Ethanolamine activated Na-montmorillonite and polymer composite biodegradable film blowing resin and preparation method

A sodium-based montmorillonite and biodegradable technology, applied in the field of blown film resin, can solve the problems of tensile properties, tear strength, elongation at break and other mechanical properties that cannot meet the needs, the development prospect is not optimistic, and cannot be completely degraded. , to achieve the effect of improving water vapor transmission rate, easy melting intercalation, and good water dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

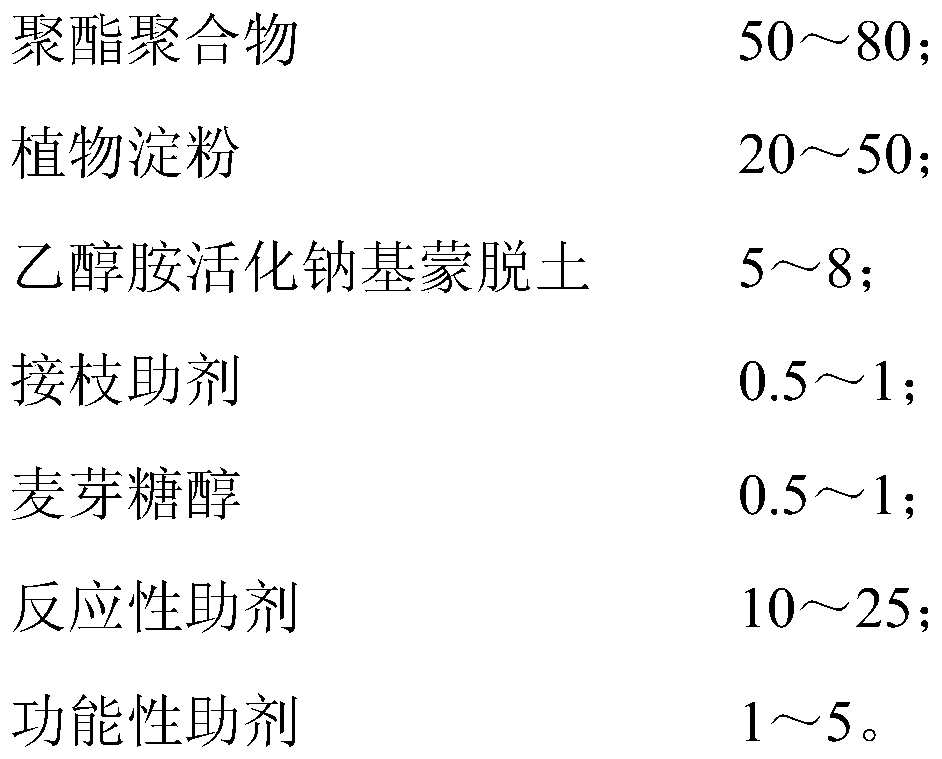

[0041] An ethanolamine-activated sodium-based montmorillonite / polymer composite biodegradable blown film resin provided in this example comprises the following components in parts by weight:

[0042]

[0043] Wherein, the polyester polymer is a mixture of polybutylene adipate / terephthalate and polylactic acid, and the mass ratio of the two is 8:2. The preparation method of ethanolamine-activated sodium-based montmorillonite is as follows: dissolve ethanolamine in water, then add sodium-based montmorillonite, stir evenly with a high-speed mixer, and dry in a constant temperature drying oven at 110°C for 6 hours. The reactive additive is glycerol The mixture of alcohol, water and silane-based coupling agent, the mass ratio of the three is 1:1:2, the functional additive is a mixture of antioxidant 1010 and tributyl citrate, the mass ratio of the two is 1: 1.

[0044] Its preparation method comprises the following steps:

[0045] S1, pour vegetable starch into the high mixer,...

