Patents

Literature

44results about How to "Improve internal pressure resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

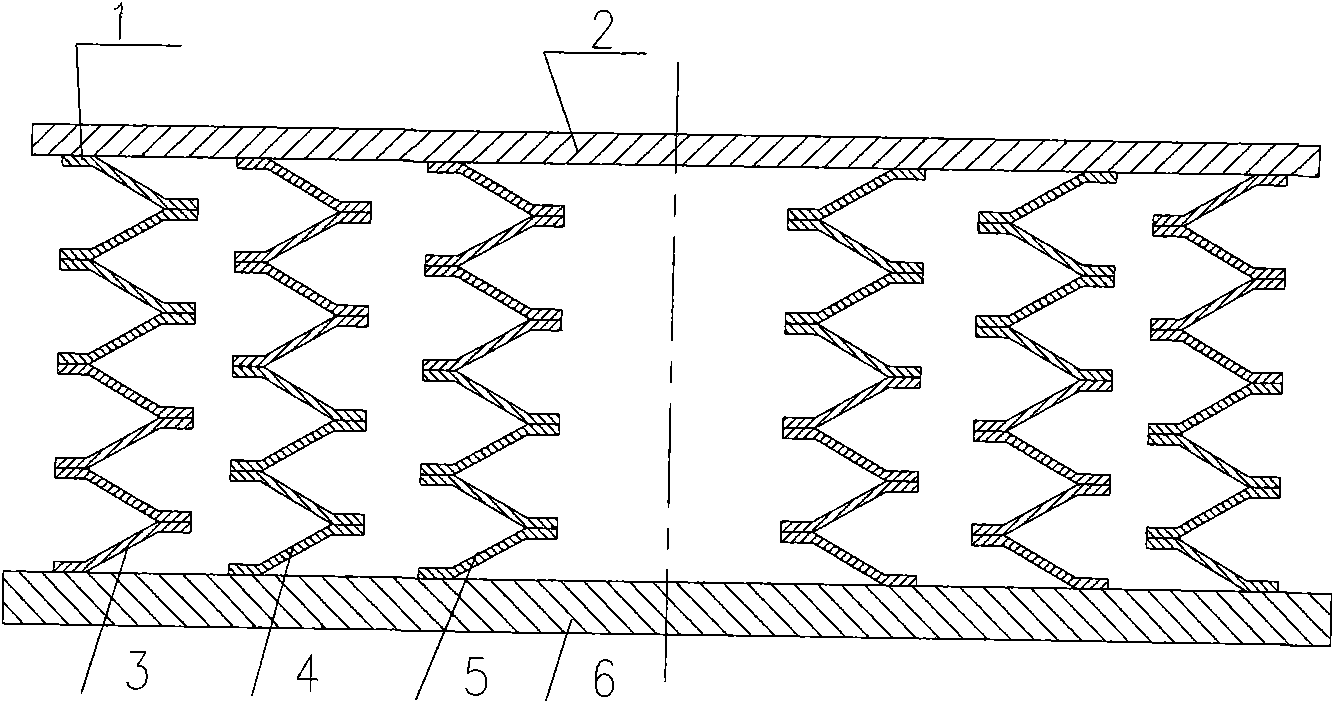

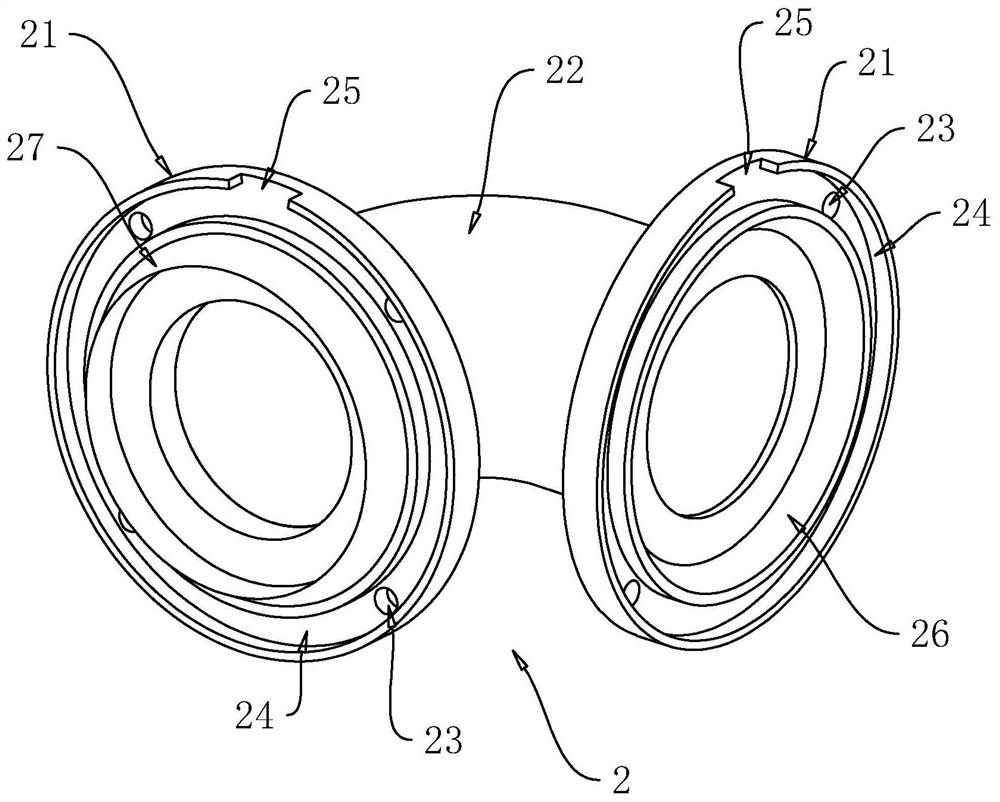

Diffusion welding multilayer structure diaphragm capsule

The invention is a diffusion welding multilayer structure diaphragm capsule, belonging to the field of diaphragm capsule manufacturing. By adopting the methods of diffusion welding, machining and shaping, the manufacturing of diaphragm capsule in the invention can be realized. The main procedures include thin wall blank preparation, surface cleaning, surface modified treatment, welding-stopping treatment, diffusion welding, machining, shaping and the like. Compared with the multilayer structure diaphragm capsule manufactured by other methods, the multilayer structure diaphragm capsule manufactured by the invention has the advantages of fine fatigue property (above 1 million times), strong pressurization performance, adjustable rigidity, high compression ratio (higher than 80%), capability of micromation of inner holes, high precision of geometric dimensions, strong destabilization resistance, precise and controllable weldingline profile, adjustable width of weldingline and the like. By using the invention, the diaphragm capsule in the shape of circle, square and other shapes can be manufactured, and can serve as a compensation element of displacement and angle in hydraulic, barometric, transferring pipeline installation, an elastic compensation element and a pore damping element as well as a measuring element for a manometer and an altimeter; besides, the diaphragm capsule can be also used as a heat transferring finned tube for air conditioning, refrigeration and other devices as well as a metal capsule of separating gas or liquid for an accumulator and a storage box. The invention can provide multilayer structure diaphragm capsule products with fine performance for related industries.

Owner:北京智创联合科技股份有限公司

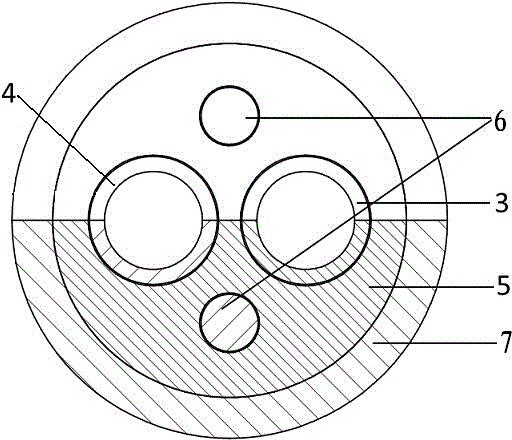

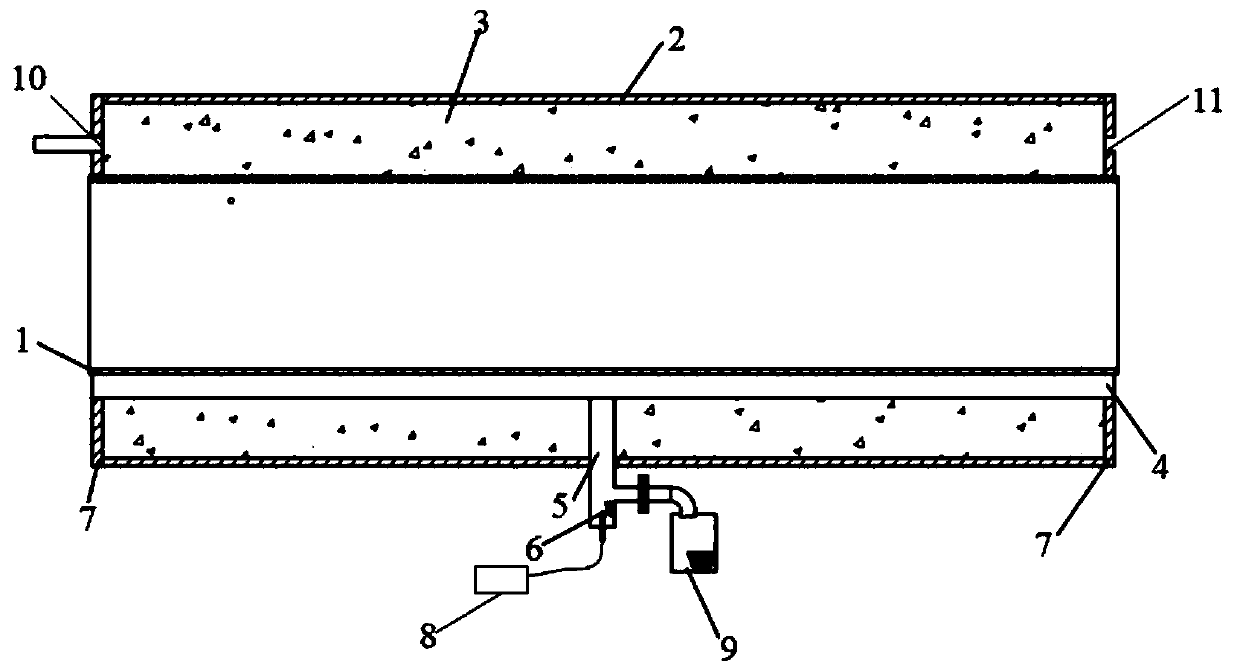

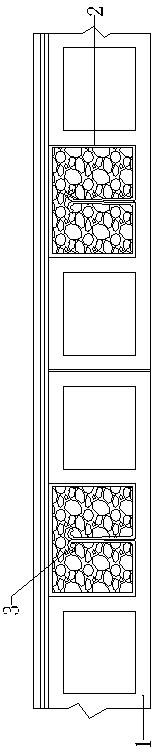

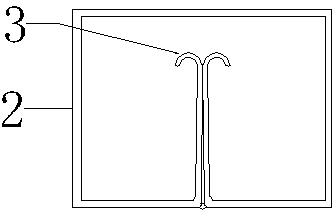

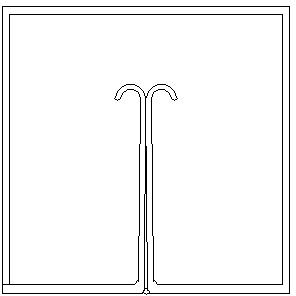

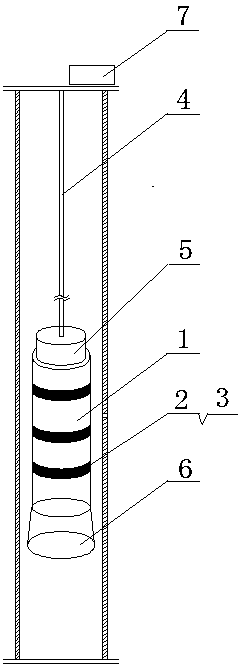

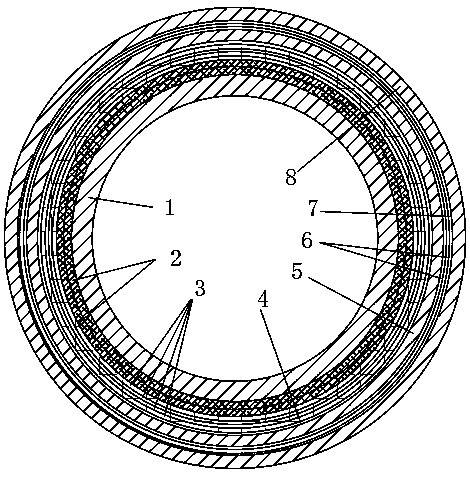

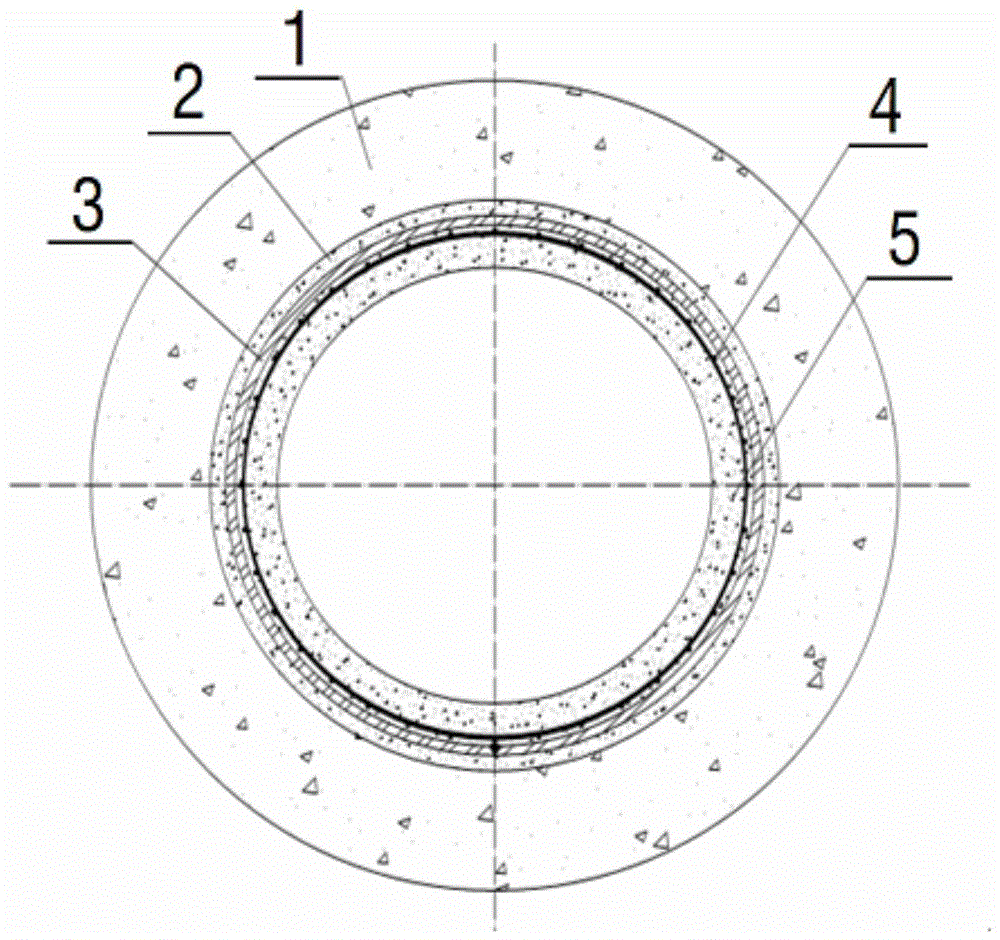

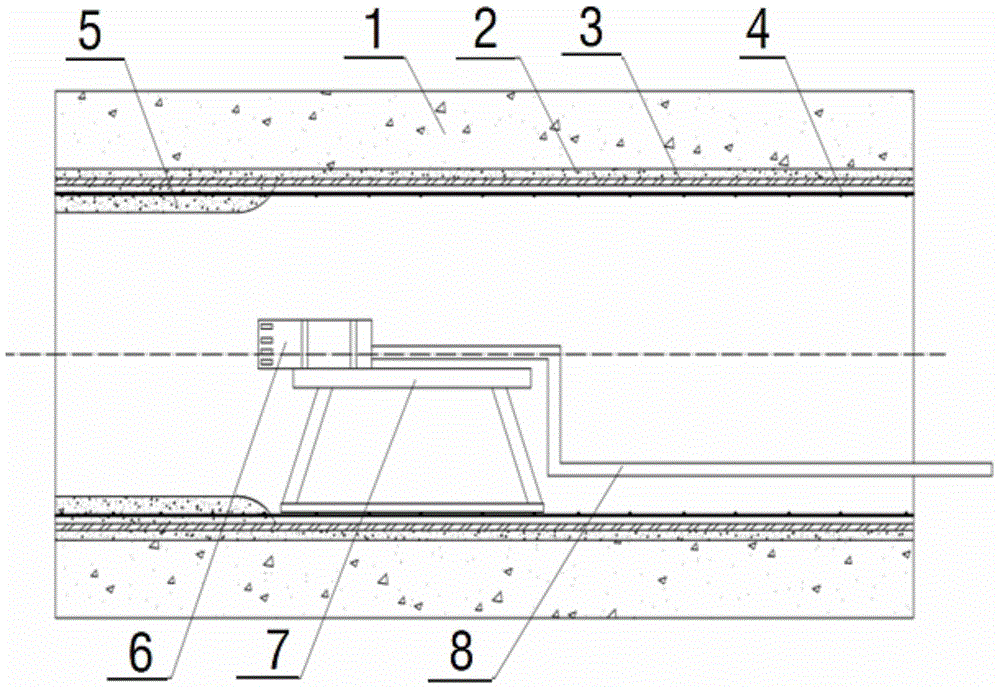

Bilayer separate injection process pipe column device for nonmetal continuous oil pipe

ActiveCN104389563ARealize regulationImprove tensile propertiesDrilling rodsFluid removalOil productionDistributor

The invention belongs to the technical field of oil production technology in petroleum and natural gas industries, and particularly relates to a bilayer separate injection process pipe column device for a nonmetal continuous oil pipe. The bilayer separate injection process pipe column device comprises the nonmetal continuous oil pipe and injection quantity adjusting devices, a first water injection passage and a second water injection passage which are symmetric according to the center of the nonmetal continuous oil pipe are arranged in the nonmetal continuous oil pipe, the injection quantity adjusting devices are arranged at the starting ends of the first water injection passage and the second water injection passage respectively, and the first water injection passage and the second water injection passage are both connected with the injection quantity adjusting devices through adapters. By the bilayer separate injection process pipe column device, an original process of using a water distributor for layered water injection is replaced, so that anticorrosion and antiscaling effects are realized. Flow adjusting is performed on the ground, so that sundry downhole testing and adjusting work is omitted, downhole accidents occurring in the testing and adjusting work are eliminated, and effective injection quantity is guaranteed for each layer.

Owner:PETROCHINA CO LTD

Polyvinyl chloride/nitrile rubber/phyllo-silicate nano composite material and preparation method thereof

InactiveCN101457000AHigh tensile strengthImprove internal pressure resistancePolymer sciencePolyvinyl chloride

The invention relates to a polyvinyl chloride / nitrile rubber / layered silicate nano-composite and a preparation method thereof, which mainly uses the polyvinyl chloride as a substrate, by adding in certain proportions of nitrile rubber powder, nano-layered silicate, conductive carbon black, light calcium carbonate, lubricant, plasticizer and heating composite stabilizer materials, a new polyvinyl chloride / nitrile rubber / layered silicate nano-composite is prepared. The raw materials mentioned above are weighed and mixed except the nitrile rubber powder, and kneaded by a high-speed kneading machine after being mixed, with a kneading temperature of 110-125 DEG C, then material being kneaded is put into a cold mixer for cold mixing, and the weighed nitrile rubber powder is added in when in cold mixing, material is discharged when being cold mixed to lower than 40 DEG C, an extruder is used for plastic extrusion or multi-layer co-extrusion mold, and finally a pipe, a fitting and a roller body are manufactured. Compared with present flame retardant and antistatic PE and PVC materials, the polyvinyl chloride / nitrile rubber / layered silicate nano-composite not only has the toughness of the PE, but also is provided with the intensity of the PVC, thus being capable of being widely applied to such combustible and explosive areas as coal mine, oil field, natural gas and mine.

