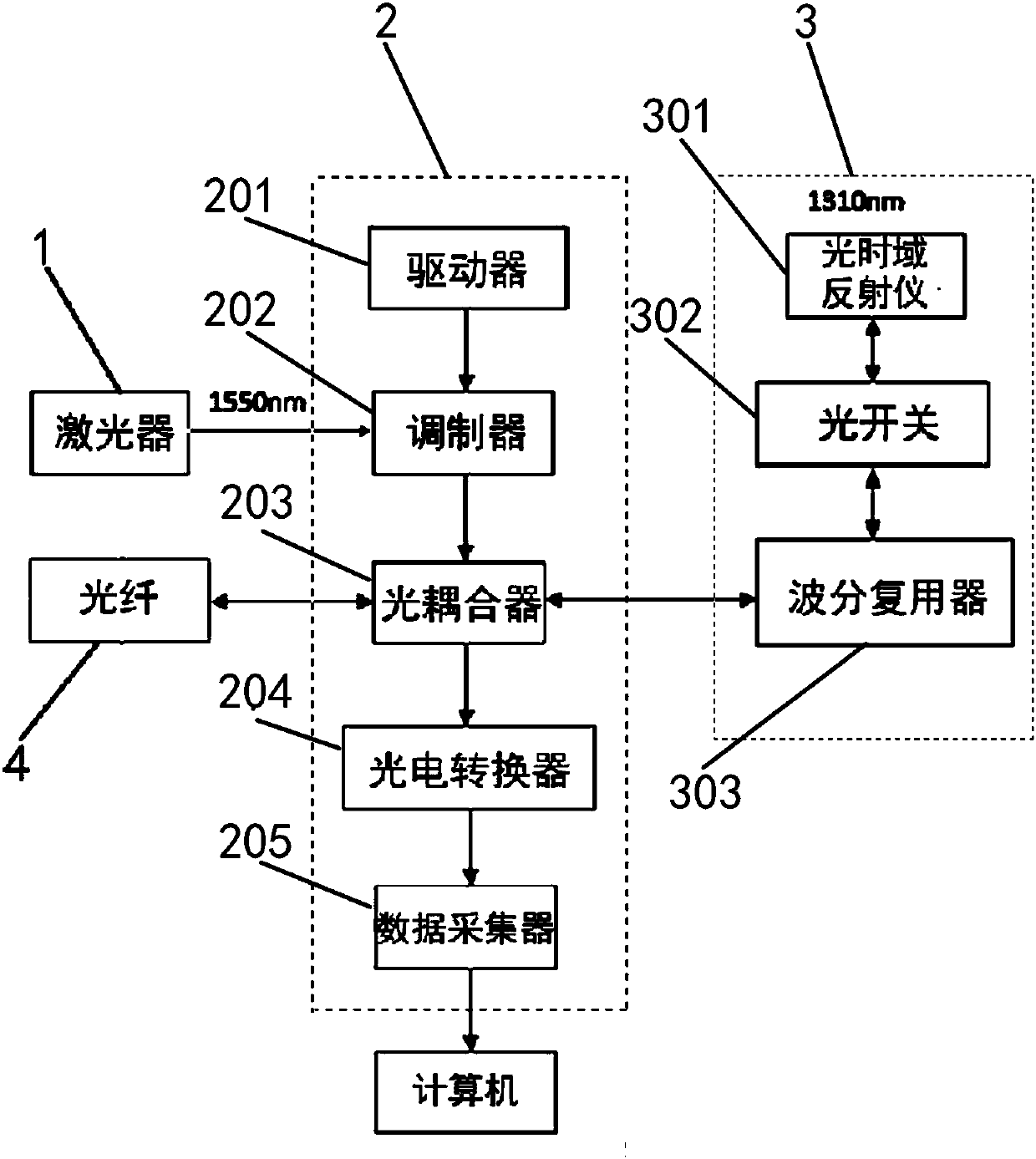

Distributed optical fiber vibration sensing system having attenuation real-time monitoring function

InactiveCN107782437ATimely detection of damageFind the location in timeSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansTime-domain reflectometerData acquisition

The invention discloses a distributed optical fiber vibration sensing system with attenuation real-time monitoring function, which is characterized in that it includes a vibration sensor, and the vibration sensor includes a driver, a modulator, an optical coupler, a photoelectric converter and a data collector, The laser is connected to the vibration sensor, and the optical fiber detector is connected to the vibration sensor for emitting laser light to the optical coupler and receiving the optical signal returned by the optical coupler. The optical fiber detector includes an optical time domain reflectometer, an optical switch and a wavelength division multiplexing device; the positive progress effect of the present invention is: real-time reading of the attenuation coefficient of the optical cable along the way, timely discovery of optical cable damage and breakpoint position, highly accurate measurement of the attenuation and damage of the entire optical cable; the wavelength division multiplexer returns when the light source reflects Other wavelengths other than the operating wavelength of the optical time domain reflectometer are filtered out, and the lasers of different wavelengths in different parts do not interfere with each other, and the measurement accuracy is high.

Owner:SHANGHAI BOOM FIBER SENSING TECH

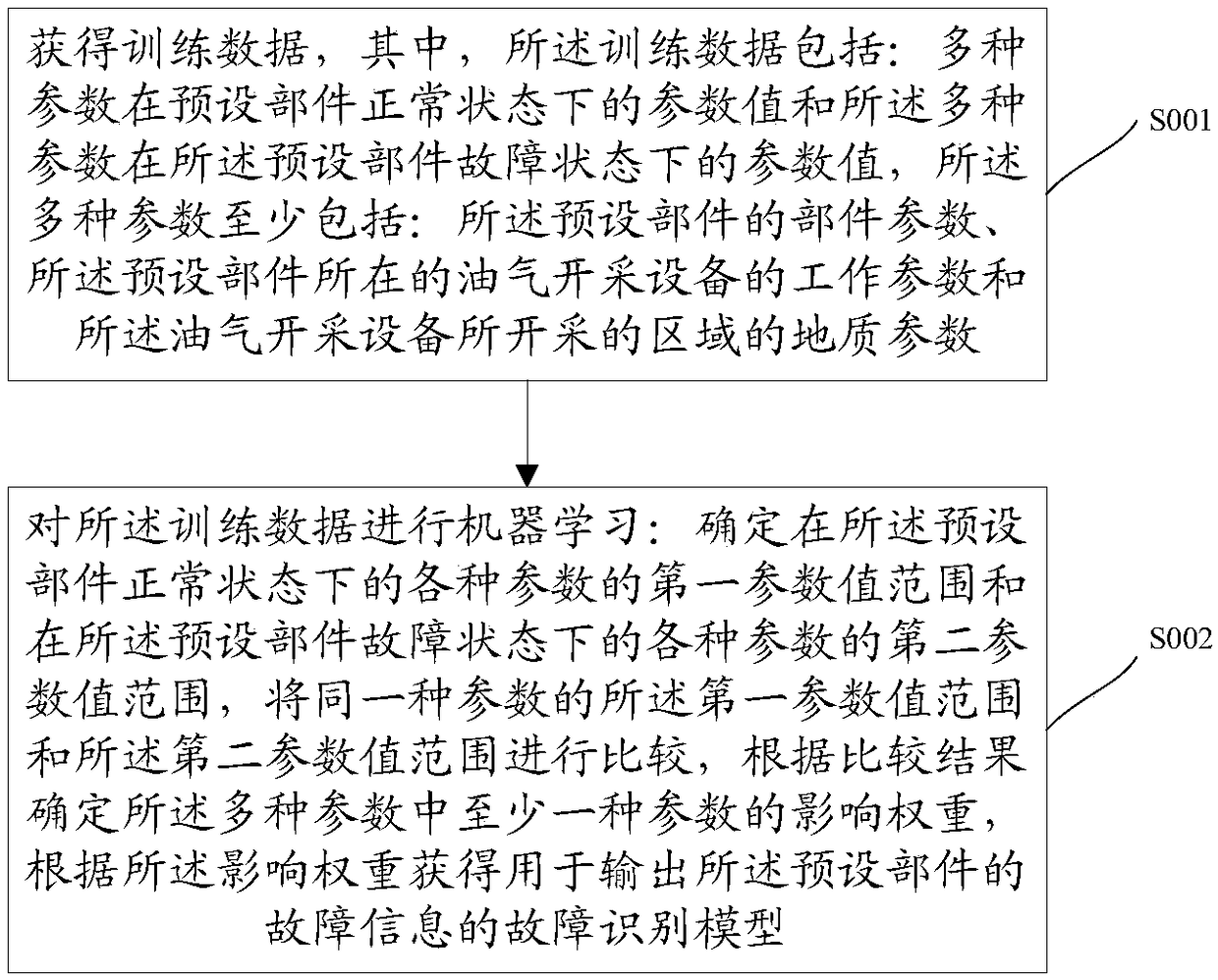

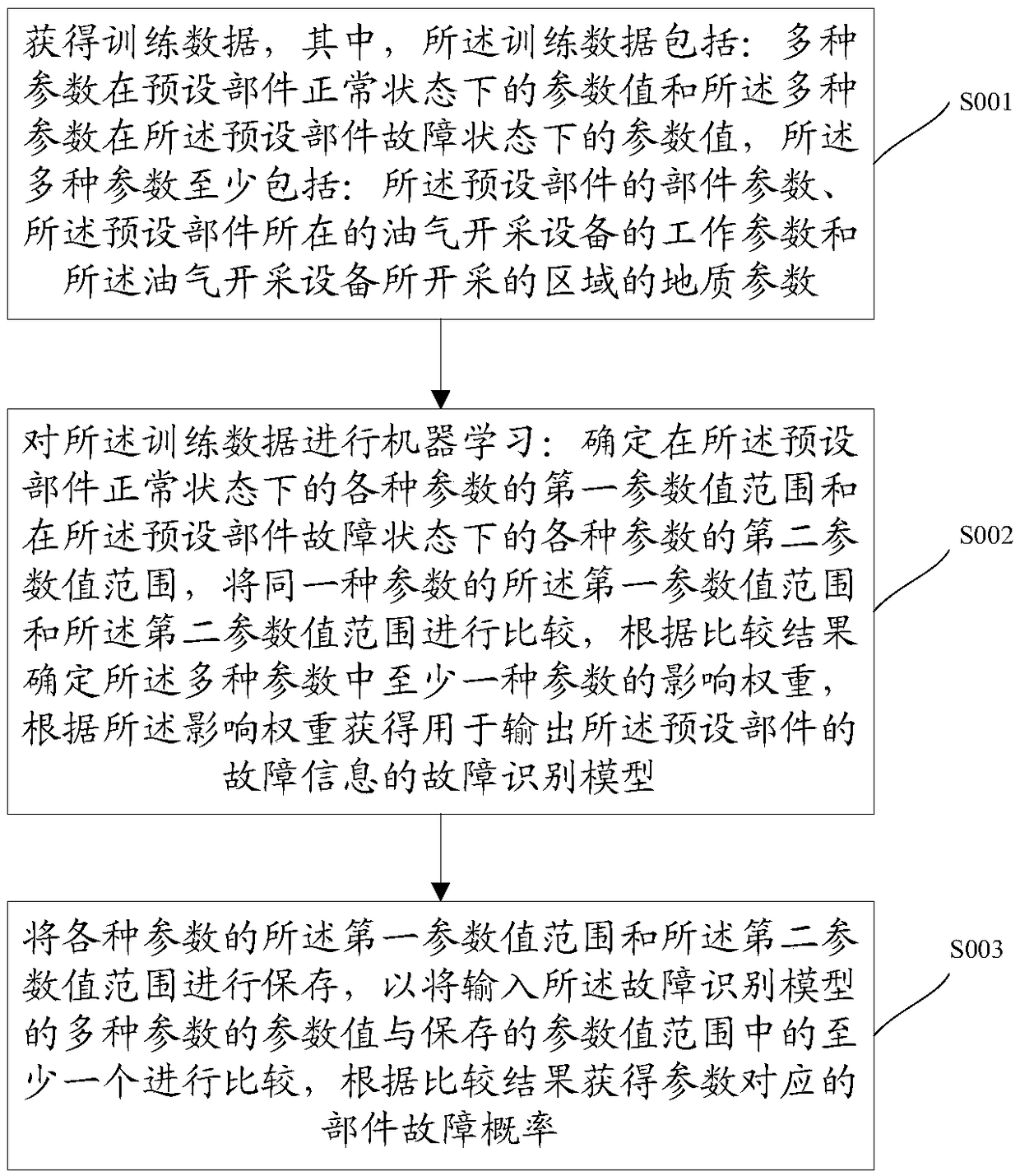

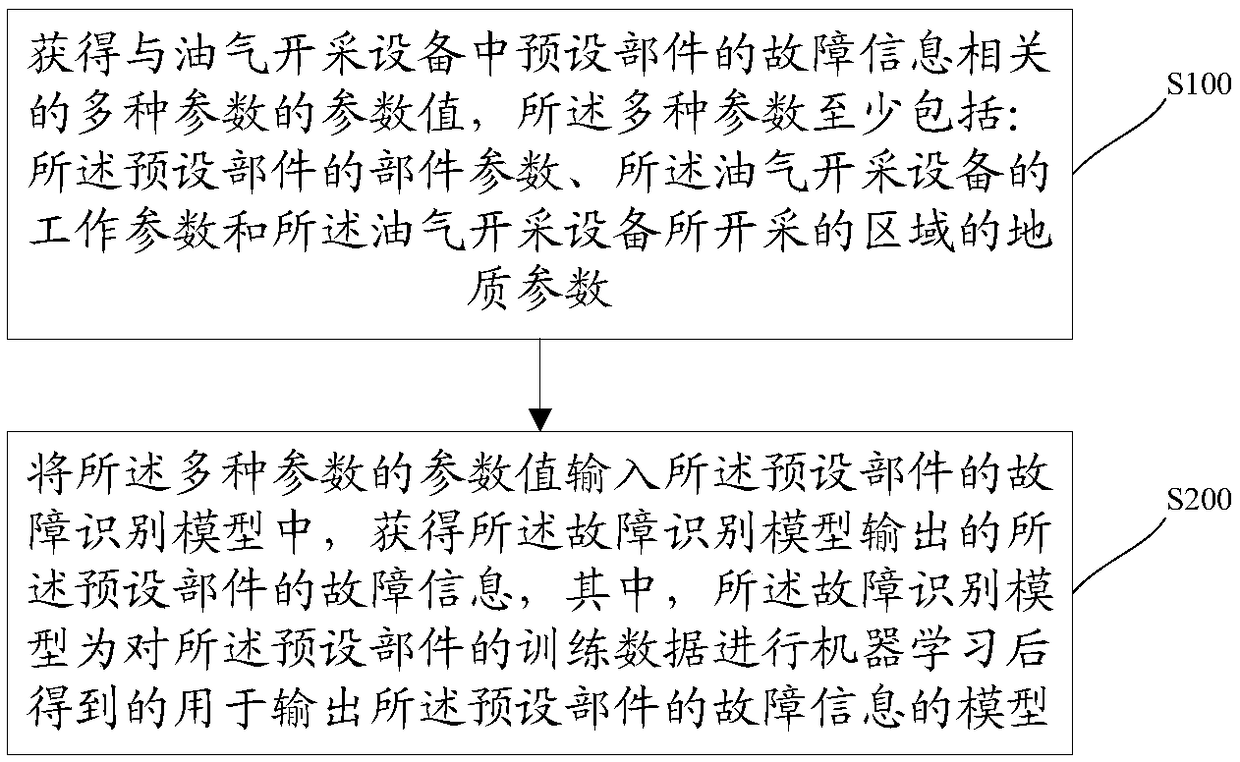

A method for monitoring oil and gas production, a method for obtaining a fault identification model and relate device

ActiveCN109446574ATimely detection of damageDesign optimisation/simulationTotal factory controlMonitoring methodsComputer science

A method for monitoring oil and gas production,a method for obtaining a fault recognition model and a related device are disclosed. The method comprises obtaining the training data, carrying out the machine learning on the training data: determining a first parameter value range of various parameters in a normal state of the preset part and a second parameter value range of various parameters in afaulty state of the preset part, comparing the first parameter value range and the second parameter value range of the same parameter, determining an influence weight of at least one parameter of theplurality of parameters according to the comparison result, and obtaining the fault identification model for outputting fault information of a preset component according to the influence weight. Thefault identification model obtained by the invention can automatically determine the fault information of the preset parts according to the inputted multiple parameters, so that the downhole operationis not required, the downhole operation is simple and convenient, and the damage of the parts in the oil and gas production equipment can be found in time.

