PE (polyurethane) water supply pipe and connection structure thereof

A water supply pipe and pipe wall technology, which is applied in the direction of pipe connection arrangement, pipe/pipe joint/pipe fittings, mechanical equipment, etc., can solve the problems of inconsistent PE pipe insertion depth, increased welding difficulty, pipe diameter limitation, etc., to reduce the number of on-site Large-scale welding equipment, saving investment and energy consumption, and reducing the effect of installation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

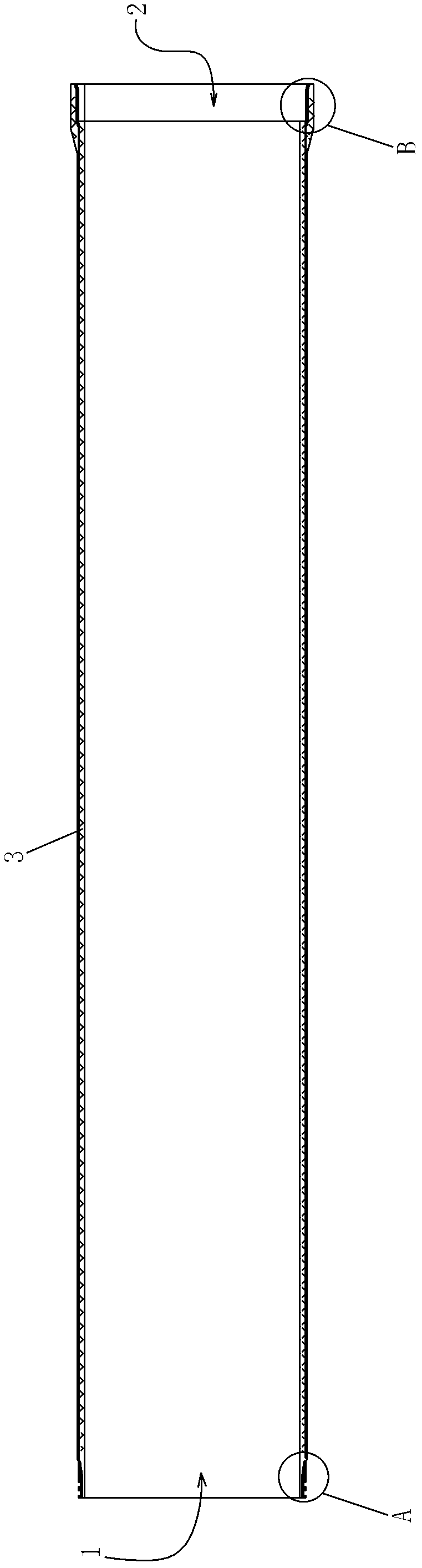

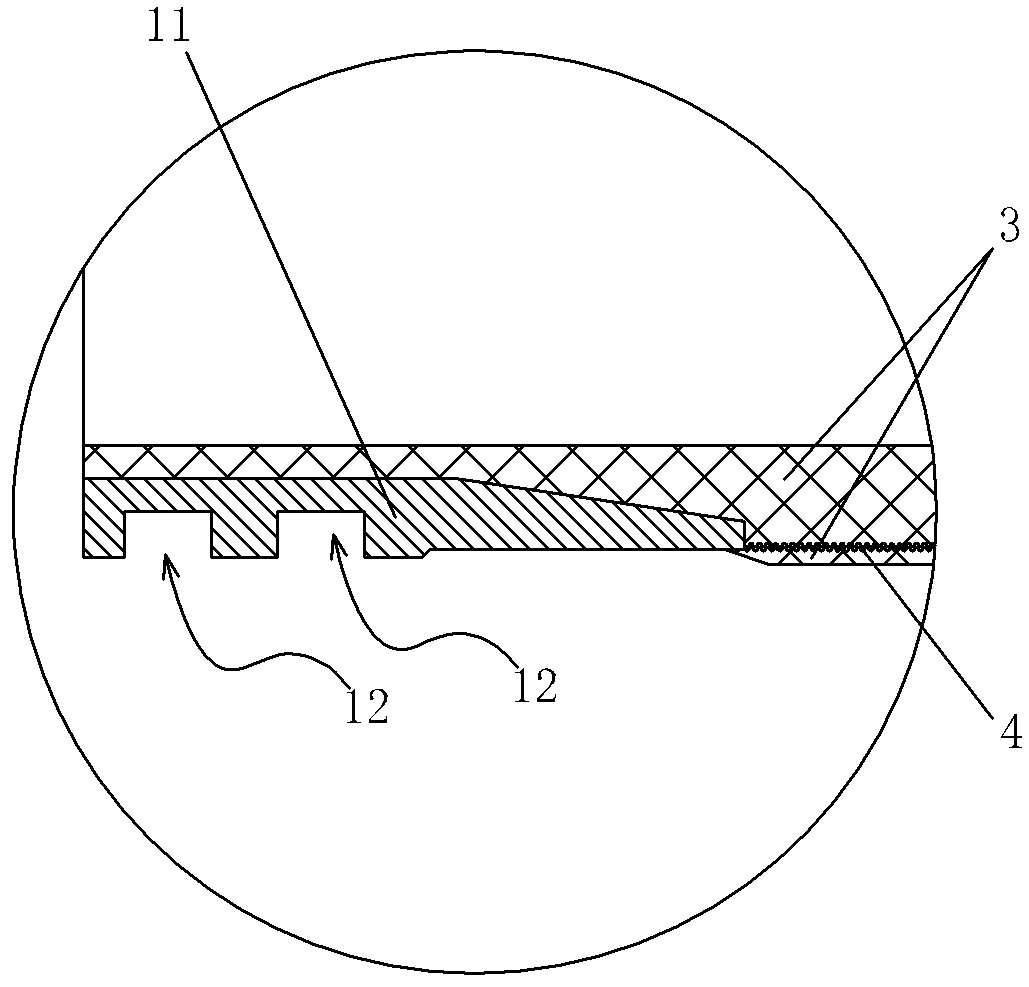

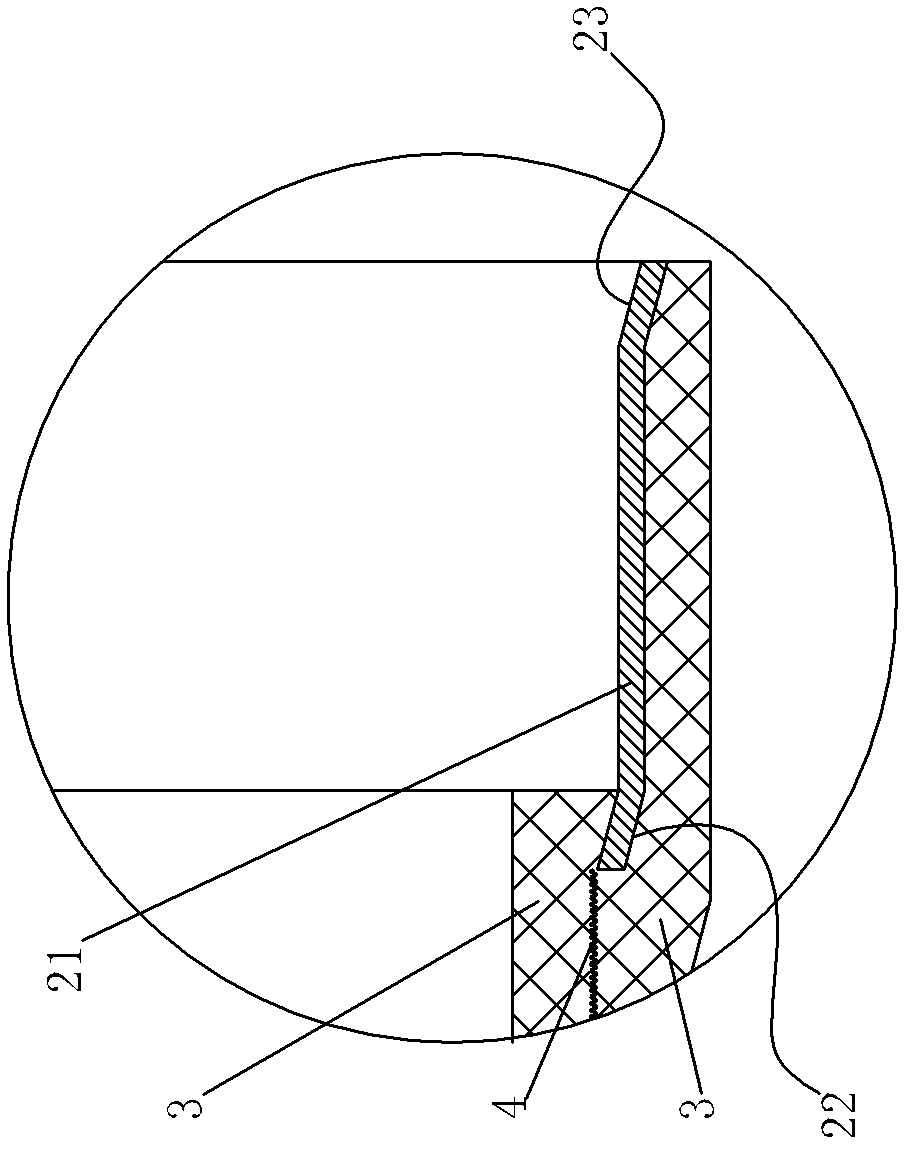

[0020] like figure 1 , figure 2 , image 3 A PE water supply pipe shown has a socket end 1 and a socket end 2, a layer of steel mesh 4 is embedded in the pipe wall 3, a socket steel ring 11 is fixed on the outer wall of the socket end 1, and the socket The outer surface of the steel ring 11 is provided with two annular sealing grooves 12 for sheathing the sealing ring 5 , and a socket steel ring 21 is fixed on the inner wall of the socket end 2 . The socket steel ring 11 and the socket steel ring 21 are respectively welded and fixed to the two ends of the steel mesh 4 . The socket steel ring 11 and the socket steel ring 21 are integrally formed with the pipe body. One end of the socket steel ring 21 is a flaring mouth 23 with a gradually increasing diameter, and the other end is a shrinking mouth 22 with a gradually decreasing diameter. The necking 22 is connected to the steel mesh 4 . Both the socket steel ring 11 and the socket steel ring 21 are shaped steel.

[0021] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com