Owner:生寿斋

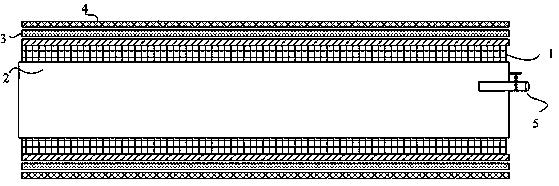

Multifunctional double-wall glass steel pipe and preparation method thereof

PendingCN110715119AEasy to assembleIt will not affectThermal insulationPipe elementsInsulation layerStructural engineering

The invention discloses a multifunctional double-wall glass steel pipe and a preparation method thereof. The double-wall pipe comprises an inner pipe, and an outer pipe arranged outside the inner pipein a sleeving mode; an insulation layer is arranged between the inner pipe and the outer pipe; a leakage channel is arranged between the insulation layer and the inner pipe in the length direction ofthe inner pipe; and the leakage channel communicates with the outer wall of the inner pipe. The preparation method comprises the following steps: the outer pipe is arranged outside the inner pipe inthe sleeving mode; a mold of the leakage channel is arranged between the inner pipe and the outer pipe; the mold is contacted with the outer wall of the inner pipe; blockage plates are fixedly arranged at the two ends of a pipe cavity between the inner pipe and the outer pipe, and are provided with injection holes and exhaust holes; foaming materials are injected from the injection holes; and themold is pulled out after foaming is finished. The double-wall pipe is simple in structure, easy to manufacture and low in cost, and integrates such multiple functions as the double-wall structure, theinsulation function, capability of detecting and alarming, capability of collecting leaked liquid and capability of positioning.

Owner:NANJING XINHE COMPOSITES CO LTD +1

Method for producing steel-plastic multi-element composite pipes

ActiveCN102230554APrevent looseningIncrease resistance to longitudinal forceRigid pipesFiberPolyvinyl chloride

The invention provides a method for producing steel-plastic multi-element composite pipes, which comprises the following steps of: modifying high-density polyethylene (HDPE) or polyvinyl chloride (PVC) plastics and manufacturing plastic plate strips; manufacturing hollow reinforcing ribs of which two side edges are recessed and overlapped; welding notches of the recessed bottoms of the reinforcing ribs by using continuous welding equipment; synchronously winding the welded reinforcing ribs with the plastic plate strips to form an inner wall of a pipe; coating and rolling on the wound pipe wall; coating a fiber mesh or winding a fiber strip and rolling on the rolled pipe wall; coating and rolling on a fiber layer to form an outer wall of the pipe; cutting the pipe which is finished in the seventh step at fixed length; sealing a port of each reinforcing rib at one end of the cut pipe, and injecting prepared cement slurry into each square reinforcing rib at the other end of the pipe by using grouting equipment; and finally, vertically erecting and fixing the pipe which is injected with the cement slurry, so that the cement slurry is solidified to form a finished pipe. The invention has the advantages that: the pipe can resist internal and external pressures and prevent cracking, an expansion on heating and contraction on cooling coefficient of the pipe is reduced, and the reinforcing ribs are prevented from rusting.

Owner:娄底市朝阳塑胶有限公司

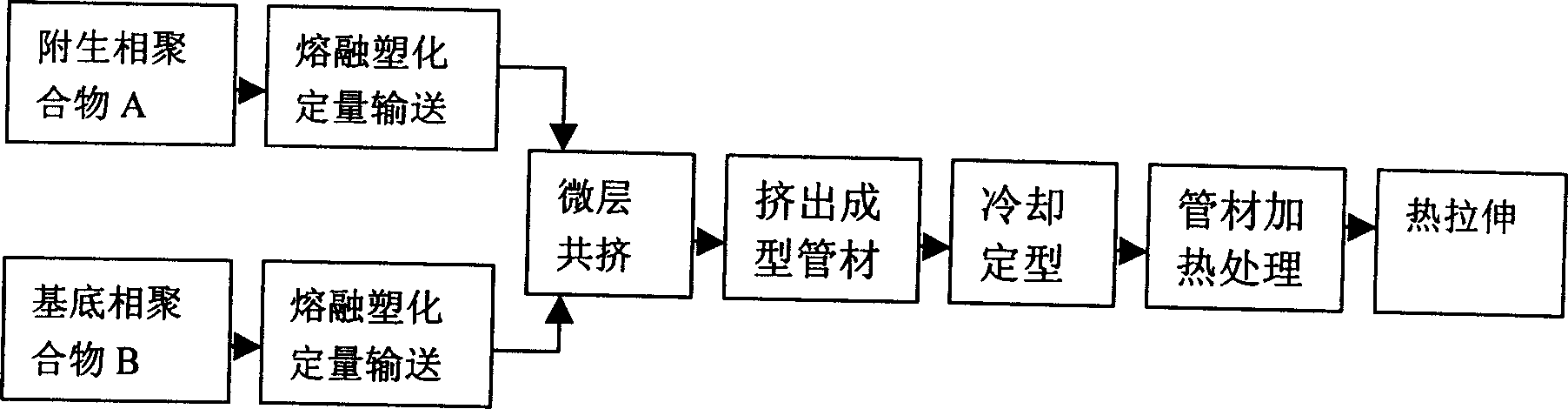

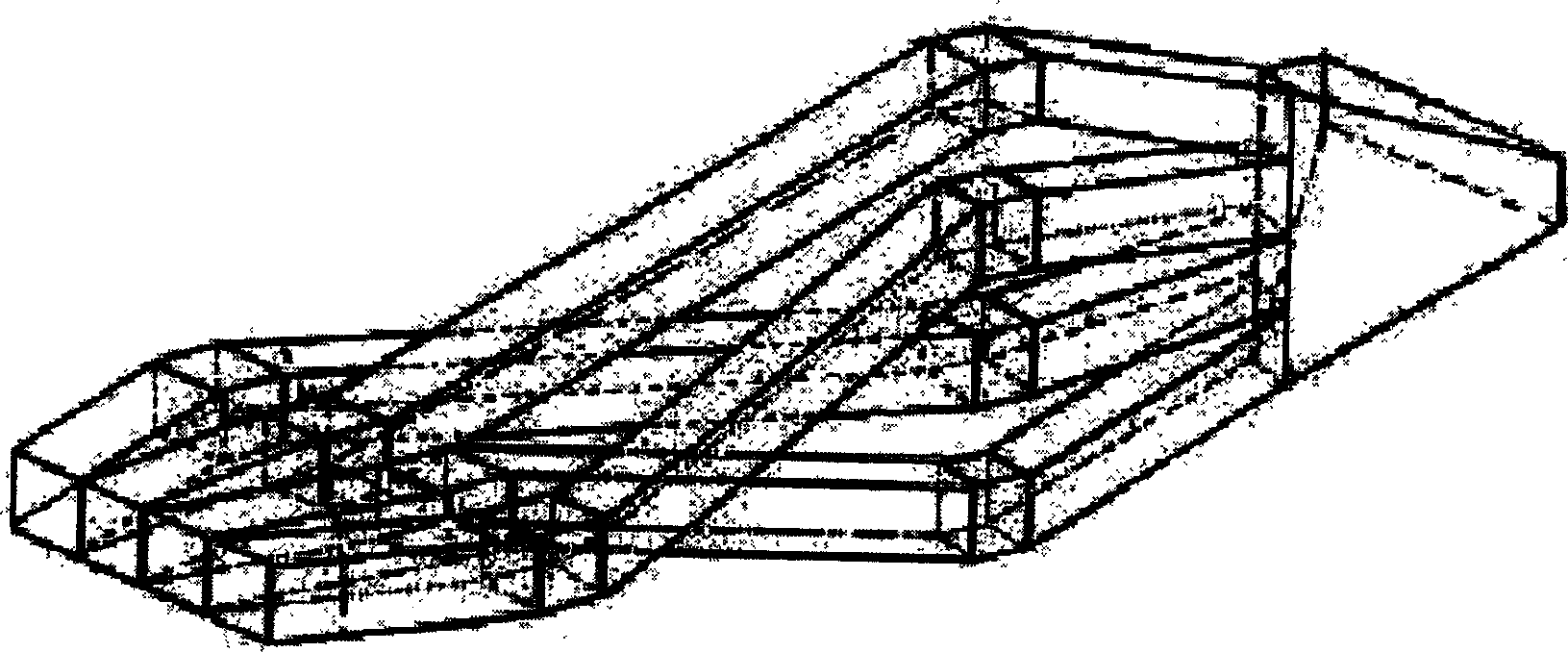

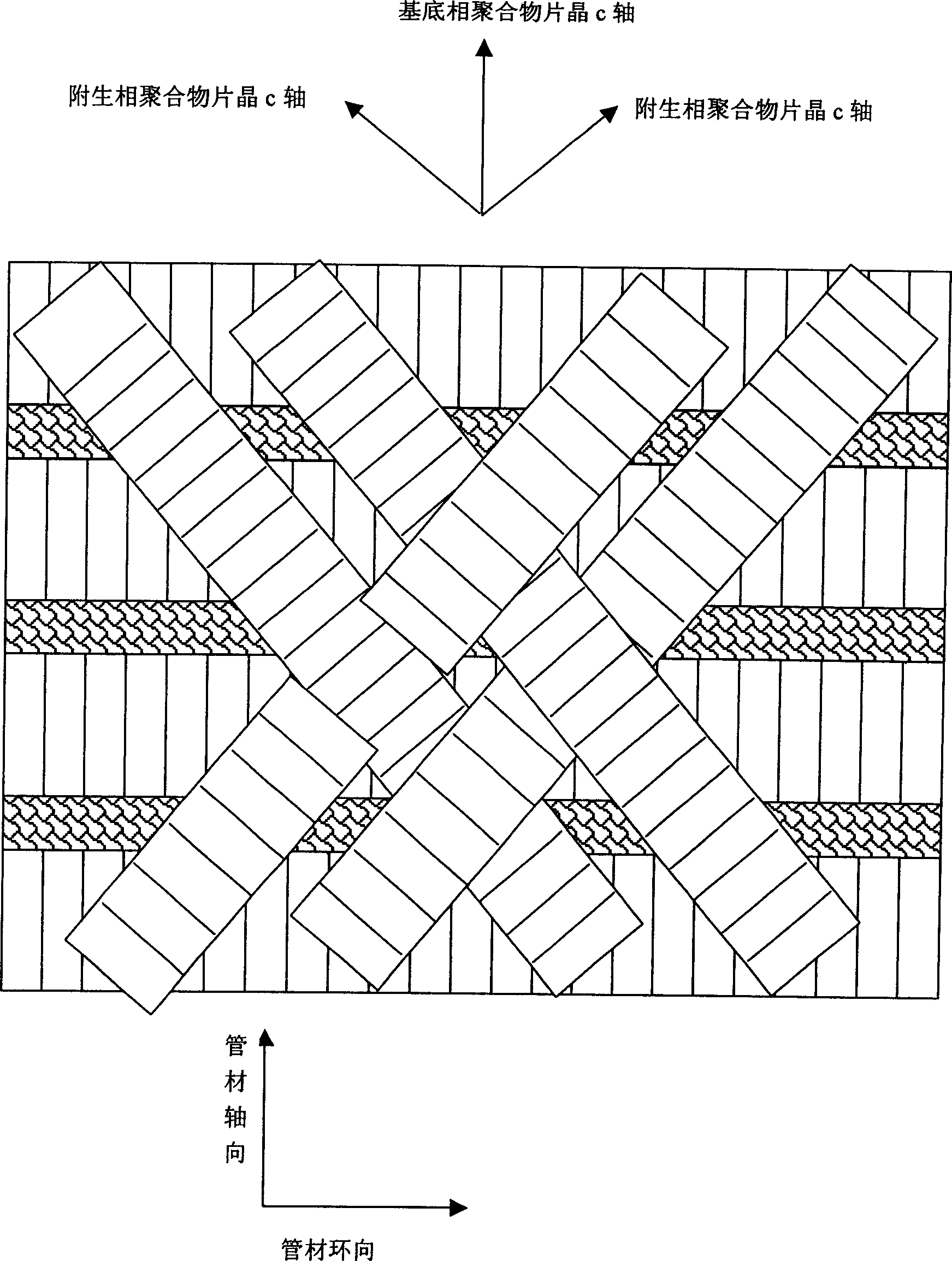

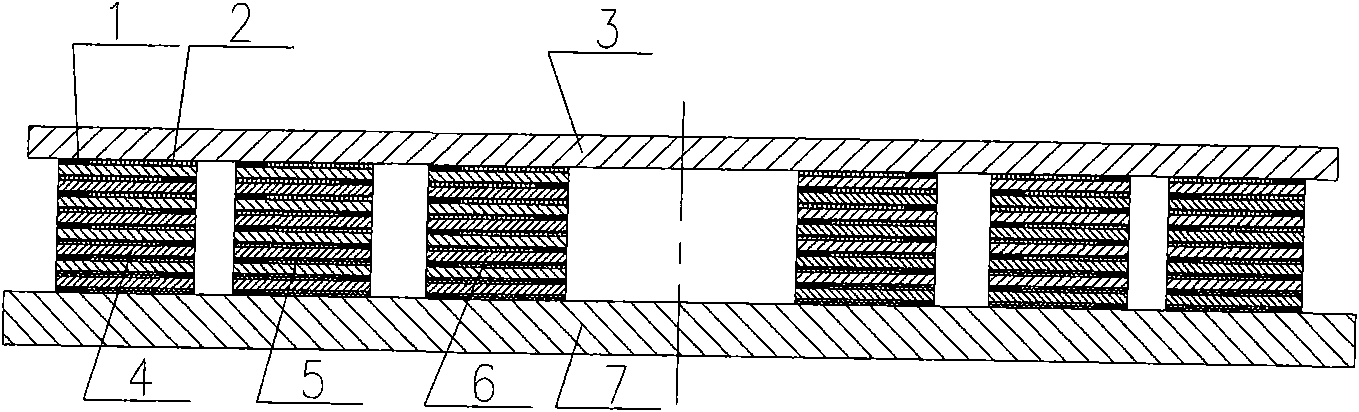

Multiplayer composite tube made from polymer possessing texture in nano layer and making method

InactiveCN1687626AHigh strengthHigh modulusRigid pipesTubular articlesPolymer scienceLayer thickness

The invention discloses the multi-layer polymer composite tubing with nanometer layer structure and its manufacturing method. The composite tubing is formed by the two polymers with non-parallel hetero crossed structure, which passes through the micro-layer coextrusion, the cooled forming, the heat processing and the heat pulling procedures. The c axis of the base polymer layer is along the axial of the tubing, and it accumulative layer thickness is 50-99%of the thickness of the tubing; the c axis of the agglomerative polymer crosses with the axis line of the tubing, and its accumulative thickness is 1-50% of that of the tubing, and the thickness of the single layer of the agglomerative polymer is 50-300 nanometers. The invention forms the reinforcing phase in the tubing in order to strengthen the intensity of the tubing and to improve the expansion of the tubing.