Owner:BEIJING GRIDSUM TECH CO LTD

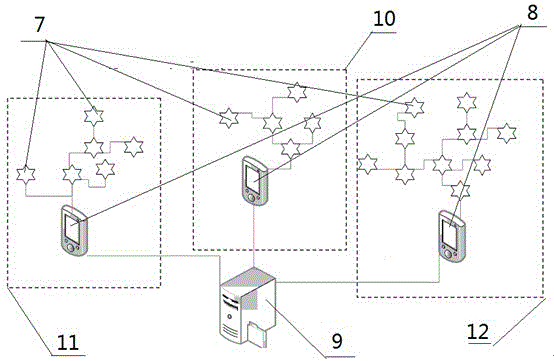

Structural deformation detection device based on Internet of Things

InactiveCN103148830ATimely detection of damageFound damageMeasurement devicesTransmissionStructural deformationThe Internet

The invention discloses a structural deformation detection device based on the Internet of Things. The structural deformation detection device comprises detection nodes, master control nodes and a data service center, wherein the detection nodes comprise a control module, a communication module, a memory module and a sensor module; the master control nodes comprise a control module, a communication module, a memory module and a local database; the data service center supports the Ethernet, a mobile wireless network and a wire communication interface and comprises an expert system and an expert database, the normal work, deformation or failure detailed data of all part detection nodes of different types and different models of movement mechanical equipment are stored in the expert database; the data is uploaded and downloaded by the master control nodes supporting all movement mechanical equipment; and deformation or failure data is analyzed by a movement module established by the expert system. The structural deformation detection device is helpful in timely discovering the damage of all mechanical equipment such as tractor loaders, forklifts and hoists, preventing accidents from occurring and improving the mechanical equipment.

Owner:广西泰绘信息科技有限公司

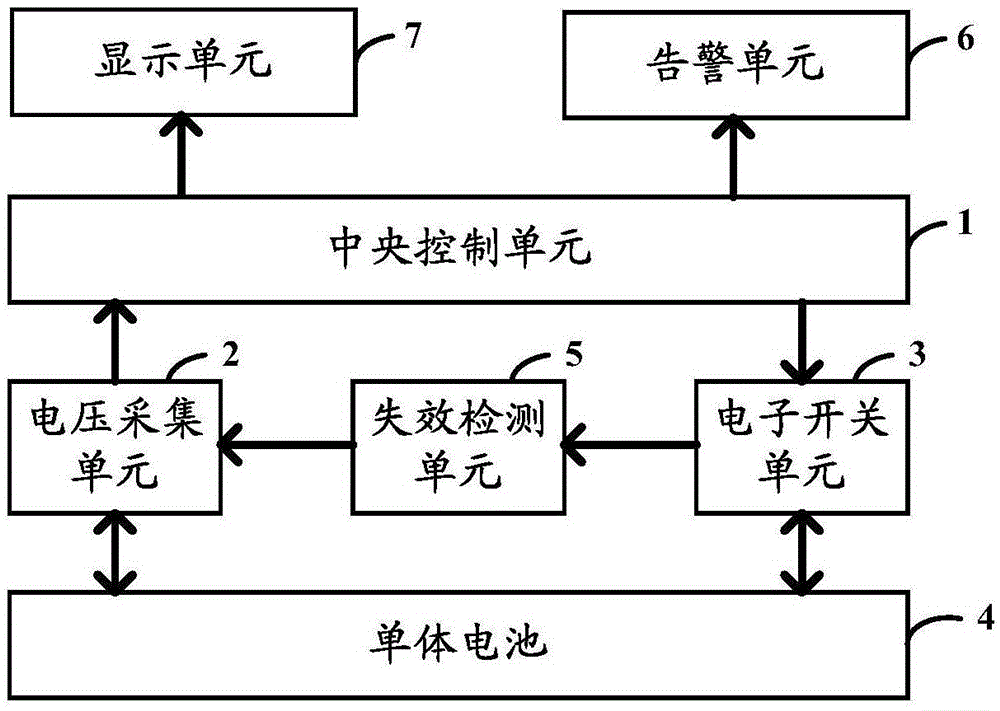

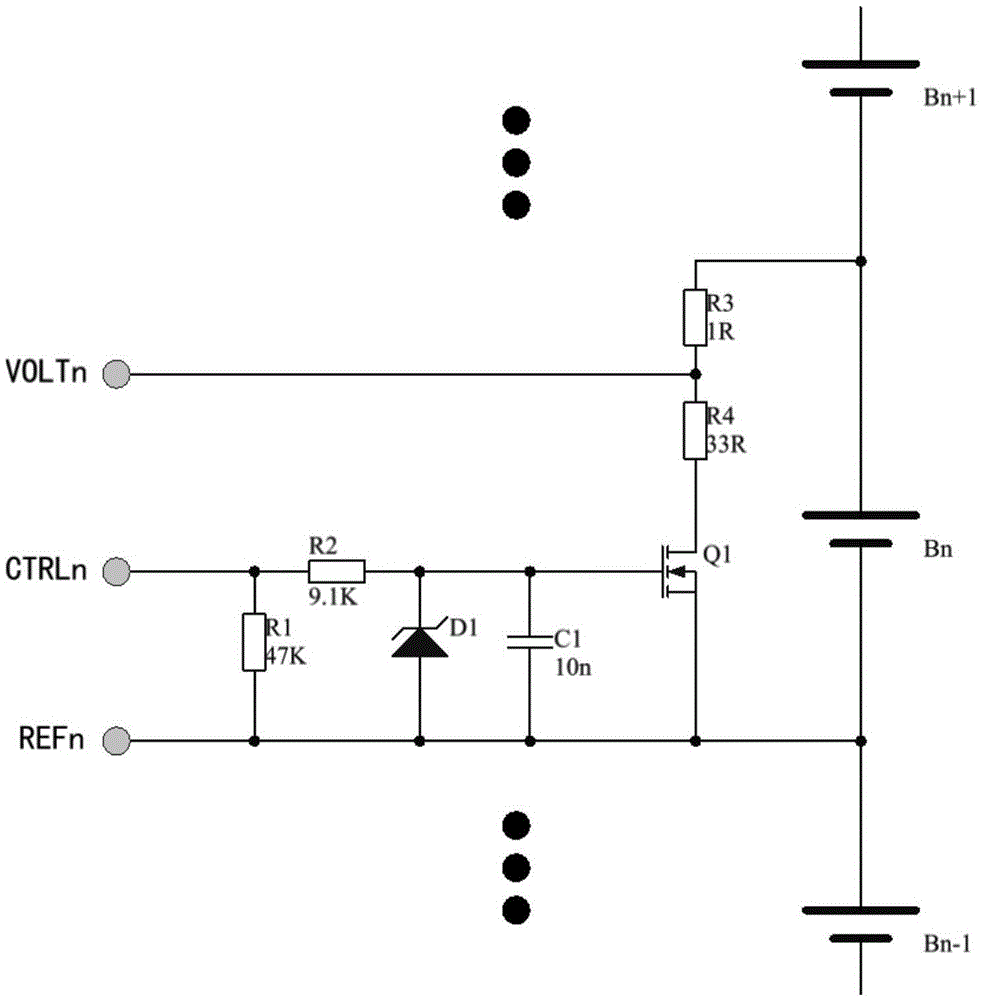

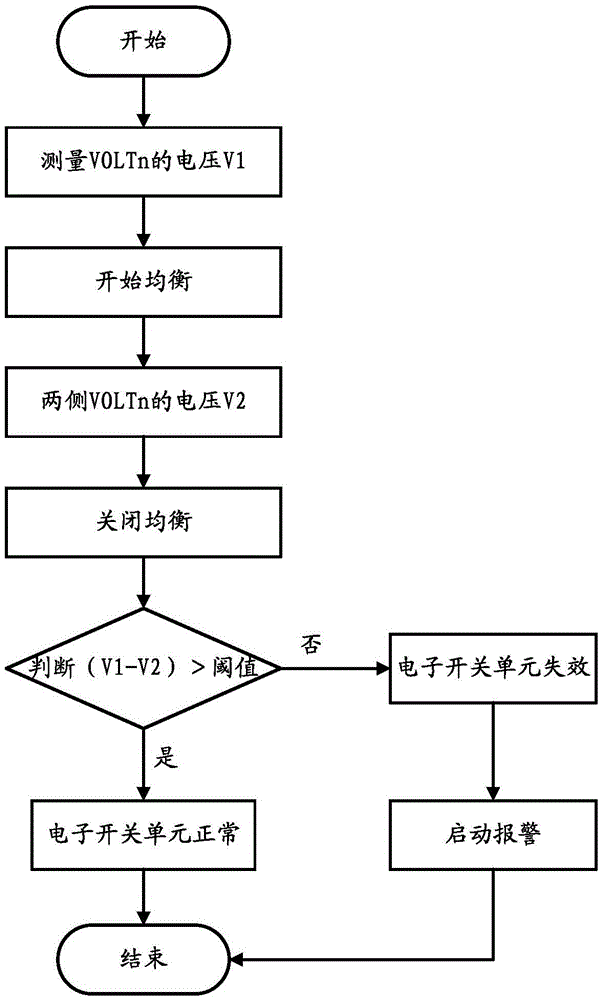

Passive equalization circuit for battery management system

InactiveCN105633491AReal-time monitoring of voltage informationAvoid over-discharge damageCells structural combinationElectrical batteryElectronic switch

The invention is applicable to battery management, and provides a passive equalization circuit for a battery management system. The passive equalization circuit comprises a central control unit, multiple voltage collection units and multiple electronic switch units, wherein the voltage collection units are used for collecting voltage information of single batteries and transmitting the voltage information to the central control unit; the central control unit analyzes according to the voltage information, and generates a discharge instruction to control the electronic switch units to discharge to the single batteries when the voltage of a certain single battery is higher than that of other single batteries, and stops the discharging process when the voltage of the certain single battery is consistent with that of other single batteries. By adoption of the passive equalization circuit, the voltage information of single batteries can be monitored in real time; discharging processing can be performed when a certain single battery is abnormal so as to enable the voltages of all the single batteries to be consistent; and furthermore, the real-time monitoring diagnostic function of the electronic switches is utilized, so that damaged switching devices can be found in time to send out an alarm so as to avoid overdischarge damage of batteries.

Owner:深圳市清友能源技术有限公司

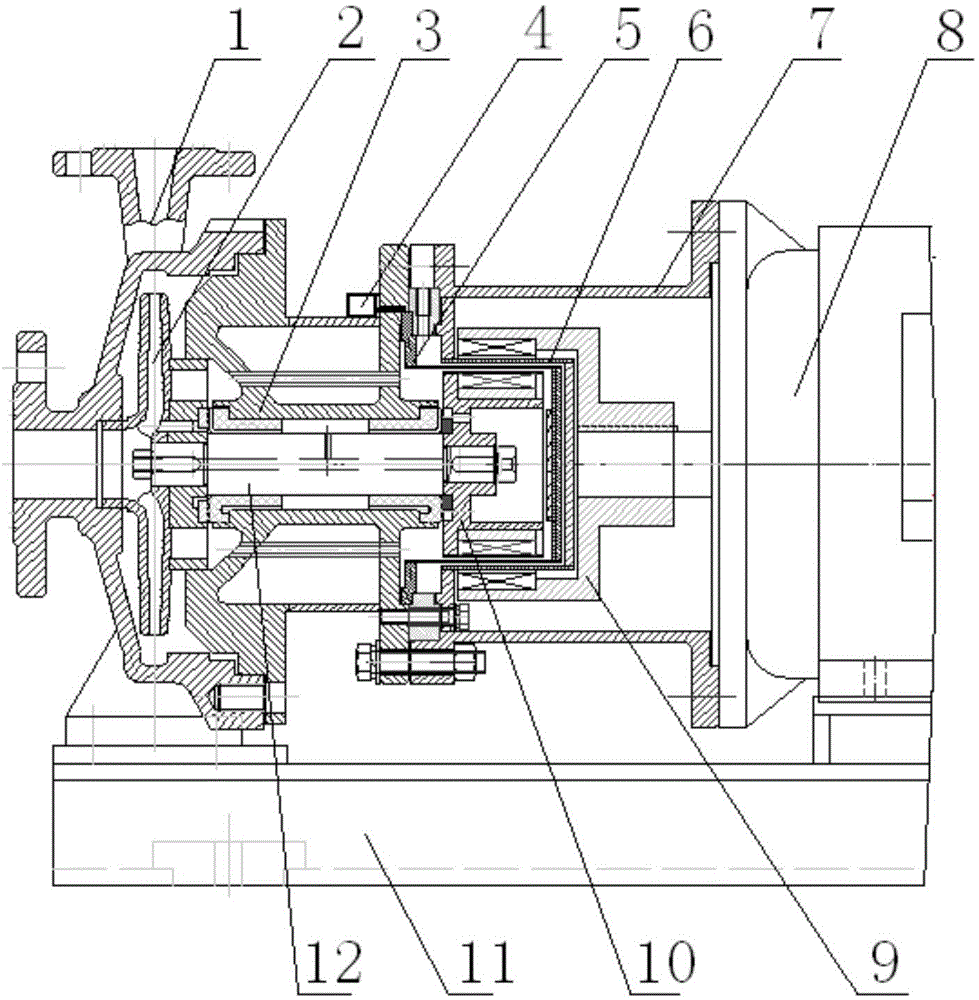

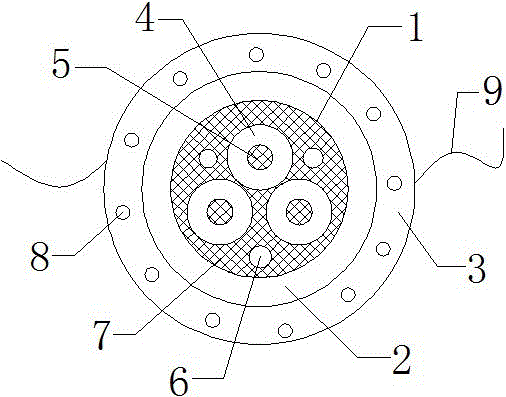

Isolation cover assembly of magnetic force pump

ActiveCN104100536AReduce restart resistanceExtended service lifePump componentsPump installationsHeat conductingEngineering

The invention discloses an isolation cover assembly of a magnetic force pump. The isolation cover assembly comprises an internal isolation cover, an external isolation cover, an electric heating mechanism, a circular heat conducting strip and a lining ring, wherein the internal isolation cover consists of an internal isolation cover flange, an internal isolation cover thin-wall barrel and an internal isolation cover bottom plate; the external isolation cover consists of an external isolation cover flange, an external isolation cover thin-wall barrel and an external isolation cover bottom plate; the lining ring is located between the internal isolation cover and the external isolation cover; a sealed cavity is formed among the internal isolation cover, the external isolation cover and the lining ring; the circular heat conducting strip is arranged in the middle part of the internal isolation cover bottom plate; the circular heat conducting strip is connected with the electric heating mechanism. As the isolation cover assembly of the magnetic force pump provided by the invention adopts such a structure, a heat source can reach an easy-to-crystallize medium area at an internal magnetic rotor after shut-down; therefore the restart resistance of the magnetic force pump is decreased; the service life of the magnetic force pump is prolonged; moreover, the damage of the isolation cover can be discovered in time, so that a leakage accident is avoided.

