Electrolyte and method for preparing ceramic layer on surface of magnesium alloy by using electrolyte

An electrolyte preparation and electrolyte technology, which is applied in the direction of surface reaction electrolytic coating, electrolytic coating, coating, etc., can solve the problems of easy ablation and coking of resin, and achieve avoiding plastic ablation, high efficiency, and excellent binding force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Step 1, add 10g / L sodium silicate, 20g / L sodium hexametaphosphate, 10g / L sodium hydroxide, 5g / L sodium fluoride, 50g / L glycerol, 20g / L potassium tartrate to deionized water in sequence sodium, to obtain the electrolyte; the electrolyte was fully stirred at room temperature for 30min, and set aside;

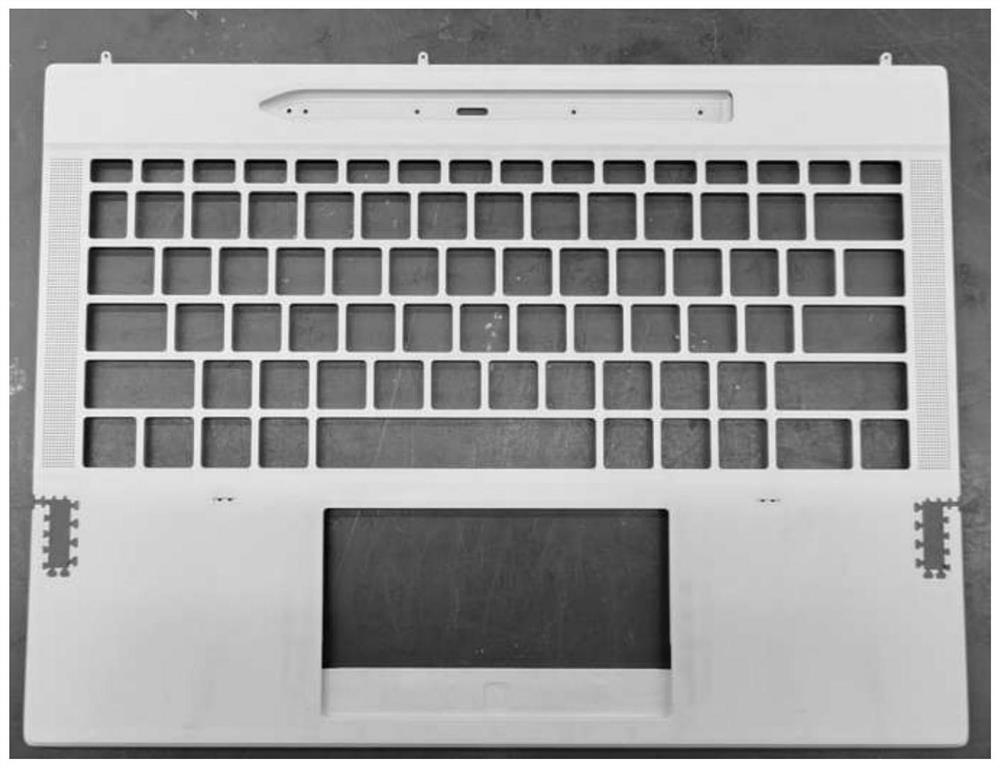

[0042] Step 2. Put plastic (plastic material: pps) AZ31B magnesium alloy computer keyboard (area is 6dm 2 ) placed in HF with a volume fraction of 15% and H with a volume fraction of 5% 2 SO 4 Wash in the mixed pickling pretreatment solution for 0.5min, and then wash with water;

[0043] Step 3. Put the plastic-containing AZ31B magnesium alloy computer keyboard treated in step 2 in the alkali cleaning pretreatment solution with a concentration of 30g / L trisodium phosphate and 30g / L sodium carbonate. The temperature is controlled at 80°C and cleaned. The time is 5min, and then washed with water;

[0044] Step 4. Place the AZ31B magnesium alloy computer keyboard processed...