Owner:SICHUAN UNIV

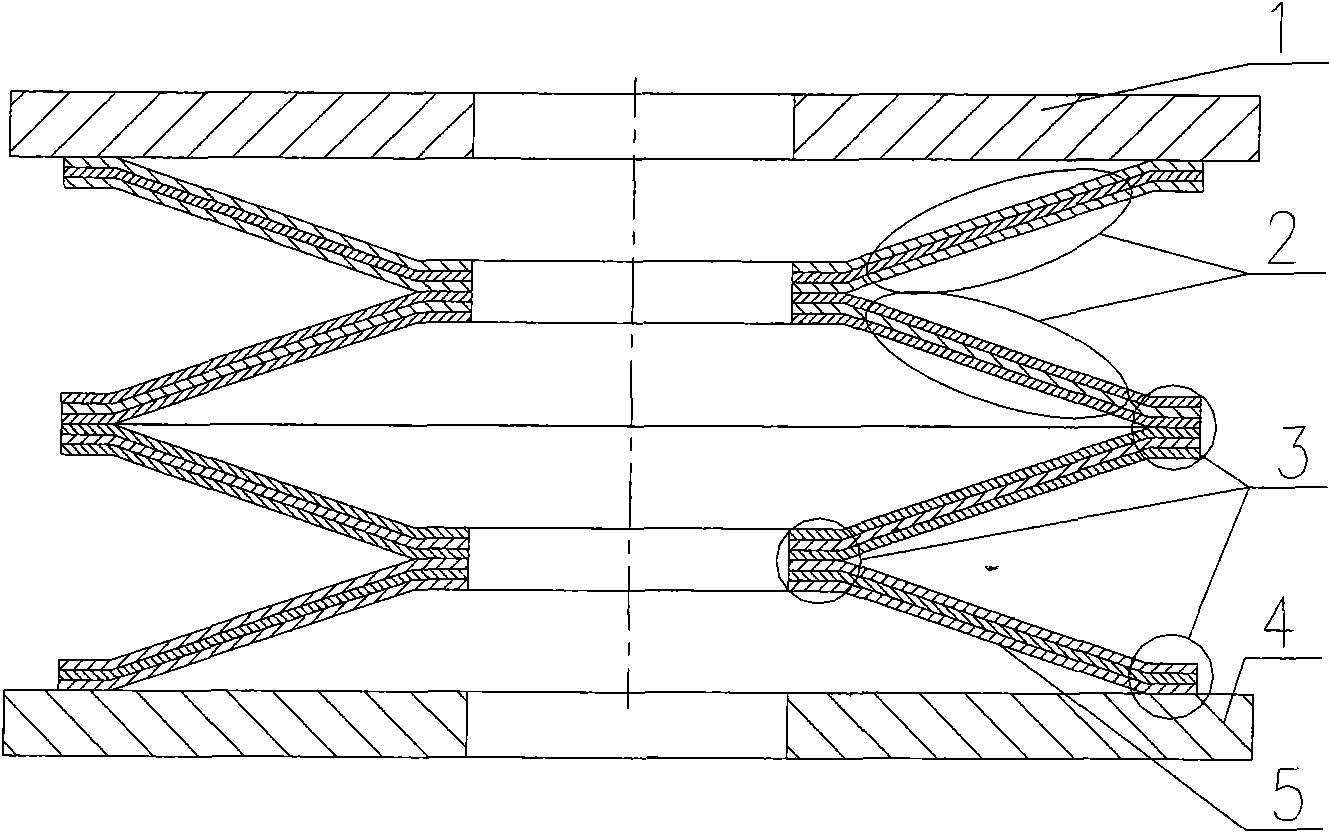

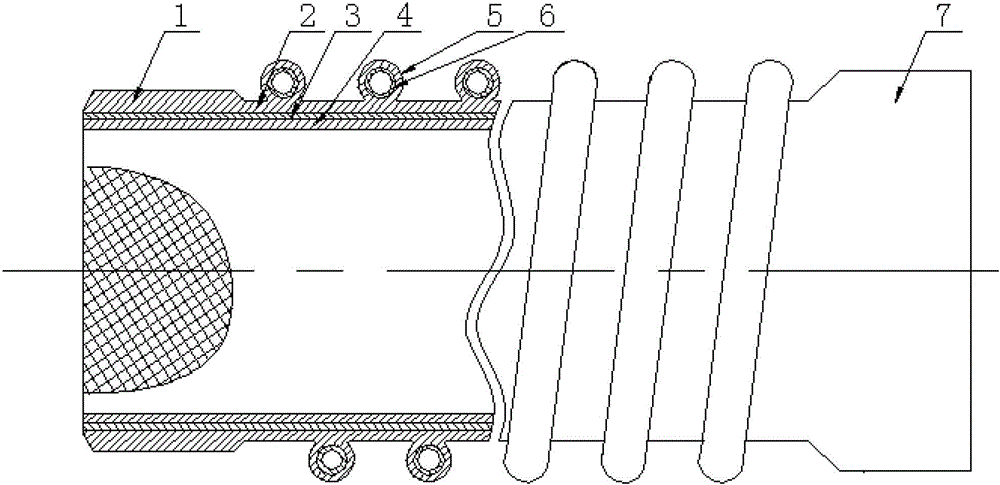

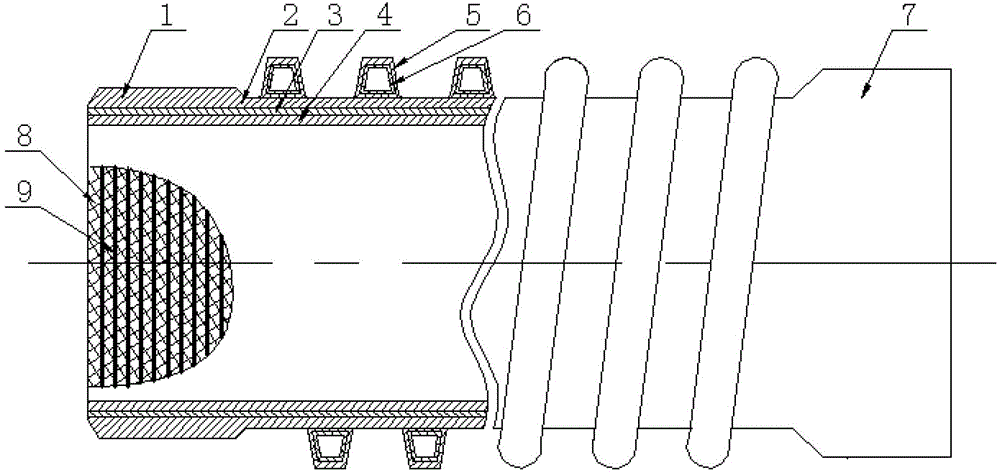

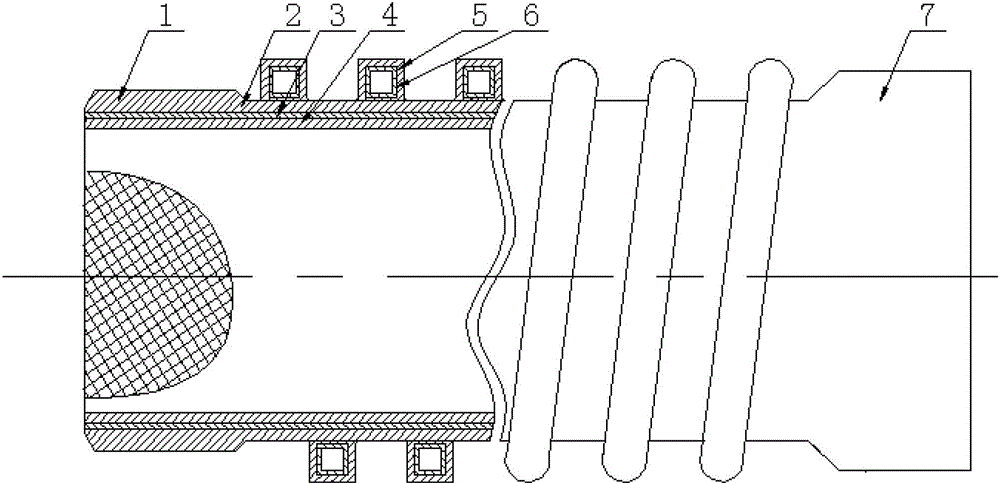

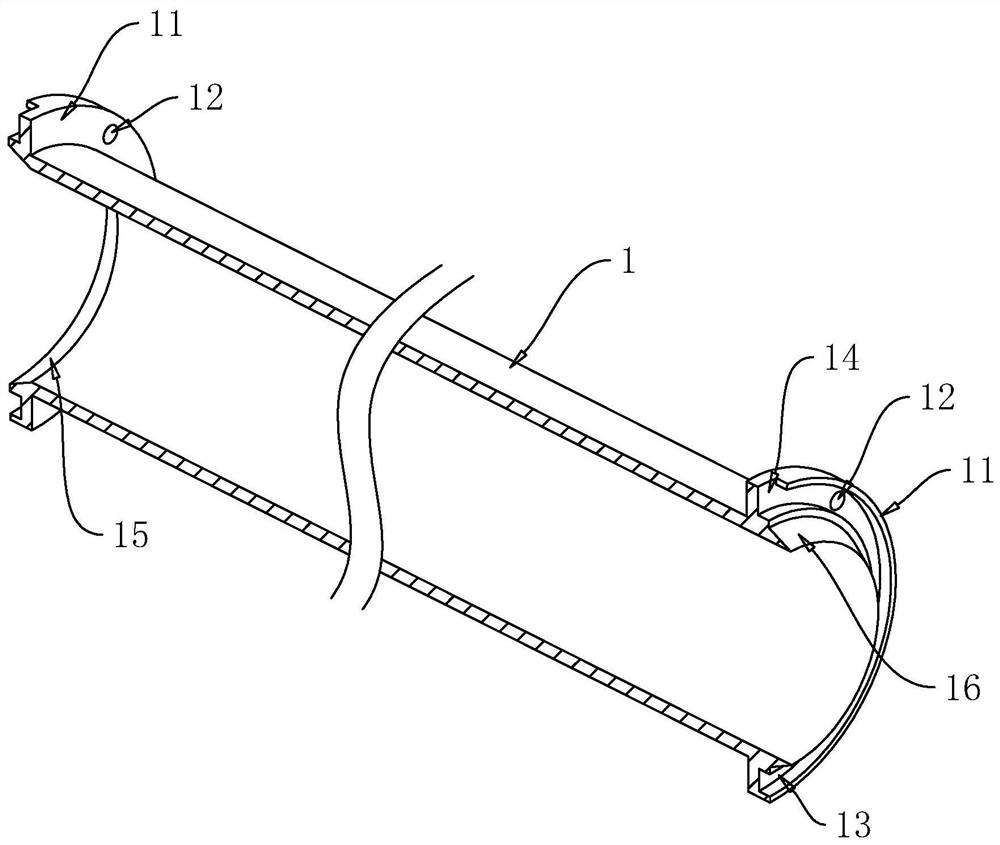

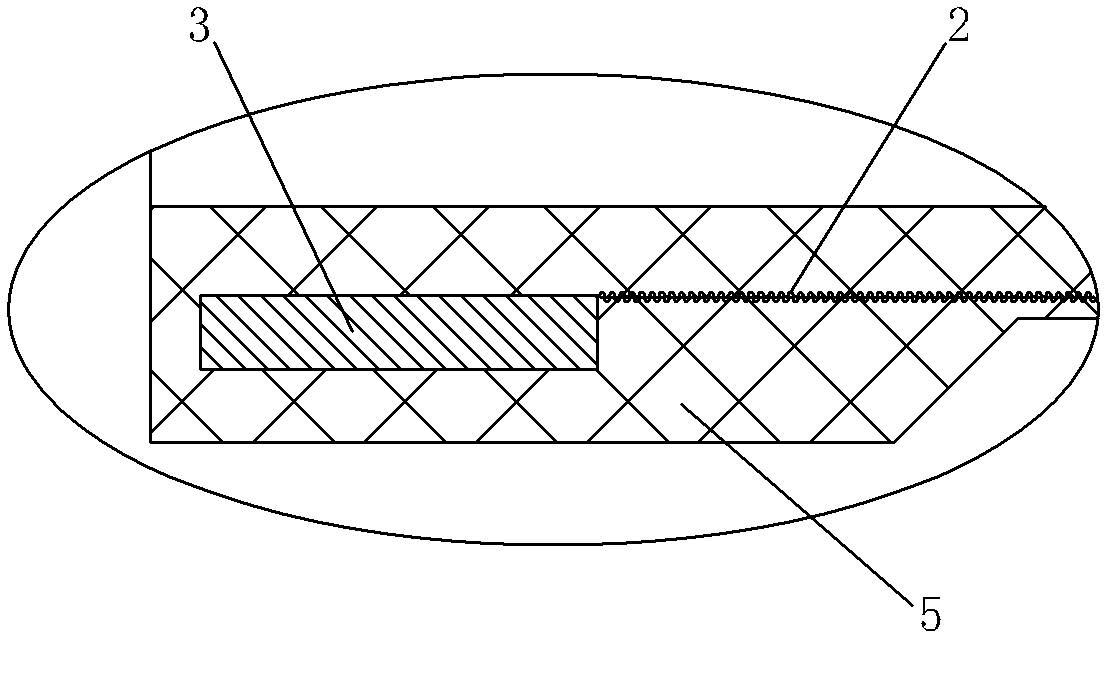

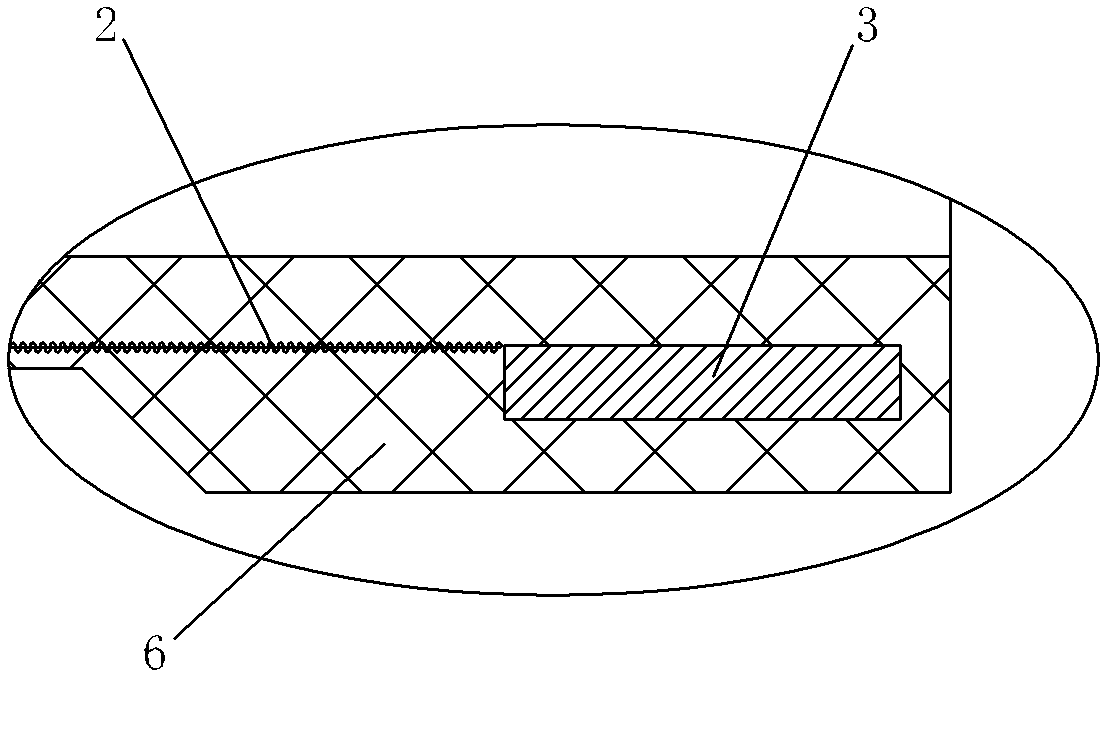

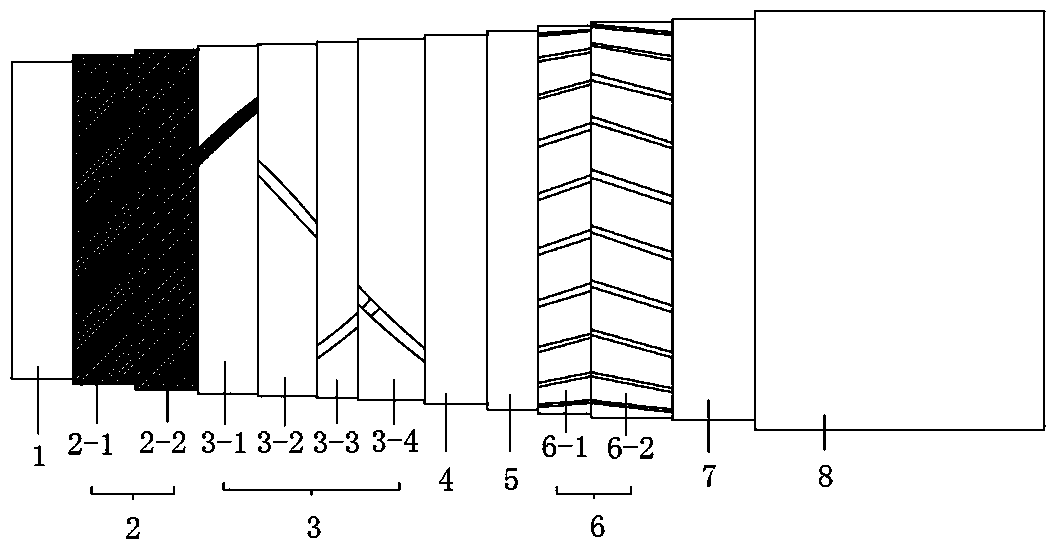

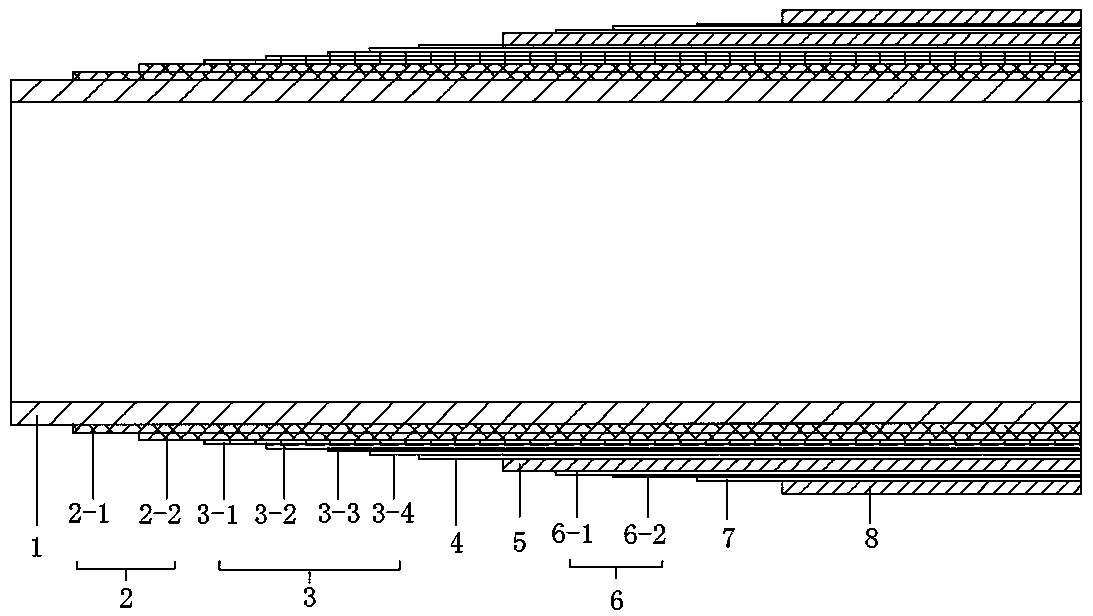

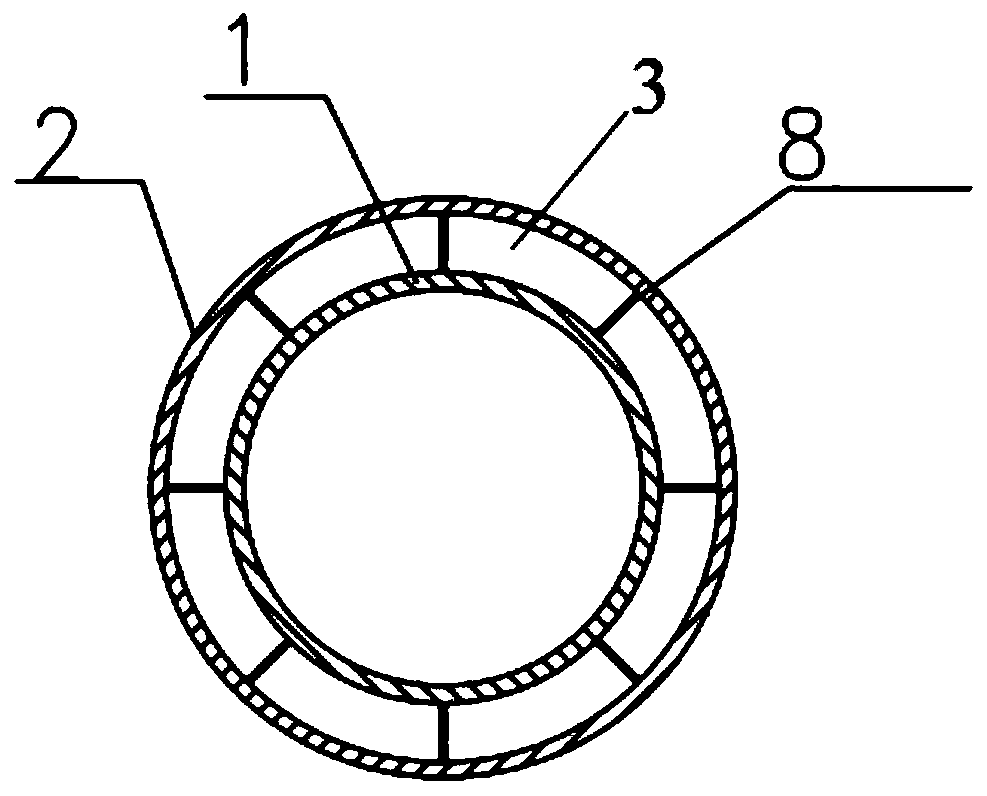

Composite structured corrugated pipe by diffusion welding

The invention provides a composite structured corrugated pipe by diffusion welding, belonging to the field of corrugated pipe manufacturing. In the invention, the manufacturing of the composite structured corrugated pipe is realized by a method of 'diffusion welding' + 'mechanical processing' + 'shaping' with the main process as follows: thin-wall blank preparation, surface cleaning, surface modification treatment, stop welding treatment, diffusion welding, mechanical processing, shaping and the like. Compared with the composite structured corrugated pipe manufactured by other methods, the composite structured corrugated pipe manufactured by the invention has good fatigue property which is over 1 million times, strong compression capacity, adjustable rigidity, high compression rate which is greater than 95%, micromation inner bore, compact structure, high precision of geometric dimension, strong anti-unstability capacity, precise and controllable welding line outline, adjustable welding line width and the like. The corrugated pipes with the outline of a round, a square and other types of shapes can be manufactured by utilizing the invention, which can be used as hydraulic pressure, air pressure, transfer pipeline installation displacement and angle compensation element, supercharging element, elastic compensation element and air hole damp element, and can also be used as the measuring element of a pressure gauge and an altimeter, thus providing composite structured corrugated pipe products with good performance for related industries.

