Elastic tube-type thermal production casing head

A casing head and tubular technology, applied in the field of elastic tubular thermal mining casing heads, can solve the problems of difficult operation, leakage of heat medium, loose connection, etc., so as to reduce mining costs, ensure safe operation, installation and maintenance. Easy to use and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

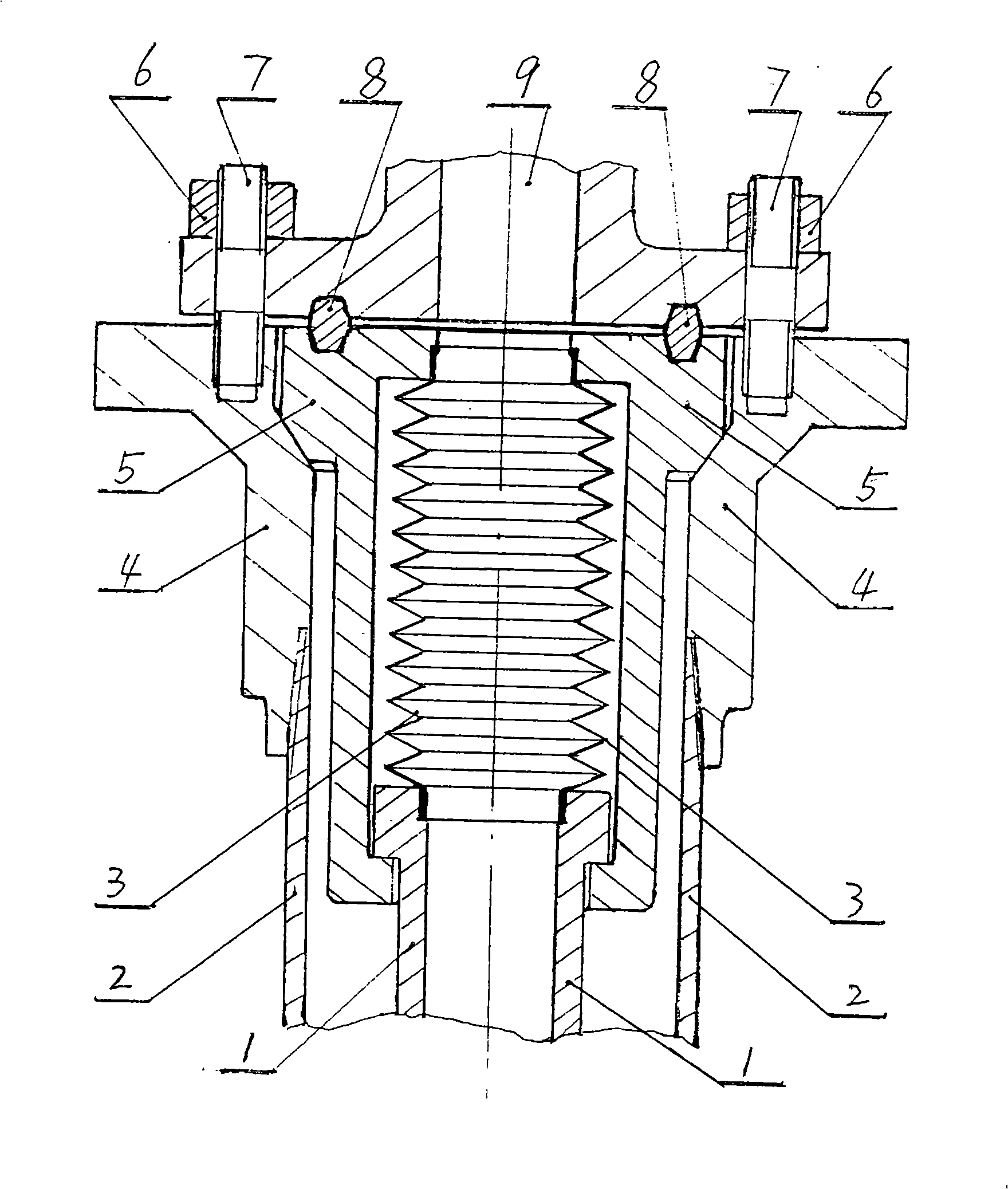

[0009] Embodiment 1: Referring to the accompanying drawings, the upper flange 9 and the lower flange 4 are connected and fixed by bolts 7 and nuts 6 . The inner strength of the lower flange 5 is inserted into the suspension body steel cylinder 5 of an integrated structure, and the top of the suspension body steel cylinder 5 is provided with a metal sealing gasket 8 on the mating surface of the upper flange 9 to increase its sealing performance under high pressure and high temperature conditions . The lower end of the suspension body steel cylinder 5 is lapped and matched with the convex edge and the convex edge of the upper end of the telescopic tube 1. Between the upper port of the telescopic tube 1 and the upper port of the suspension body steel cylinder 5, there is a hole that penetrates the inner chamber of the suspension body steel cylinder. The elastic tube 3 is used to ensure that the telescopic tube 1 is released through the elastic tube provided in the inner cavity of...

Embodiment 2

[0010] Embodiment 2: On the basis of Embodiment 1, only the steel cylinder of the suspension body is designed as a combined structure with connecting pipe fittings in the middle.

[0011] The telescopic tube referred to in the present invention is also called the inner casing, and the lower flange is also called the housing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com