Modified metal wire drawing powder and preparation method thereof

A wire drawing powder and metal technology, applied in the petroleum industry, lubricating compositions, etc., can solve problems such as the impact on the health of operators, and achieve the effects of good adhesion, excellent lubricating performance, and smooth appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

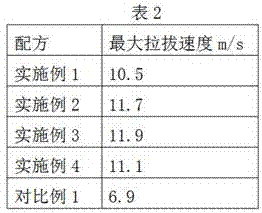

Examples

Embodiment 1

[0021] A modified metal wire drawing powder is prepared from the following raw materials in mass percentage: 60% lubricant, 10% anti-friction additive, 10% extreme pressure agent, 2% antirust agent, and 18% sodium hydroxide.

[0022] The preparation method is as follows: respectively add lubricant, anti-friction additive and anti-rust agent in the corresponding ratio into a container equipped with a stirrer and a heating device, raise the temperature to 75-85 ° C, and then add sodium hydroxide aqueous solution (weight content 20%), heat preservation reaction for 30 minutes, finally add extreme pressure agent, pour out after stirring evenly, dry and pulverize to 100 mesh, and obtain the finished product of modified metal wire drawing powder after packaging.

Embodiment 2

[0024] A modified metal wire drawing powder is made of the following raw materials in mass percentage: 55% lubricant, 15% anti-friction additive, 10% extreme pressure agent, 2% rust inhibitor, and 18% sodium hydroxide.

[0025] The preparation method is as follows: respectively add lubricant, anti-friction additive and anti-rust agent in the corresponding ratio into a container equipped with a stirrer and a heating device, raise the temperature to 75-85 °C, and then add aqueous sodium hydroxide solution (weight content 20%), heat preservation reaction for 30 minutes, finally add extreme pressure agent, pour out after stirring evenly, dry and pulverize to 100 mesh, and obtain the finished product of modified metal wire drawing powder after packaging.

Embodiment 3

[0027] A modified metal wire drawing powder is made of the following raw materials in mass percentage: 50% lubricant, 15% anti-friction additive, 15% extreme pressure agent, 2% antirust agent, and 18% calcium hydroxide.

[0028] The preparation method is as follows: respectively add the lubricant, anti-friction additive and anti-rust agent in the corresponding proportions in each embodiment into a container equipped with a stirrer and a heating device, raise the temperature to 75-85 °C, and then add calcium hydroxide And water, keep warm for 30 minutes, finally add extreme pressure agent, pour out after stirring evenly, dry and pulverize to 100 mesh, and get the finished product of modified metal wire drawing powder after packaging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com