Embodiment 2

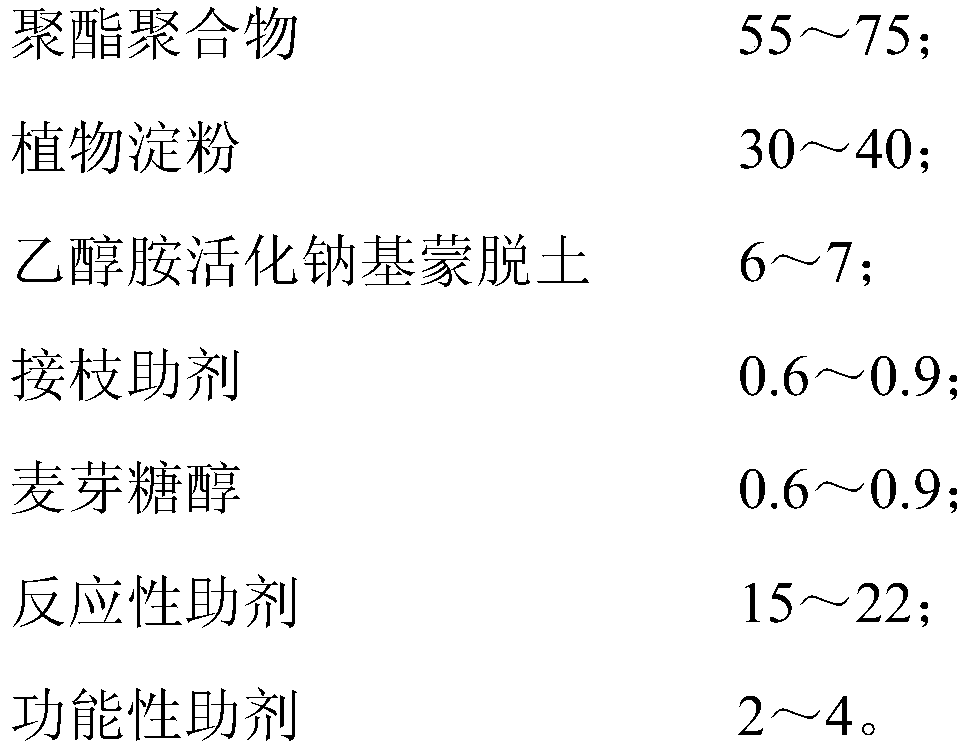

[0052] An ethanolamine-activated sodium-based montmorillonite / polymer composite biodegradable blown film resin provided in this example comprises the following components in parts by weight:

[0053]

[0054]

[0055] Wherein, the polyester polymer is a mixture of polybutylene adipate / terephthalate and polylactic acid, and the mass ratio of the two is 9:1. The preparation method of ethanolamine-activated sodium-based montmorillonite is as follows: dissolve ethanolamine in water, then add sodium-based montmorillonite, stir evenly with a high-speed mixer, and dry in a constant temperature drying oven at 115°C for 5 hours. The reactive additives are propylene glycol, The mixture of xylitol and titanate coupling agent, the mass ratio of the two is 2:1:1, the functional auxiliary agent is the mixture of antioxidant 168, polyethylene wax, stearamide, the mass ratio of the three is 3:2:1.

[0056] Its preparation method comprises the following steps:

[0057] S1, pour potato ...

Embodiment 3

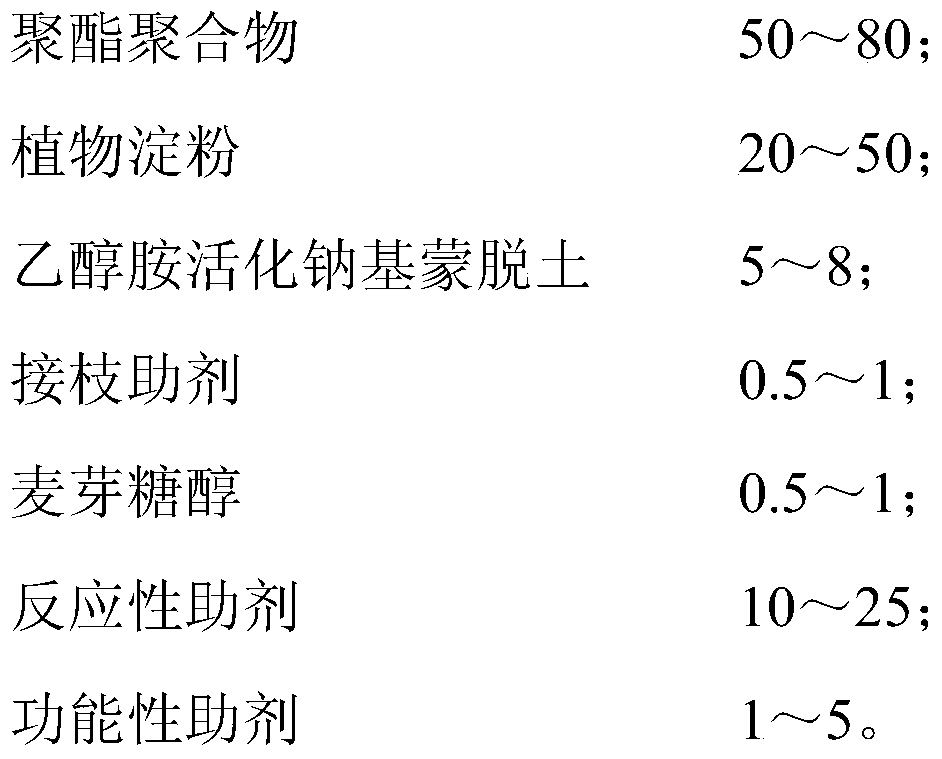

[0064] An ethanolamine-activated sodium-based montmorillonite / polymer composite biodegradable blown film resin provided in this example comprises the following components in parts by weight:

[0065]

[0066]

[0067] Wherein, the polyester polymer is a mixture of polybutylene adipate / terephthalate and polylactic acid, and the mass ratio of the two is 7:3. The preparation method of ethanolamine-activated sodium-based montmorillonite is as follows: dissolve ethanolamine in water, then add sodium-based montmorillonite, stir evenly with a high-speed mixer, and dry in a constant temperature drying oven at 105°C for 7 hours. The reactive auxiliary agent is alumina Lipid coupling agent, the functional additive is a mixture of antioxidant 2246, paraffin and stearic acid amide, the mass ratio of the three is 1:2:3.

[0068] Its preparation method comprises the following steps:

[0069] S1, pour corn starch into the high mixer, then add reactive additives into the high mixer, mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com