Integral gearbox of road roller

An integral, transmission technology, applied in the direction of roads, roads, machinery and equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

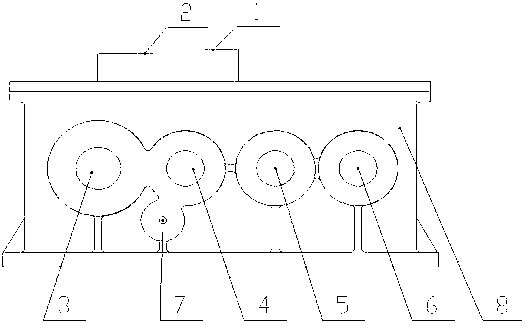

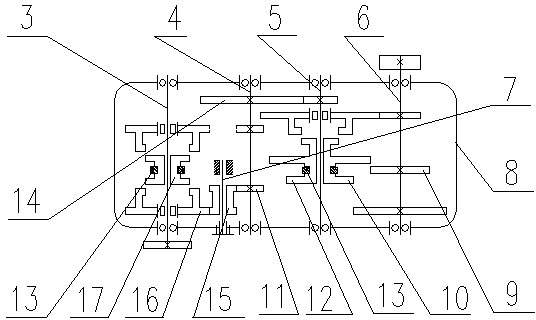

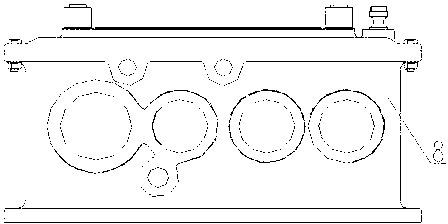

[0016] With reference to the drawings, the following embodiments of the present invention are given, but the present invention is not limited to the following embodiments.

[0017] Such as Figure 1-3 As shown: the integrated gearbox of the roller in this embodiment includes a box body 8 and a transmission shaft, a transmission gear, a speed change and a reversing operation, etc., arranged in it. The box body 8 is an integral structure, and a plurality of transmission shafts and mounting holes are provided on the box body 8. In this embodiment, there are five transmission shafts and ten mounting holes. The first transmission shaft 6 and the second transmission shaft 5 are arranged at the front end of the box body 8, the third transmission shaft 4, the fourth transmission shaft 3 and the bridge shaft 7 are arranged at the rear end of the box body 8, and the shift lever 1 and The reverse operating lever 2 is arranged at the upper end of the box body 8. Each transmission shaft is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com