Embodiment 2

[0050] Step 1. Add 20g / L potassium dihydrogen phosphate, 10g / L sodium hydroxide, 5g / L potassium fluoride, 80g / L hexamethylenetetramine, 8g / L sodium metavanadate, 2g to deionized water in sequence / L sodium citrate, 10g / L sodium pyrophosphate to obtain the electrolyte; fully stir the electrolyte at room temperature for 30min, and set aside;

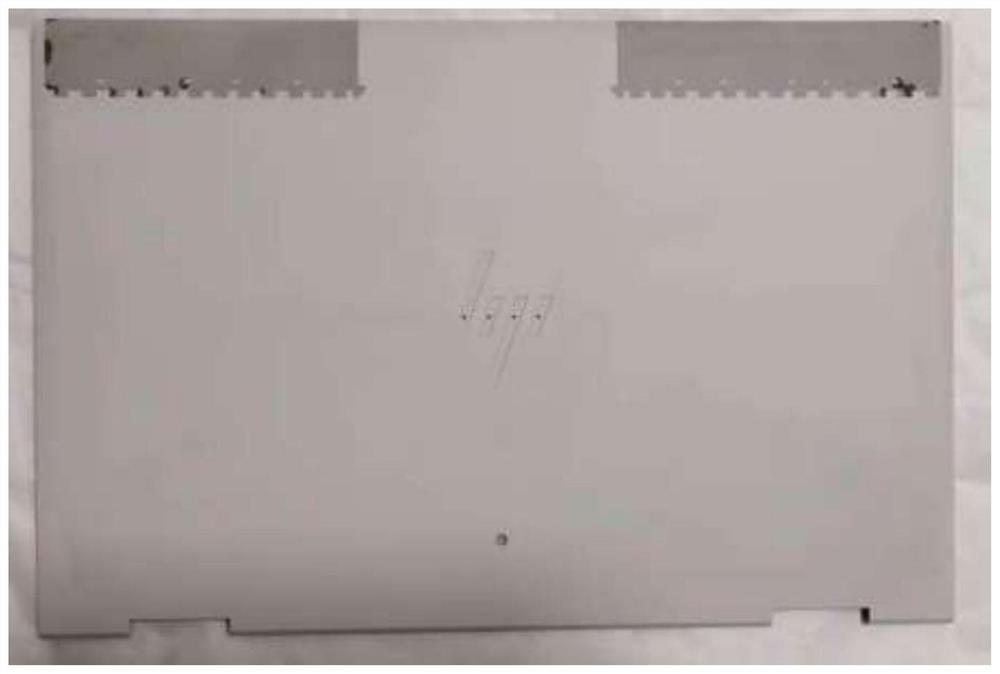

[0051] Step 2. Place the AZ91D magnesium alloy computer case containing plastic (plastic material: PPS) (with an area of 12dm 2 ) into 8% (volume fraction) HF, 6% (volume fraction) HNO 3 The cleaning time in the pretreatment solution for pickling is 0.2min, and then washed with water;

[0052] Step 3. Then put the plastic-containing AZ91D magnesium alloy computer case treated in step 2 into 60g / L sodium hydroxide, the temperature is controlled at 60°C, the cleaning time is 3min, and then washed with water;

[0053] Step 4. Place the AZ91D magnesium alloy computer case treated in step 3 in the prepared electrolyte, connect the AZ91D mag...

Embodiment 3

[0058] Step 1. Add 15g / L disodium hydrogen phosphate, 10g / L potassium hydroxide, 10g / L sodium fluoride, 30g / L isopropanol, 5g / L ferric citrate, 5g / L vanadium to deionized water in sequence ammonium phosphate, 5g / L sodium gluconate, and 2g / L disodium edetate to obtain the electrolyte; the electrolyte was fully stirred at room temperature for 30min and set aside;

[0059] Step 2. Put plastic (material: PBT) AZ31B magnesium alloy case (area is 12dm 2 ) into 10% (volume fraction) HF, 5% (volume fraction) HNO 3 The cleaning time in the pre-pickling treatment solution is 1min, and then washed with water;

[0060] Step 3. Put the plastic-containing AZ31B magnesium alloy treated in step 2 into the cleaning solution of 40g / L sodium carbonate and 10g / L sodium hydroxide. The temperature is controlled at 85°C, the cleaning time is 4min, and then washed with water;

[0061] Step 4. Place the plastic-containing AZ31B magnesium alloy treated in step 3 in the prepared electrolyte, connect t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com