Owner:北京智创联合科技股份有限公司

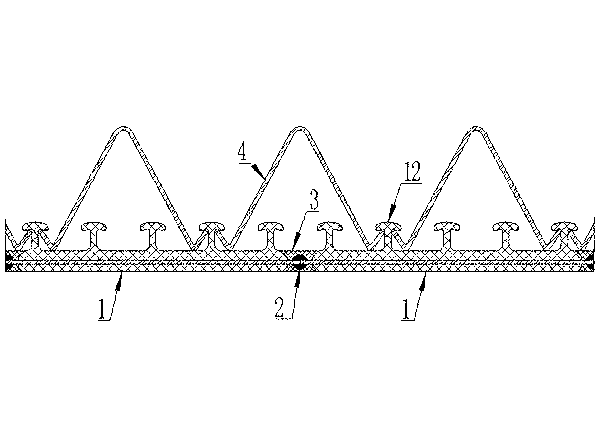

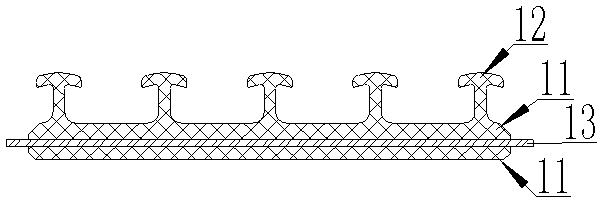

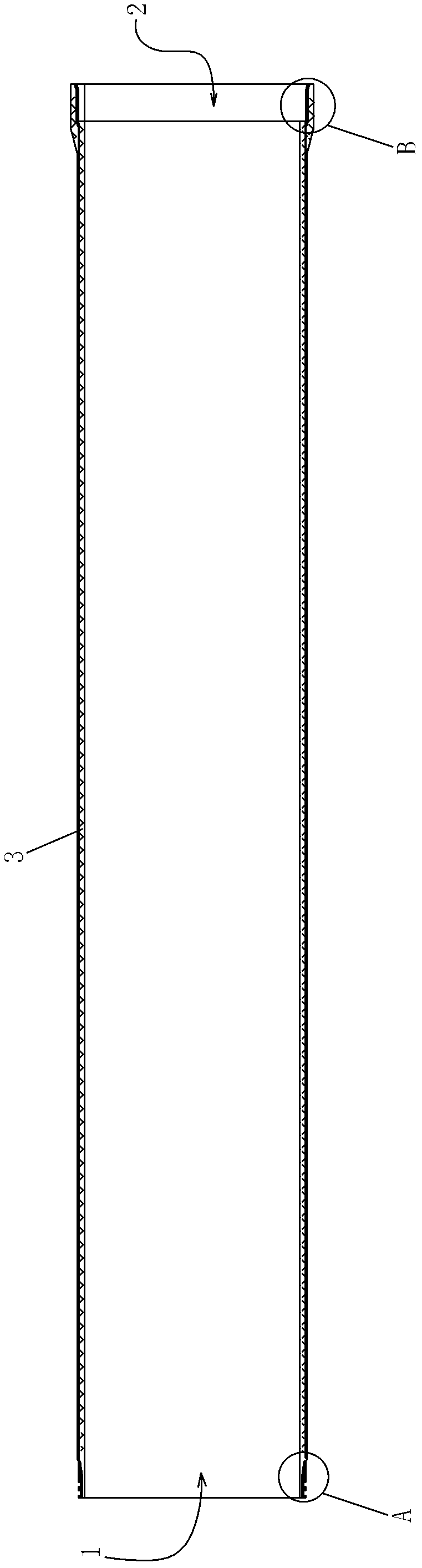

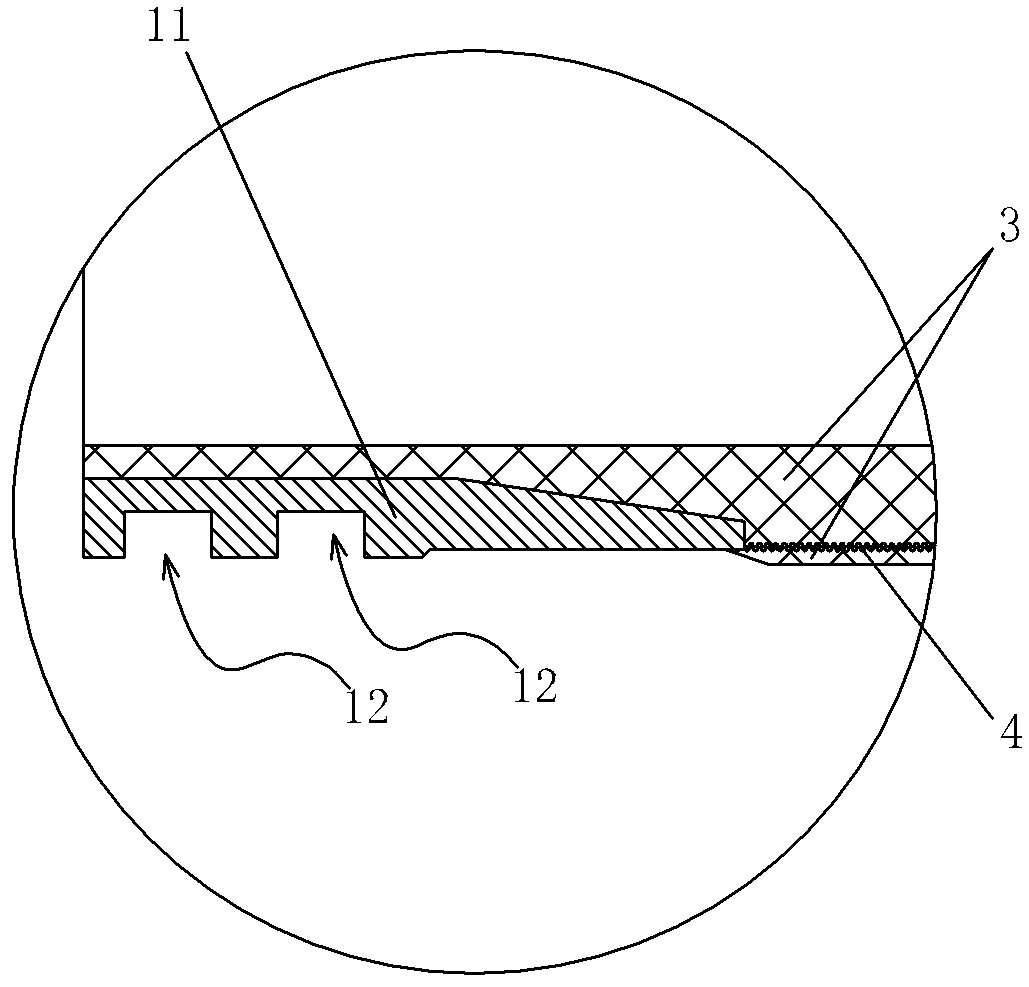

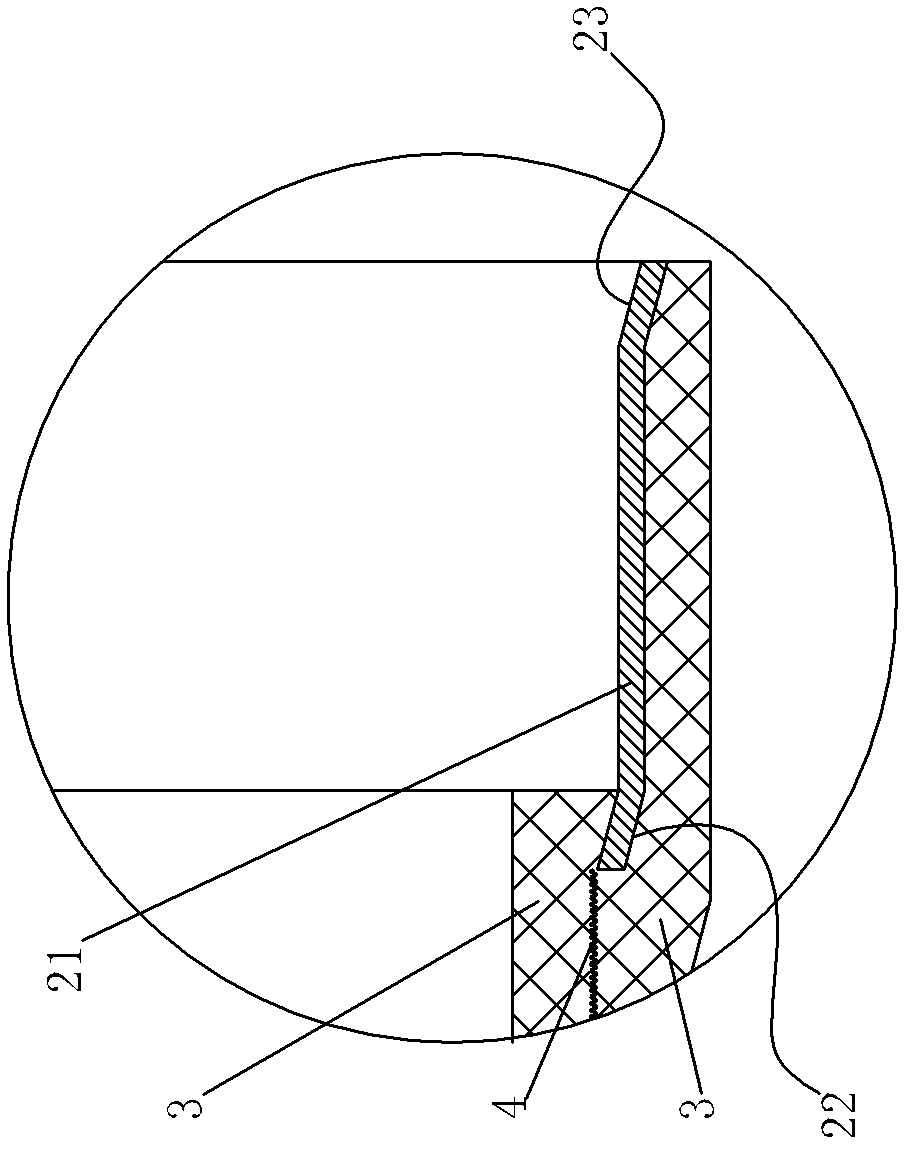

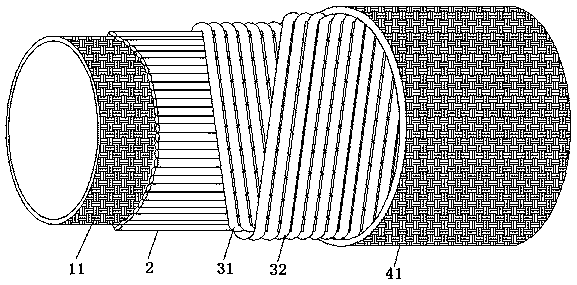

Large-caliber lower pressure water feeding polythene wire mesh winding pipe and production method and production equipment

ActiveCN103335173AIncreased ring stiffnessImprove internal pressure resistanceRigid pipesInternal pressureEngineering

The invention relates to a large-caliber lower pressure water feeding polythene wire mesh winding pipe which is characterized by comprising a solid wall pipe body layer and a protrusive reinforcing structure layer. The solid wall pipe body layer is composed of an inner wall layer, a reinforcing layer and an outer wall layer, the inner wall layer is a continuous inner wall layer which is formed in the mode that sheet-like polythene strips wind around a rotary drum mould spirally, the reinforcing layer is a steel wire mesh reinforcing layer which is formed in the mode that a steel wire mesh winds around the inner wall layer spirally, the outer wall layer is a continuous outer wall layer which is formed in the mode that sheet-like polythene strips wind around the rotary drum mould spirally, and the protrusive reinforcing structure layer is a protrusive reinforcing rib which is formed in the mode that tubular polythene strips which are used for wrapping a framework tube wind around the outer wall layer of the solid wall pipe body spirally. The large-caliber lower pressure water feeding polythene wire mesh winding pipe has a large caliber, can be used for delivering water from a great distance and has the advantages of being good in ring stiffness and good in internal pressure resistance. The production method of the large-caliber lower pressure water feeding polythene wire mesh winding pipe is simple, power consumption is little, the production equipment of the large-caliber lower pressure water feeding polythene wire mesh winding pipe has the advantages of being high in efficiency and stable in operation, and the large-caliber lower pressure water feeding polythene wire mesh winding pipe can be manufactured integrally on assembly lines.

Owner:天津业和科技有限公司

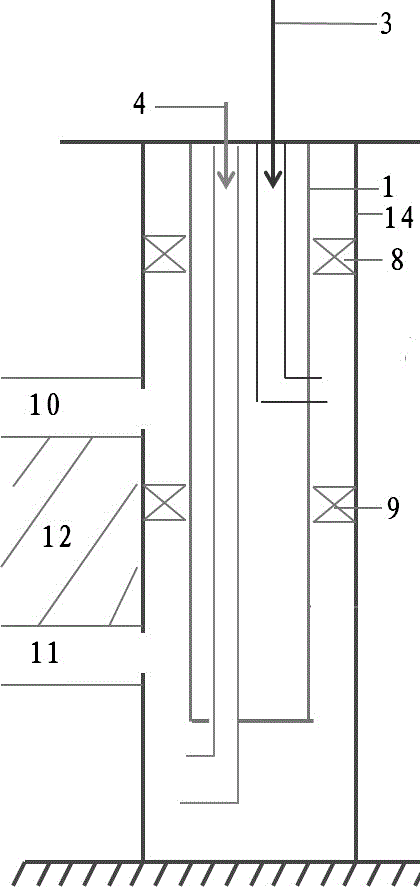

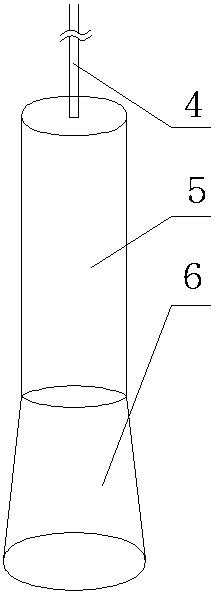

Self-expanding subsidizing device for oil well casing and subsidizing method thereof

The invention discloses a self-expanding patching device and method for an oil well casing. The method comprises the following steps: taking a memory alloy pipe of which the outer diameter is smaller than the inner diameter of the casing as a patching pipe substrate; fixing a rubber seal ring on the outer wall of the memory alloy pipe via a temperature-resistant adhesive, so as to obtain a patching pipe; lowering the patching pipe to the damaged position of the casing with an underground tool releasing device; heating the patching pipe with temperature in a well, so that the memory alloy pipe expands fast when temperature of the memory alloy pipe reaches a training temperature, and is tightly patched to the inner wall of the casing, that is, the casing pipe is repaired, wherein the training temperature depends on the damaged position of the casing. As the patching pipe deforms in one direction, the sealing and the blocking are reliable, the strength is high, and the internal pressure resistance and the external collapse resistance of the damaged casing can be improved obviously after the casing is repaired. Moreover, as the patching pipe has a self-expanding property at a set temperature, the casing can be repaired without taking measures such as hydraulic expansion or gunpowder explosion. Therefore, the operation is convenient, the construction is safe, the flaking off possibility is low, and the service life is long.

Owner:PETROCHINA CO LTD

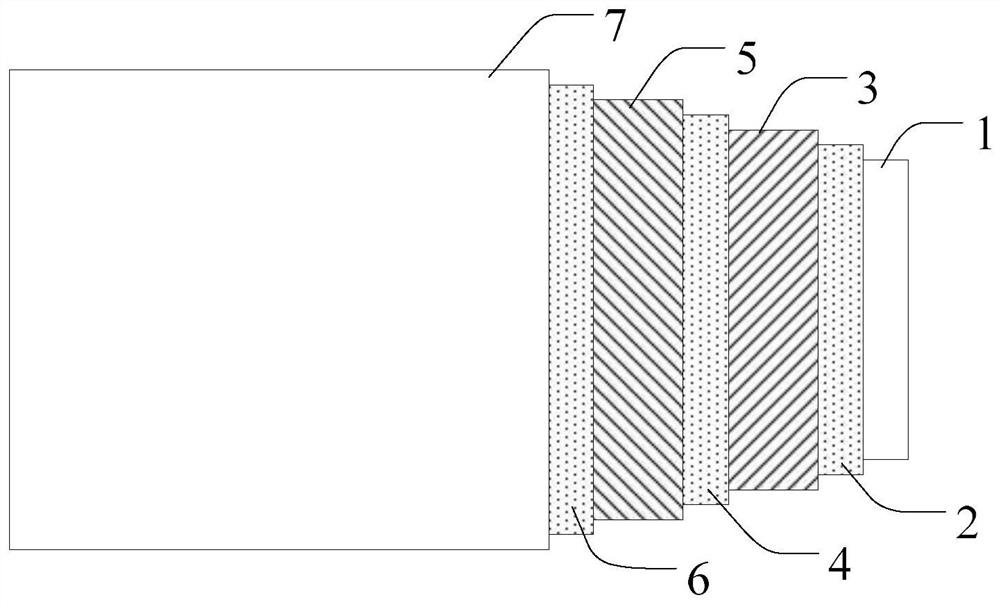

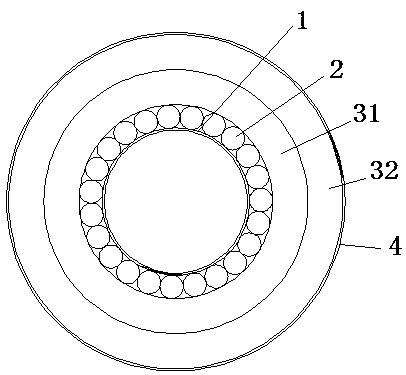

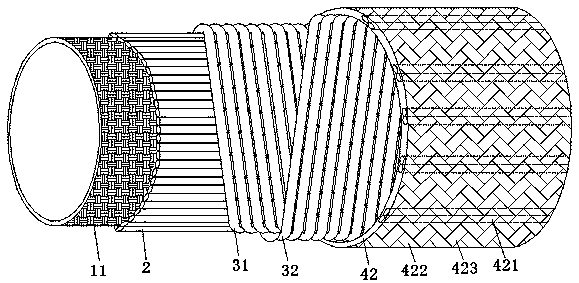

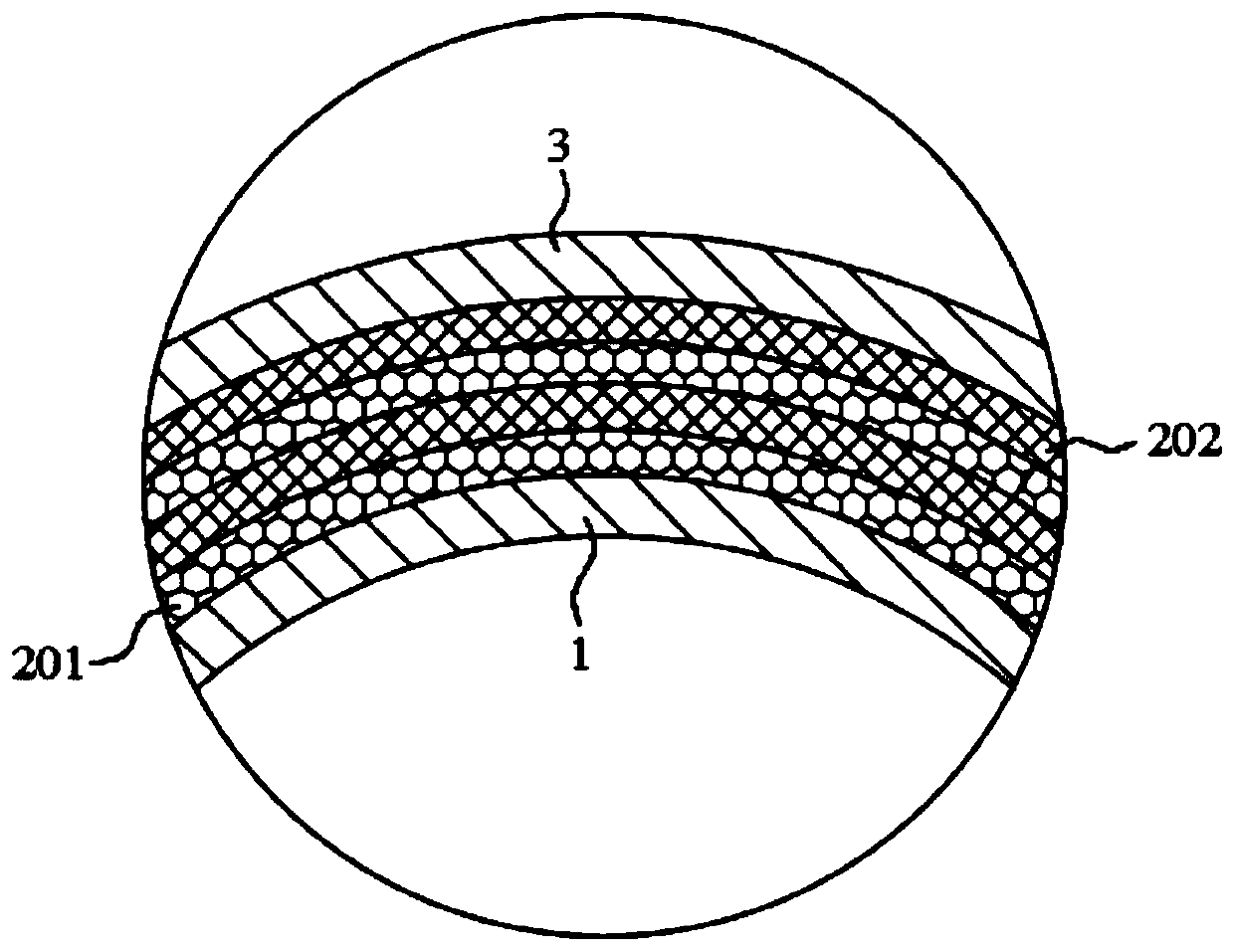

Internal-pressure-resistant fiber weaving, winding and pultrusion composite pipe and preparation method thereof

PendingCN113898798AEnhance the ability to resist internal and external pressureIncrease productivityRigid pipesPipe protection against damage/wearPolymer chemistryPultrusion

The invention relates to the technical field of pressure-resistant pipelines, in particular to an internal-pressure-resistant fiber weaving, winding and pultrusion composite pipe. The composite pipe sequentially comprises an anti-leakage layer, an annular winding layer and a fiber weaving layer from inside to outside in a composite mode, the anti-leakage layer is composed of anti-leakage fibers cured through gum dipping first thermosetting resin, and the annular winding layer and the fiber weaving layer are subjected to pressurized gum dipping by second thermosetting resin and are simultaneously cured with the first thermosetting resin to form an integrated structure. The invention further discloses a preparation method of the internal-pressure-resistant fiber weaving, winding and pultrusion composite pipe. The preparation method sequentially comprises the steps of inner layer preimpregnation, annular winding, outer layer weaving, secondary gum dipping and curing and pultrusion. According to the composite pipe and the preparation method thereof, through pressurized gum dipping of the second thermosetting resin, gaps among the anti-leakage layer, the annular winding layer and the fiber weaving layer and respective gaps are effectively filled, so that the three parts of a pipe body are cured into a whole.