Owner:安徽星球盛唐泵业有限公司

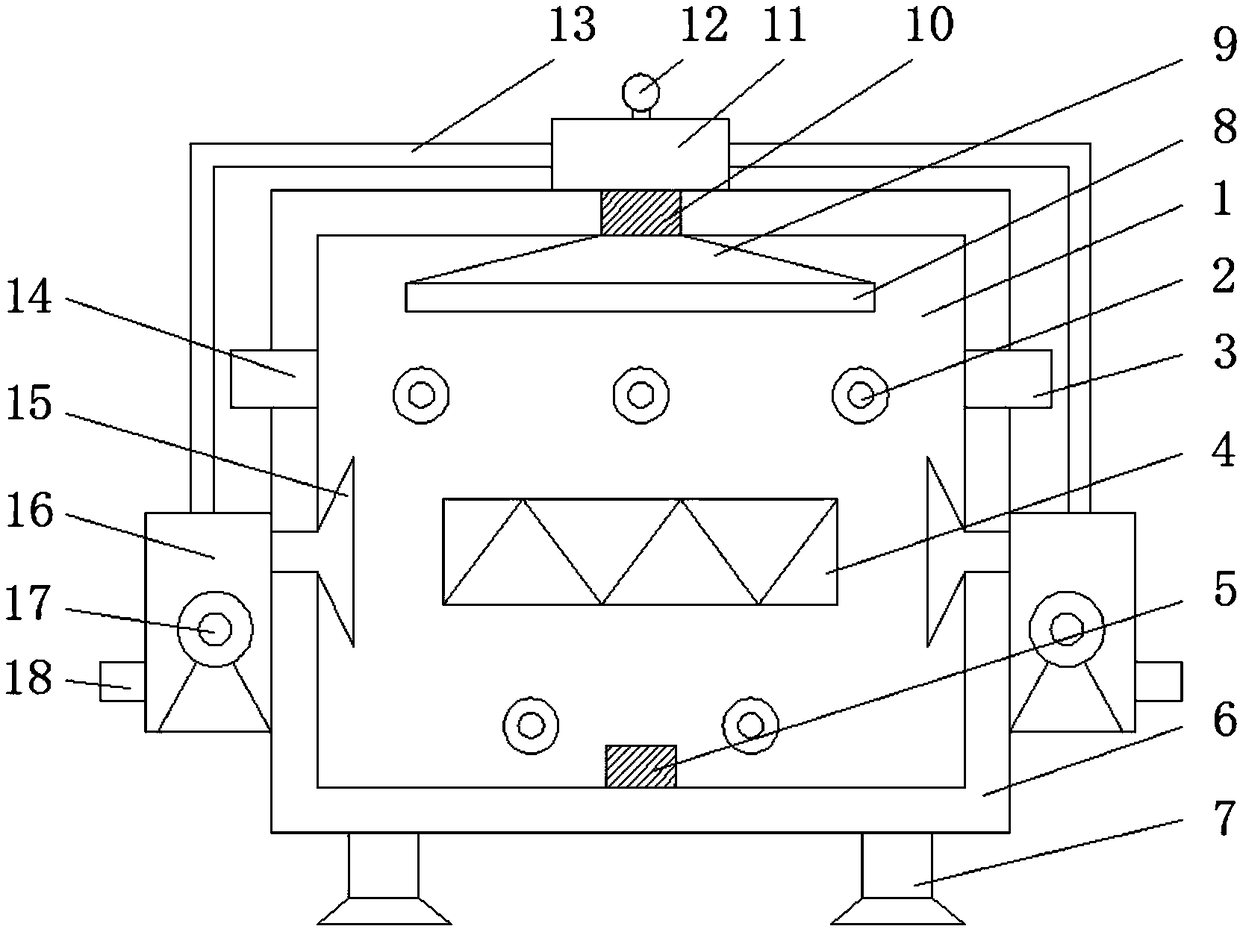

Spinning cloth quick drying box

InactiveCN108168268AGuarantee product qualityTimely detection of damageDrying gas arrangementsDrying machines with progressive movementsEngineeringWater collection

The invention discloses a spinning cloth quick drying box which comprises a box body. Roll shafts and a heating board are fixedly connected to the inner portion of the box body, the heating board is arranged among the roll shafts, a cloth outlet is fixedly connected to the vertical outer side wall on one side of the box body, a cloth inlet is fixedly connected to the outer wall on the side, away from the cloth outlet, of the box body, a temperature sensor is fixedly connected to the bottom position of the inner wall of the box body, supporting legs are fixedly connected to the lower end of thebox body, an air collection hood is fixedly connected to the top position of the inner wall of the box body, a condensate water tank is clamped to the lower surface of the air collection hood, a ventilation pipe is inserted in the condensate water tank, and the upper surface of the ventilation pipe is fixedly connected with a fixing rod. The spinning cloth quick drying box is simple in structureand convenient to operate, an alarm device, a condensate water collection device and a cyclic drying device are additionally arranged, the drying speed is higher, efficiency is higher, potential safety hazards of the box are reduced, the quality of spinning cloth is guaranteed, and resources are saved.

Owner:XIANGSHUI AITE TEXTILE CO LTD

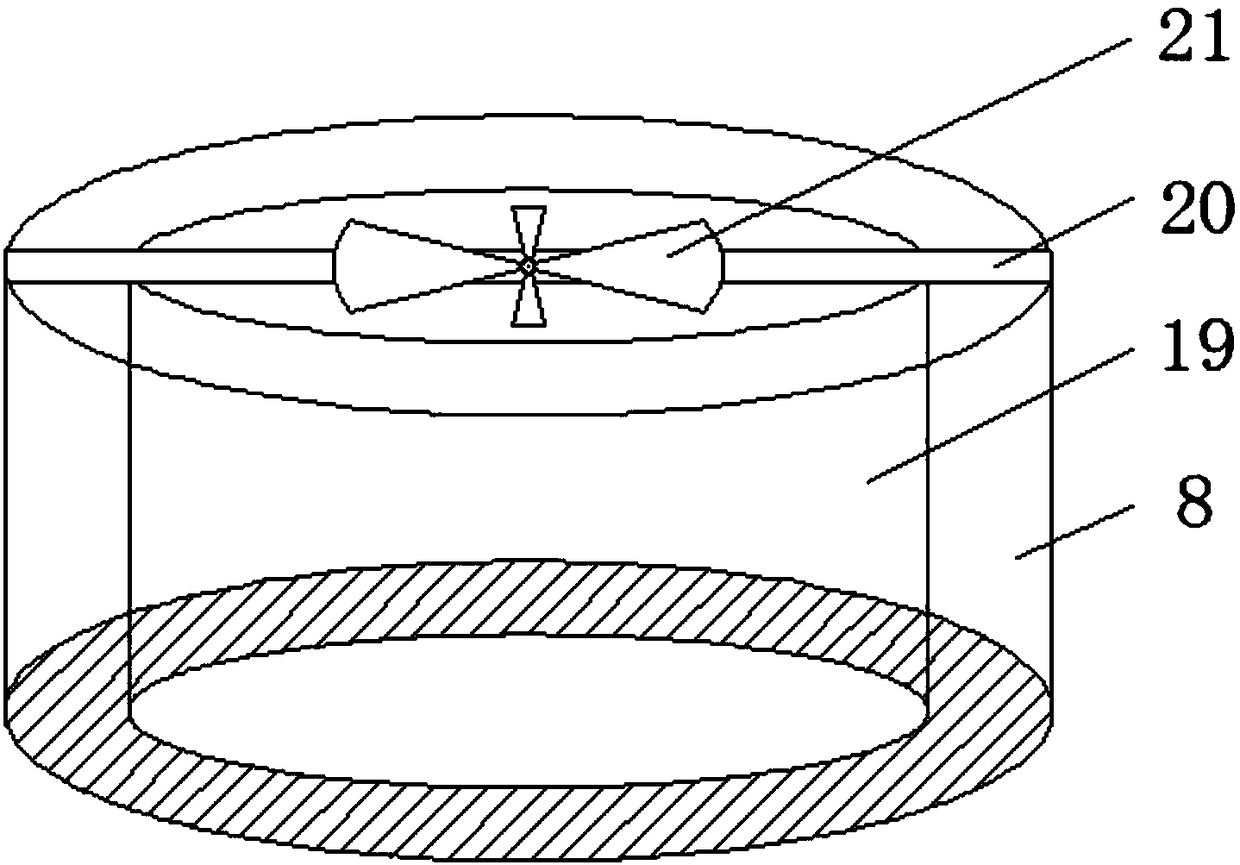

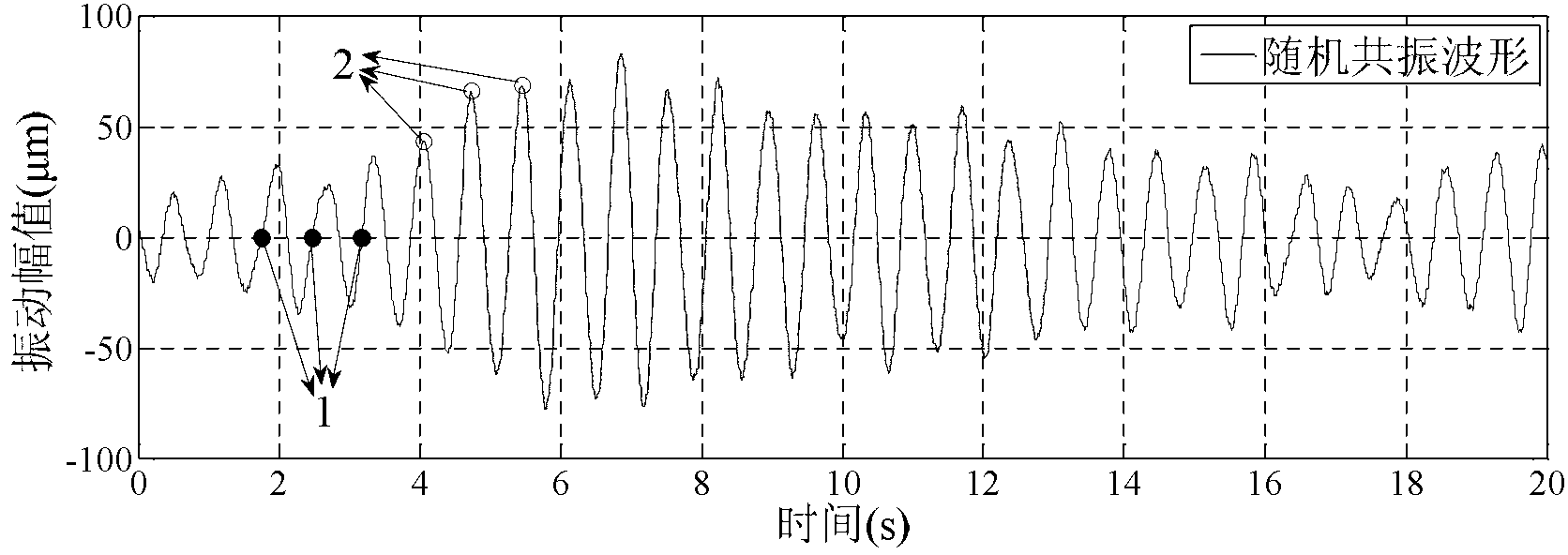

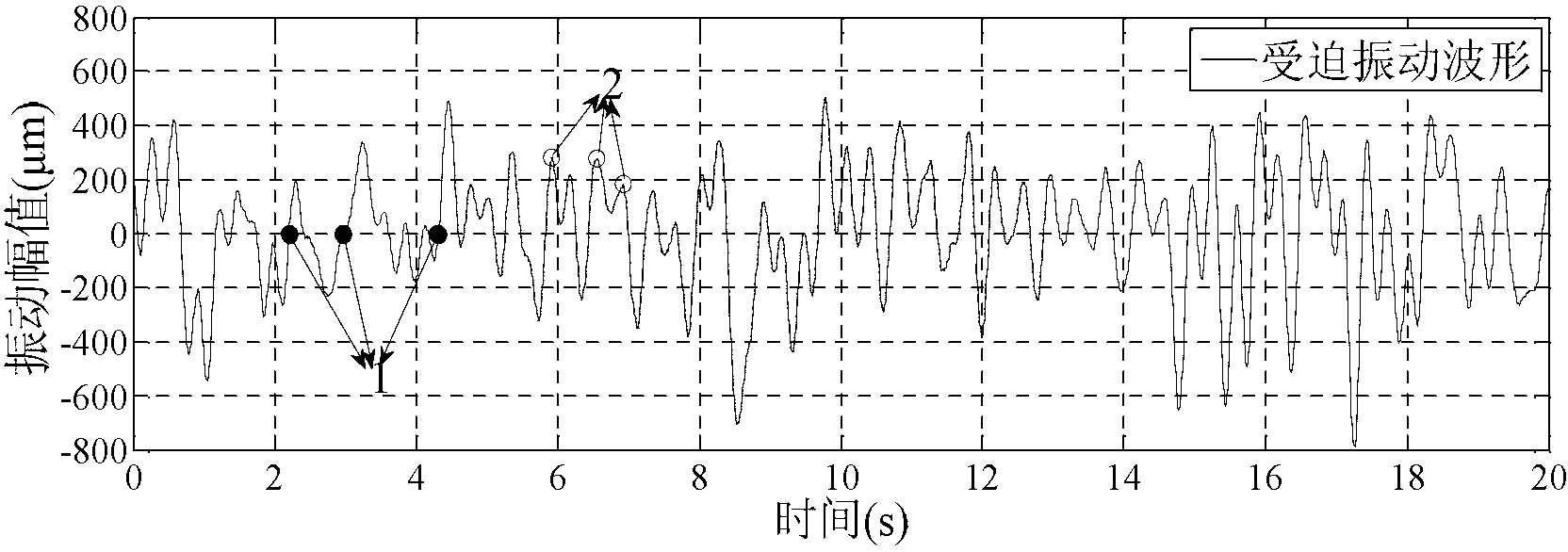

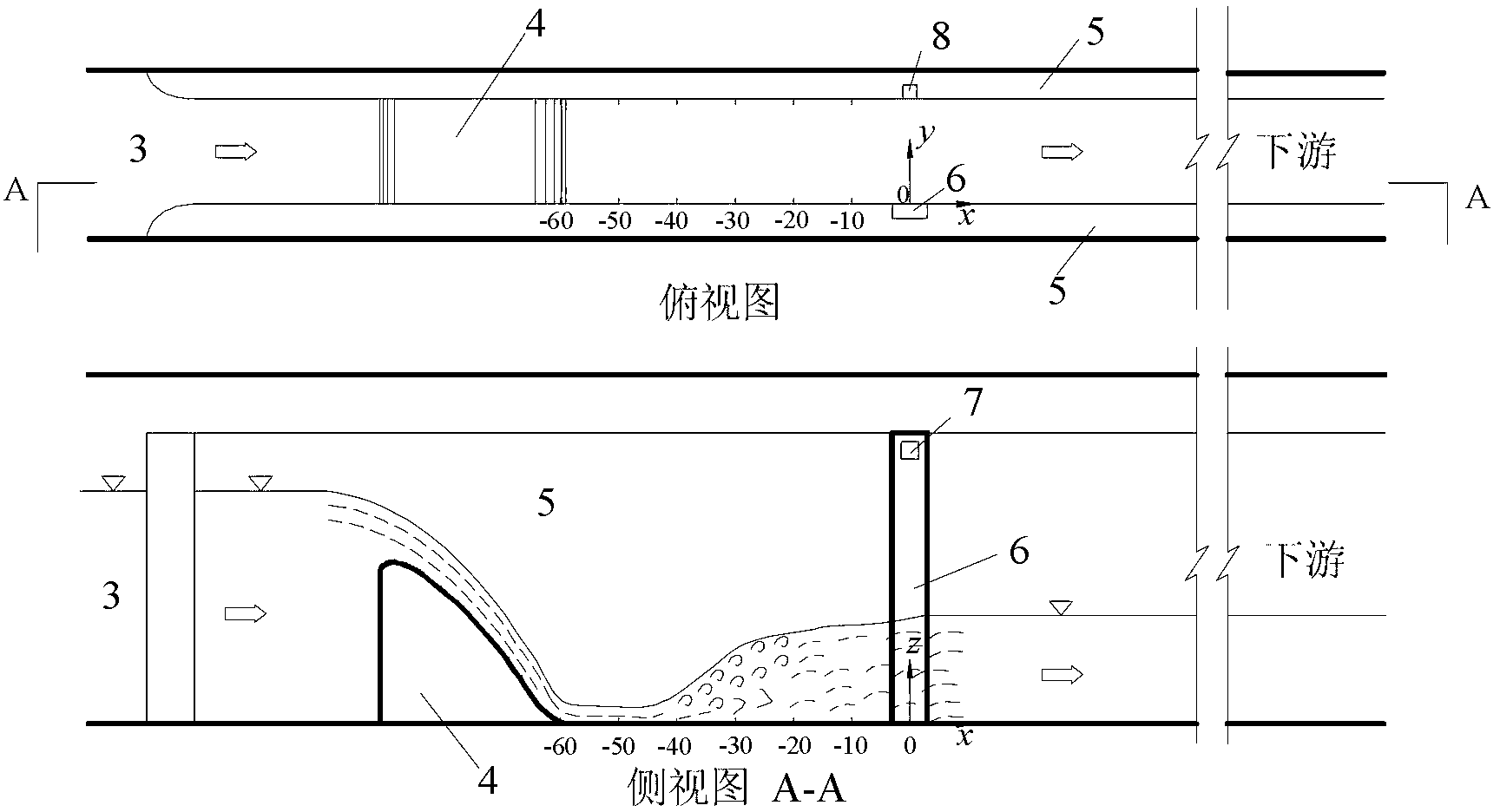

Monitoring method for damages of drainage structure based on stochastic resonance

ActiveCN102841140ATimely detection of damageDamage sensitiveAnalysing solids using sonic/ultrasonic/infrasonic wavesRemote controlArch dam

The invention discloses a monitoring method for damages of a drainage structure based on stochastic resonance. Firstly, a sensor disposed in the structure collects vibration responses under normal state of the structure, and the vibration responses are respectively stored according to different operation conditions. Secondly, waveform judging parameters and damage criterions are constructed. Lastly, the drainage structure is monitored in real time and observed of characteristics of dynamic vibration waveforms, meanwhile, the waveform judging parameters in every statistic period are calculated in real time and compared with criterion values of the normal structure under corresponding operation states in order to obtain the damage criterions and judge the operation states of the structure. According to the method, the sensor arranged on the drainage structure is adopted to monitor, so the method has the advantages of simple structure, convenient construction, easy maintenance and low project cost and can achieve remote control, online real-time monitoring of dynamic security criterions of arch dams or offline detailed analysis to data.

