Oil way system for aerodynamic engine

An aerodynamic and oil circuit system technology, applied in the direction of engine lubrication, engine components, machines/engines, etc., can solve problems such as insufficient lubrication of parts and components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

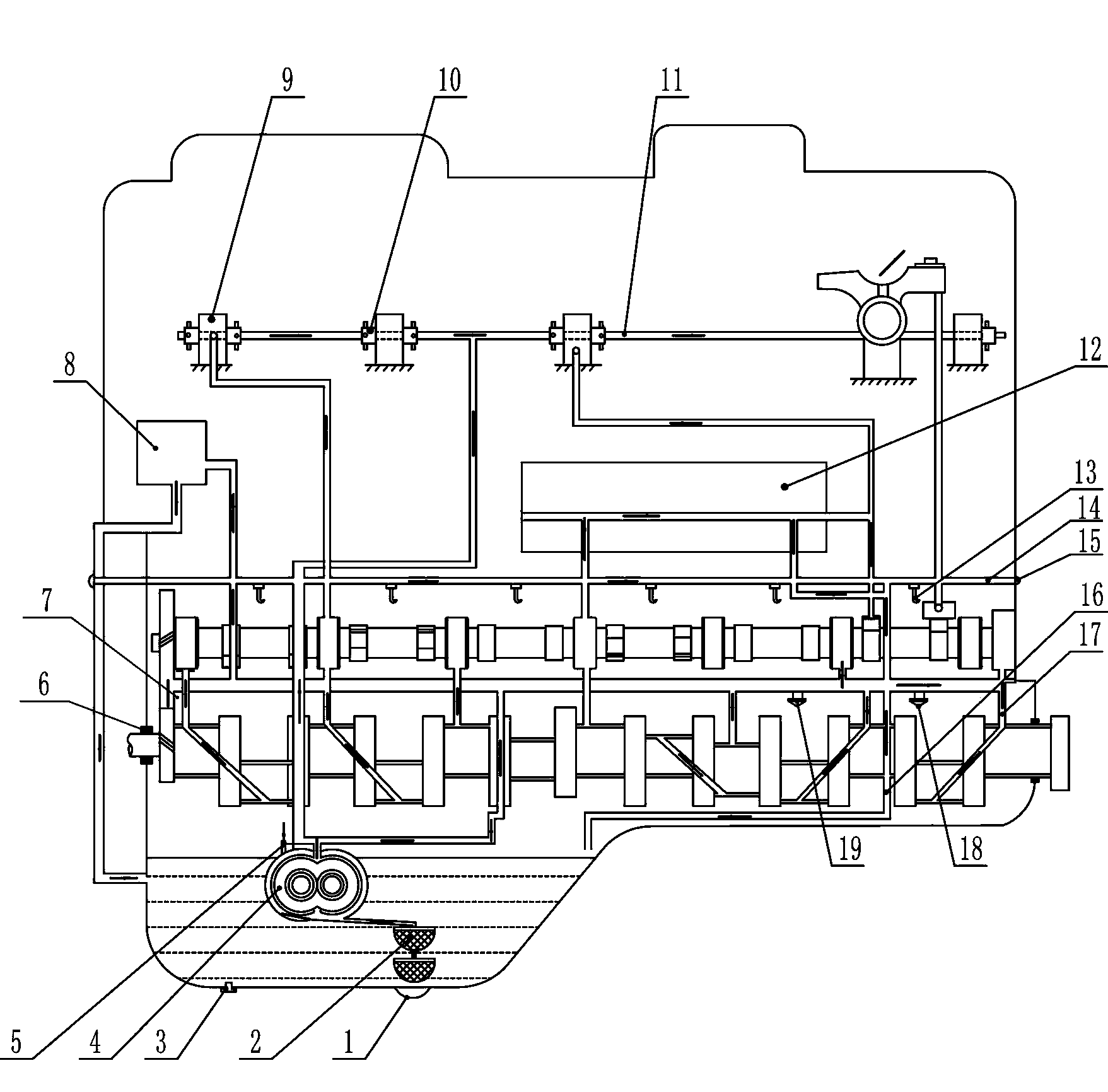

[0028] The following description is merely exemplary in nature and not intended to limit the disclosure, application or use. The specific implementation of the oil circuit system of the aerodynamic engine of the present invention will be further described below in conjunction with the accompanying drawings.

[0029] see figure 1 (The direction of the arrow is the direction of oil flow), which shows the structural schematic diagram of a preferred embodiment of the oil circuit system of the aerodynamic engine. The lubrication method of this engine adopts the parallel filter lubrication method, and the crankshaft shaft diameter, connecting rod shaft diameter, camshaft shaft diameter, camshaft thrust flange, timing gear, rocker arm shaft 11 and rocker arm 10 of the engine adopt pressure lubrication ; When the engine is working, the oil droplets or oil mist splashed by the moving parts are used to lubricate the piston, piston ring, piston pin, cylinder wall, valve, tappet and cam....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com