Method for producing steel-plastic multi-element composite pipes

A multi-component composite, production method technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of easy rust, poor rigidity and temperature resistance, and cannot be used for oil transportation and high-pressure water transportation, etc. Achieve the effect of preventing rust, increasing the anti-cracking performance, and improving the resistance to longitudinal force and deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

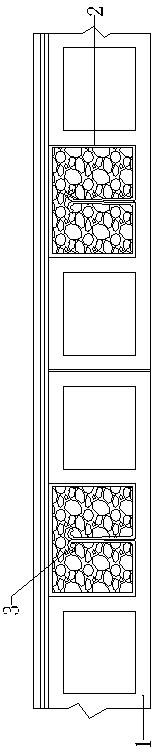

[0024] The present invention will be further described below in conjunction with all accompanying drawings. A preferred embodiment of the present invention is: the production method of the steel-plastic multi-component composite pipe described in this embodiment includes the following steps:

[0025] Step 1: Reinforce and toughen HDPE or PVC plastic through modification equipment, and make it into a plastic strip 1;

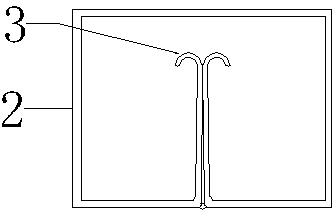

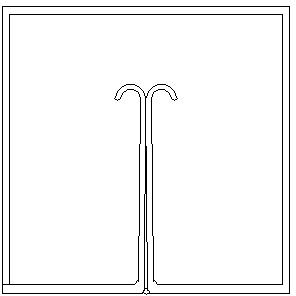

[0026] The second step: the steel strip is rolled by rolling equipment to form a hollow reinforcing rib 2 with both sides concave and overlapped; The cross-section of the rib can be square, trapezoidal, arc-shaped or triangular; it can also be designed into other geometric shapes as required. Fixed hook 3 is used for fixing the cement slurry after solidification.

[0027] The third step: use continuous welding equipment to weld the notch at the bottom of the reinforcing rib to make the reinforcing rib form a whole;

[0028] The fourth step: use spiral winding e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com