Perfluoropolyether lubricant and preparation method thereof

A perfluoropolyether lubricant and perfluoropolyether technology are applied in lubricating compositions and the petroleum industry, which can solve the problems of high cost and achieve the effects of low cost, good compatibility and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

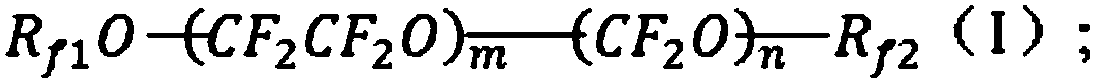

[0025] 5g polytetrafluoroethylene powder is joined in 5g perfluoropolyether oil (the structural formula of perfluoropolyether oil is formula (I), wherein R f1 For—CF 3 , R f2 for-C 2 f 5 , m=36, n=2; 20°C kinematic viscosity is 60cSt), stirred at room temperature for 30min at a speed of 100±10r / min, then added the obtained mixture and 90g of ethyl perfluorobutyl ether solvent to In the dispersion kettle, stir at a speed of 200±10r / min for 45min, add an empty tank for filling to obtain the product, and the performance characteristics of the product are shown in Table 1.

Embodiment 2

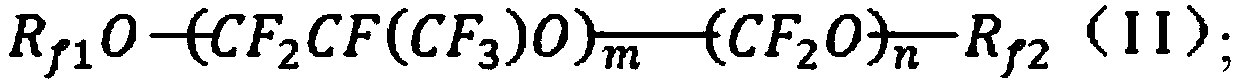

[0027] The chlorotrifluoroethylene-polyethylene powder of 5g is joined in the 5g perfluoropolyether oil (the structural formula of perfluoropolyether oil is formula (II), wherein R f1 For—CF 3 , R f2 for-C 3 f 7 , m=65, n=4; kinematic viscosity at 20°C is 135cSt), stirred at room temperature for 30min at a speed of 100±10r / min, then added the obtained mixture and 90g of ethyl perfluorobutyl ether solvent to In the dispersion kettle, stir at a speed of 200±10r / min for 45min, add an empty tank for filling to obtain the product, and the performance characteristics of the product are shown in Table 1.

Embodiment 3

[0029] The polytetrafluoroethylene powder of 3g is joined in the perfluoropolyether oil of 8g (the structural formula of perfluoropolyether oil is formula (II), wherein R f1 For—CF 3 , R f2 for-C 3 f 7 , m=70, n=5; 20°C kinematic viscosity is 164cSt), stirred at room temperature for 30min at a speed of 100±10r / min, then added the obtained mixture and 89g of methyl perfluorobutyl ether solvent to In the dispersion kettle, stir at a speed of 200±10r / min for 45min, add an empty tank for filling to obtain the product, and the performance characteristics of the product are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com