Hub bearing with spline structure

A hub bearing and spline technology, applied in the field of hub bearings, can solve the problems of harsh working environment, affecting the use effect of the overall structure, easy to enter the bearing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

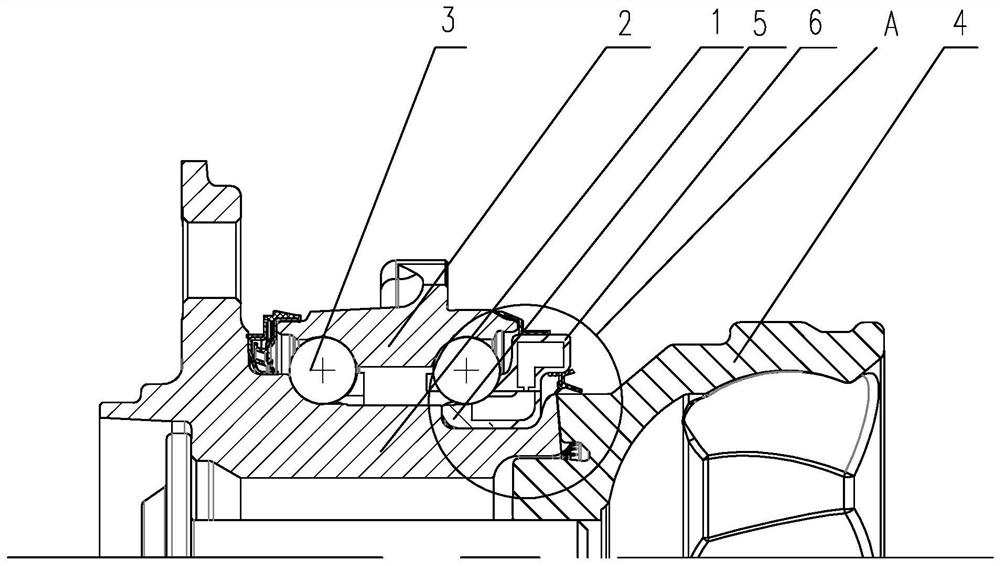

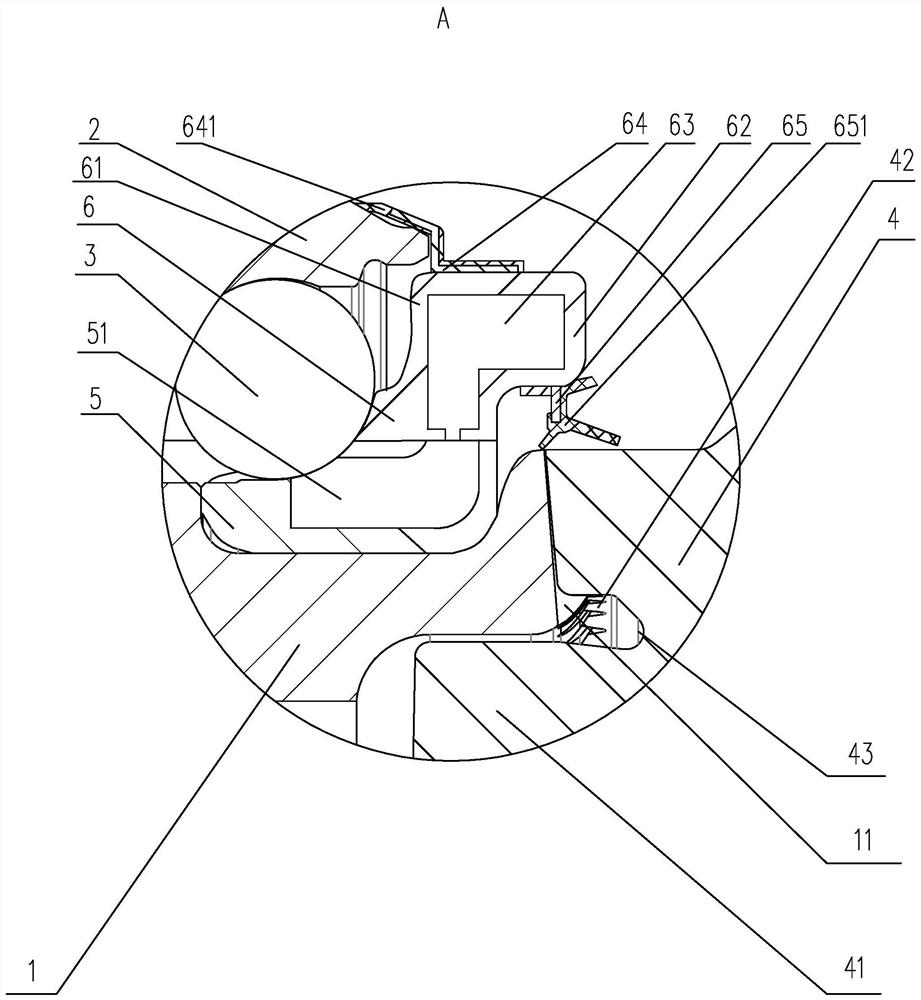

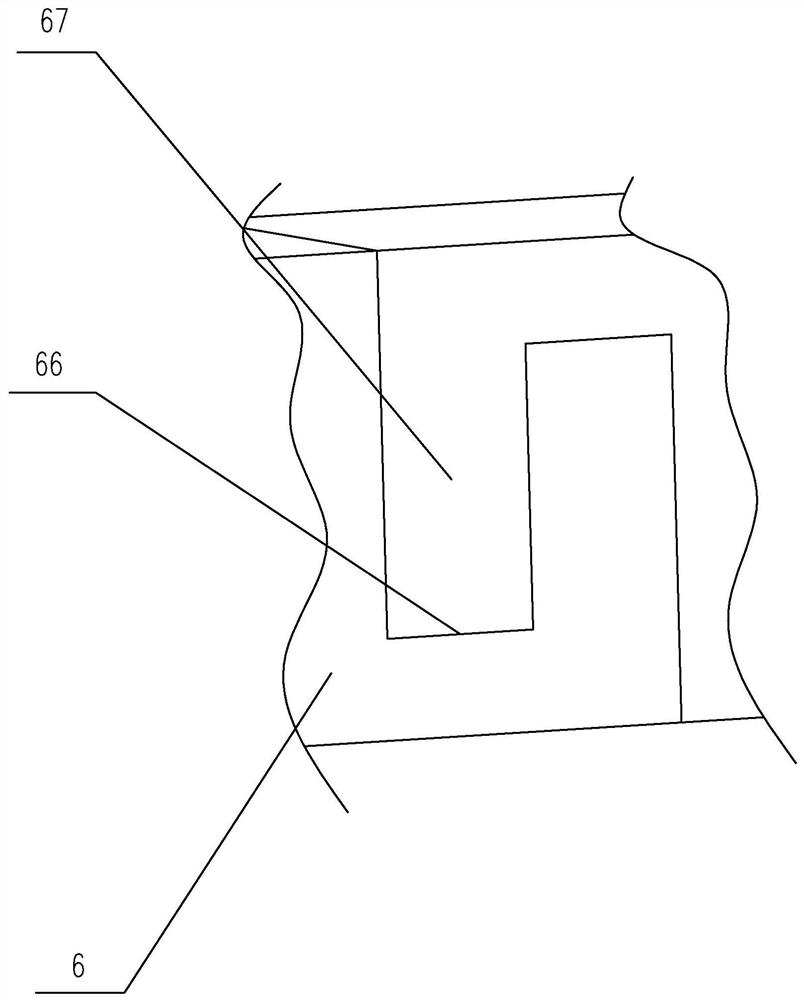

[0023] An embodiment of a wheel hub bearing with a spline structure in the present invention is as follows Figure 1 to Figure 3 As shown: including the rotary joint 4, the flange inner ring 1, the flange outer ring 2 and the connecting inner ring, the first rolling groove is formed between the flange inner ring 1 and the flange outer ring 2, and the connection The outer wall of the inner ring is provided with a first raceway, and the flange outer ring 2 is provided with a second raceway corresponding to the position of the first raceway, and the first raceway and the second raceway are combined to form a second raceway, so Both the first rolling groove and the second rolling groove are provided with steel balls 3, the flange inner ring 1 is formed with a clamping groove, and the connecting inner ring is separately arranged to form a first ring body 5 and a second ring body. The ring body 6, a number of guide grooves and guide blocks are arranged between the first ring body 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com