Corrugated pipe damage detecting instrument

A bellows and detector technology, applied in engine components, mechanical equipment, valve devices, etc., can solve the problem of valve bellows endangering personal and property safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

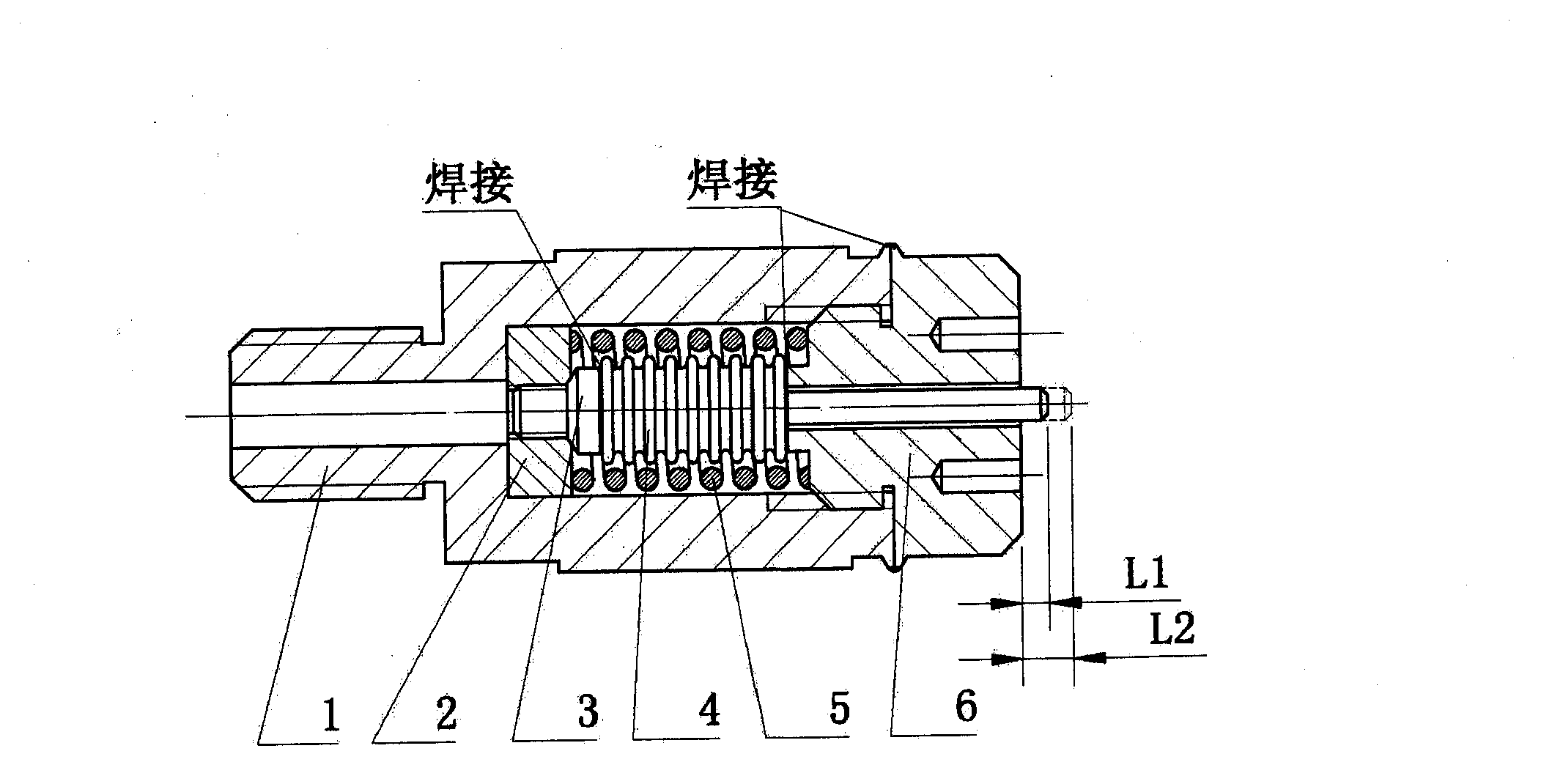

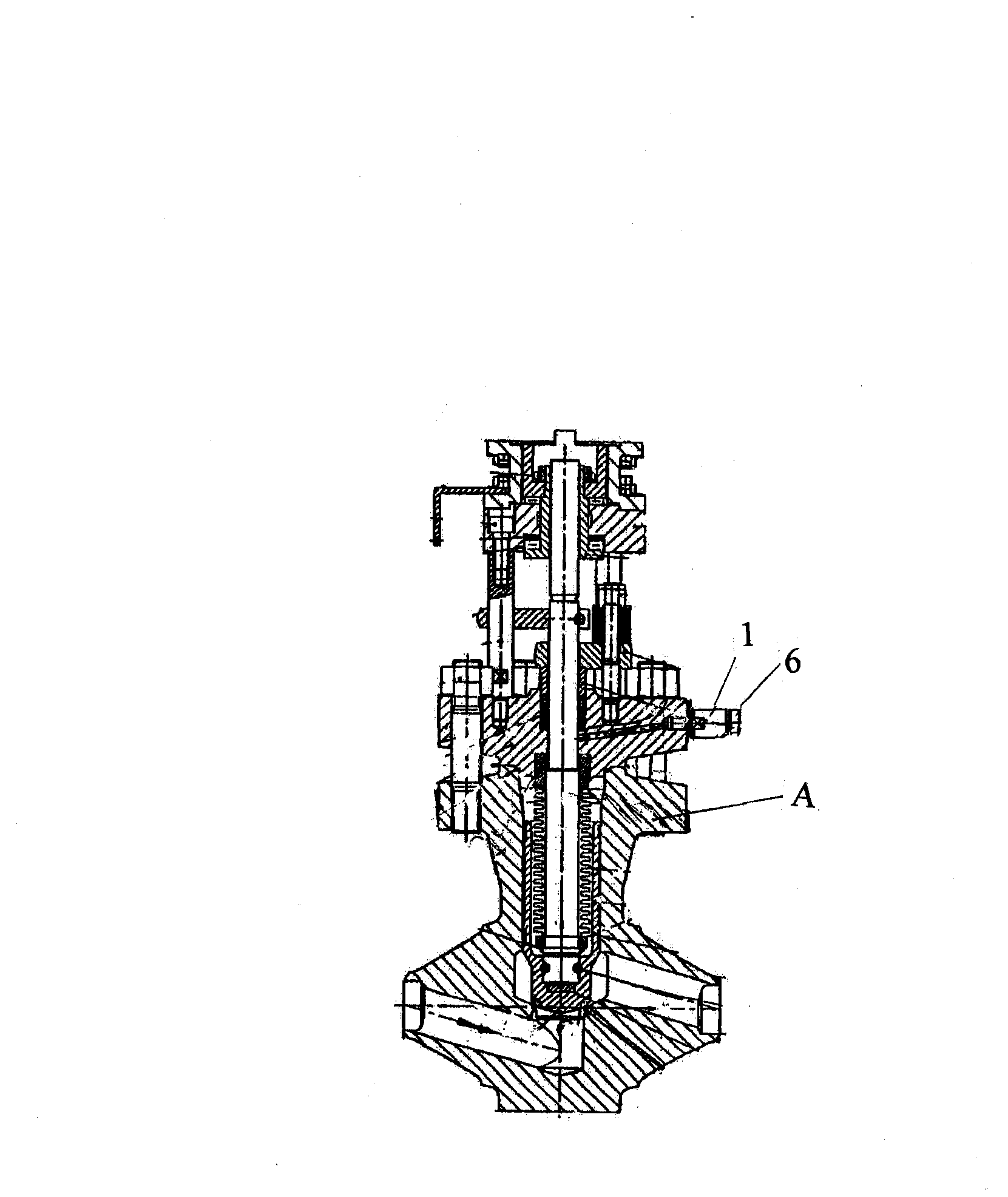

[0011] The structure of the present invention is as figure 1 As shown, it consists of housing 1, piston 2, piston rod 3, bellows 4, coil spring 5 and cover plug 6. The casing 1 has a stepped hole through both ends, and the front end of the casing 1 is screwed into the bellows valve A (see figure 2 ) neck 11 of the leak hole at the bonnet. Piston 2, piston rod 3, bellows 4, and coil spring 5 are located in the stepped hole at the rear end of housing 1, and are sealed with a cover plug 6, and both piston 2 and cover plug 6 have a central through hole. The piston rod 3 has a shaft shoulder to divide the shaft into two parts, a short shaft and a long shaft. The short shaft penetrates into the central through hole of the piston 2, and the long shaft passes through the bellows 4 and enters the central through hole of the cap plug 6. inside the hole. Wherein the two ends of the bellows are respectively sealed and welded to the shaft shoulder end face on the piston rod 3 and the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com