Owner:TIANJIN UNIV

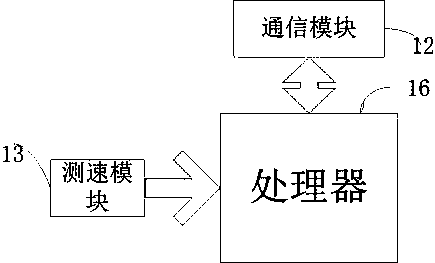

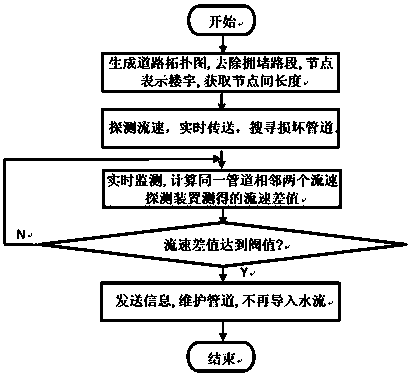

Method for determining damage of water pipe with monitoring system

InactiveCN108679453ATimely detection of damageEasy maintenancePipeline systemsComputer moduleMonitoring system

The invention discloses a method for determining the damage of a water pipe with a monitoring system. The monitoring system comprises multiple flow rate detection devices installed in the water pipe.Each flow rate detection device comprises a speed detection module for detecting the flow rate and a processor. The processors receive data collected by the speed detection modules and upload the datato a central computer through communication modules after processing, and meanwhile the communication modules send a received command from the central computer to a maintenance engineering command center and workers after processing. Pipeline damage is detected in time, the damaged pipe is maintained quickly, and the maintenance path is optimized. By the adoption of the method, the work and costof maintenance and repair can be greatly reduced, the difficulty of maintenance is reduced, and the installation and maintenance by workers are easier; and the satisfaction of building users is improved, and the risk of residents suffering from water stop loss is greatly reduced.

Owner:东莞产权投资有限公司

Wearing type intelligent body temperature monitoring device

ActiveCN113273971AAvoid harmAvoid sudden convulsionsSensorsTelemetric patient monitoringConvulsionMedicine

The invention discloses a wearing type intelligent body temperature monitoring device, which comprises a wearing element used for wearing, wherein the wearing element is provided with a plurality of temperature sensors; a monitoring thermometer is mounted to the wearing element; temperature signals detected by the plurality of temperature sensors are transmitted to the monitoring thermometer to be processed; and the monitoring thermometer transmits detected body temperature signals to a mobile terminal and / or a remote server terminal. The wearing type intelligent body temperature monitoring device disclosed by the invention is mainly used for the body temperature monitoring of a hyperpyretic convulsion child, can find a situation that the temperature measurement sensor of the thermometer is damaged or unstable in time, can monitor the body temperature of the hyperpyretic convulsion child under various situations, including daily activities, sleeping at night and the like so as to warn and give an alarm about a fever situation, and also can remind a child guardian to carry out cooling and preventing processing in time so as to avoid injuries to the child by multi-time hyperpyretic convulsion.

Owner:深圳市三五智能科技有限公司

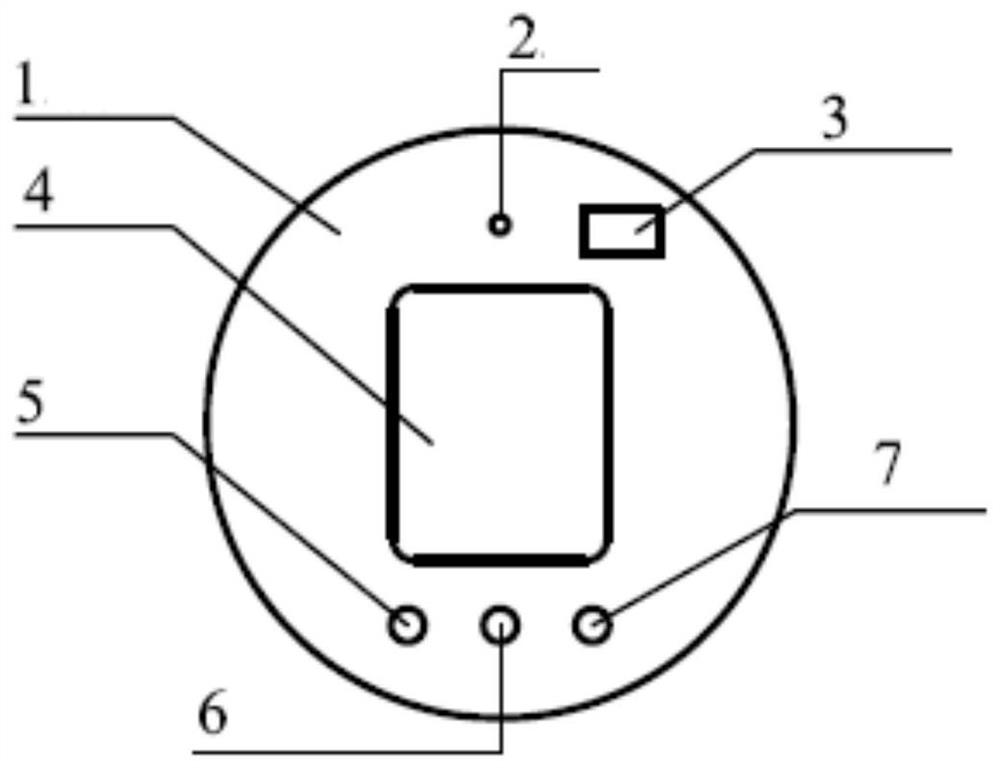

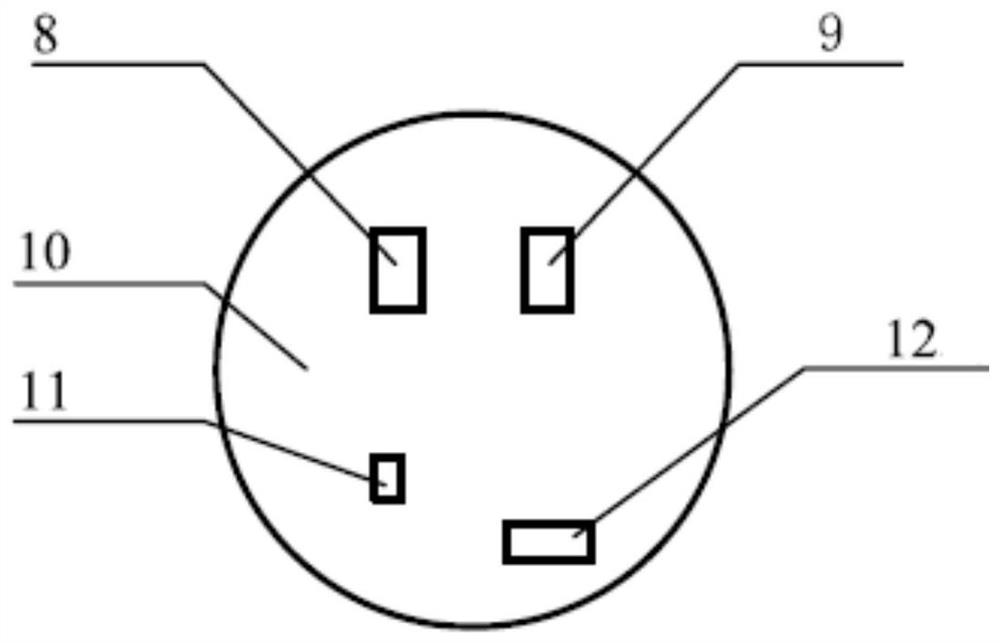

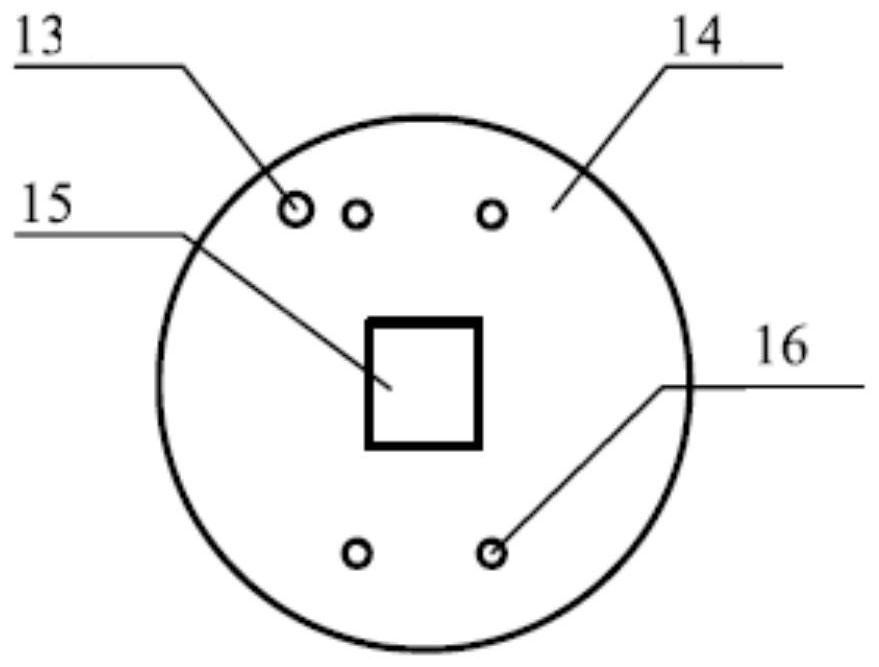

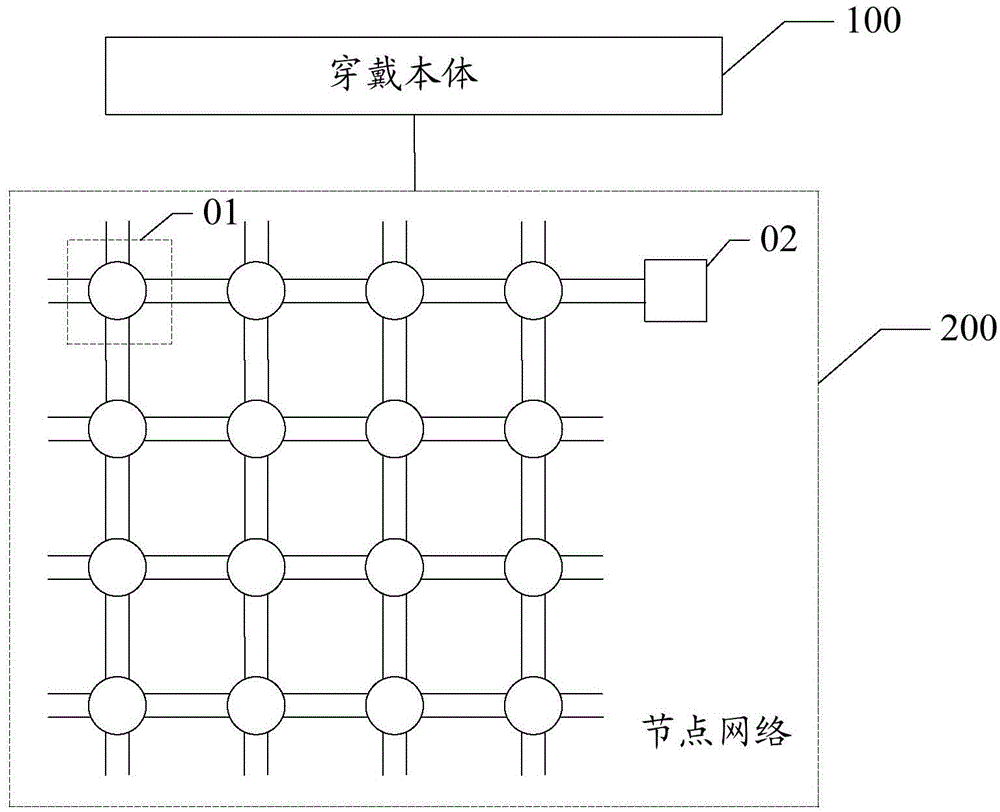

Wearable equipment for assessing human body injury condition and method thereof

InactiveCN104865937AQuick checkRapid assessmentTotal factory controlProgramme total factory controlHuman bodyMultiple node

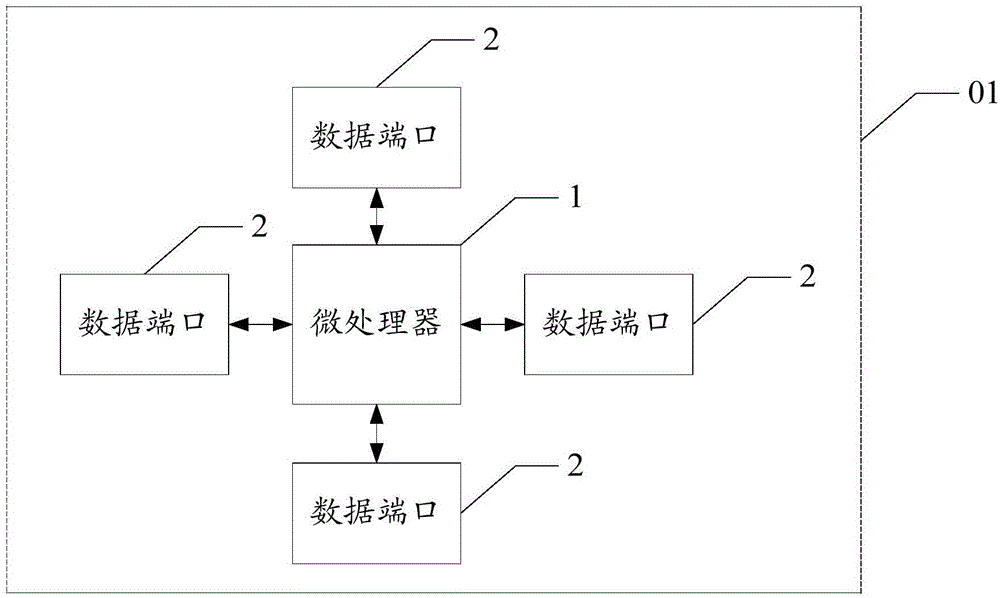

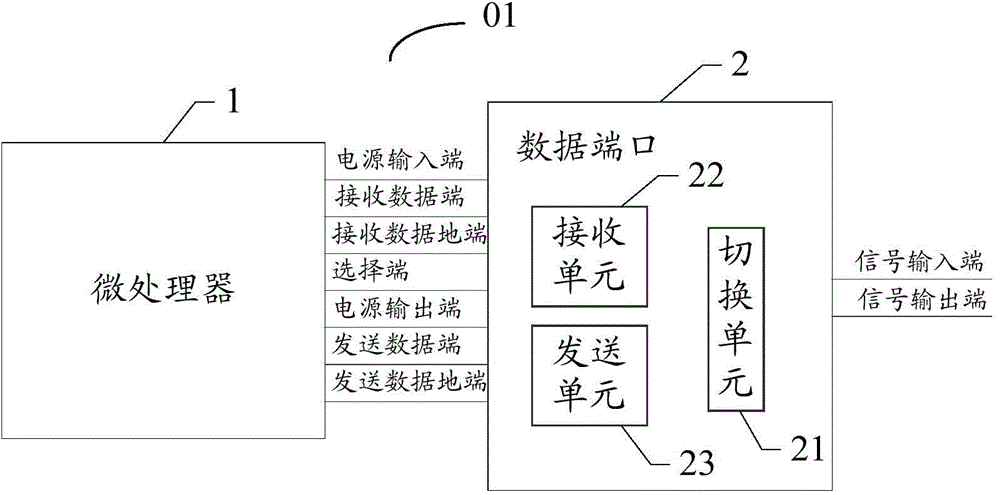

The invention discloses wearable equipment for assessing the human body injury condition. The wearable equipment comprises a wearing body and a node network which is arranged on the wearing body. The node network is formed by a central processor and multiple nodes. The central processor is connected with at least one node in a signaling way and used for receiving concrete node information via the node network. Each node comprises a microprocessor and data ports. Other nodes can be extended via the data ports. The data ports are controlled to perform data communication with other nodes via the microprocessor, and finally the concrete node information is transmitted to the central processor. The wearable equipment is applied to assess the human body injury condition so that the human body injury condition can be accurately and rapidly detected and assessed.

