Double-wall glass fiber reinforced plastic pipeline and pipeline assembly

A pipeline component and fiberglass technology, applied in the direction of pipes/pipe joints/fittings, piping systems, pipes, etc., can solve problems such as hidden safety hazards, failure to find leakage points in time, soil and environmental pollution, etc., to improve internal pressure resistance, The effect of avoiding a large amount of leakage and solving the pollution problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

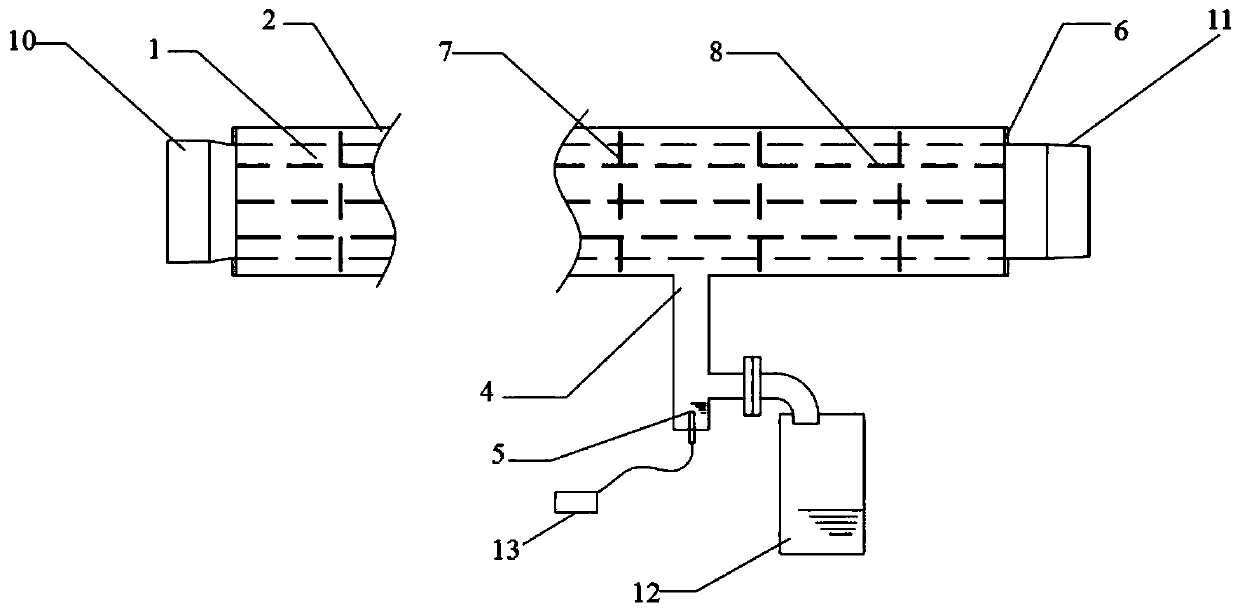

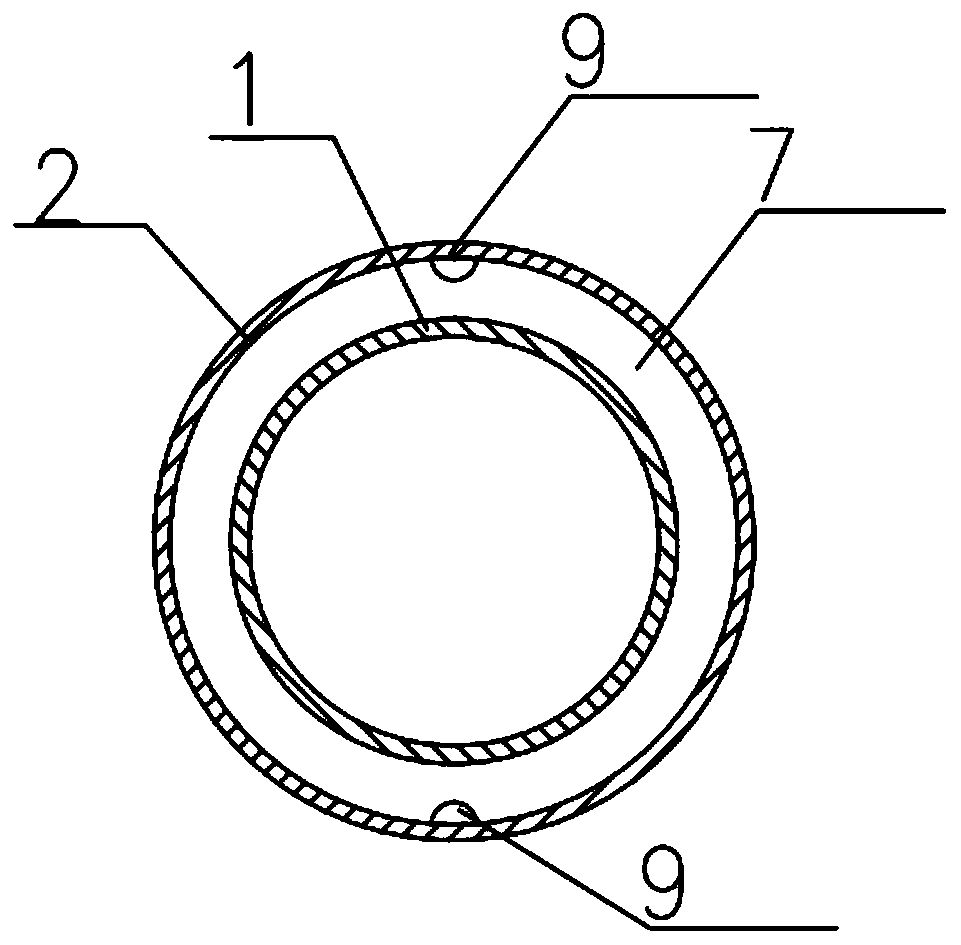

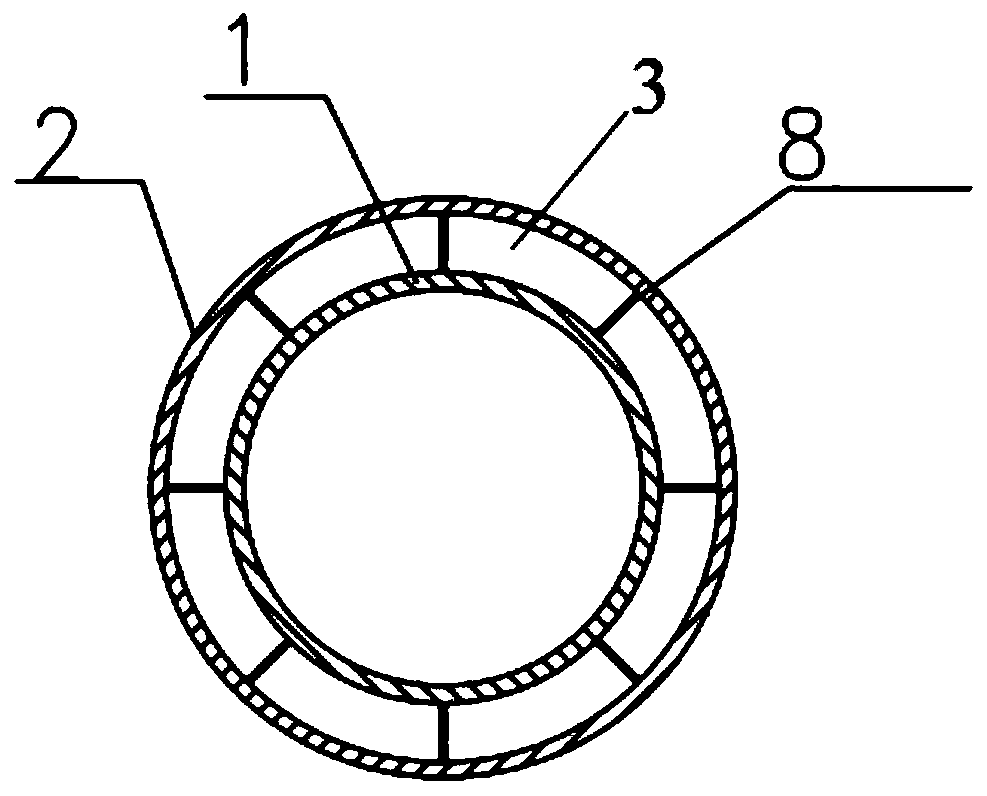

[0026] Such as figure 1 Shown is a schematic structural view of the double-wall FRP pipeline of the present invention, the double-wall FRP pipeline includes an inner tube 1, an outer tube 2 sleeved outside the inner tube 1, and a lumen 3 is formed between the inner tube 1 and the outer tube 2, where lumen 3 visible image 3 shown. The inner pipe 1 and the outer pipe 2 are made of glass fiber reinforced plastics, and the inner and outer walls of the inner pipe 1 and the inner wall of the outer pipe 2 are provided with an anti-corrosion layer to prevent medium corrosion, so as to effectively improve the service life of the double-walled pipe; the anti-corrosion layer is an existing technology, which will not be described in detail here. The length of the inner tube 1 is slightly longer than the length of the outer tube 2, the two ends of the inner tube 1 protrude, one end of the inner tube 1 is a socket 10, the other end is a socket 11, and both ends of the outer tube 2 are fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com