Owner:江西致通管业有限公司

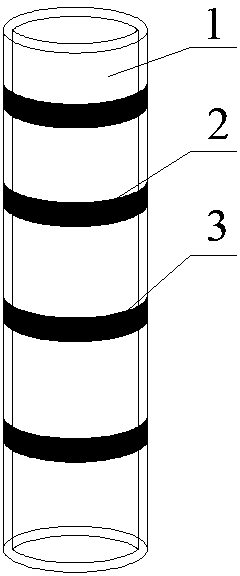

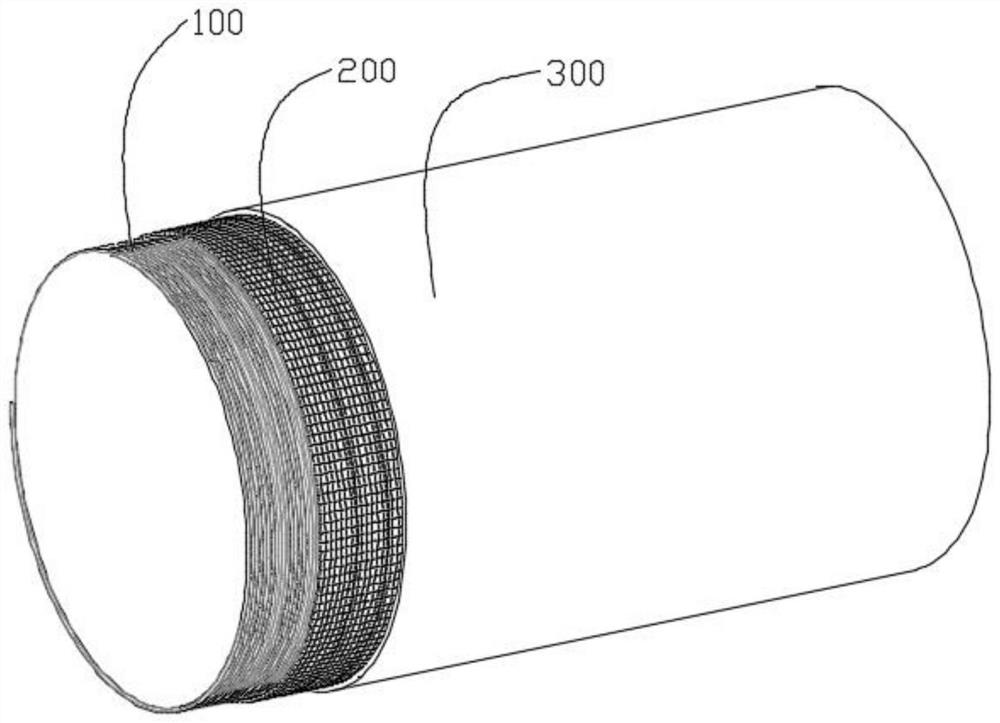

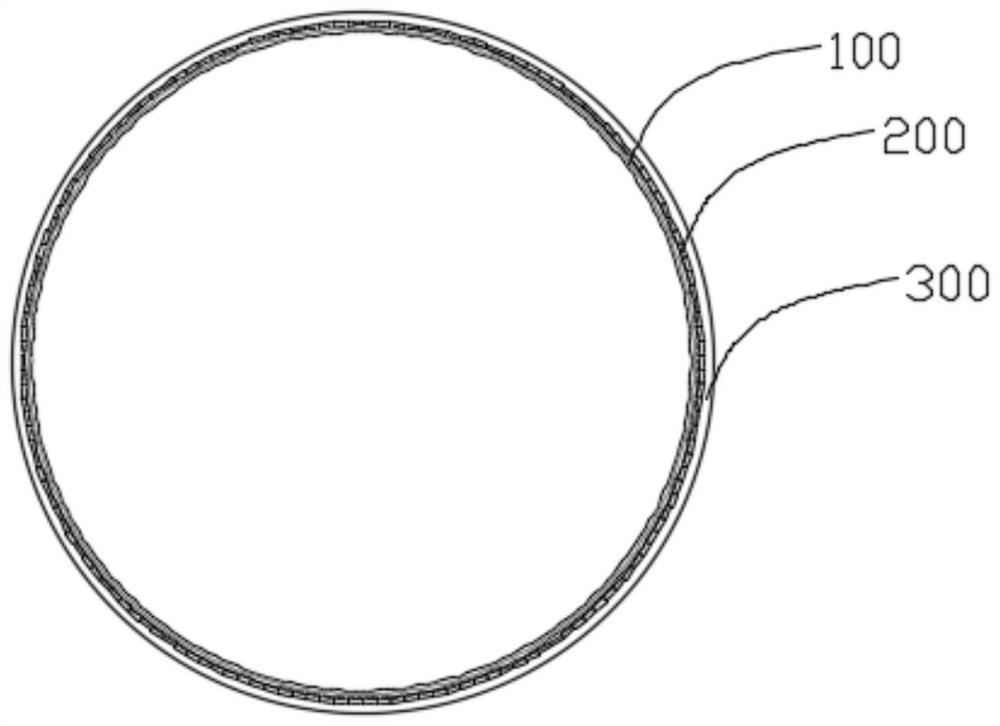

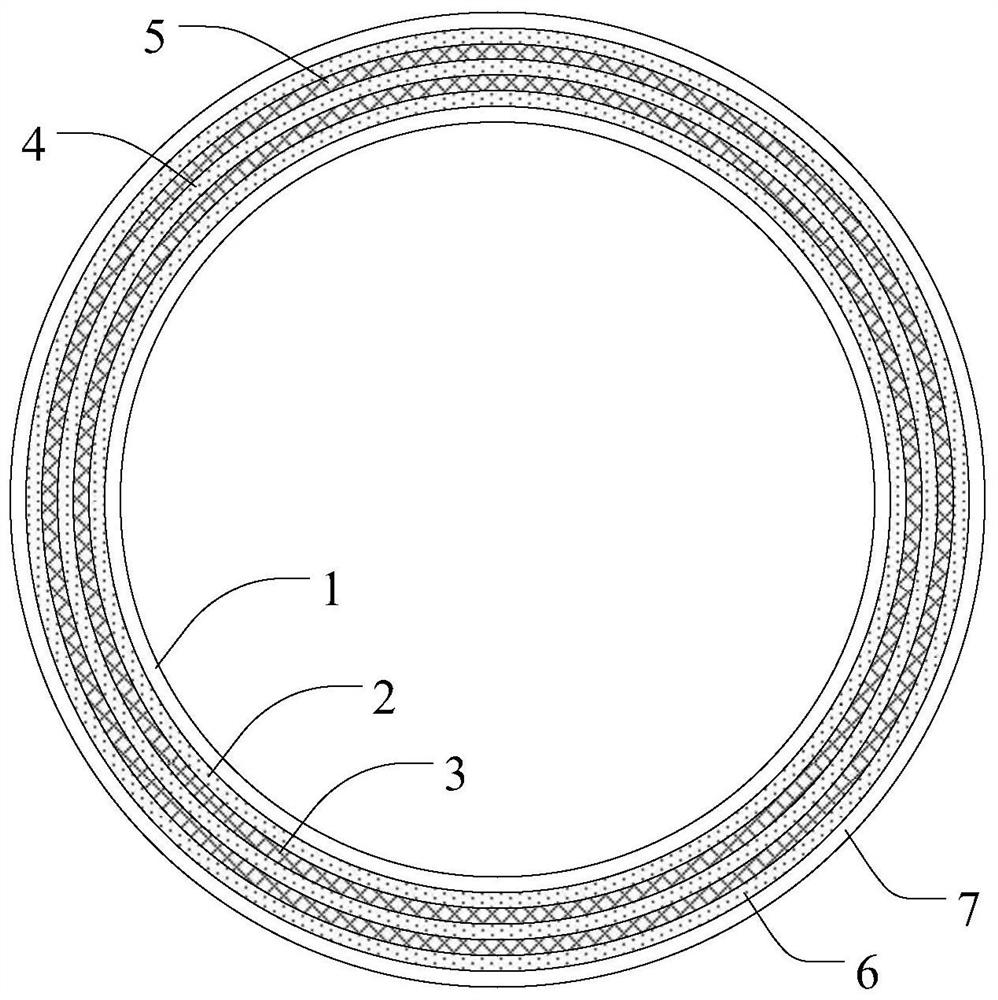

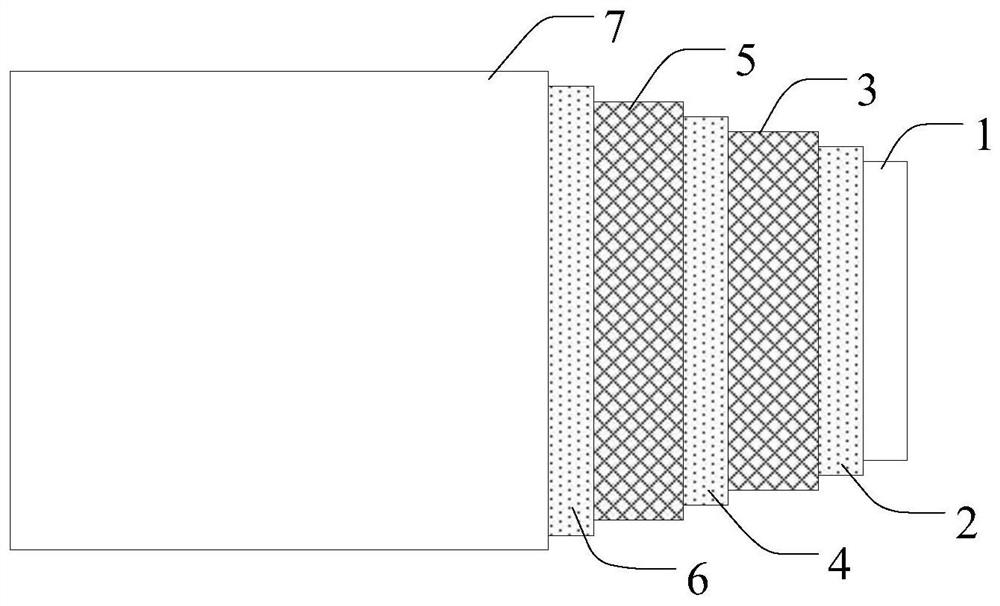

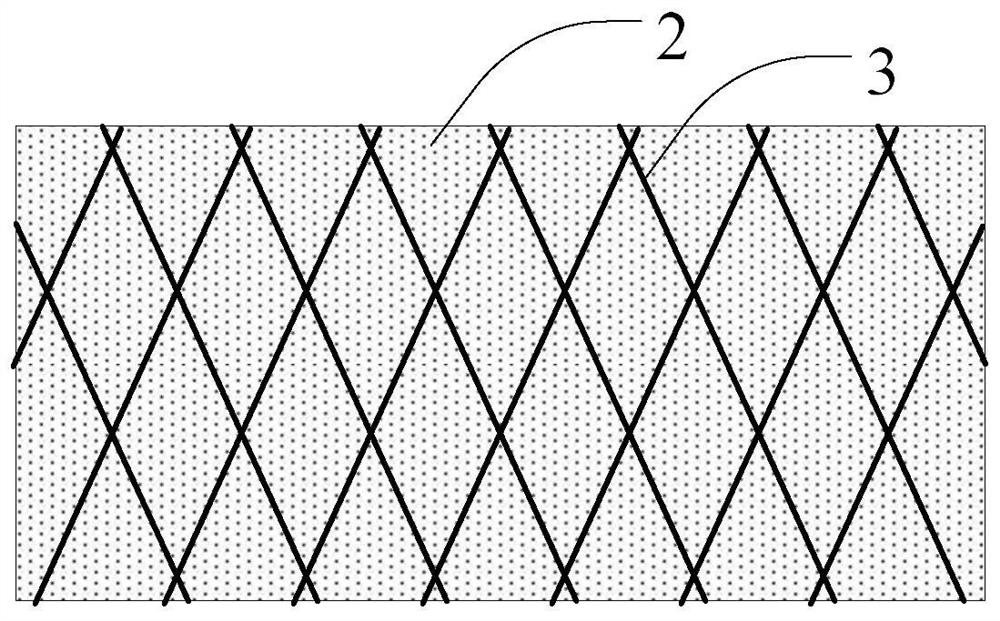

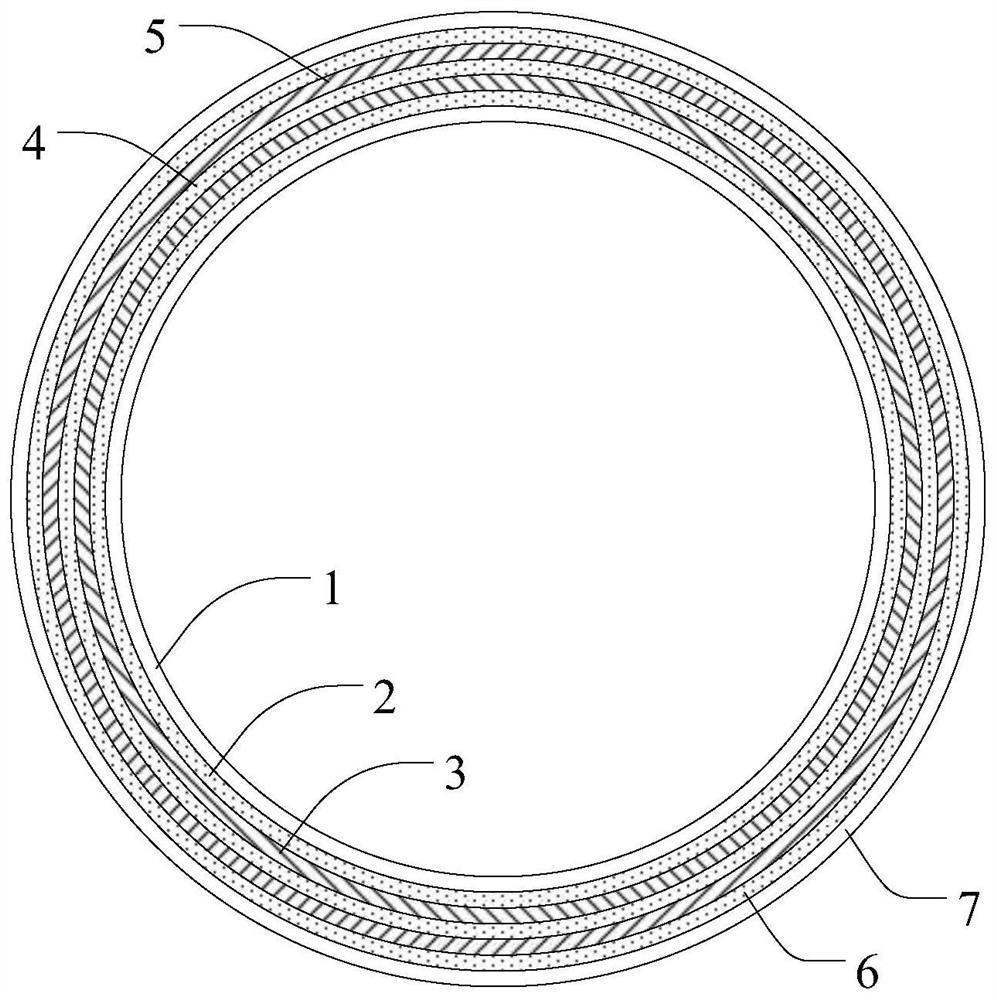

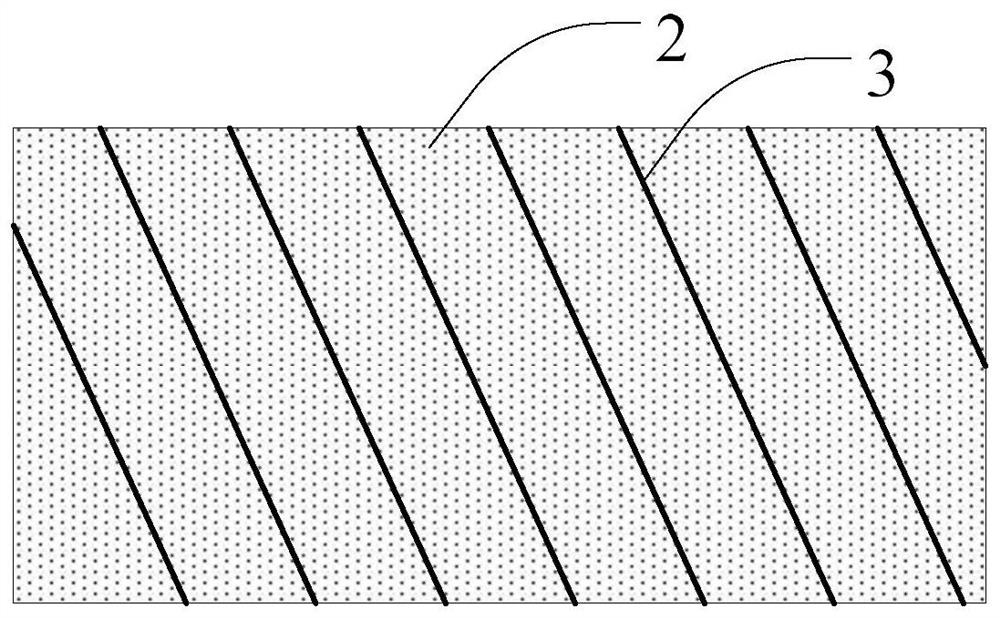

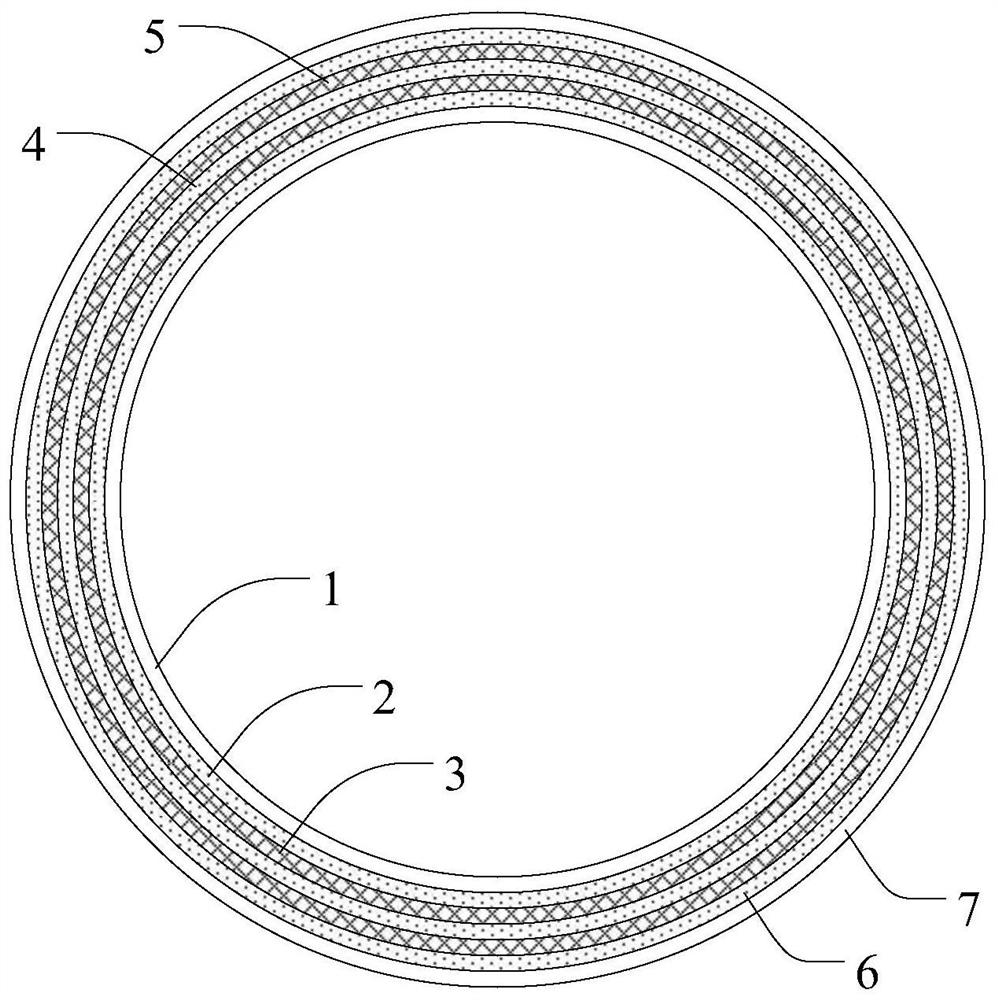

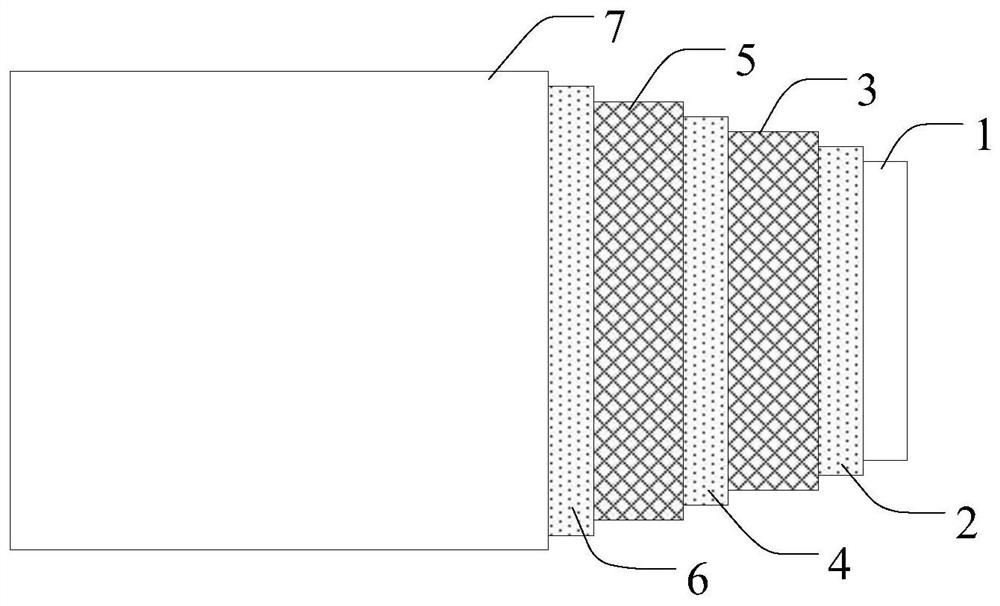

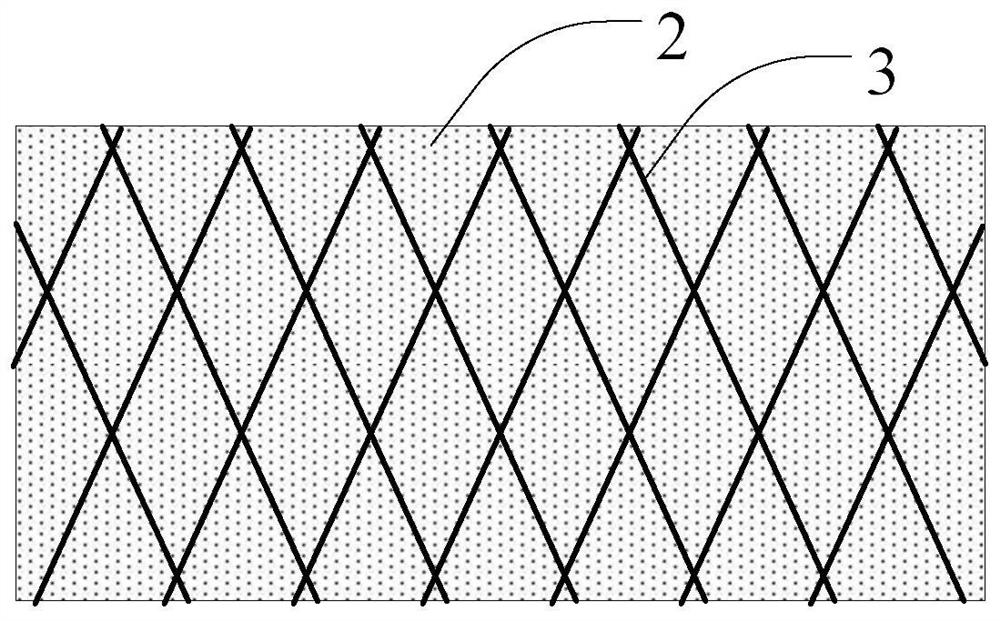

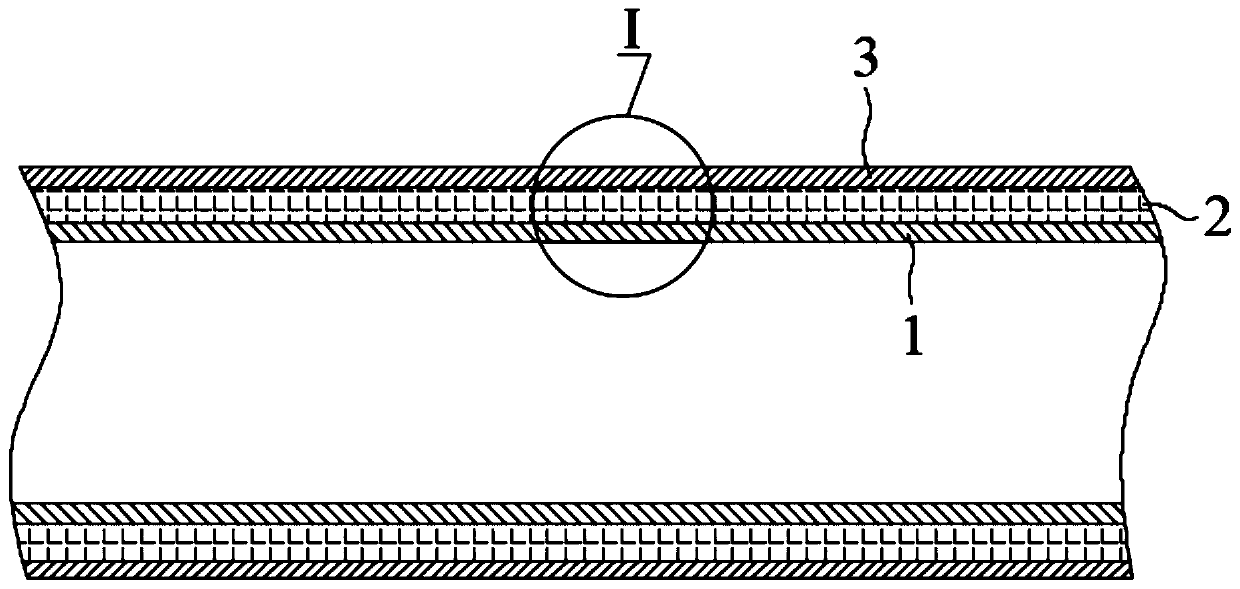

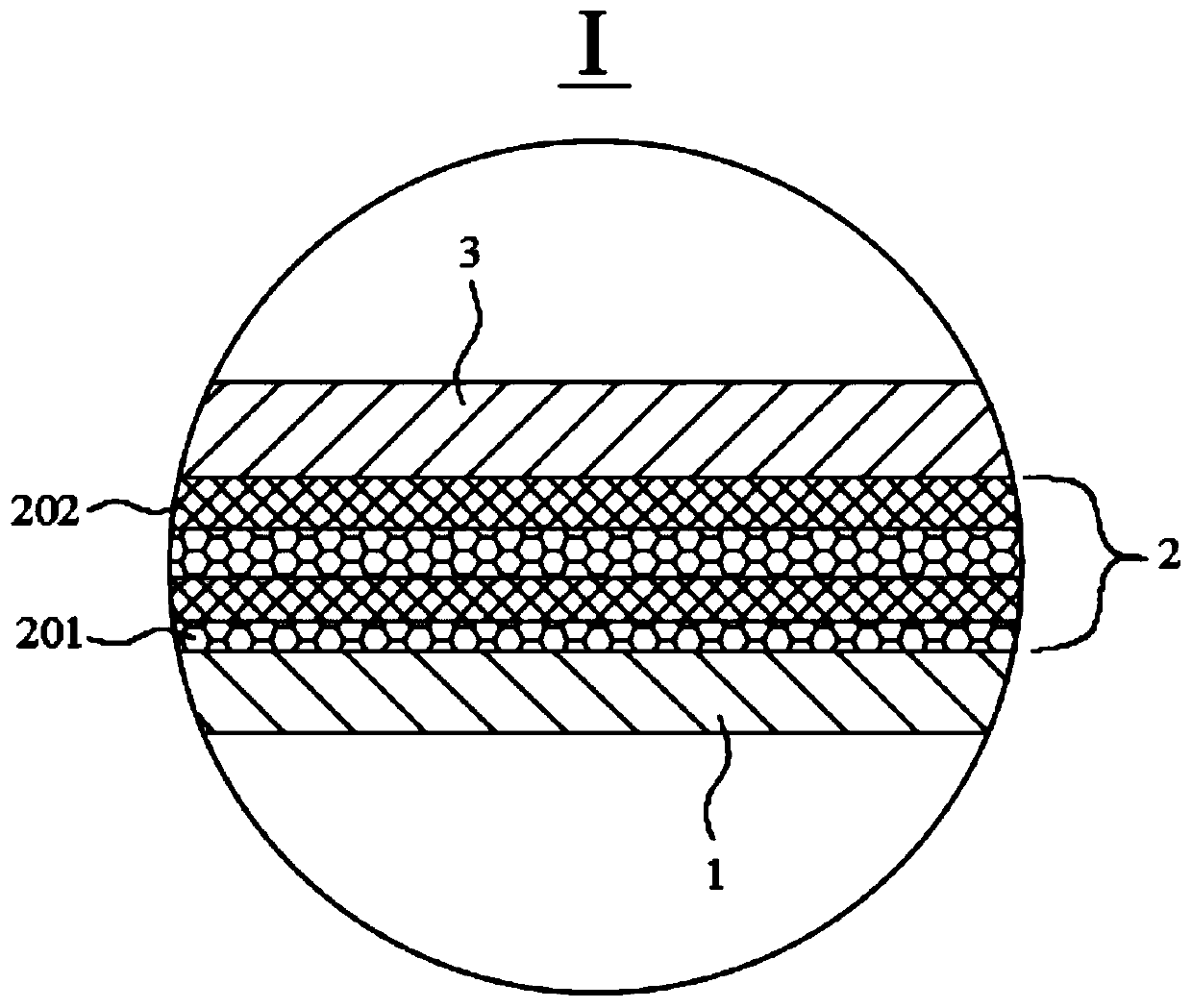

Multilayer steel wire mesh reinforced composite pipe

ActiveCN112303345AImprove internal pressure resistanceHigh strengthRigid pipesTubular articlesUltimate tensile strengthWire mesh

The invention is applicable to the field of composite pipes, and provides a multilayer steel wire mesh reinforced composite pipe which comprises a plastic pipe, a reinforcing structure and a plastic layer. The plastic pipe is wrapped by the reinforcing structure, the reinforcing structure is wrapped by the plastic layer, and the reinforcing structure comprises a first bonding resin layer, a firststeel wire mesh, a second bonding resin layer, a second steel wire mesh and a third bonding resin layer. The plastic pipe, the bonding resin layers and the steel wire meshes are mutually overlapped toform a multilayer structure, the first bonding resin layer can improve the fixing strength of the first steel wire mesh on the outer surface of the plastic pipe, and the first steel wire mesh and thesecond steel wire mesh are each of a rhombus-shaped net structure and are arranged in a staggered mode in the vertical direction to form a staggered rhombus-shaped net structure with the smaller single rhombus area. By means of the arrangement, the strength and rigidity of internal pressure resistance and external pressure resistance of the multilayer steel wire mesh reinforced composite pipe canbe improved, the pressure resistance is more stable, the pressure resistance is not prone to being lost in the using process, and therefore the service life of the multilayer steel wire mesh reinforced composite pipe is prolonged.

Owner:DENG QUAN PLASTIC TECH HUNAN CO LTD

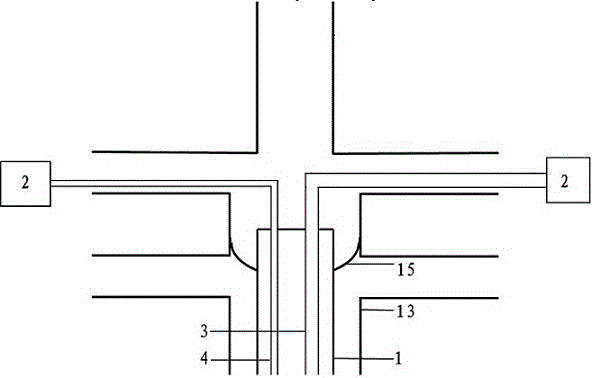

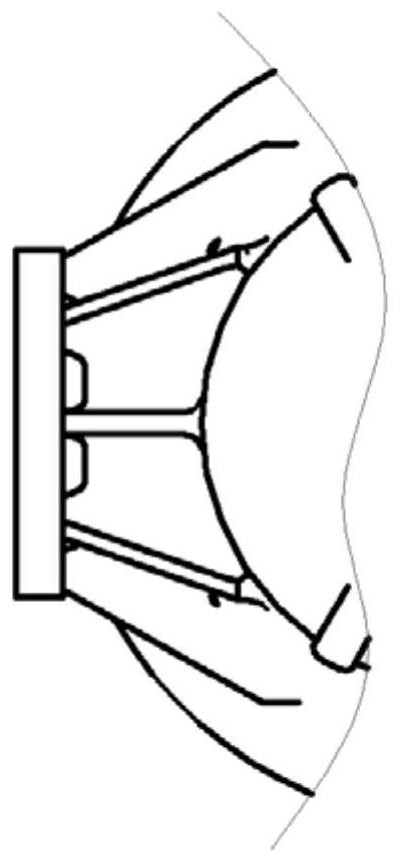

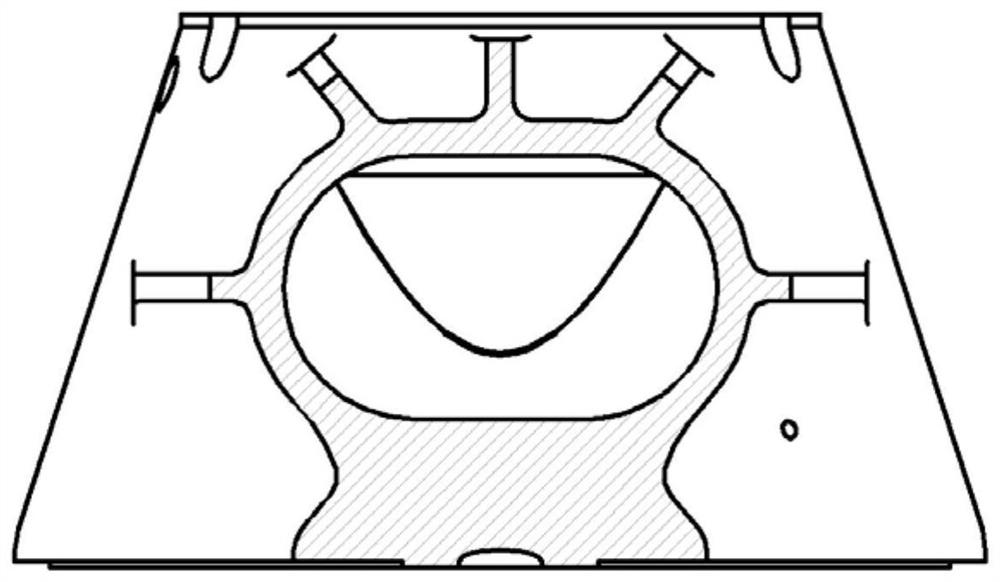

Integrated force-bearing and flow-equalizing top cover device

ActiveCN113738536AReduce weldingSolving Ablation ProblemsRocket engine plantsStructural engineeringTop cap

The invention provides an integrated force-bearing and flow-equalizing top cover device, which comprises a butt flange, an inlet section, a top cover, a force-bearing device, a rectifying device and supporting ribs; a port of the butt flange is a propellant inlet, the butt flange is connected with the top cover through an inlet section, the radial supporting ribs are arranged around the inlet section, and the supporting ribs are connected with the butt flange, the inlet section and the top cover respectively; the upper end of the top cover is connected with the force-bearing device for transmitting thrust; the lower end of the top cover is connected with the rectifying device for ensuring uniform distribution of propellants entering nozzles; the cross section of the top cover passing through the axis is in a double-peak shape, and a center concave cavity is a circular-truncated-cone-shaped platform with a center hole and used for connection and installation of an igniter; the top cover is provided with a radial window for operating and installing the igniter or leading out an igniter cable; and the top cover is also provided with a hoisting hole for hoisting. The integrated force-bearing and flow-equalizing top cover device provided by the invention can bear internal pressure, can transmit thrust, is high in pressure and flow distribution uniformity, and is integrally formed without welding.