Owner:ANYCHECK INFORMATION TECH +3

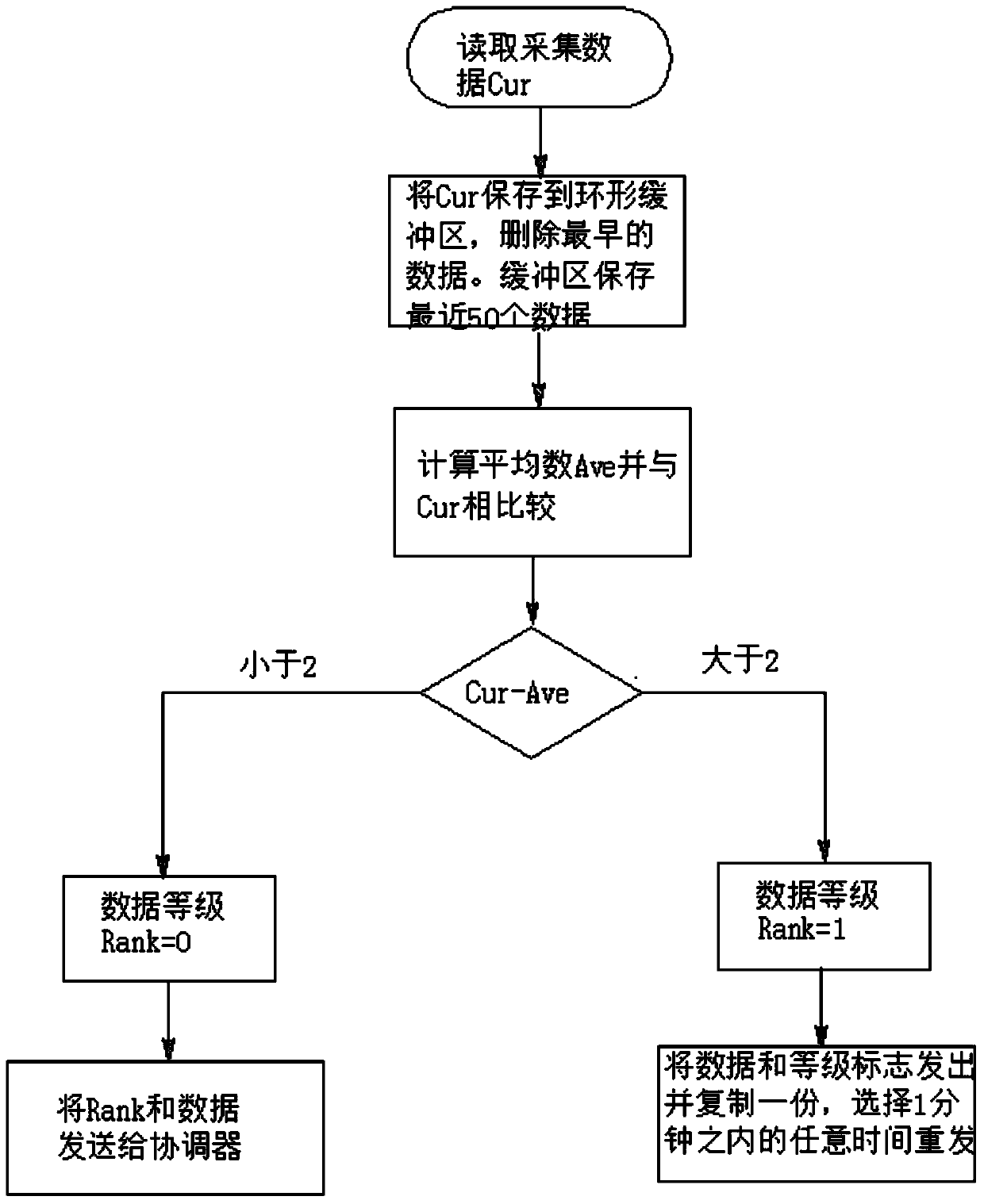

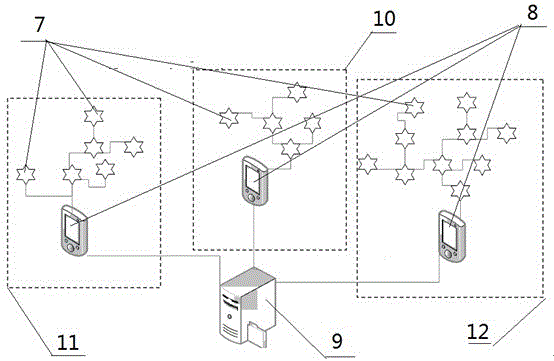

Fan blade lightning stroke monitoring system based on ZigBee protocol

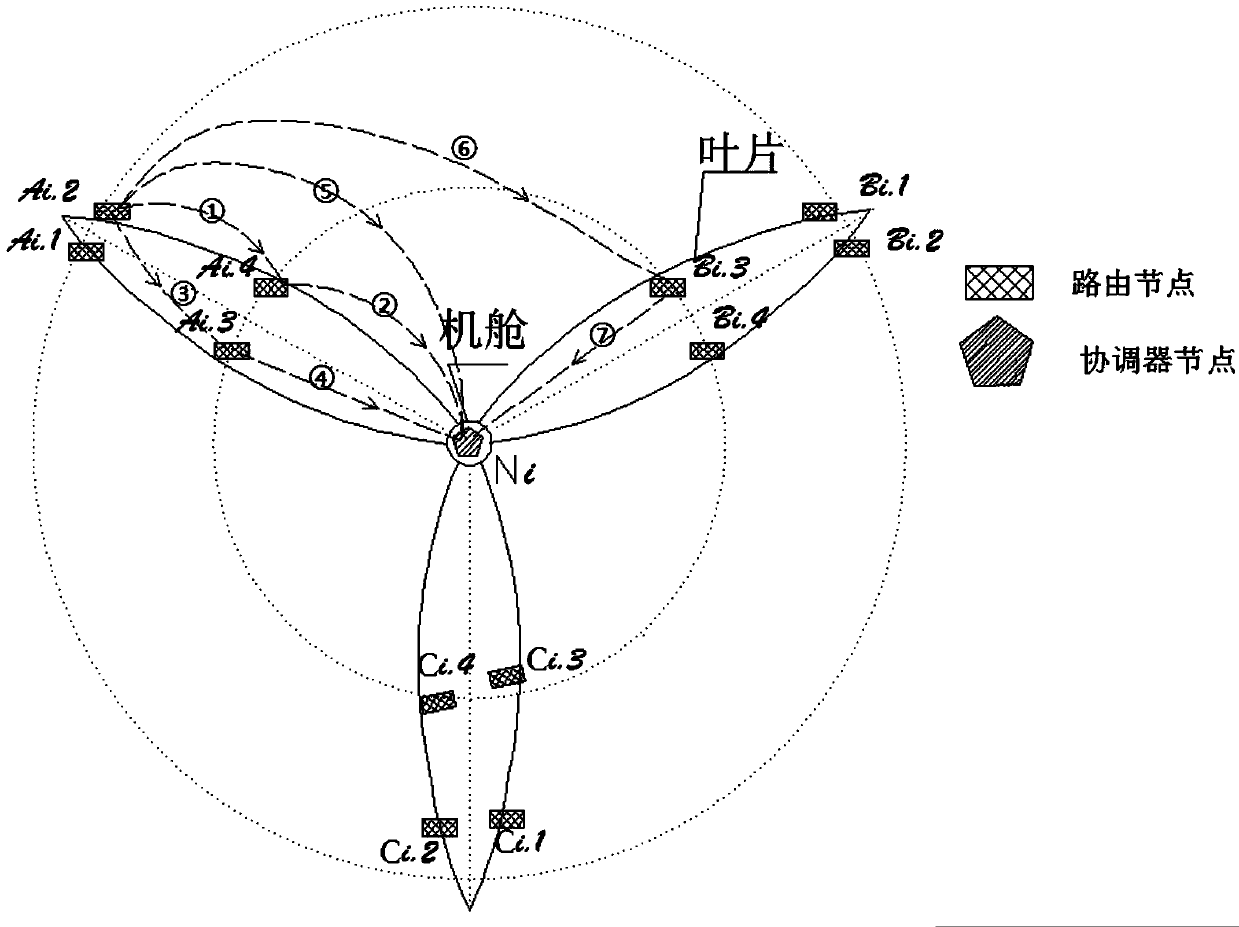

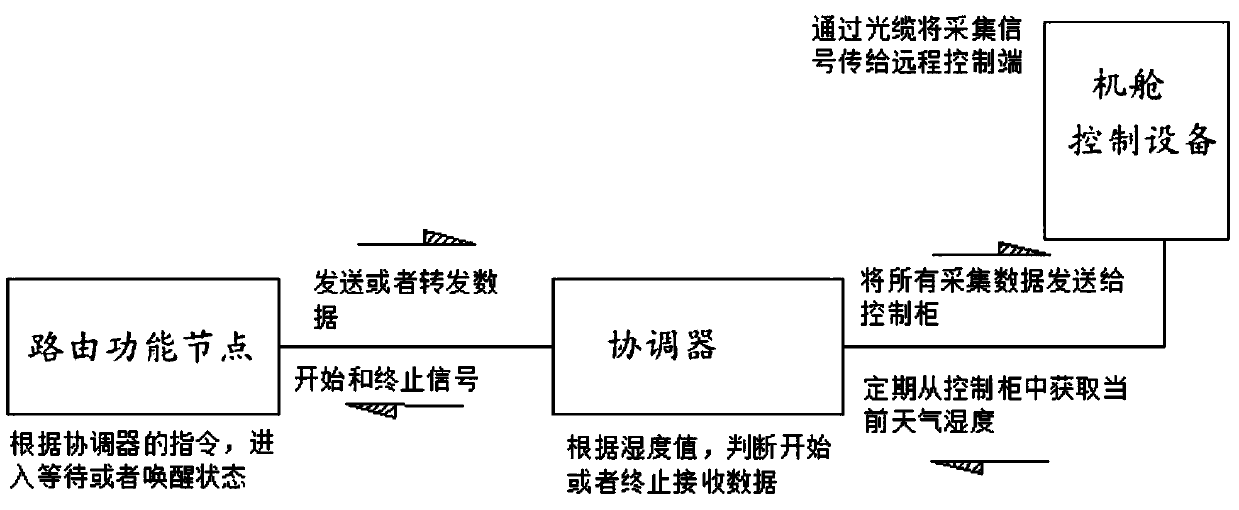

InactiveCN103994088ATimely detection of damagePump controlNon-positive displacement fluid enginesLightning strokesNacelle

This invention puts forward a fan blade lightning stroke monitoring method based on a ZigBee protocol. A system comprises a plurality of routing function nodes, a coordinator and a cabin control cabinet, wherein the routing function nodes are arranged in fan blades and used for collecting the temperature and the light brightness in the fan blades in a starting state; the routing function nodes are in mutual communication based on the ZigBee protocol and are in communication with the coordinator based on the ZigBee protocol, and therefore any routing function node can directly transmit collected data representing the temperature and the light brightness in the fan blades to the coordinator or transmit the collected data to the coordinator through other routing function nodes; besides, when the coordinator receives the collected data from the routing function nodes, the collected data are transmitted to the cabin control device.

Owner:SHANGHAI DIANJI UNIV

Structural deformation detection method based on Internet of Things

InactiveCN103148829ATimely detection of damageFound damageMeasurement devicesStructural deformationWired communication

The invention discloses a structural deformation detection method based on the Internet of Things. Detection nodes, a master control node and a data service center are used in the structural deformation detection method. The master control node is communicated with the detection nodes in a wireless way, can be connected to the data service center in a wireless or wire communication way, downloads data from the data service center to update a local database, and uploads data to the data service center. One master control node and more than one detection nodes are arranged on one movement mechanical equipment, and the data of the detection nodes, such as linear acceleration speed, angular speed and terrestrial magnetism are collected by sensor modules on the detection nodes and compared with reference nodes to judge whether parts on the movement mechanical equipment are normal, deform, loosen or fall off. The three-dimensional dynamic movement module of the movement mechanical equipment is established by an expert system of the data service center to restore the movement trajectory and the deformation and failure conditions of the movement mechanical equipment, thereby discovering other potential problems of the movement mechanical equipment.

Owner:广西泰绘信息科技有限公司

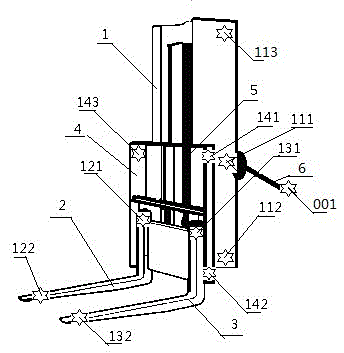

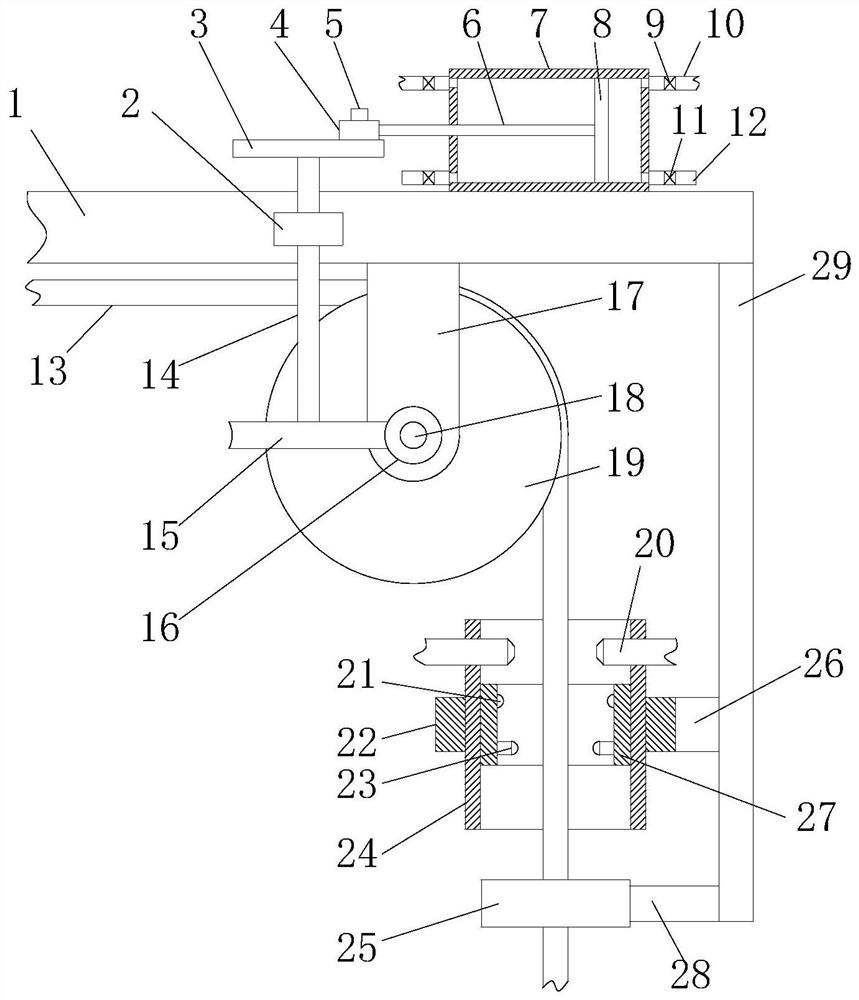

Steel cable detection device for constructional engineering hoisting equipment

PendingCN113203749AImprove detection accuracyTimely detection of damageOptically investigating flaws/contaminationStructural engineeringDust control

The invention relates to the field of building equipment detection, in particular to a steel cable detection device for building engineering hoisting equipment. The device comprises a suspension arm, wherein a support rod is fixed on the suspension arm, a fixed shaft at the lower end of the support rod is rotatably connected with a rotating shaft, a work guide wheel for supporting and guiding a steel cable is fixed on the rotating shaft, a detection mechanism used for detecting the steel cable is arranged on the suspension arm, an air pumping mechanism used for removing dust on the detection mechanism and the steel cable is further arranged on the suspension arm, and the guide wheel is in transmission connection with the air pumping mechanism. According to the steel cable detection device for the constructional engineering hoisting equipment, a camera is arranged on the outer side of the steel cable, and the outer surface of the steel cable is detected through the camera, so that a damaged part on the surface of the steel cable can be found in time, and potential safety hazards can be found in time. In addition, by means of removing dust on the surfaces of the steel cable and the camera in real time through the air pumping mechanism, it is ensured that the camera can clearly photograph the surface condition of the steel cable, and the detection accuracy is improved.

