Full-automatic assembling equipment for environment-friendly rotor

A fully automatic technology for assembly equipment, applied in metal processing equipment, devices for coating liquid on surfaces, metal processing, etc. It can solve the problems of inability to operate manually, cause great harm to human body, and low work efficiency, and achieve good market application value. , The effect of less harm to human body and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

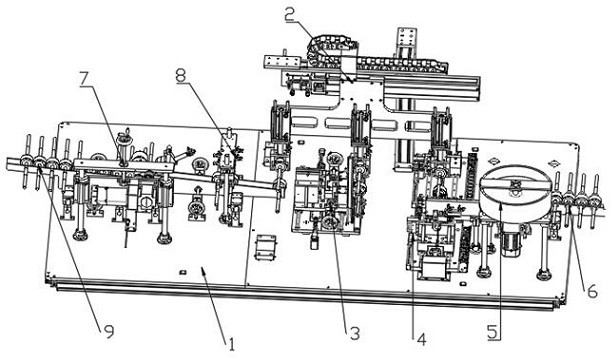

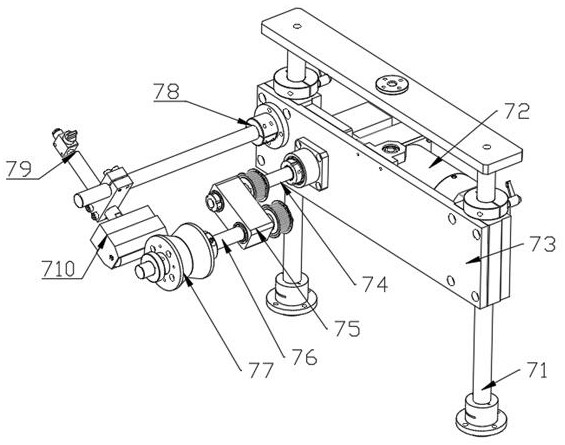

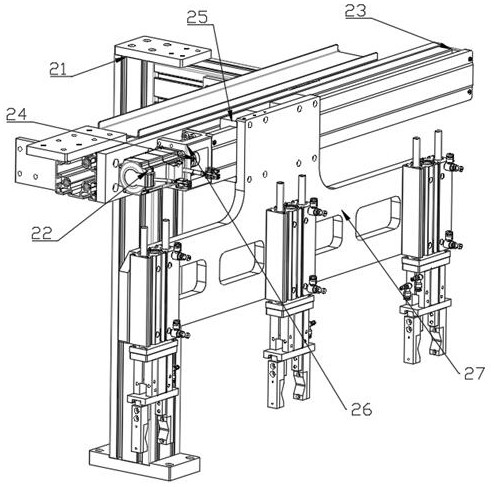

[0026] like Figure 1-Figure 6One of the described embodiments: a fully automatic assembly equipment for an environmental protection rotor, comprising a mounting plate 1, on which are respectively provided an environmental protection oiling device, a transplanting device 2, a circlip device 3, and a material waiting device 4. , the first feeding device 5, the second feeding device and the feeding chute 6, the circlip device 3 is arranged in the upper middle part of the mounting plate 1, the rear side of the circlip device 3 is provided with a transplanting device 2, The left side of the circlip device 3 is provided with an environmental protection oiling device, the right side of the circlip device 3 is provided with a material waiting device 4, and the right side of the material waiting device 4 is provided with a feeding chute 6, and the feeding chute 6 A first feeding device 5 and a second feeding device are respectively provided on both sides, and the environmental protect...

Embodiment 2

[0035] The difference between the second embodiment and the above is that the snap ring device 3 and the environmental protection oiling device are both provided with photoelectric sensors.

Embodiment 3

[0036] The difference between the third embodiment and the above is that the blanking sensor is set as a square functional sensor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com