Owner:BEIJING AEROSPACE PROPULSION INST

Method for producing steel-plastic multi-element composite pipes

ActiveCN102230554BPrevent looseningImprove deformation resistanceRigid pipesTubular articlesFiberPolyvinyl chloride

The invention provides a method for producing steel-plastic multi-element composite pipes, which comprises the following steps of: modifying high-density polyethylene (HDPE) or polyvinyl chloride (PVC) plastics and manufacturing plastic plate strips; manufacturing hollow reinforcing ribs of which two side edges are recessed and overlapped; welding notches of the recessed bottoms of the reinforcing ribs by using continuous welding equipment; synchronously winding the welded reinforcing ribs with the plastic plate strips to form an inner wall of a pipe; coating and rolling on the wound pipe wall; coating a fiber mesh or winding a fiber strip and rolling on the rolled pipe wall; coating and rolling on a fiber layer to form an outer wall of the pipe; cutting the pipe which is finished in the seventh step at fixed length; sealing a port of each reinforcing rib at one end of the cut pipe, and injecting prepared cement slurry into each square reinforcing rib at the other end of the pipe by using grouting equipment; and finally, vertically erecting and fixing the pipe which is injected with the cement slurry, so that the cement slurry is solidified to form a finished pipe. The invention has the advantages that: the pipe can resist internal and external pressures and prevent cracking, an expansion on heating and contraction on cooling coefficient of the pipe is reduced, and the reinforcing ribs are prevented from rusting.

Owner:娄底市朝阳塑胶有限公司

Differential method tubular product radial stretching equipment and method

The invention belongs to the field of tubular product stretching, and relates to differential method tubular product radial stretching equipment and method. An equipment body comprises a closed cylindrical air bag, one end of the air bag is provided with an air nozzle used for air inflation and air deflation of the air bag is arranged at one end of the air bag, a plurality of steel bars distributed in the axial direction of the air bag are evenly fixed to the outer surface of the air bag, the outmost side of the equipment body is provided with an electromagnetic device wrapping the air bag andthe steel bars, and the tubular product containing position is located between the electromagnetic device and the steel bars wrapping the surface of the air bag. According to the equipment and method, through mutual cooperation of the electromagnetic device, the air bag and the steel bars, a tube wall is firstly divided into a plurality of small units equally in the tubular product stretching process, and it is guaranteed that the pipe wall can be evenly stretched. After tubular products are stretched in the radial direction and the axial direction, the toughness and the inner pressure resistance of the tubular products are strengthened. The equipment is reasonable in structure and convenient to operate; and the method of conduct stretching through the equipment is simple and convenient,operation is easier, the beneficial effect of saving time and labor are achieved, and the tubular product stretching working efficiency is improved.

Owner:SHANDONG BOYUAN COMPOSITE MATERIALS TECH CO LTD

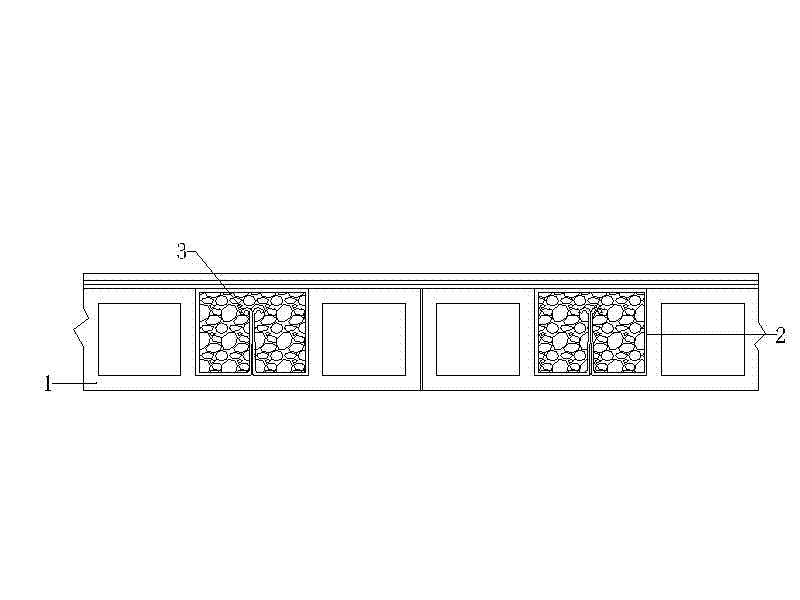

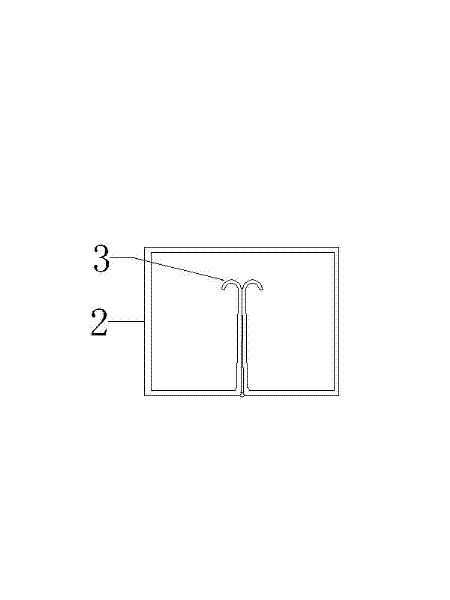

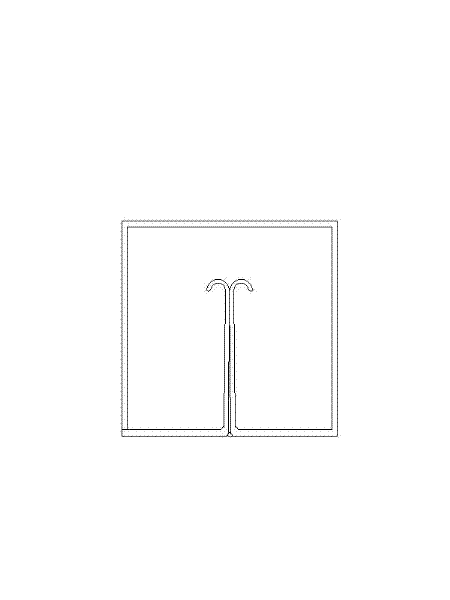

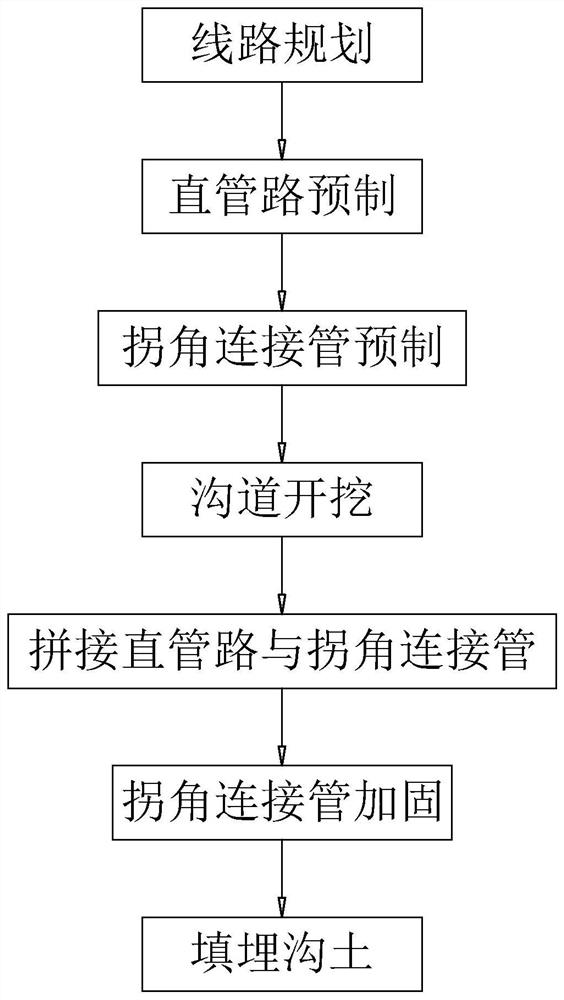

Municipal pipeline laying construction process

ActiveCN113073696AAvoid deformationAchieving shape fixationPipe laying and repairClimate change adaptationStraight tubeArchitectural engineering