Owner:东安县三合建筑工程有限责任公司

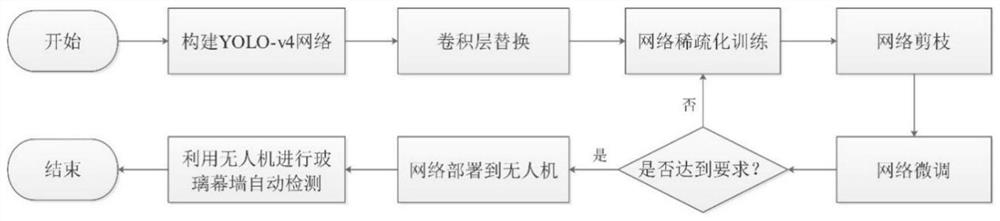

Automatic detection method for damage of glass curtain wall of high-rise building

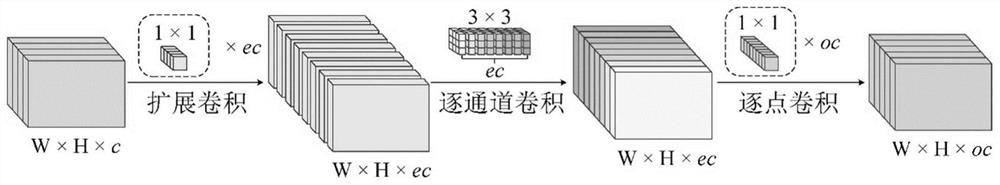

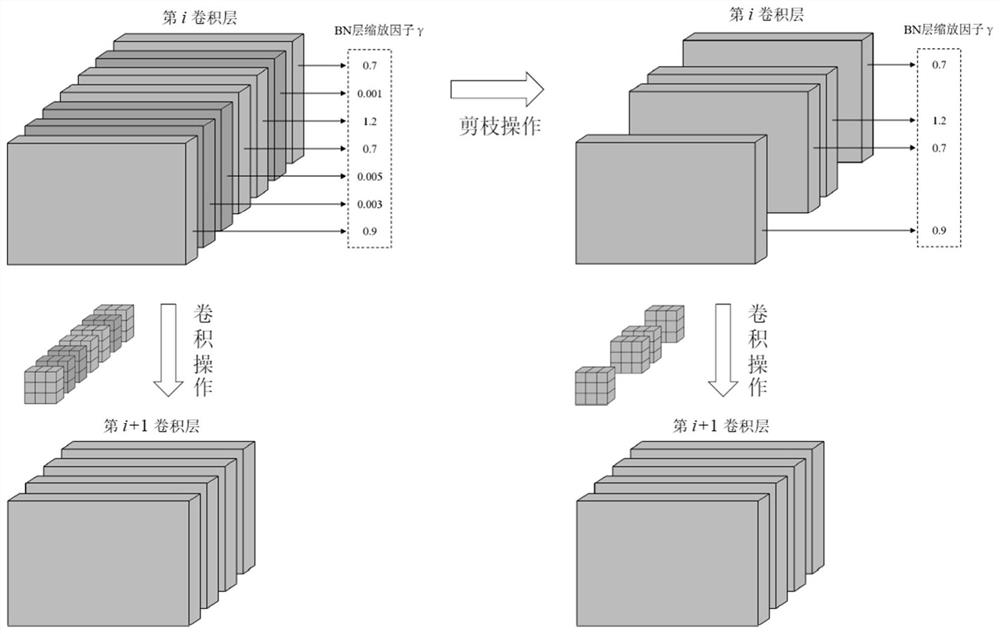

ActiveCN114120154AReduce the amount of parametersChange manual inspectionCharacter and pattern recognitionNeural architecturesArchitectural glassAlgorithm

The invention relates to an automatic detection method for damage of a glass curtain wall of a high-rise building, and the method comprises the steps: constructing a detection network, carrying out the training and verification of the constructed detection network through a sample set, and obtaining a detection network with optimal parameters. A convolutional layer in the YOLO v4 network is replaced by expansion convolution, channel-by-channel convolution and point-by-point convolution which are connected in sequence to obtain a new convolutional layer, and finally, the YOLO v4 network after replacement is used as a constructed detection network; pruning the detection network with the optimal parameters according to the scaling factor vectors of all the BN layers; and finally, performing fine tuning on the pruned detection network with the optimal parameters by using the sample set to obtain a final detection network. Therefore, the method further reduces the parameter quantity of the model on the premise of ensuring high accuracy, and realizes the full-automatic detection of the glass curtain wall of the urban high-rise building based on the unmanned aerial vehicle.

Owner:NINGBO UNIV

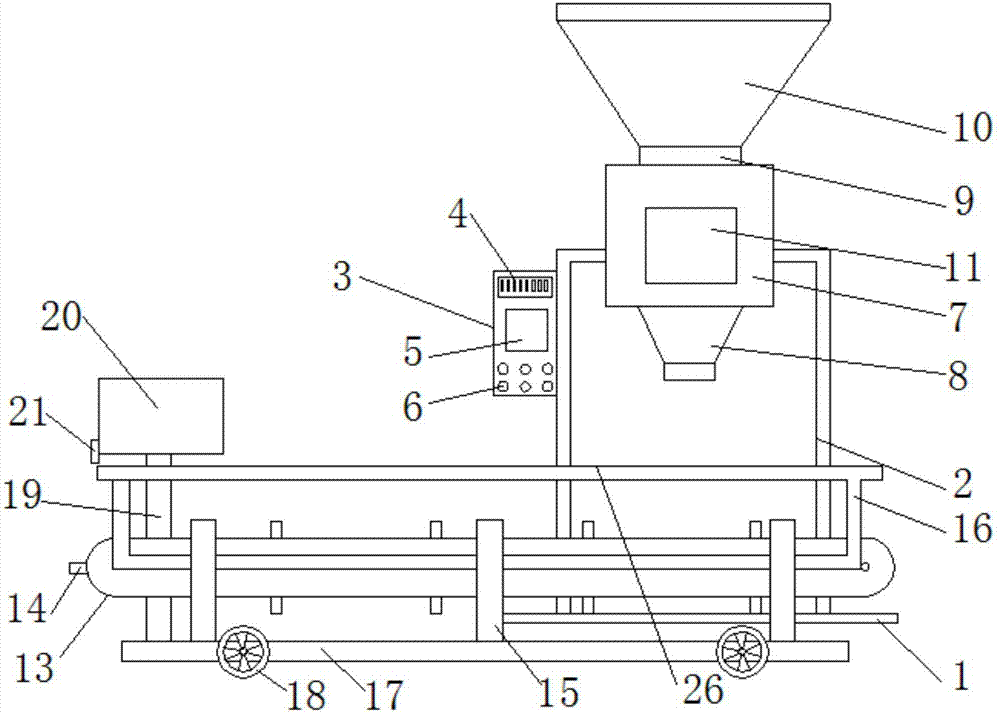

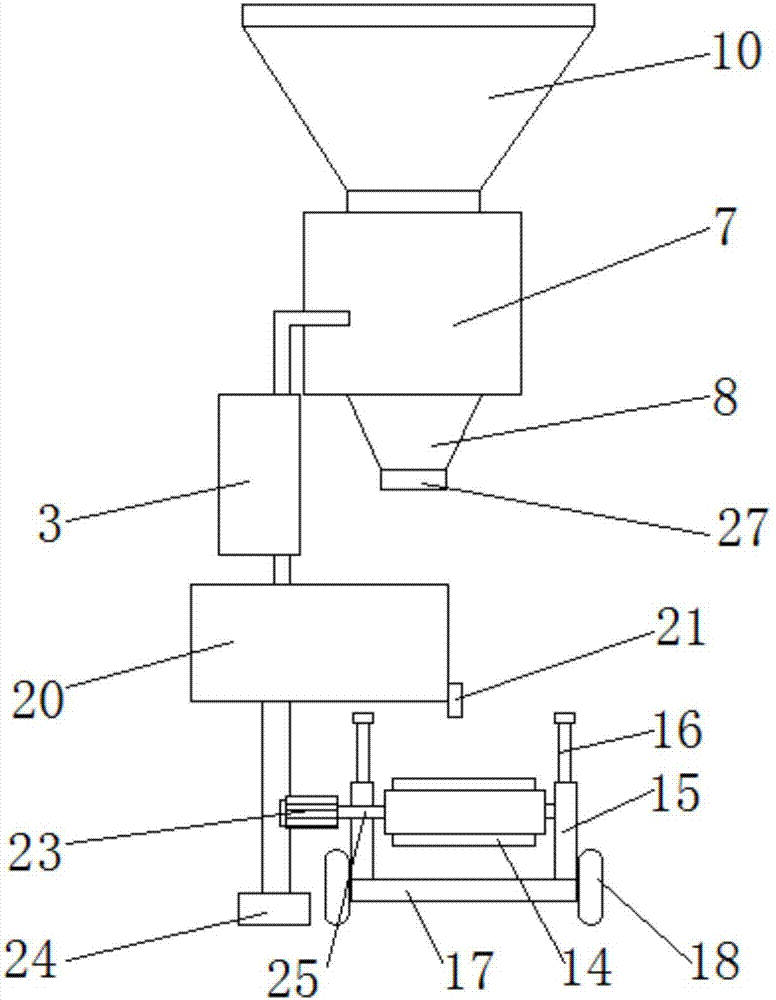

Packaging machine

The invention discloses a packaging machine comprising a material storage bin, an observation window, a temperature and humidity sensor, a conveyor belt, a limiting block, a fixing frame, a bag sewing machine, a code scanner and a bar code. The temperature and humidity sensor is installed on the inner wall of the material storage bin. The lower portion of the material storage bin is connected with a discharge bin. The conveyor belt is arranged at the position of the lower portion of the discharge bin. The limiting block is arranged at the top end of the conveyor belt. The bar code is arranged on one side of the limiting block. The fixing frame is arranged on one side of the conveyor belt. The bag sewing machine is arranged at the top end of the fixing frame. The code scanner is arranged at the position, corresponding to the bar code, at one end of the bag sewing machine. According to the packaging machine, by arranging the limiting block, packaging bags can be conveniently placed in order; by arranging the temperature and humidity sensor, users can conveniently know temperature and humidity data inside the material storage bin, and product deterioration caused to products due to damping or excessively-high temperature is prevented; and by arranging the code scanner and the bar code, the bag sewing position can be more precise, and the packaging quality is improved.

Owner:FOSHAN HANGESI ENVIRONMENTAL PROTECTION TECH CO LTD

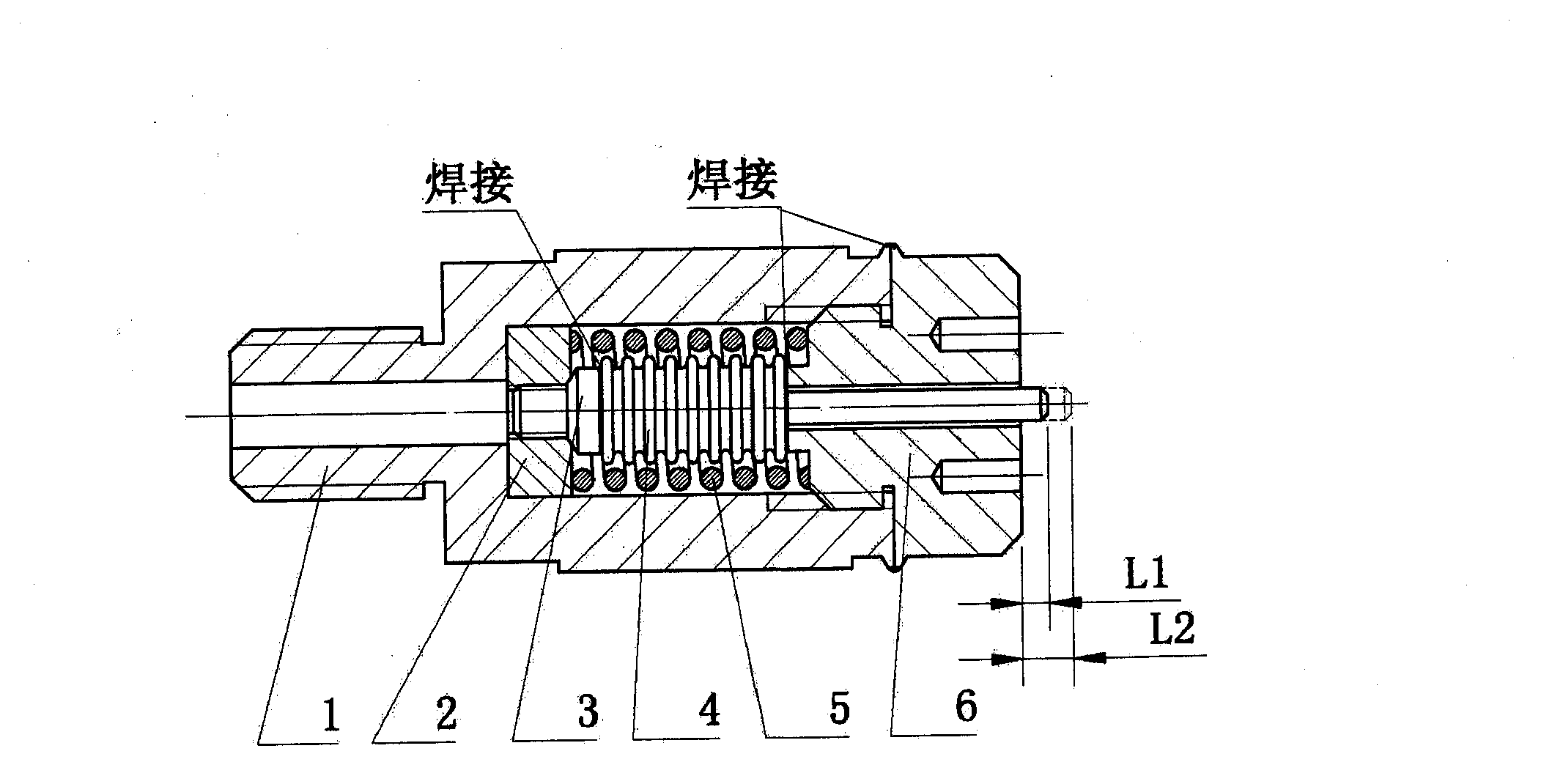

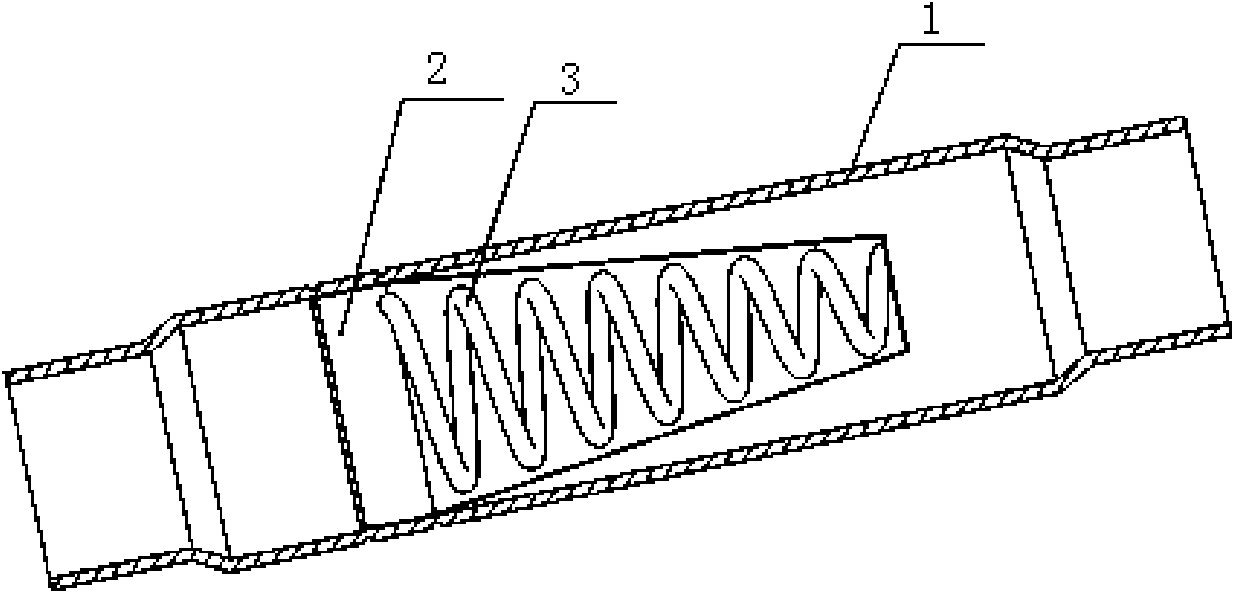

Corrugated pipe damage detecting instrument

The invention belongs to instruments, and discloses a corrugated pipe damage detecting instrument. The corrugated pipe damage detecting instrument is characterized in that the corrugated pipe damage detecting instrument is composed of a shell, a piston, a piston rod with a shaft shoulder, a corrugated pipe, a spiral spring and a capping plug. The shell is provided with a step hole penetrating through the two ends of the shell, and one end of the step hole is a neck part in threaded connection with a drainage guide hole in the valve deck of a corrugated pipe valve. The capping plug seals the piston, the piston rod, the corrugated pipe and the spiral spring in the step hole, the piston and the corrugated pipe are arranged on the rod body on the two sides of the shaft shoulder of the piston rod respectively in a sleeved mode, one end of the corrugated pipe is in sealing welding with the shaft shoulder, and the other end is in sealing welding with the end surface of the capping plug. The spiral spring is arranged on the periphery of the corrugated pipe in a sleeved mode, the two ends of the spiral spring abut against the piston and the end face of the capping plug respectively, and the tail end of the piston rod is flush with the outer end face of the capping plug or extends outwards for a certain length L1. The effects that the breakage of a valve corrugated pipe can be found out in time at an early stage without dismounting and media leakage is prevented from endangering the human body safety and the property safety in a detection process are achieved.

