Dry film lubricant coating composition and preparing method thereof

A technology of dry film lubrication and composition, which is applied in the field of molybdenum disulfide-based dry film lubricating coating composition and its preparation, can solve the problems of binding force, oil resistance and wear resistance that cannot be applied to the core components of aero-engine high-speed rotation, and achieve Excellent tribological properties, excellent lubricating properties, the effect of reducing vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

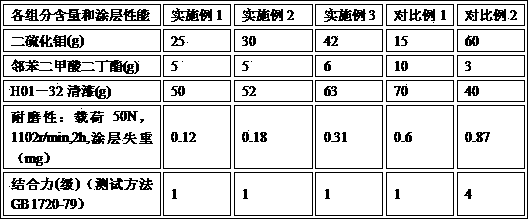

Examples

Embodiment 1

[0020] At normal temperature and pressure, molybdenum disulfide was added to the X-13 stainless steel drum according to the components specified in Table 1, and stirred evenly. The amount of X-13 added was 25g. Shake in the washing machine for 10 minutes. Then add dibutyl phthalate to the mixed solution in the above-mentioned stainless steel drum, and stir evenly. Take the two-component H01-32 varnish, add it to the above stainless steel roller, mix it in the above two liquids, and place the roller in an ultrasonic cleaning machine with a proper amount of water to vibrate for 10 minutes. Add 300 g of stainless steel beads with a diameter of 8 to 10 mm to the mixture prepared above, then put the drum into a ball mill, and ball mill for 2 hours at a speed of 120 r / min to prepare a slurry coating composition. Then, the coating composition is coated on the surface of the aircraft engine transfer component by a spraying method, and dried in an air environment at room temperature f...

Embodiment 4

[0025] Formulated paint

[0026](1) Accurately weigh 28g of calcined molybdenum disulfide, add it into a stainless steel drum equipped with X-13 (25g), stir evenly, and vibrate for 10min in an ultrasonic cleaner with an appropriate amount of water.

[0027] (2) Accurately weigh 6g of dibutyl phthalate, add it to the mixture in (1), and stir evenly.

[0028] (3) Accurately weigh two-component H01-32 varnish, component one 48g, component two 8g.

[0029] (4) Mix the two liquids in (2) and (3) in a stainless steel drum, and place the drum in an ultrasonic cleaner with an appropriate amount of water to vibrate for 10 minutes.

[0030] (5) Add 300g of stainless steel beads with a diameter of 10mm to the mixture of (4), then put the drum into the ball mill, and mill for 2 hours at a speed of 120r / min.

Embodiment 5

[0032] Preparation before spray coating

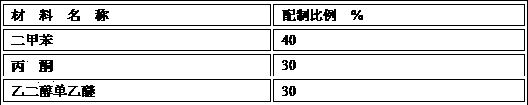

[0033] (1) After degreasing the parts with gasoline without additives by means of a brush, dry them in the air for not less than half an hour. Clean the dried parts with a mixed solvent. The composition of the mixed solvent is shown in Table 4.

[0034] Table 2 Composition of mixed solvents

[0035]

[0036] (2) After cleaning, dry the parts in a covered environment for 30 minutes until the solvent is completely evaporated. Do not allow dust and dirt to fall on the surface to be sprayed.

[0037] (3) For parts working in lubricating oil, first clean them with acetone or a mixed solvent, dry them in the air for 30 minutes, and then use filter paper to check whether there is oil on the surface of the parts to be sprayed. If there is still oil, repeat this process until the parts The surface of the coating to be sprayed is free of oil.

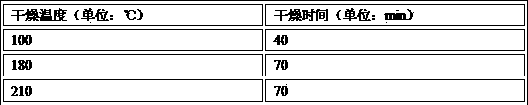

[0038] Ball mill the prepared dry film lubricating paint for another 15 minutes, stir evenly, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com