The invention relates to a municipal pipeline laying construction process. The process comprises the following steps of S1, route planning, wherein a construction route is planned; S2, straight pipeline prefabrication, wherein a straight pipeline is prefabricated according to the constructed route; S3, corner connecting pipe prefabrication, wherein a corner connecting pipe is prepared, and the corner connecting pipe comprises two connecting discs and at least one stainless steel hose fixedly connected between the two connecting discs; S4, trench excavation, wherein an outer trench is excavated according to the construction route; S5, straight pipeline and corner connecting pipe splicing, wherein the straight pipeline and the corner connecting pipe are connected and sealed; S6, corner connecting pipe reinforcing, wherein the outer side of the corner connecting pipe is sleeved with a polymer hose, concrete is injected into the polymer hose, the outer side of the stainless steel hose of the corner connecting pipe is wrapped with the concrete, and the concrete is waited to be condensed; and S7, trench soil filling, wherein the trench is filled with soil. The process has the effects that the connection of the corner connecting pipe and the straight pipeline is guaranteed, and the situation that the straight pipeline connection is affected by prefabrication errors is avoided.

Owner:北京华业恒基工程项目管理有限公司

Steel wire mesh reinforced composite pipe

PendingCN112303346AImprove internal pressure resistanceHigh strengthRigid pipesTubular articlesExternal pressurePressure resistance

The invention is applicable to the field of composite pipes, and provides a steel wire mesh reinforced composite pipe which comprises a plastic pipe, a reinforcing structure and a plastic layer. The plastic pipe is coated with the reinforcing structure, and the reinforcing structure is coated with the plastic layer. The reinforcing structure comprises a first bonding resin layer, a first steel wire layer, a second bonding resin layer, a second steel wire layer and a third bonding resin layer, the plastic pipe, the bonding resin layers and the steel wire layers are stacked to form a multilayerstructure, and the first bonding resin layer can improve the fixing strength of the first steel wire layer on the outer surface of the plastic pipe. The first steel wire layer and the second steel wire layer are respectively formed by spirally winding independent steel wires and form a rhombic net-shaped structure in the vertical direction, so that strength and rigidity of the internal pressure resistance and the external pressure resistance of the steel wire mesh reinforced composite pipe can be improved, the pressure resistance is more stable, the pressure resistance is not liable to lose inthe use process, and therefore, the service life of the steel wire mesh reinforced composite pipe is prolonged.

Owner:DENG QUAN PLASTIC TECH HUNAN CO LTD

Preparation process of cover glass of wet-type water meter

ActiveCN106746609AThe preparation process is simple to operateCompatibility is reasonableGlass shaping apparatusVolume meteringChemistryCover glass

The invention discloses a preparation process of cover glass of a wet-type water meter. The preparation process comprises the following steps: step 1), preparing a component A; step 2), preparing a component B; step 3), preparing a component C; step 4), preparing a glass plate; and step 5), preparing cover glass. The preparation process of cover glass of a wet-type water meter in the invention is simple to operate, and suitable for large-scale production, and the cover glass produced is excellent in property.

Owner:天津市金凤来仪科技有限公司

A multi-layer steel wire mesh reinforced composite pipe

ActiveCN112303345BImprove internal pressure resistanceHigh strengthRigid pipesTubular articlesUltimate tensile strengthWire mesh

The invention is applicable to the field of composite pipes, and provides a multilayer steel wire mesh reinforced composite pipe, including a plastic pipe, a reinforcement structure and a plastic layer; the reinforcement structure covers the plastic pipe, the plastic layer covers the reinforcement structure, and the reinforcement structure Including the first bonding resin layer, the first steel wire mesh, the second bonding resin layer, the second steel wire mesh and the third bonding resin layer, the present invention adopts plastic pipes, bonding resin layers and steel wire mesh to overlap each other to form a multi-layer structure, the first bonding resin layer can improve the fixing strength of the first steel mesh on the outer surface of the plastic pipe, the first steel mesh and the second steel mesh both have a diamond-shaped mesh structure, and are staggered in the vertical direction to form a single diamond-shaped area Smaller staggered diamond-shaped mesh structure, this setting can improve the internal pressure and external pressure resistance and stiffness of the multi-layer steel mesh reinforced composite pipe, and the pressure resistance is more stable, and it is not easy to lose the compressive strength during use. Thereby prolonging the service life of the multi-layer steel wire mesh reinforced composite pipe.

Owner:DENG QUAN PLASTIC TECH HUNAN CO LTD

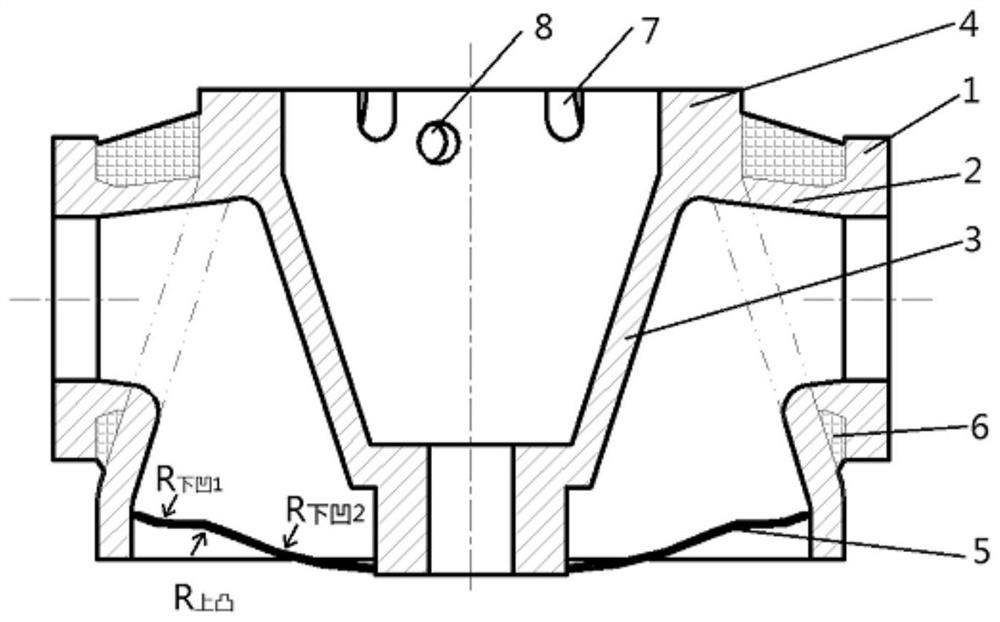

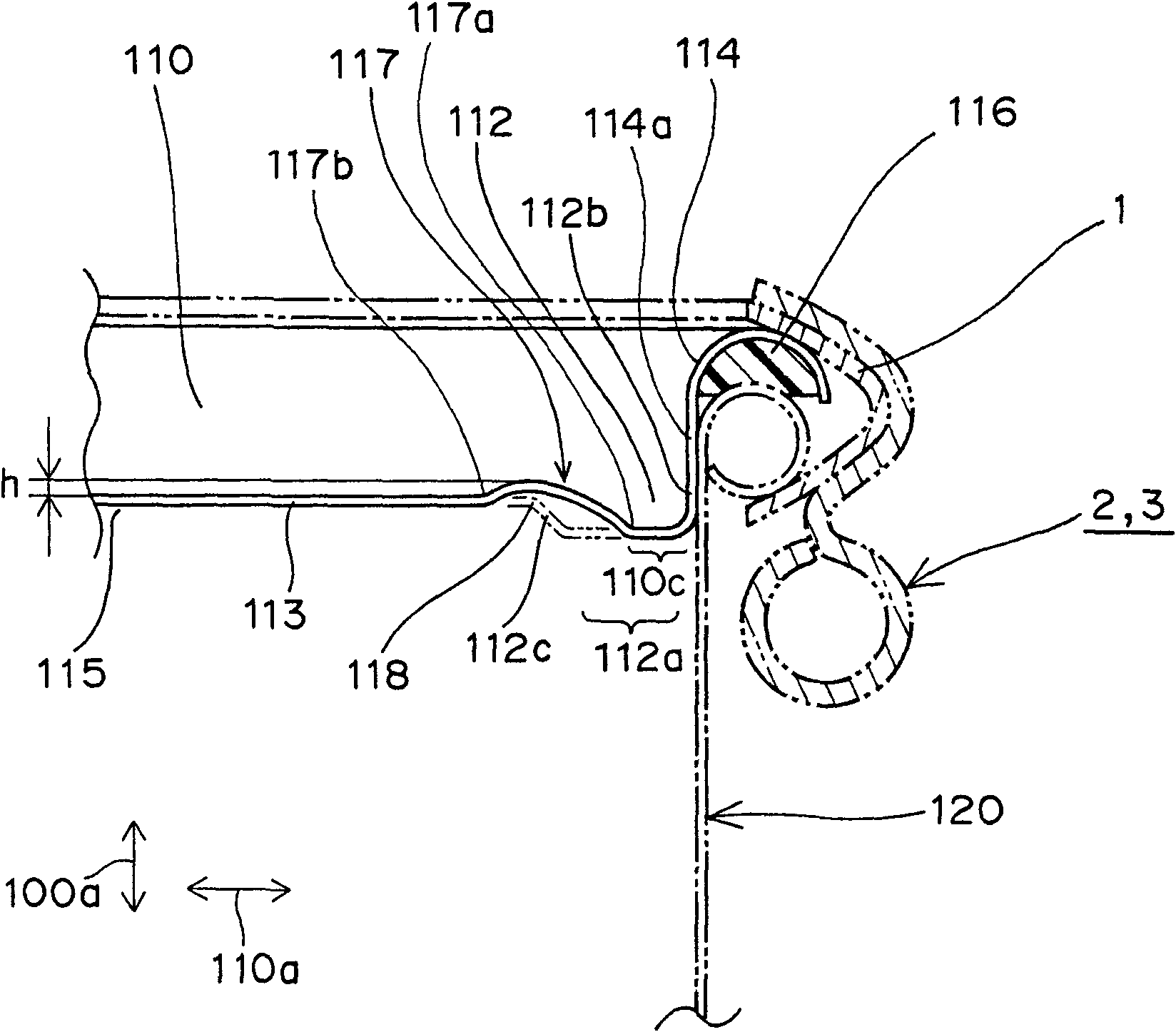

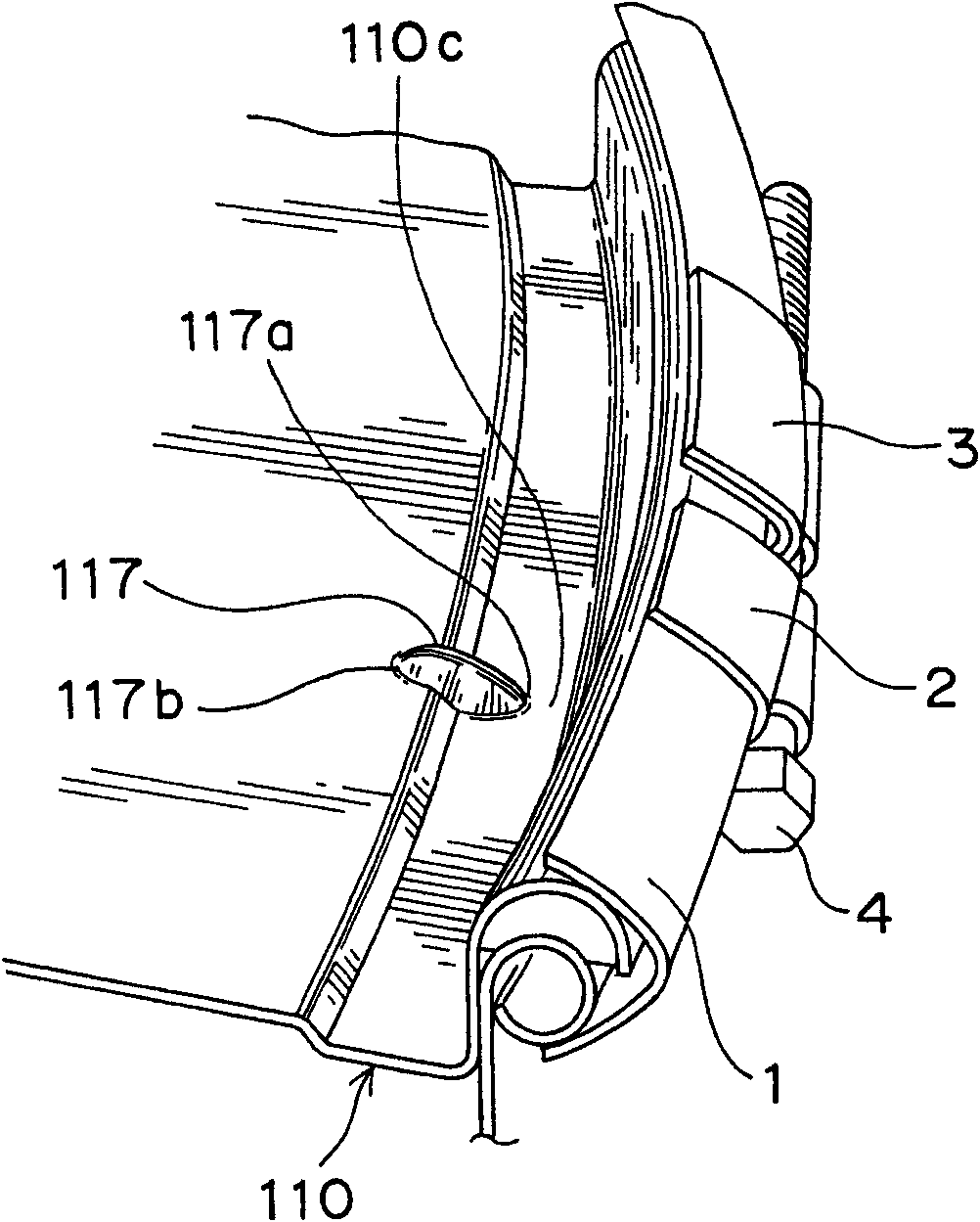

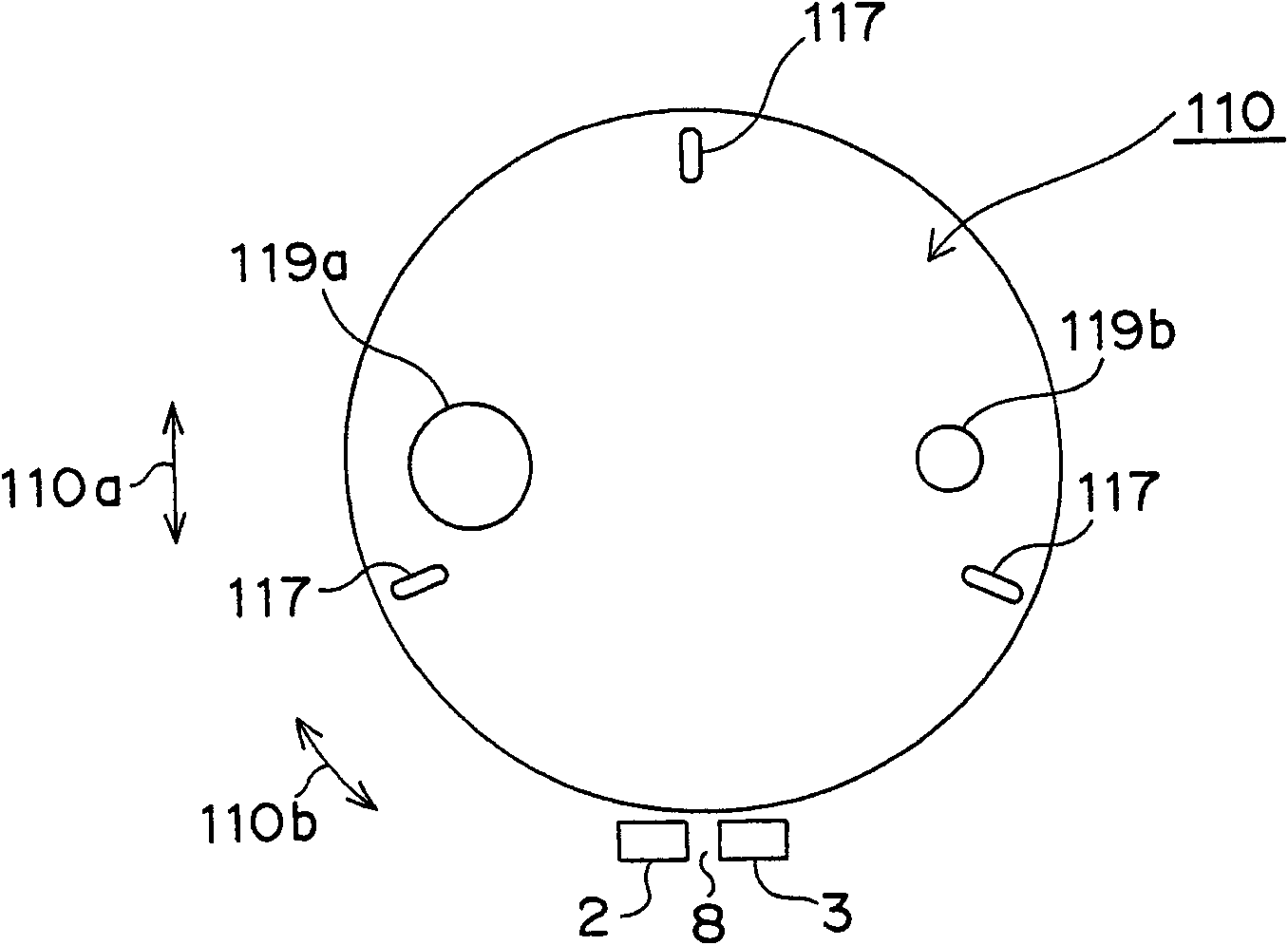

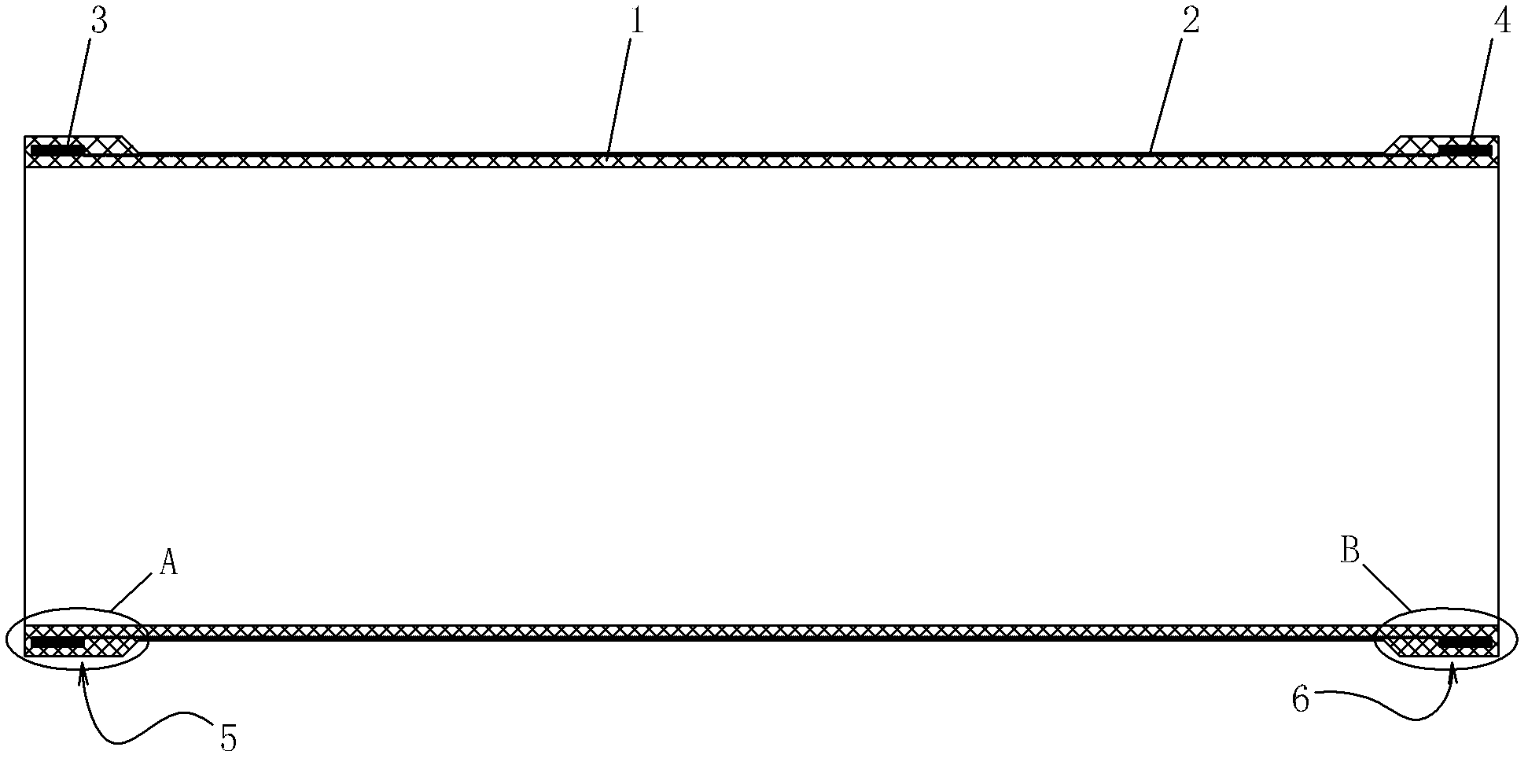

Top cover for a metal drum and metal drum

ActiveCN101786518AImprove internal pressure resistanceSmall amount of deformationRemovable lids/coversRigid containersInternal pressureStress concentration

