Concrete extrusion wallboard and preparation method thereof

A technology of concrete and wall panels, applied in the field of building materials, can solve the problems of large thermal expansion and contraction coefficient, large drying shrinkage value, and unstable compactness, etc., and achieve small thermal expansion and cold contraction coefficient, large drying shrinkage value, and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

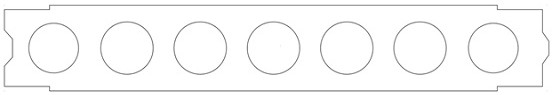

Image

Examples

preparation example Construction

[0043] A method for preparing a concrete extruded wallboard, comprising the following steps:

[0044] Mix Portland cement, sulphoaluminate cement, gypsum, aggregate and water and stir to prepare concrete blank;

[0045] performing vibratory extrusion on the concrete billet to prepare a concrete extruded wallboard;

[0046] The technological parameter of described vibration extrusion comprises:

[0047] The vibration amplitude of the vibration is 0.9mm-1.1mm, and the main vibration frequency is 45Hz-55Hz;

[0048] The helix pitch of the reamer is 65mm-80mm, the helix length is 290mm-310mm, the taper of the helix bottom diameter is 35°-45°, and the reamer speed is 210r / min-230r / min;

[0049] The boosting frequency for controlling the travel speed of the concrete slab is 35Hz-39Hz.

[0050] Based on the traditional use of Portland cement as the gel material, the present invention mixes sulphoaluminate cement and gypsum to optimize the performance of lightweight concrete, formi...

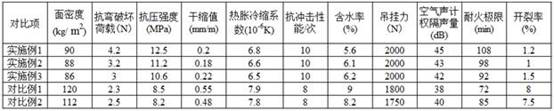

Embodiment 1

[0103] This embodiment provides a concrete extruded wallboard and a preparation method thereof, the steps are as follows:

[0104] In parts by weight, weigh 19 parts of P.O 42.5 Portland cement, 4 parts of Yunyan low-alkali 42.5 sulfoaluminate cement, 1.5 parts of anhydrous gypsum, 5.5 parts of secondary fly ash, 15 parts of recycled aggregate; stone powder 10 parts; cinder 30 parts; ceramsite 15 parts.

[0105] First pre-wet the recycled aggregate and ceramsite. During production, mix the pre-wetted recycled aggregate and ceramsite with stone powder and cinder, stir for 30 seconds, add fly ash, gypsum, and Yunyan low-alkali 42.5 sulfoaluminate cement , P.O 42.5 Portland cement, stir for 30s, then add a certain amount of water (water-cement ratio is 0.25), stir for 60s to get dry hard concrete, that is, concrete blank.

[0106] The above-mentioned concrete billet is conveyed to the feeding port of the extrusion molding machine through the belt, and the concrete billet is cont...

Embodiment 2

[0111] This embodiment provides a concrete extruded wallboard and a preparation method thereof, the steps are as follows:

[0112] In parts by weight, weigh 20 parts of P.O 42.5 Portland cement, 5 parts of Yunyan low-alkali 42.5 sulfoaluminate cement, 2 parts of anhydrous gypsum, 3 parts of secondary fly ash, 16.5 parts of recycled aggregate; stone powder 6 parts; cinder 34 parts; ceramsite 13.5 parts.

[0113] First pre-wet the recycled aggregate and ceramsite. During production, mix the pre-wetted recycled aggregate and ceramsite with stone powder and cinder, stir for 30 seconds, add fly ash, gypsum, and Yunyan low-alkali 42.5 sulfoaluminate cement , P.O 42.5 Portland cement, stir for 30s, then add a certain amount of water (water-cement ratio is 0.23), stir for 60s to get dry hard concrete, that is, concrete blank.

[0114] The above-mentioned concrete billet is conveyed to the feeding port of the extrusion molding machine through the belt, and the concrete billet is conti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com