Split type solid dust mechanical seal system

A mechanical shaft, split type technology, applied in the direction of mechanical equipment, engine seals, engine components, etc., can solve the problems of easily damaged shafts or sleeves, packing seal hardening, no compensation force, etc., to achieve easy manufacturing and installation, The effect of improving the cycle and extending the time of continuous power-on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

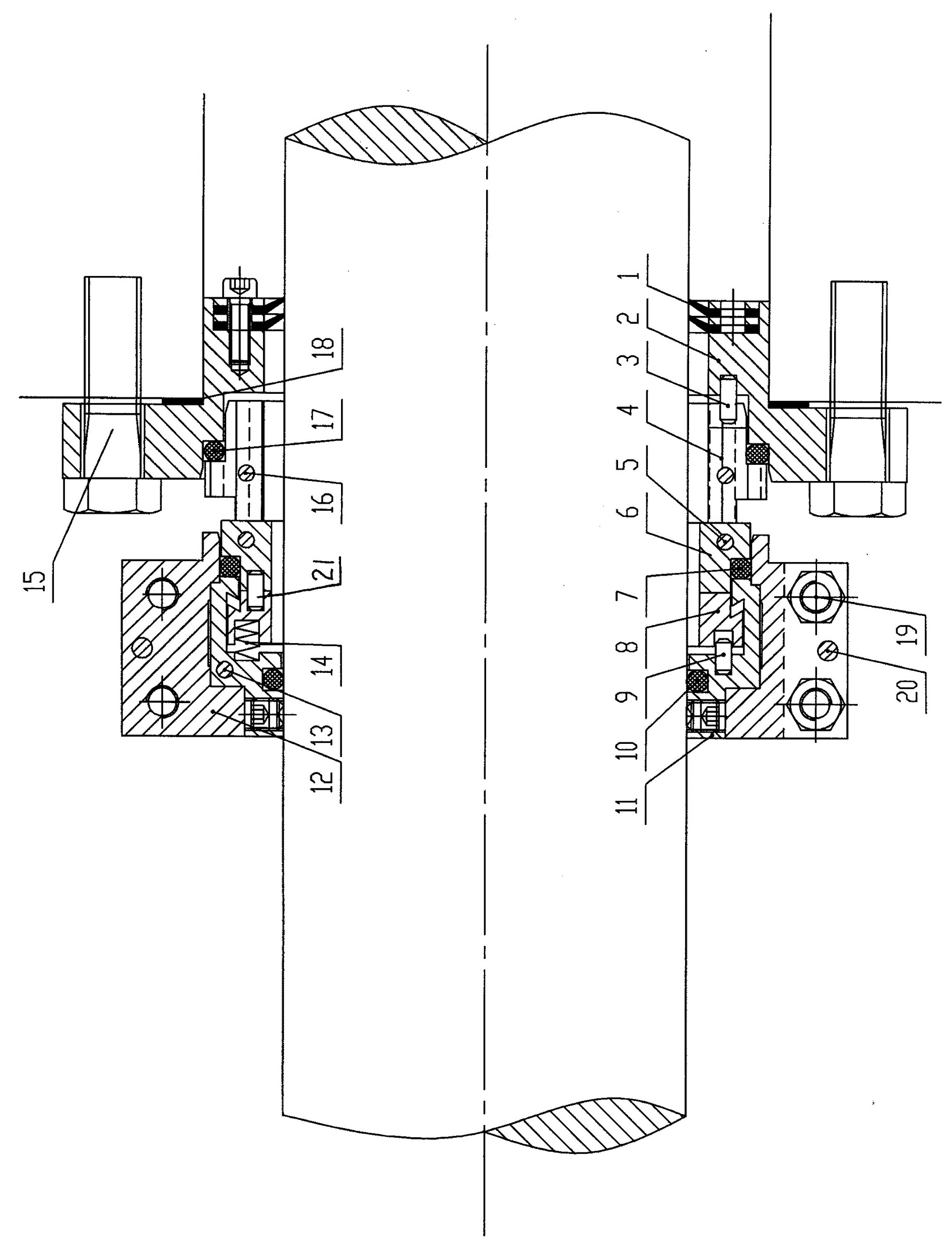

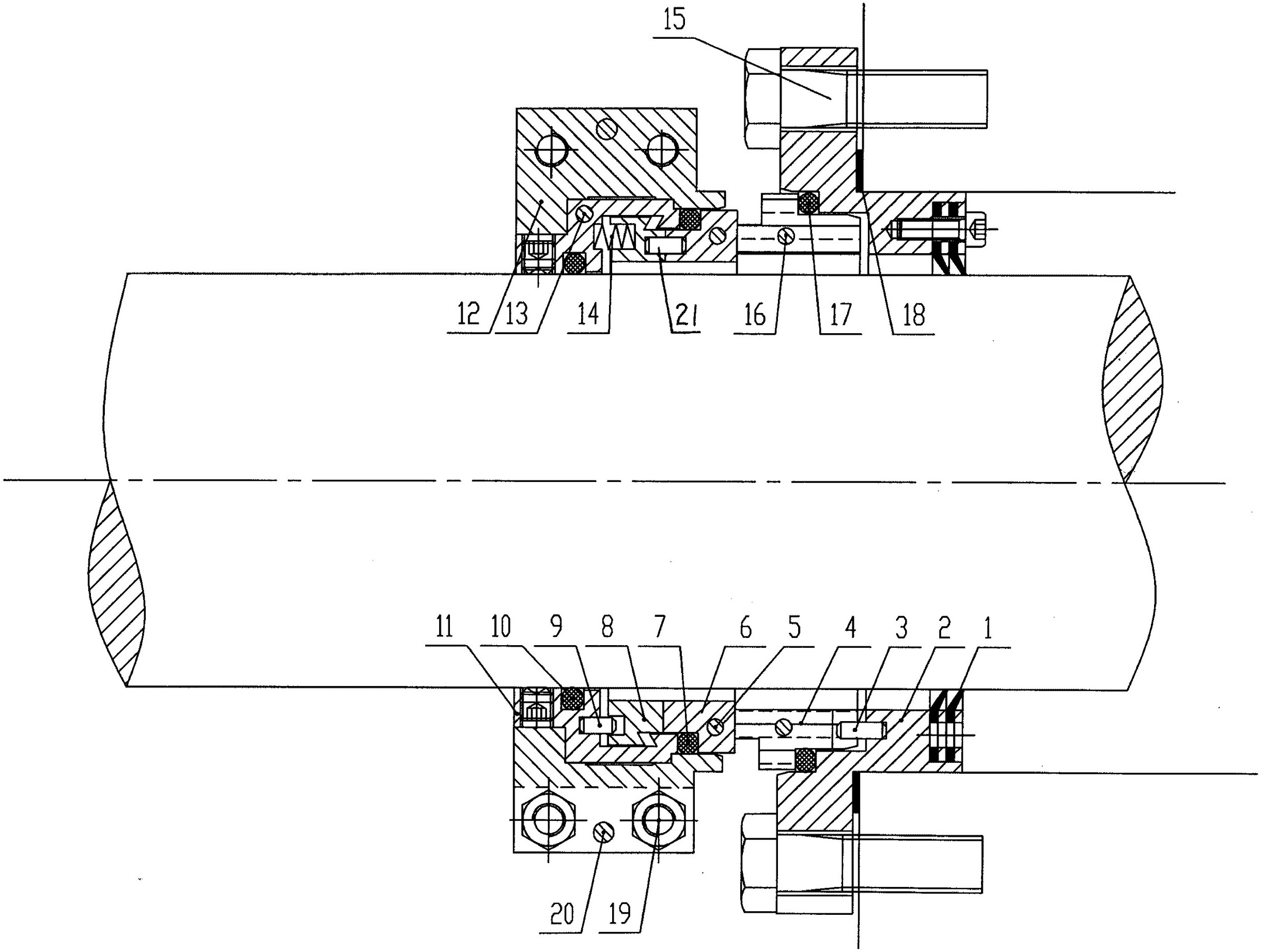

[0009] A split type solid dust mechanical shaft seal system, such as figure 1 As shown, it includes a shaft seal gland 2 installed on the machine box, a PTFE gasket 18 is arranged between the gland 2 and the sealing surface of the box, and a multi-layer sealing contact with the rotating shaft is arranged on the inner side of the center hole of the gland. Lip seal ring 1 is used to slow down the dust leakage. After a period of operation, the lip seal will wear out quickly when there is no liquid lubrication. After wear, there will be a small gap between the lip seal and the shaft. The lip seal belongs to Multi-layer, can play the effect of labyrinth seal at the same time.

[0010] The outer side of the central hole of the gland is in the shape of a stepped hole, and a sealing stationary ring 4 fixedly connected to the gland is set on the rotating shaft in the stepped hole. The outer peripheral surface of the stationary ring 4 has an annular shoulder. An O-ring 17 is arranged b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com