The invention provides a top cover for a metal drum. For a top cover 110, when the inner pressure of the metal drum rises, a deformation inducement part 117 for generating the deformation is formed at the desired parts along the perimeter of the top cover. Thus when the inner pressure of the metal drum rises, the stress on the top cover is prevented from concentrating on one part of the top coverand dispersed for many deformation inducement parts. Compared with the prior technology, the inner pressure resistance performance of the metal drum is increased.

Owner:JFE CONTAINER

Steel reinforced polyurethane (PE) water supply pipe and connection structure

InactiveCN102359669AAvoid deformation out of roundReduce installation difficultyRigid pipesPipe connection arrangementsPressure resistanceWater supply

The invention discloses a steel reinforced polyurethane (PE) water supply pipe. At least one layer of steel mesh is embedded into the pipe wall of a pipe body; pipe walls at interface positions of two ends of the pipe body are thickened walls; and steel rings are embedded into the thicken walls. The invention also discloses a steel reinforced PE water supply pipe connection structure. The connection structure comprises two water supply pipes, wherein one end interface of the first water supply pipe is welded and fixed with one end interface of the second water supply pipe. Through the scheme, the thickened walls and the steel rings are formed at connection positions to keep the roundness of a pipe orifice, the requirement of welding difficulty is reduced, pressure resistance is improved, service life is prolonged, and deformation and water leakage are avoided.

Owner:ZHEJIANG SHUANGLIN ELECTROMECHANICAL TECH

Polyethylene steel and plastic composite winding pipe

InactiveCN103185178AIncreased ring stiffnessReduce weightRigid pipesInternal pressureComposite plate

The invention relates to a polyethylene steel and plastic composite winding pipe. A pipe body of the composite winding pipe is wound and formed by steel and plastic composite plate belt materials, the adjacent steel and plastic composite plate belt materials are welded by adopting a metal welding process, a polyethylene resin covering layer is covered on a welding line between the adjacent steel and plastic composite plate belt materials, and V-shaped reinforced steel ribs are wound and embedded between T-shaped caps arranged at the outer wall of the pipe body. The pipe body of the polyethylene steel and plastic composite winding pipe is wound and formed by the steel and plastic composite plate belt materials, the complete pipe is welded by the steel belts inside the pipe wall to be used as the internal pressure resistance support pipe, the internal pressure resistance level of a large-caliber plastic pipe is greatly improved, meanwhile, compared with a plastic pipe, the polyethylene steel and plastic composite winding pipe has higher annular rigidity, the pipe wall of the steel belt welding pipe is completely covered in the polyethylene resin, the corrosion resistance performance is greatly improved, the outer wall adopts the V-shaped reinforced steel bars as a main body for realizing the effect of supporting the external pressure, on the use premise of greatly saving steel and plastics, the annular rigidity of the integral pipe material is greatly improved, in addition, the weight of the integral pipe materials is light, and the construction and the installation are favorably realized.

Owner:福建亚通新材料科技股份有限公司

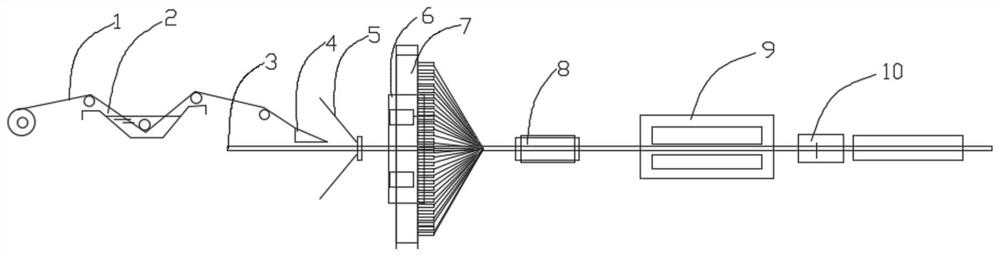

Production process for continuous fiber reinforced composite pipe

InactiveCN111300910AEnhanced creep resistance and internal pressure resistanceReduce the number of winding layersSynthetic resin layered productsGlass/slag layered productsManufacturing engineeringFiber-reinforced composite

The invention discloses a production process for a continuous fiber reinforced composite pipe. The production process comprises the following process steps: molding of an inner pipe, winding and covering of an auxiliary layer, winding of a reinforcing layer, winding of a functional layer, molding of an anti-abrasion layer, winding of an axial tensile layer, winding of a functional isolation layerand molding of an outer protective layer. Compared with a conventional production process for the continuous fiber reinforced composite pipe, the production process provided by the invention has the following advantages: the inner pipe is wound with industrial filaments, so the creep resistance and the internal pressure resistance of the inner pipe are enhanced; when the pressure is low, the winding layer number of the reinforcing layer is reduced; the requirements on angular tolerance and clearance during winding of the reinforcing layer are reduced; the controllability of a pressure pipelinein production is enhanced; the raw material cost of a product is reduced; and the axial loading capacity of a pipe material is enhanced, and the pipe material can be generally used for marine pipelines, jumper pipelines and pressure pipelines in dynamic and non-dynamic environments.

Owner:杭州智海人工智能有限公司

A kind of equipment and method for radial stretching of pipe material by differential method

The invention belongs to the field of pipe stretching, and relates to a differential pipe radial stretching device and method. The equipment body includes a closed cylindrical airbag, and one end of the airbag is provided with an air nozzle for inflating and deflating the airbag; the outer surface of the airbag is uniformly fixed with a plurality of bars distributed along the axial direction of the airbag; the most An electromagnetic device covering the airbag and steel bar is arranged on the outside, and the pipe is placed between the electromagnetic device and the steel bar covering the surface of the airbag. In the present invention, the mutual cooperation of the electromagnet, the air bag and the bar steel realizes that in the stretching process of the pipe, the pipe wall is firstly divided into several small units to ensure that the pipe wall can be stretched evenly. After the pipe is stretched both radially and axially, its toughness and ability to resist internal pressure are enhanced. The structure of the device is reasonable and the operation is convenient; the stretching method using the device is simple and easy to operate, has the advantages of saving time and labor, and improves the efficiency of pipe stretching work.

Owner:SHANDONG BOYUAN COMPOSITE MATERIALS TECH CO LTD

Wet-type water meter

ActiveCN106746610ACompatibility is reasonableImprove internal pressure resistanceGlass shaping apparatusVolume meteringCalciteTransmittance

The invention belongs to the technical field of instruments and meters, and discloses a wet-type water meter comprising a meter shell and cover glass on the top of the meter shell, wherein the cover glass is prepared from the following raw materials: cryolite, potassium permanganate, flux, zinc oxide, antimony oxide, kaolin, fluorite, calcite, boron oxide, soda ash, and quartz sand. The cover glass of the wet-type water meter in the invention is reasonable in compatibility, and such indices as rupture strength, compression resistance, and light transmittance are all greatly improved.

Owner:临沂瑞新水表有限公司

A frost-proof wet water meter with a watch glass

ActiveCN106706061BGood frost resistanceCompatibility is reasonableVolumetric apparatus damage preventionChemistryWatch glass

The invention belongs to the technical field of instruments and meters and discloses an anti-freezing wet water meter with meter glass, comprising a meter shell, meter glass and a meter enclosure, and the meter glass is fixedly clamped between the meter enclosure and the top of the meter shell; the anti-freezing wet water meter is characterized in that the meter glass is produced via the steps of 1) preparing a cosolvent; 2) crushing, and grinding; 3) stirring and grinding; 4) casting, annealing and cooling; 5) pickling, boiling and cooling. The anti-freezing wet water meter is suitable for use in extreme cold weather; the meter glass has good anti-freezing property and rarely breaks.

Owner:山东智敏仪表科技有限公司

PE (polyurethane) water supply pipe and connection structure thereof

InactiveCN102359689APrevent nozzle deformationReduce installation difficultyPipe connection arrangementsEngineeringWater supply

The invention discloses a PE (polyurethane) water supply pipe, which is provided with a jack end and a socket end, wherein at least one layer of steel mesh is buried in the pipe wall; a jack steel ring is fixed on the outer wall of the jack end; the outer surface of the jack steel ring is provided with an annular seal groove used for sleeving of a seal ring; and a socket steel ring is fixed on the inner wall of the socket end. The invention also discloses a connection structure of the PE water supply pipe, comprising two PE water supply pipes, wherein the jack end of the second PE water supply pipe is inserted into the socket end of the first PE water supply pipe, and a seal ring is arranged between the jack steel ring of the second PE water supply pipe and the socket steel ring of the first PE water supply pipe. The connection structure provided by the invention has the advantages of convenience for pipeline installation and connection, reduced installation difficulty and installation cost, difficulty in deformation and water leakage, greatly-prolonged service life and capability of realizing connection of more than 3m of large-caliber water supply pipe.

Owner:ZHEJIANG SHUANGLIN ELECTROMECHANICAL TECH

High-strength fiber pultrusion pipeline

PendingCN110239154AGuaranteed integrityGuaranteed performanceGlass/slag layered productsGlass fiberPerformance index

The invention discloses a high-strength fiber pultrusion pipeline. The high-strength fiber pultrusion pipeline is prepared from a dip dyeing thermosetting base body; the dip dyeing thermosetting base body comprises a fiber integral body layer with a circular cross section; a plurality of radially-distributed fiber filaments are arranged on the external side of the fiber integral body layer; the external sides of the radially-distributed fiber filaments are provided with a twining layer; the external side of the twining layer is provided with a strengthening layer; the twining layer comprises a glass fiber layer used for forward twining and a glass fiber layer used for backward twining. The tearing resistance and the shock resistance of the high-strength fiber pultrusion pipeline reaches industry required standard values. According to the high-strength fiber pultrusion pipeline, the performance indexes of the high-strength fiber pultrusion pipeline are ensured to reach the standards, and pultrusion pipeline production efficiency is increased, and production cost is reduced at the same time.

Owner:江苏华盟新型材料科技有限公司

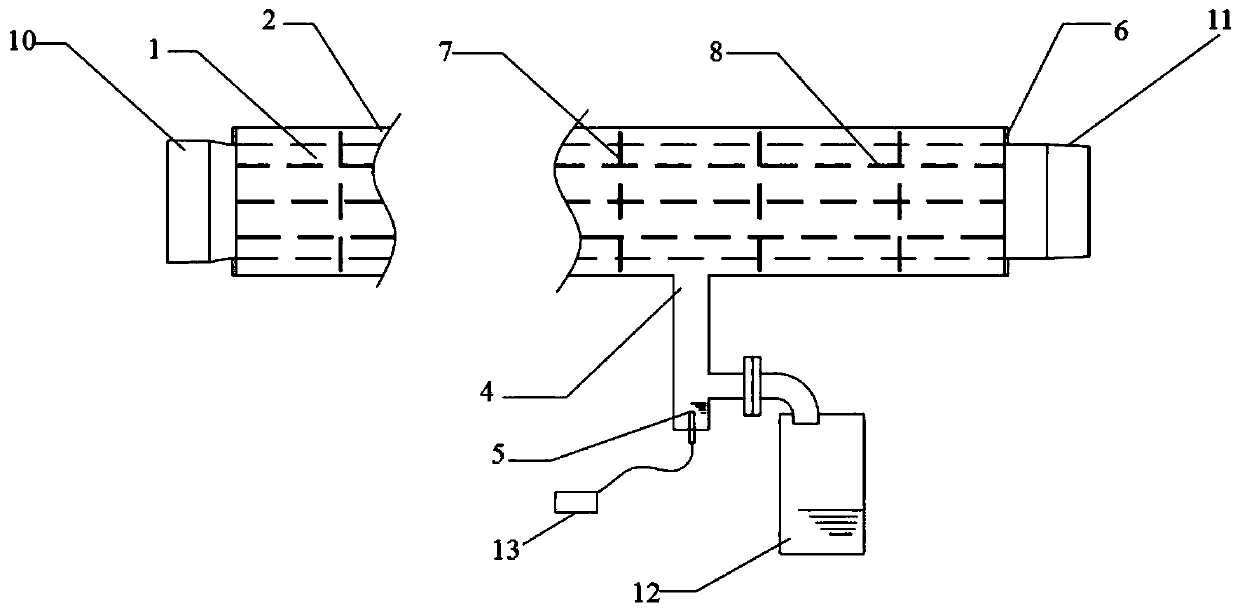

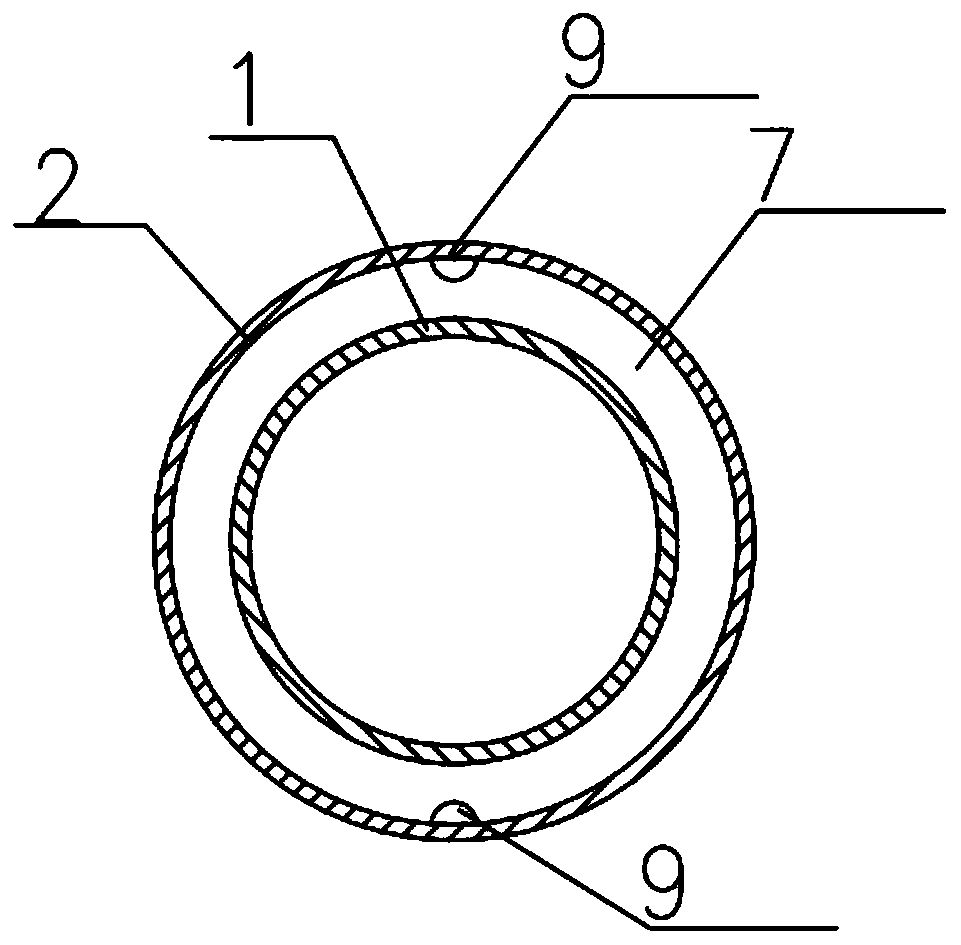

Double-wall glass fiber reinforced plastic pipeline and pipeline assembly

PendingCN110701395APrevent mutual rotationPrevent tamperingPipeline systemsRigid pipesGlass fiberPollution

The invention discloses a double-wall glass fiber reinforced plastic pipeline and a double-wall glass fiber reinforced plastic pipeline assembly. The double-wall glass fiber reinforced plastic pipeline comprises an inner pipe and an outer pipe which sleeves the inner pipe. A pipe cavity is formed between the inner pipe and the outer pipe. Supporting plates are arranged between the inner pipe and the outer pipe and fixedly connected with the outer wall of the inner pipe. The double-wall glass fiber reinforced plastic pipeline assembly comprises multiple double-wall glass fiber reinforced plastic pipelines which are connected with each other. Multiple liquid discharging outlets are formed in the outer pipe wall of the double-wall glass fiber reinforced plastic pipeline assembly and communicate with the pipe cavities. Detection probes are arranged in the liquid discharging outlets. The double-wall glass fiber reinforced plastic pipeline comprises a double-wall structure, the double-wall glass fiber reinforced plastic pipeline assembly, a liquid collecting device and a detection and warning system can be combined and used, the multiple functions of leakage prevention, warning, positioning, collection and the like are integrated, the recovery of leaking media is facilitated, and the pollution to the environments such as the soil and the atmosphere can be avoided.

Owner:NANJING XINHE COMPOSITES CO LTD +1

Method of spraying mortar composite inner lining of steel cylinder with hanging net and non-excavation repair of pressure pipeline

Owner:漳州安越新材料科技有限公司

Bamboo-hemp winding composite pressure pipe and preparation method thereof

PendingCN110645419AImprove internal pressure resistanceIncreased ring stiffnessCane mechanical workingWood working apparatusExternal pressureHemp fiber

The invention discloses a bamboo-hemp winding composite pressure pipe and a preparation method thereof, and belongs to the technical field of bamboo composite pipelines. A liner layer, a structure layer and an outer protection layer are sequentially arranged on the bamboo-hemp winding composite pressure pipe in the radial direction. The structure comprises at least one hemp winding unit and at least one bamboo winding unit, each hemp winding unit comprises at least two hemp fibers formed by winding and bonding hemp fiber curtains, and each bamboo winding unit comprises at least two axial bamboo skin layers formed by winding and bonding bamboo skin curtains. Meanwhile, the sum of the numbers of the hemp fiber layers and the axial bamboo skin layers in the structure layer is not smaller than6. The bamboo-hemp winding composite pressure pipe is simple in structure, the preparation method is convenient and rapid, the performance advantages of bamboo materials and hemp materials can be fully achieved, the composite pressure pipe has good internal pressure resisting capacity and excellent external pressure resisting capacity, the ring stiffness and bending resisting capacity of the composite pressure pipe are greatly improved, the application range of the pipe is effectively widened, and good practical value is achieved.

Owner:中林鑫宙竹缠绕发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com