Environment-friendly waterborne cold spray paint and application thereof

An environment-friendly, water-based technology, applied in coatings, surface pretreatment, and devices for coating liquids on surfaces, etc., can solve problems such as poor working environment and volatilization of oily solvents, and achieve low human harm, green manufacturing, and washing strength high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a kind of preparation method of spray paint slider, comprises the following steps:

[0035] Step 1) Phosphating the rough slider, drying, drying, and roughening to obtain a pretreated slider;

[0036] 2) adopt the environment-friendly water-based cold spray paint described in the above technical scheme to spray on the surface of the pretreatment slider, air-dry, bake, and cool;

[0037] 3) Repeat step 2) 8 to 10 times to obtain a painted slider.

[0038] In the invention, the rough slider is treated with phosphating, spin-dried, and roughened. Specifically, the present invention pours the blank slider into the pre-treatment automatic line for processing, and bakes it in a baking machine through degreasing and coating processes to remove surface oil and roughen the surface of the slider.

[0039] After the pretreatment slider is obtained, the present invention adopts the environmental-friendly water-based cold spray paint described in the above t...

Embodiment 1

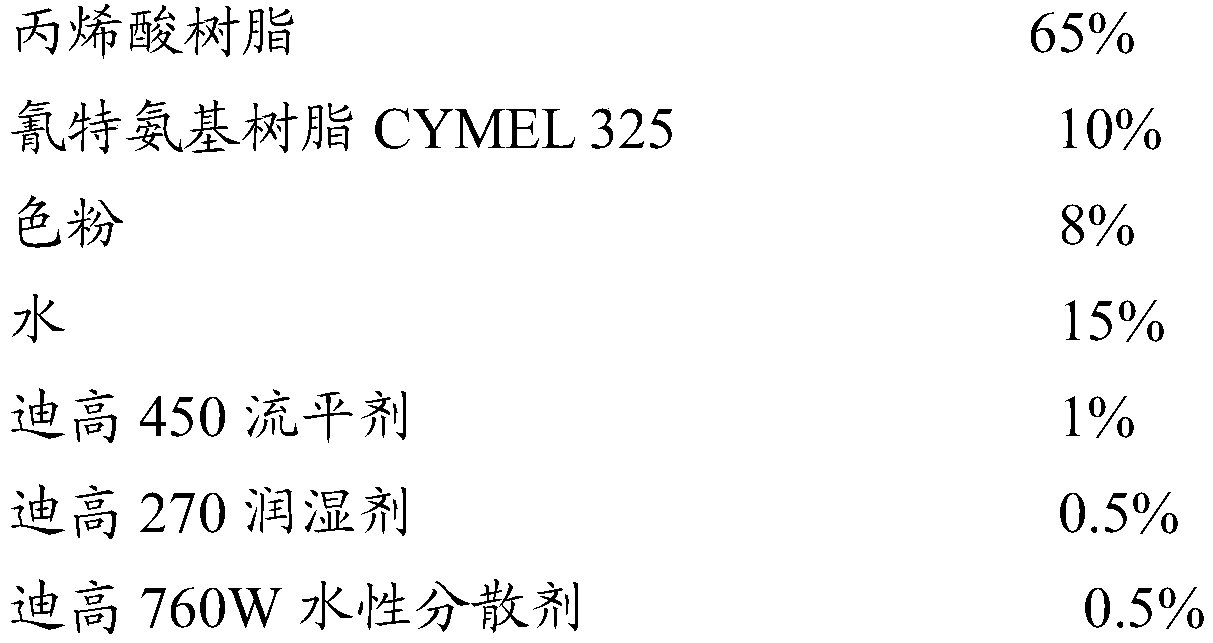

[0044] Water-based paint formula:

[0045]

[0046] Put the raw materials of the above ratio into the disperser according to the proportion, regardless of the order, and mix them through high-speed dispersion to form a water-based cold spray paint to be sprayed;

[0047] Pour the rough slider into the pre-treatment automatic line for processing, and bake it in the baking machine through the degreasing and coating process to remove the surface oil and roughen the surface of the slider to obtain the pre-treated slider;

[0048] Put the above-mentioned water-based cold spray paint and water into the spray gun according to the mass ratio of 1:1, spray at room temperature for 2 minutes, pour out the slider, spread it out and air-dry, bake in a baking machine at 160°C for 30 minutes, cool, and spray-baking-cooling cycle The number of times is 8 times to obtain a painted slider.

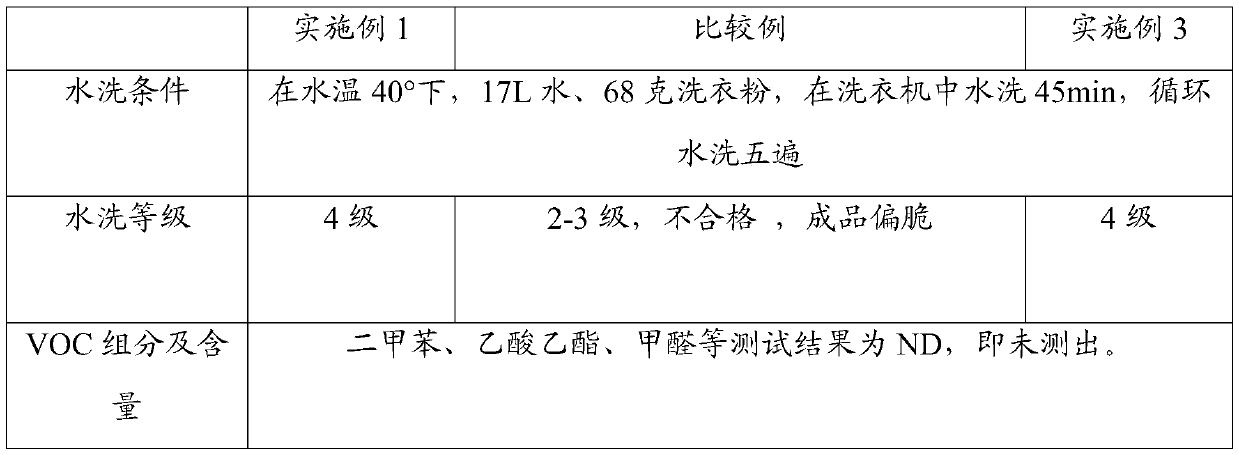

[0049] The present invention carries out water-washing test to spray-painted slider, and the results...

Embodiment 2

[0053] Water-based paint formula:

[0054]

[0055]

[0056] Put the raw materials of the above ratio into the disperser according to the proportion, regardless of the order, and mix them through high-speed dispersion to form a water-based cold spray paint to be sprayed;

[0057] Pour the rough slider into the pre-treatment automatic line for processing, and bake it in the baking machine through the degreasing and coating process to remove the surface oil and roughen the surface of the slider to obtain the pre-treated slider;

[0058] Put the above-mentioned water-based cold spray paint and water into the spray gun according to the mass ratio of 1:1, spray at room temperature for 2 minutes, pour out the slider, spread it out and air-dry, bake in a baking machine at 160°C for 30 minutes, cool, and spray-baking-cooling cycle The number of times is 8 times to obtain a painted slider.

[0059] The present invention carries out washing test to the spray paint slider, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com