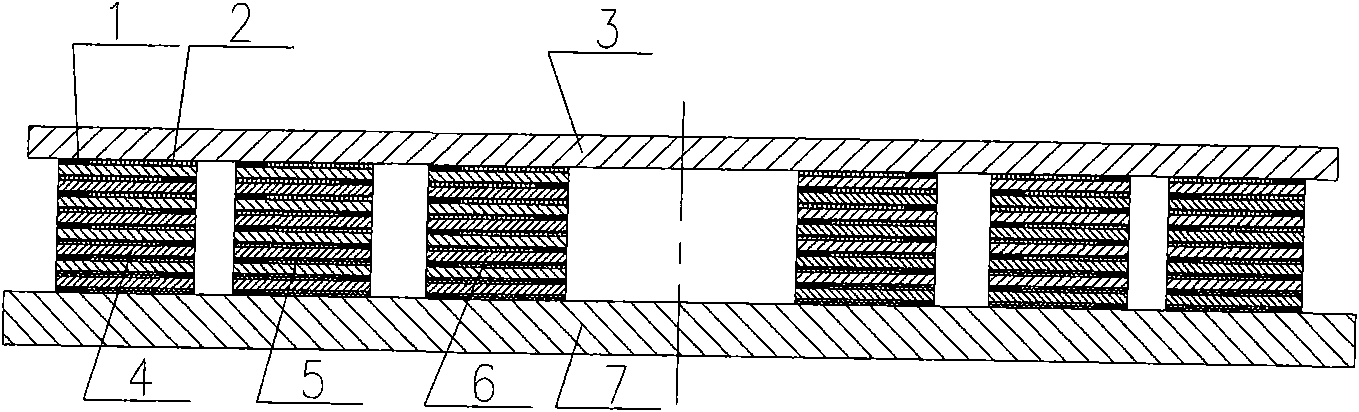

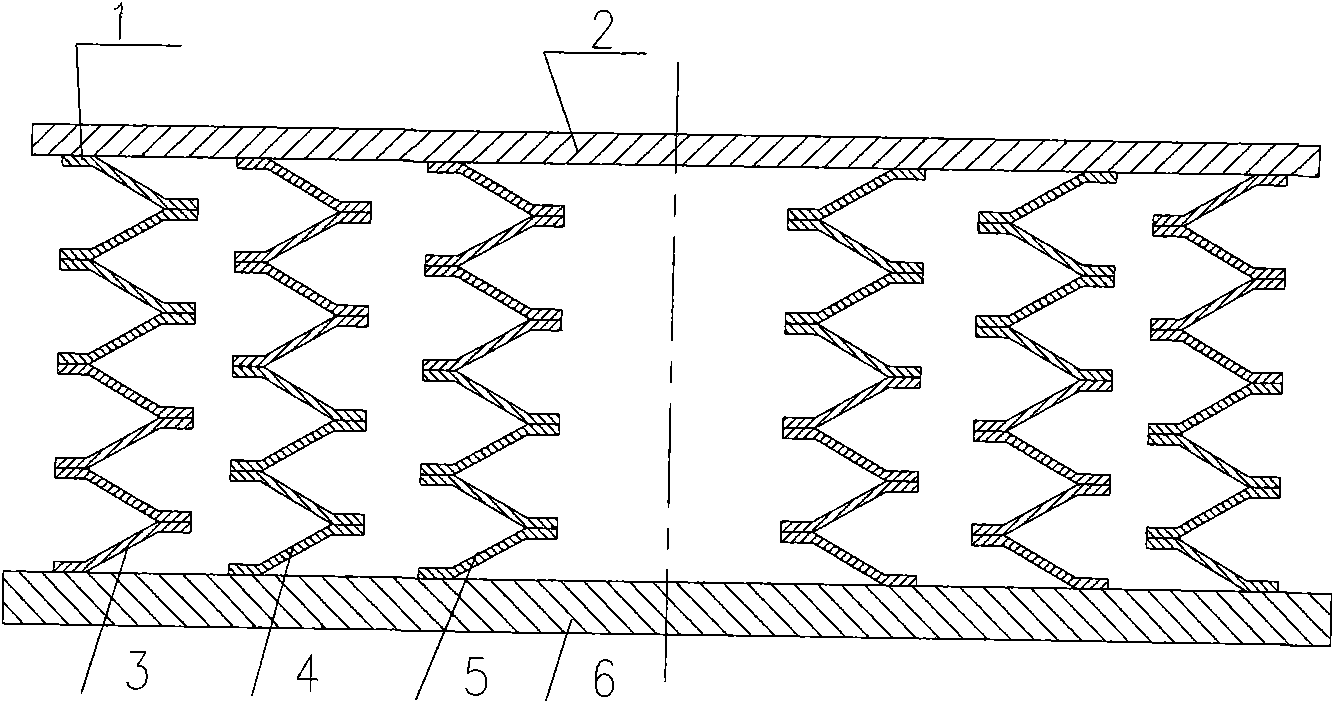

Composite structured corrugated pipe by diffusion welding

A diffusion welding and composite structure technology, applied in the direction of pipes/pipe joints/fittings, hoses, pipes, etc., can solve the problems that composite structure bellows cannot be realized, achieve no welding stress and strength drop, improve pressure resistance and Anti-instability, the effect of reducing the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] 1. Manufacture circular (or square or other shapes) foil plate materials by mechanical processing, laser processing, electrical processing, etc.;

[0030] 2. Clean the surface of the material through various surface treatments to remove all dirt on the surface of the material;

[0031] 3. Realize the precise control of the boundary line between the welding area and the non-welding area of the diffusion-welded composite structure bellows by applying surface protective glue and engraving;

[0032] 4. Stop welding for parts that do not require diffusion welding;

[0033] 5. For the parts that need to be welded by diffusion welding, the surface modification treatment of materials is carried out by means of ion implantation, deposition, coating, etc. (some grades of materials may not be carried out);

[0034] 6. Assemble the materials according to a certain assembly relationship and assembly sequence;

[0035] 7. Under certain temperature, protective environment (includi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com