Owner:SHANGHAI YIHE VALVE CO LTD

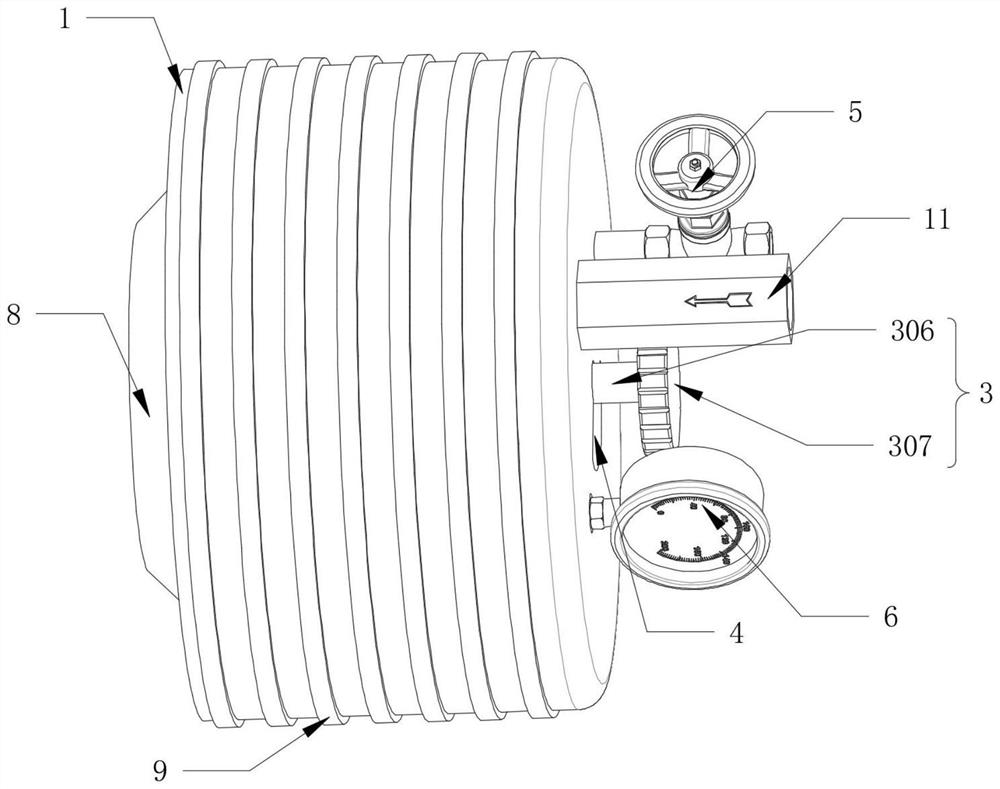

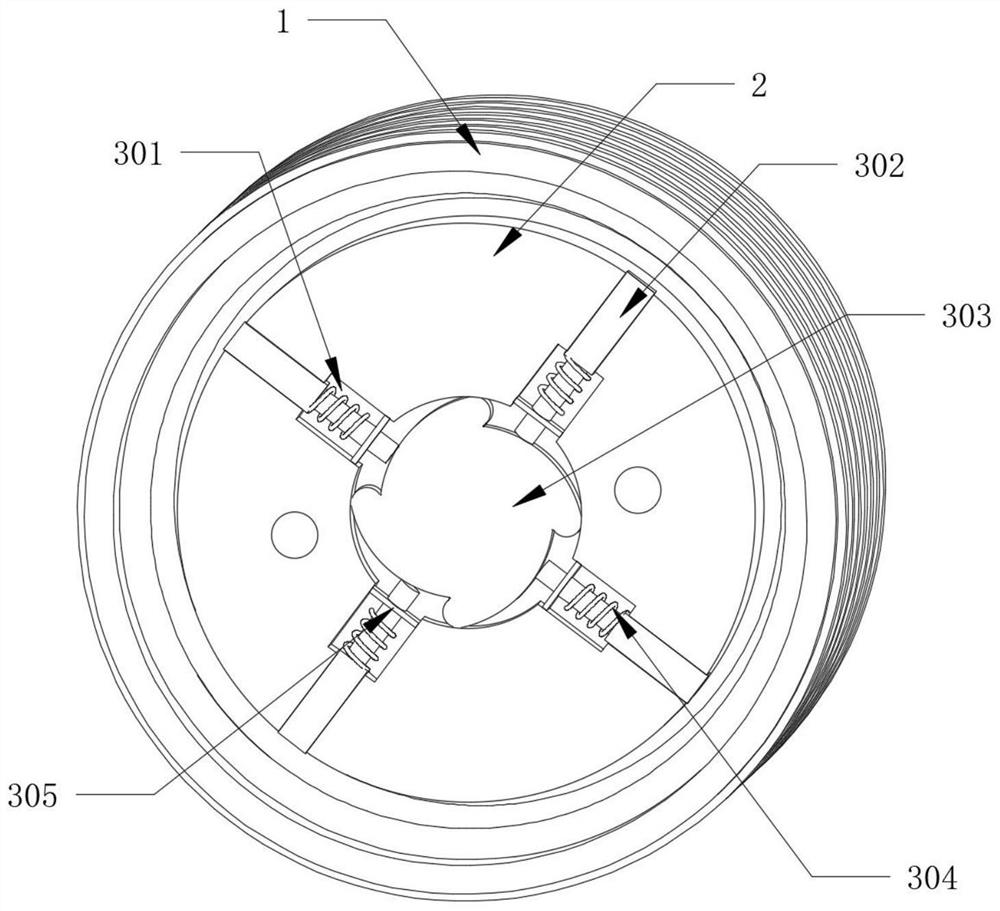

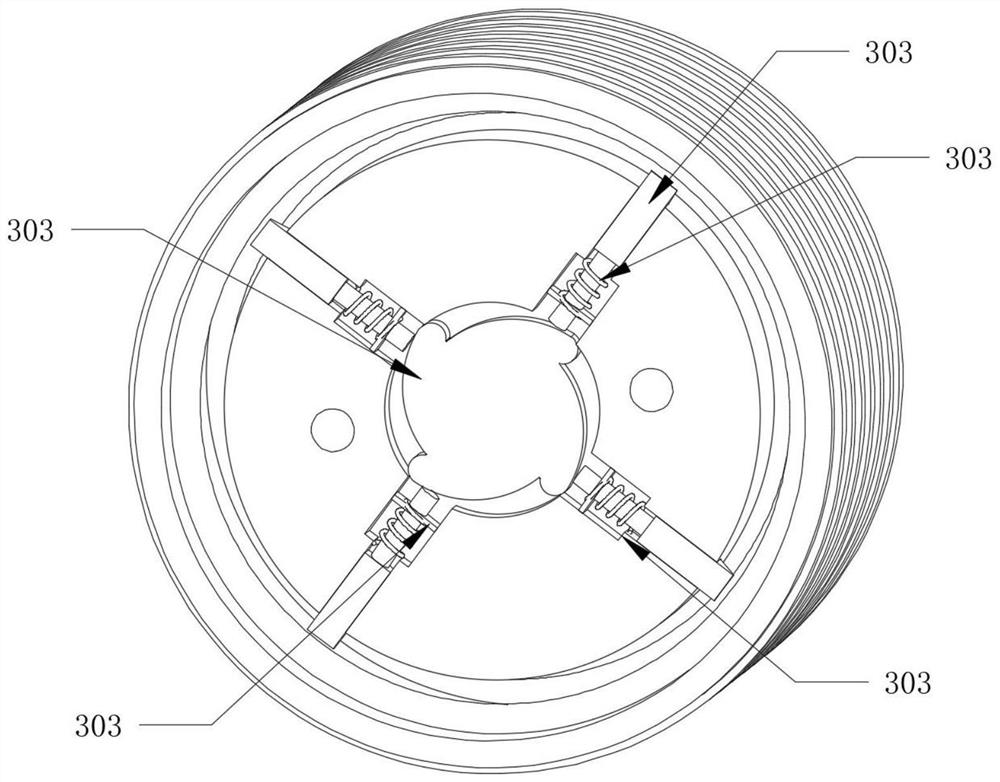

Protective pipe plug device for building construction and construction method of protective pipe plug device

The invention provides a protective pipe plug device for building construction and a construction method of the protective pipe plug device.The protective pipe plug device comprises a shell and a body, the body is fixedly connected to the inner part of the shell, a clamping mechanism is installed at one end of the body, an outer limiting mechanism is arranged at one end of the shell, through holesare symmetrically formed in the body, and an air valve is fixedly connected to one end of the outer wall of the shell; a pressure gage is fixedly connected to the end, close to the air valve, of theshell, the air valve communicates with one end of the body through the corresponding through hole, sliding grooves are equidistantly formed in one end of the body, limiting claws are slidably connected to the inner walls of the sliding grooves, baffles are fixedly connected to one ends of the limiting claws, and springs sleeve the limiting claws; one ends of the springs are fixedly connected to one side surfaces of the baffles, and the other ends of the springs are fixedly connected to the inner walls of the sliding grooves; and a rotating shaft is rotatably connected to the middle part of thebody through a bearing, and the end, close to the sliding grooves, of the rotating shaft is fixedly connected with a petal wheel. The protective pipe plug device for building construction is simple in structure, convenient to install, stable in structure, more convenient and rapid to use, and high in practicability.

Owner:ANHUI GUODENG PIPE IND TECH CO LTD

Cable

InactiveCN104575812AReasonable designSimple structureInsulated cablesInsulated conductorsFiberCopper conductor

The invention discloses a cable. The cable comprises a conductive layer, a high-temperature-resistant layer and an insulating layer, wherein the high-temperature-resistant layer is arranged between the conductive layer and the insulating layer; a plurality of aluminum conductors and a plurality of copper conductors are arranged inside the conductive layer; heat-radiating ports are formed in the conductive layer; a filler is arranged inside the conductive layer; sensing fibers are arranged inside the insulating layer; ropes are arranged on the insulating layer. The cable is simple in structure and convenient to use; the copper conductors and the aluminum conductors are arranged inside the conductive layer, and the advantages of the two conductors are combined, so that the conductivity is good; the plurality of heat-radiating ports are formed in the conductive layer, so that the using amount of the filler is reduced; the sensing fibers are arranged inside the insulating layer, so that damage of the insulating layer can be found timely; the ropes are arranged on the insulating layer, and a sleeve can be connected as required to prevent short circuit caused on snowy days, hailing days and the like, so that the life safety of people is ensured.

Owner:李怀玉

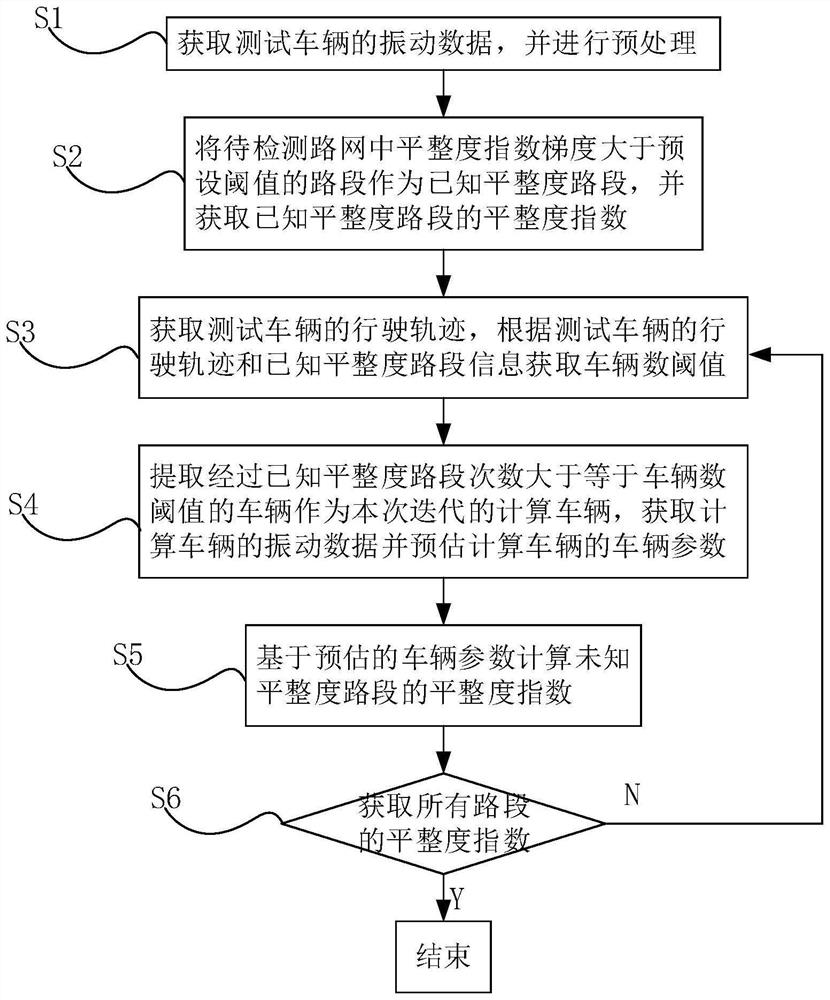

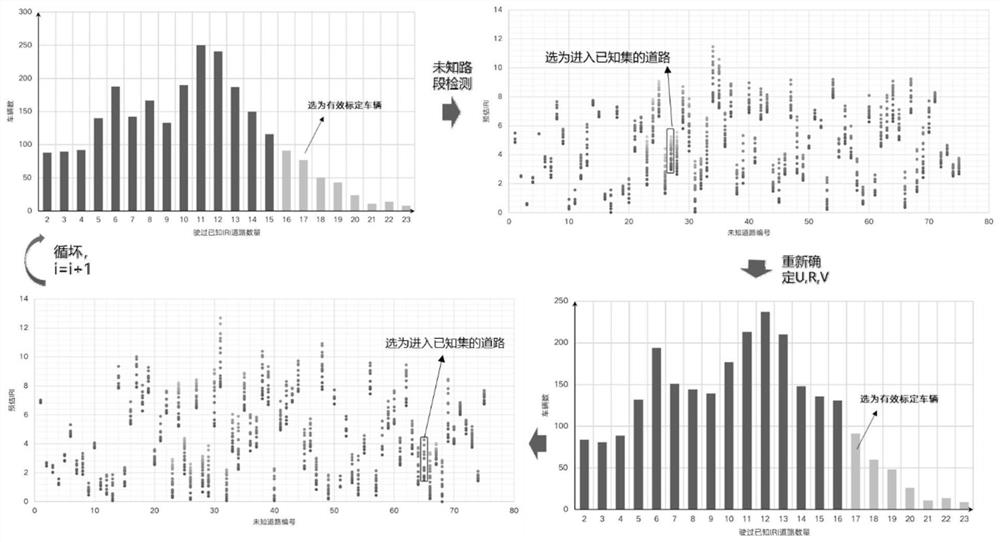

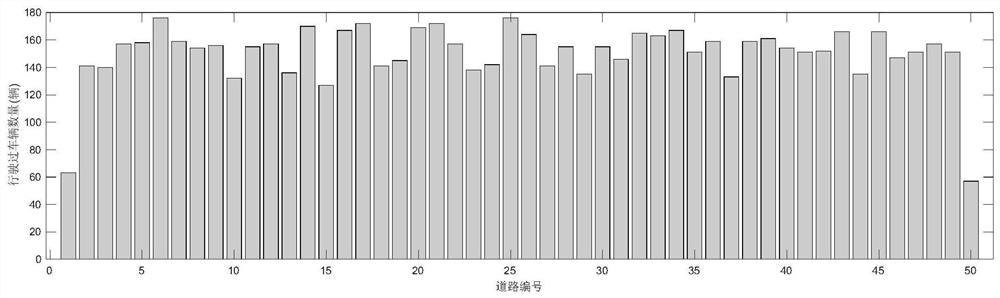

Road network level pavement flatness detection method based on multi-vehicle crowdfunding vibration data

PendingCN114541222ASolve problems such as time-consuming, laborious and expensiveTimely detection of abnormal bumpsSustainable transportationRoads maintainenceRoad networksRoad surface

The invention relates to a road network level pavement flatness detection method based on multi-vehicle crowdfunding vibration data, and the method comprises the following steps: obtaining the vibration data of a test vehicle, and carrying out the preprocessing of the vibration data; taking a road section of which the flatness index gradient is greater than a preset threshold value in the road network to be detected as a known flatness road section, and obtaining the flatness index of the known flatness road section; acquiring a driving track of the test vehicle, acquiring a vehicle number threshold value according to the driving track of the test vehicle and the known flatness road section information, extracting the vehicle of which the number of times of passing through the known flatness road section is greater than or equal to the vehicle number threshold value as a calculation vehicle for current iteration, acquiring vibration data of the calculation vehicle, and pre-estimating vehicle parameters of the calculation vehicle; calculating a flatness index of the road section with unknown flatness based on the estimated vehicle parameters; and repeatedly carrying out iteration for multiple times until the flatness indexes of all the road sections in the road network to be detected are obtained. Compared with the prior art, the method has the advantages of high accuracy, good stability, low cost and the like.

