External lubrication device for transmission and method

A technology for lubricating devices and gearboxes, which is applied to transmission parts, gear lubrication/cooling, belts/chains/gears, etc. It can solve problems such as splash lubrication failure, abnormal wear of third and fourth gears, and failure to discharge heat in time. problems, to achieve the effect of meeting the needs of lubrication and cooling, high reliability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

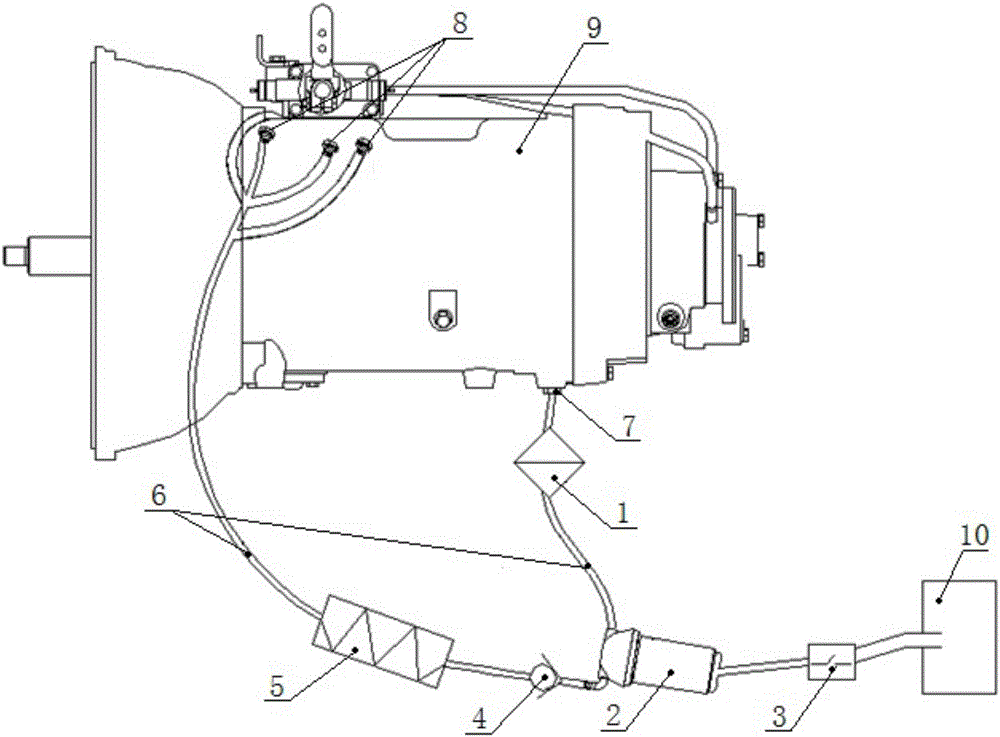

[0014] figure 1 Shown is the structural representation of the present invention.

[0015] The present invention adds an external lubricating system on the basis of the existing transmission lubricating system. The external lubricating system uses an external lubricating pump 2 as a power source and an angle switch 3 as a control element. Slope value, the external lubrication pump 2 is turned on by itself, and the constant meshing gear and the third and fourth gears of the gearbox are lubricated by spray nozzles. When the slope is less than the set value, the angle switch 3 is turned off, and the gearbox relies on its own internal lubrication system.

[0016] The external lubrication system includes a filter 1, an external lubrication pump 2, an angle switch 3, a one-way valve 4, a cooler 5, an oil circuit 6, an oil suction joint 7, a nozzle 8, a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com