Packaging machine

A packaging machine and sewing machine technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of no limit block, inconvenient packaging discharge, misplacement of sewing bags, etc., so as to improve packaging quality and prevent product deterioration. , The effect of precise sewing position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

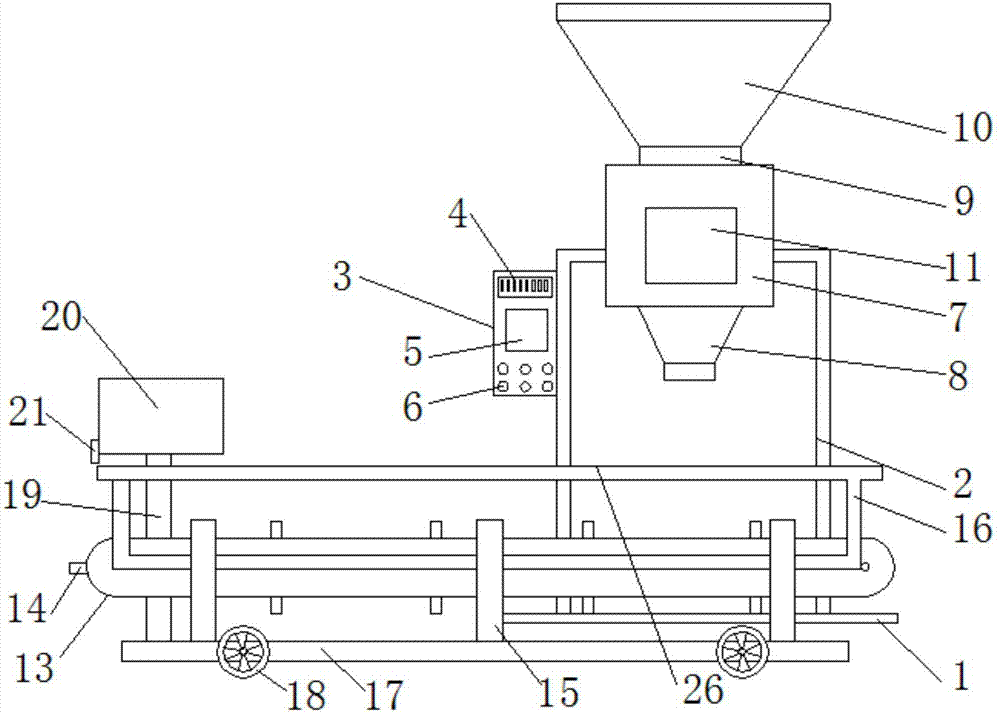

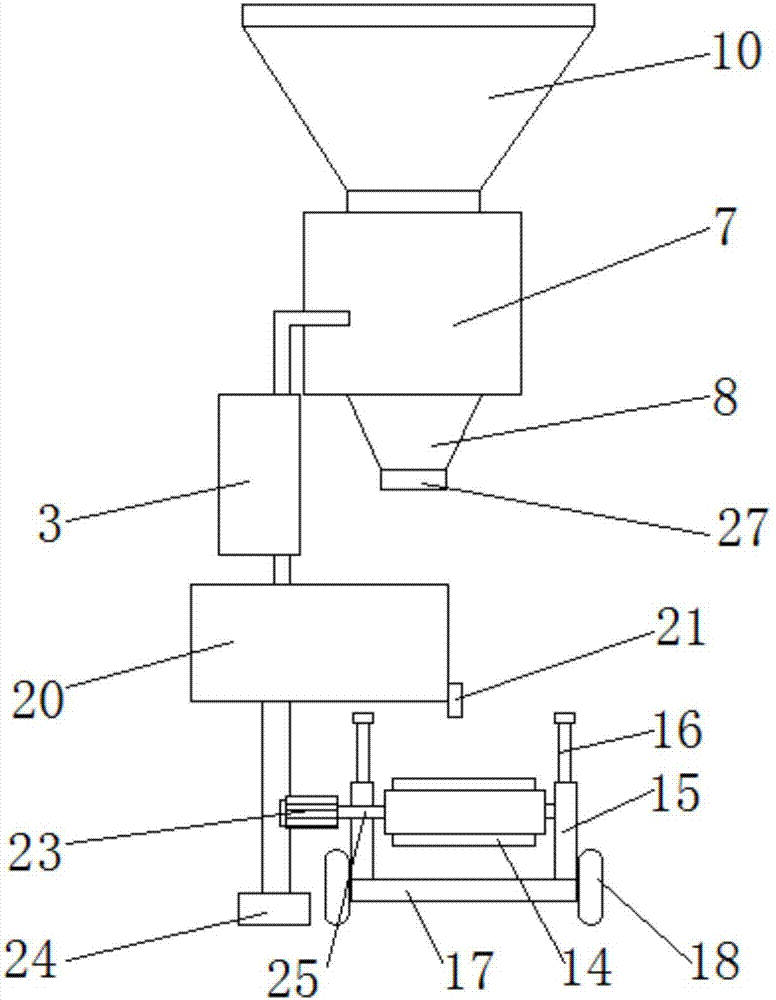

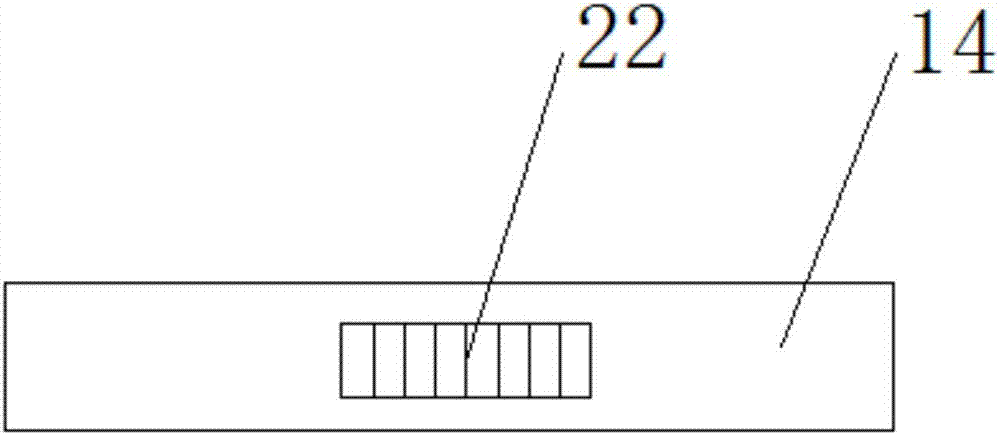

[0024] Example: such as Figure 1-6 As shown, the present invention provides a packaging machine, comprising a fixed rod 1, a support rod 2, a control box 3, a PLC controller 4, a display screen 5, a control panel 6, a storage bin 7, a discharge bin 8, and a material control valve Shell 9, hopper 10, observation window 11, temperature and humidity sensor 12, conveyor belt 13, limit block 14, fixed column 15, protective frame 16, base 17, wheels 18, fixed frame 19, sewing machine 20, code scanner 21 , barcode 22, first motor 23, fixed seat 24, rotating shaft 25, beam 26, discharge port 27, material limiting groove 28, second motor protective shell 29 and second motor 30, the top of the fixed rod 1 is connected with a support Rod 2, the top of the support rod 2 is connected with a storage bin 7, the inner wall of the storage bin 7 is equipped with a temperature and humidity sensor 12, and one end of the storage bin 7 is provided with an observation window 11, and the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com