Owner:TONGJI UNIV

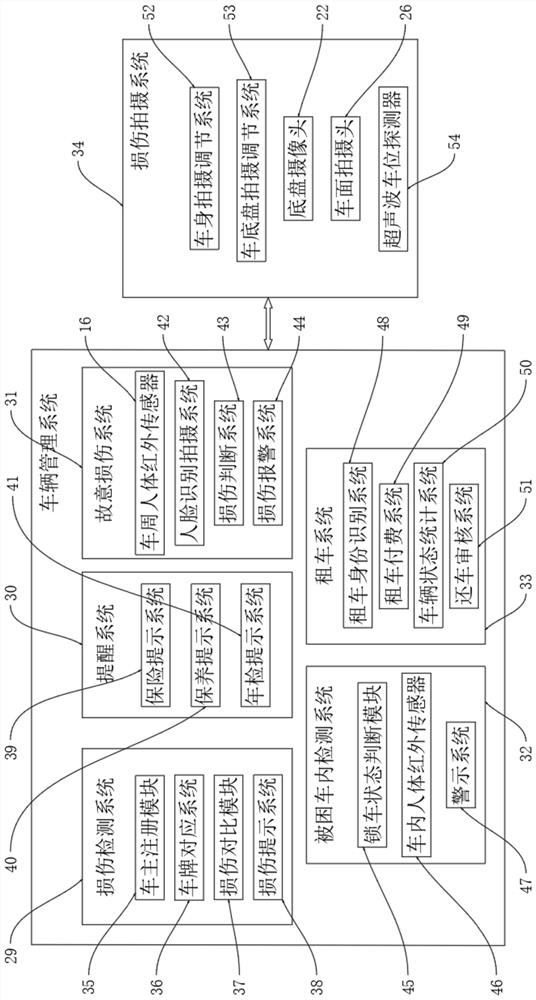

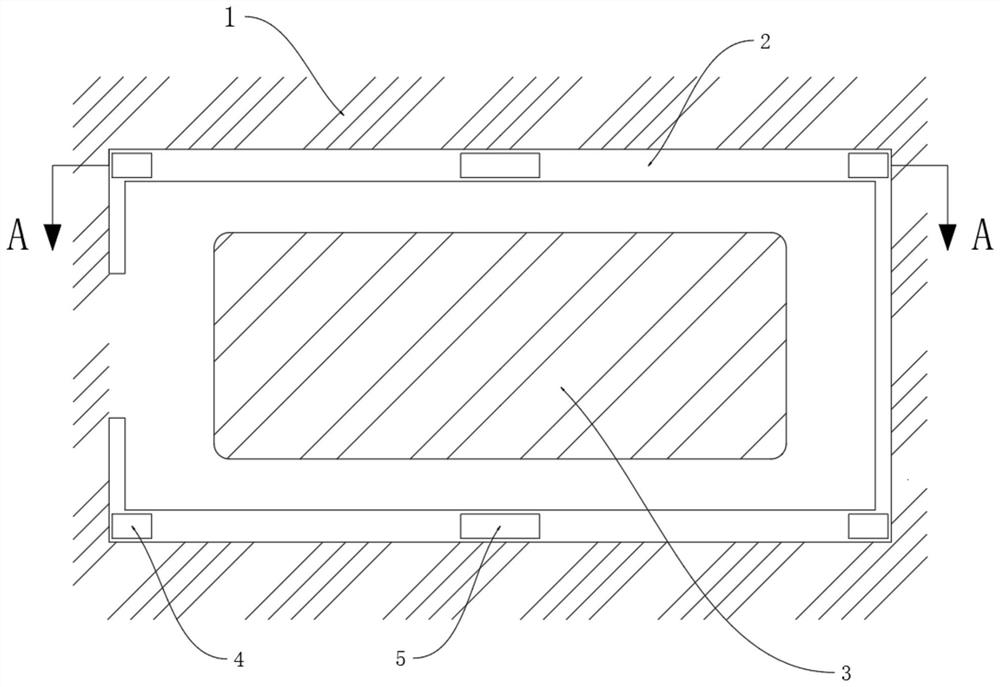

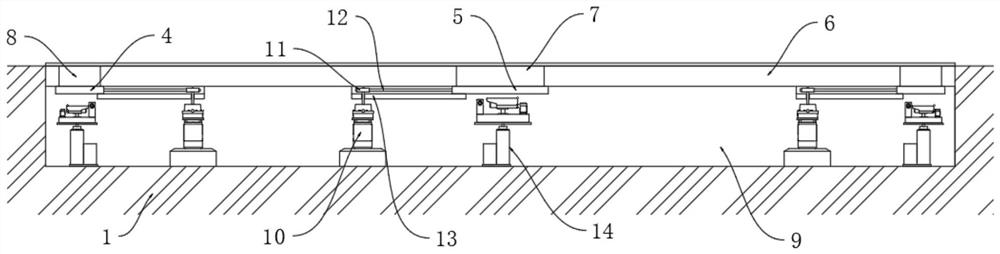

Vehicle management system of green building

InactiveCN113873172AEasily damagedTimely detection of damageImage enhancementTelevision system detailsAutomotive engineeringParking space

The invention discloses a vehicle management system of a green building, relates to the technical field of vehicle management systems, and aims to solve the problems that a vehicle management system in the current market cannot detect whether collision damage occurs or not during use of a vehicle, and the damage cannot be found in time. The damage detection system comprises a vehicle owner registration module, a license plate corresponding system, a damage comparison module and a damage shooting system, and the intentional damage system comprises a surrounding human body infrared sensor, a face recognition shooting system, a damage judgment system and a damage alarm system. The damage shooting system comprises a vehicle body shooting adjusting system, a vehicle chassis shooting adjusting system, an ultrasonic parking space detector, a chassis camera and a vehicle surface shooting head, a parking space frame is arranged on the upper surface of the ground, a center protection glass plate is arranged in the middle of the interior of the parking space frame, and a supporting layer is arranged below the parking space frame, and a storage groove is formed below the supporting layer.

Owner:SHENGDA ECONOMICS TRADE & MANAGEMENT COLLEGE OF ZZ

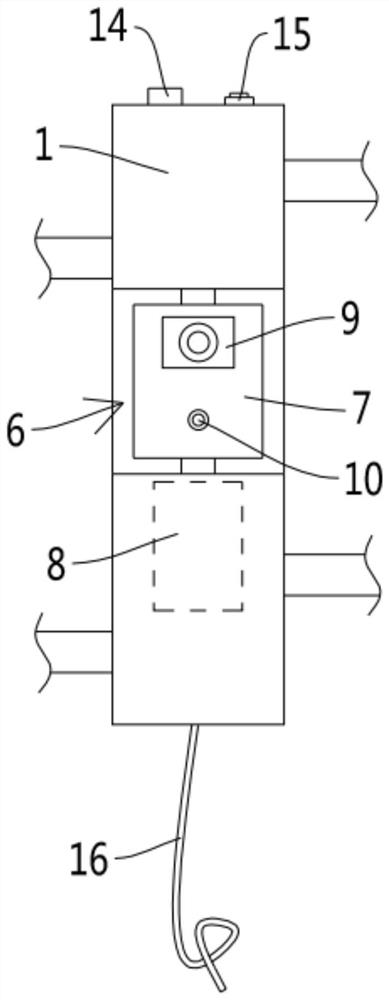

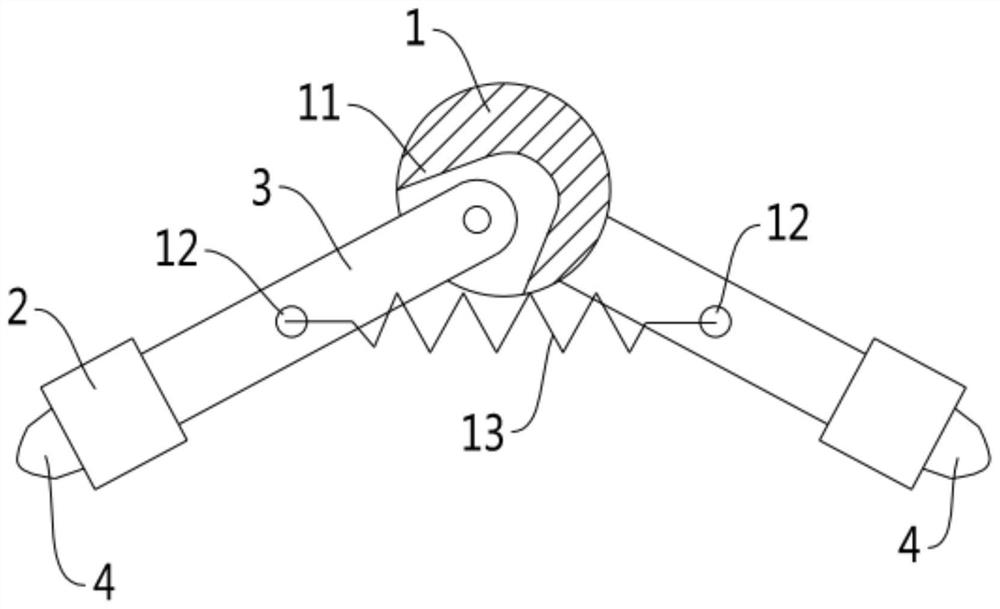

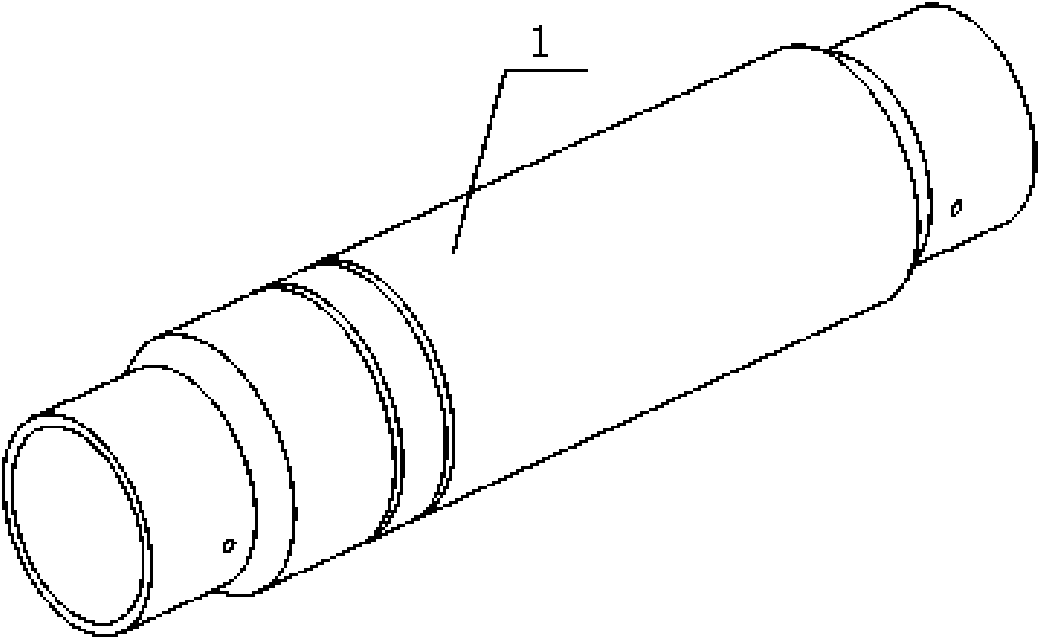

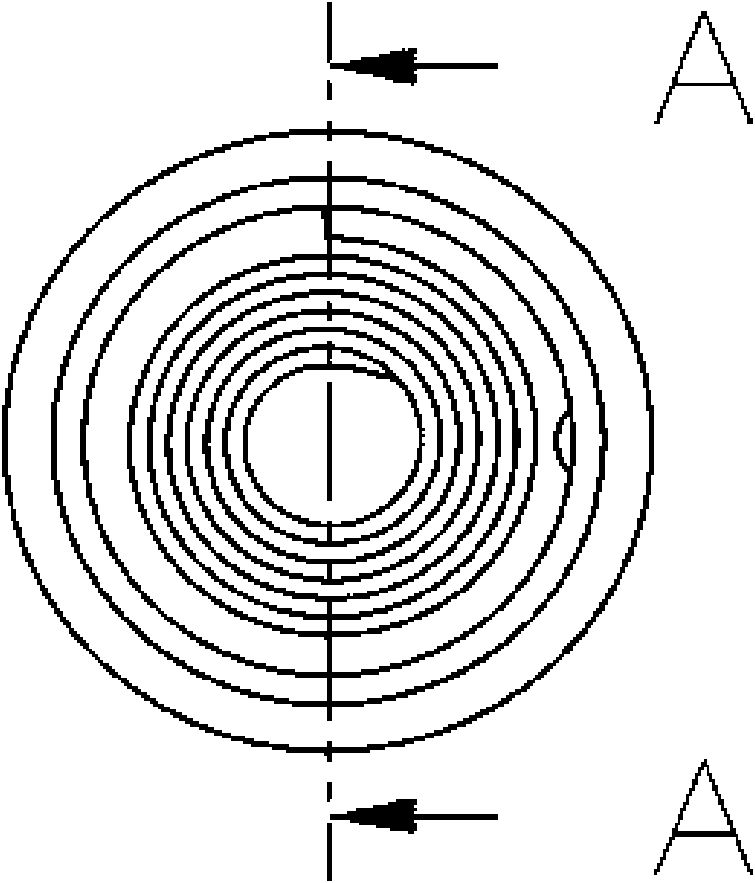

Underground pipeline in-well image survey measuring instrument

InactiveCN113624768ATimely detection of damageRealize data collectionOptically investigating flaws/contaminationMeasuring instrumentEngineering

The invention discloses an underground pipeline in-well image survey measuring instrument which comprises a columnar measuring instrument body, walking mechanisms are arranged on the two sides of the measuring instrument body respectively, each walking mechanism comprises a connecting arm, one end of each connecting arm is hinged to the measuring instrument body, and the other end of each connecting arm is provided with a wheel carrier. A wheel carrier is rotatably connected with a row of rollers arranged along the length direction of the wheel carrier, one of the rollers is in transmission connection with a first power assembly fixed on the wheel carrier, the bottom of the measuring instrument body is provided with a mounting groove with a downward notch, and the mounting groove is internally and rotatably connected with a measuring assembly. A second power assembly for controlling the measuring assembly to rotate is also arranged in the measuring instrument body; and the measuring assembly comprises a CCD camera and an illuminating lamp. The image survey measuring instrument has the advantages of crawling across the air and being clear in image shooting, complete in overall function and high in practicability.

Owner:嘉兴市中测测绘有限公司

Level glass structure of air conditioning refrigerant filter

InactiveCN102032729ASimple structureEasy to make and installRefrigeration componentsMountingsEngineeringGlass structure

The invention discloses a level glass structure of an air conditioning refrigerant filter, which comprises a shell; a filtering structure formed from a filtering net and a spring supporting the filtering net is arranged in the shell; and the shell is provided with a level window for observing the working state of the interior filtering structure and the flow direction of a refrigerant. The level window comprises an opening formed on the shell and a door-shaped window frame inlaid on the periphery of the opening, and an insertion slot is formed on the door-shaped window frame; the level window is also provided with a level glass, and the level glass is installed on the door-shaped window along the insertion slot and is fixed through a fixing element. A sealing element is also inlaid in the insertion slot. The level glass structure of the air conditioning refrigerant filter is simple in structure and convenient to manufacture and install. The flow situation of the refrigerant in the filter shell can be clearly observed and the filtering net can be observed through the level glass provided by the invention, the damage of the filtering net can be found in time, the filtering net or the filter can be replaced in time, and the normal operation of an air conditioner can be effectively ensured.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com