Attapulgite interior wall putty powder and preparation method thereof

A technology for interior wall putty powder and attapulgite sticks, which is applied in filling slurry and other directions, can solve the problems of high cost and complex components, and achieve the effects of improving weather resistance, stable storage and good adsorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

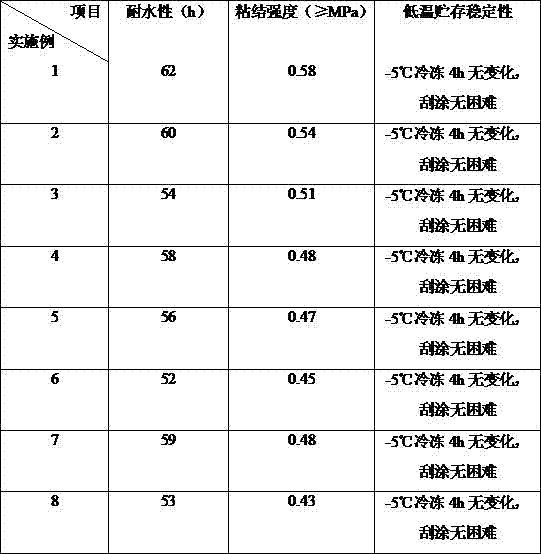

Examples

Embodiment 1

[0021] An attapulgite interior wall putty powder, comprising the following raw materials in parts by weight: 22 parts of attapulgite clay, 16 parts of white cement, 8 parts of calcium oxide, 22 parts of anhydrous calcium sulfate, 3 parts of polyacrylamide, carboxypropyl methyl 1 part of base cellulose, 2 parts of fly ash, and 0.5 part of pure iron powder, wherein the viscosity of the carboxypropyl methylcellulose is 50-100 Pa / s, and the fly ash is a primary or secondary fly ash.

[0022] The preparation method of above-mentioned putty powder, comprises the steps:

[0023] 1) Take attapulgite clay, soak it in water 20-25 times its mass, heat to 40-50°C, stir for 20-30 minutes, filter, bake the filtrate at 50°C for 2 hours, crush it and pass through 200-300 mesh Sieve to obtain purified attapulgite clay;

[0024] 2) Mix calcium oxide, anhydrous calcium sulfate, polyacrylamide, fly ash, and pure iron powder, pulverize with an ultrafine pulverizer, and pass through a 80-100 mesh...

Embodiment 2

[0027] An attapulgite interior wall putty powder, comprising the following raw materials in parts by weight: 15 parts of attapulgite clay, 12 parts of white cement, 5 parts of calcium oxide, 20 parts of anhydrous calcium sulfate, 3 parts of polyacrylamide, carboxypropyl methyl 1 part of base cellulose, 2 parts of fly ash, and 0.5 part of pure iron powder, wherein the viscosity of the carboxypropyl methylcellulose is 50-100 Pa / s, and the fly ash is a primary or secondary fly ash.

[0028] The preparation method of above-mentioned putty powder, comprises the steps:

[0029] 1) Take attapulgite clay, soak it in water 20-25 times its mass, heat to 40-50°C, stir for 20-30 minutes, filter, bake the filtrate at 50°C for 2 hours, crush it and pass through 200-300 mesh Sieve to obtain purified attapulgite clay;

[0030] 2) Mix calcium oxide, anhydrous calcium sulfate, polyacrylamide, fly ash, and pure iron powder, pulverize with an ultrafine pulverizer, and pass through a 80-100 mesh...

Embodiment 3

[0033] An attapulgite interior wall putty powder, comprising the following raw materials in parts by weight: 18 parts of attapulgite clay, 15 parts of white cement, 8 parts of calcium oxide, 22 parts of anhydrous calcium sulfate, 3 parts of polyacrylamide, carboxypropyl methyl 1 part of base cellulose, 2 parts of fly ash, and 0.2 part of pure iron powder, wherein the viscosity of the carboxypropyl methyl cellulose is 50-100 Pa / s, and the fly ash is a primary or secondary fly ash.

[0034] The preparation method of above-mentioned putty powder, comprises the steps:

[0035] 1) Take the attapulgite clay, soak it in water 20-25 times its mass, heat it to 40-50°C, stir it for 20-30 minutes, filter it, bake the filtrate at 60°C for 1 hour, crush it and pass it through 200-300 mesh Sieve to obtain purified attapulgite clay;

[0036] 2) Mix calcium oxide, anhydrous calcium sulfate, polyacrylamide, fly ash, and pure iron powder, pulverize with an ultrafine pulverizer, and pass throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com