Method of spraying mortar composite inner lining of steel cylinder with hanging net and non-excavation repair of pressure pipeline

A technology for pressure pipelines and spraying mortar, which is applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., which can solve the problems of reduced cross-section of old pipelines, difficult construction, and insufficient pipeline flow capacity, etc., to achieve shrinkage Over-current section, improved internal pressure resistance, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

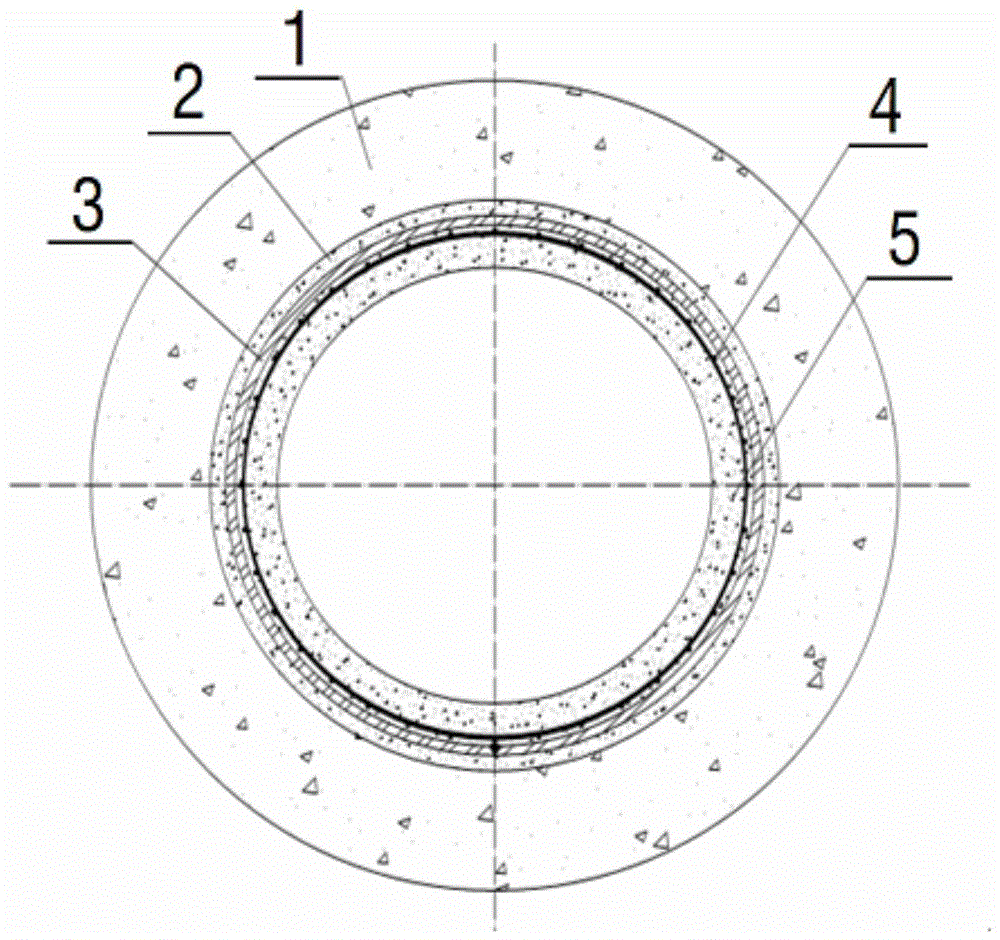

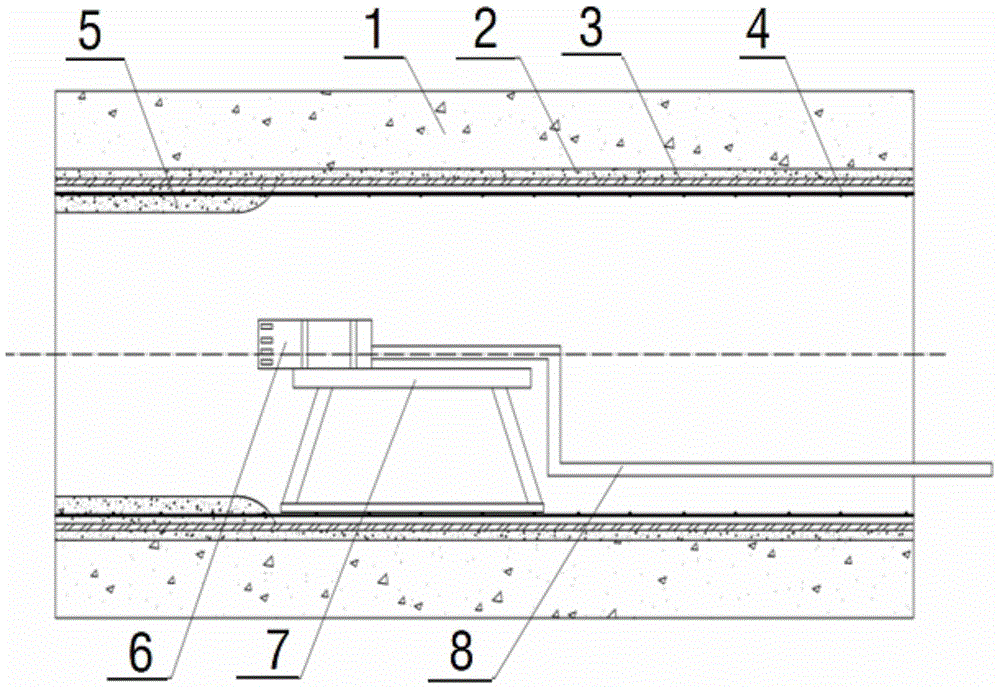

[0026] Embodiment 1: The present invention provides a kind of steel cylinder hanging mesh spraying mortar composite lining for the non-excavation repair of pressure pipeline, including steel cylinder layer 3 and steel wire mesh reinforced mortar layer 5, its structure is as follows figure 1 shown. The composite inner lining is composed of a steel cylinder layer 3 and a steel wire mesh reinforced mortar layer 5 from the outside to the inside; the steel cylinder layer 3 is installed on the inner side of the mortar primer layer 2 in the old pipeline, and the mortar primer layer is placed on the inner side of the old pipeline. Spray directly on the inner wall of the cleaned old pipeline when repairing the old pipeline; the steel mesh reinforced mortar layer 5 is wrapped with a steel mesh 4, and the steel mesh is anchored on the inside of the steel cylinder of the steel cylinder layer 3 by welding, and then placed on the steel cylinder 1. The surface of the steel wire mesh 4 is spr...

Embodiment 2

[0029] Embodiment 2: The present invention provides a method for the non-excavation repair of steel cylinder hanging net spraying mortar composite lining and pressure pipeline. First, the inside of the old pipeline 1 to be repaired is thoroughly cleaned, and the debris inside the old pipeline 1 is removed , sediment and raised hard fulcrums; then follow the steps below to implement:

[0030] Step (1) Use the centrifugal sprayer 6 to construct the inner wall of the cleaned old pipeline 1, and spray the mortar to lay the bottom layer 2, so that the inner wall of the old pipeline 1 is round and free of raised hard points.

[0031] Step (2) According to the specifications, embedding conditions, design pressure and other conditions of the old pipeline 1, design the thickness of the steel cylinder bearing the internal pressure and the thickness of the steel mesh reinforced mortar layer 5 bearing the external pressure and vacuum pressure, select the steel plate and the steel mesh mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com