Municipal pipeline laying construction process

A construction process and municipal pipeline technology, applied in the field of pipeline construction, can solve the problems of corner angle deviation of corner connecting pipes, inability to connect pipes, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following is attached Figure 1-5 The application is described in further detail.

[0044] The embodiment of the application discloses a municipal pipeline laying construction process.

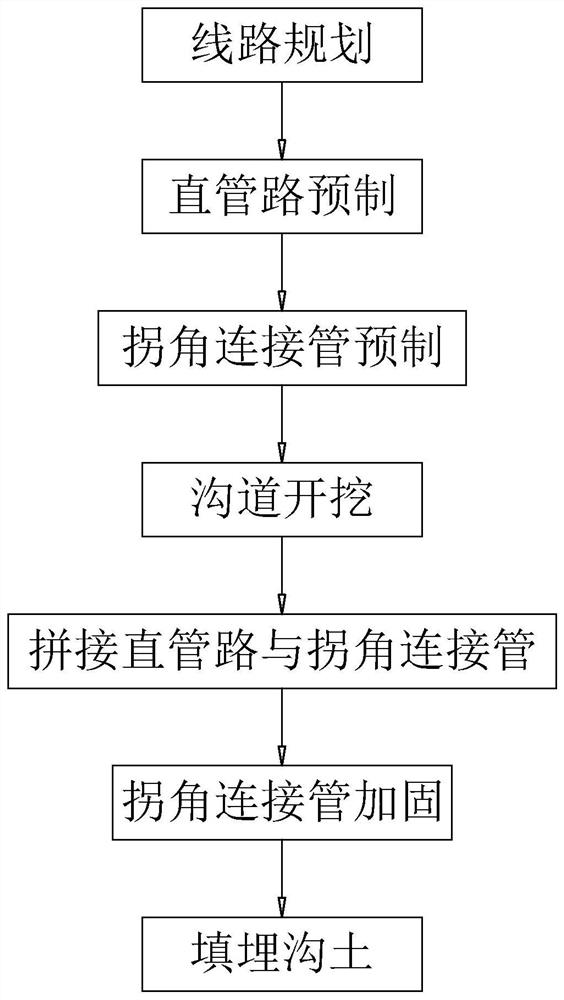

[0045] refer to figure 1 , a municipal pipeline laying construction process, comprising the following steps:

[0046] S1 route planning, planning construction route;

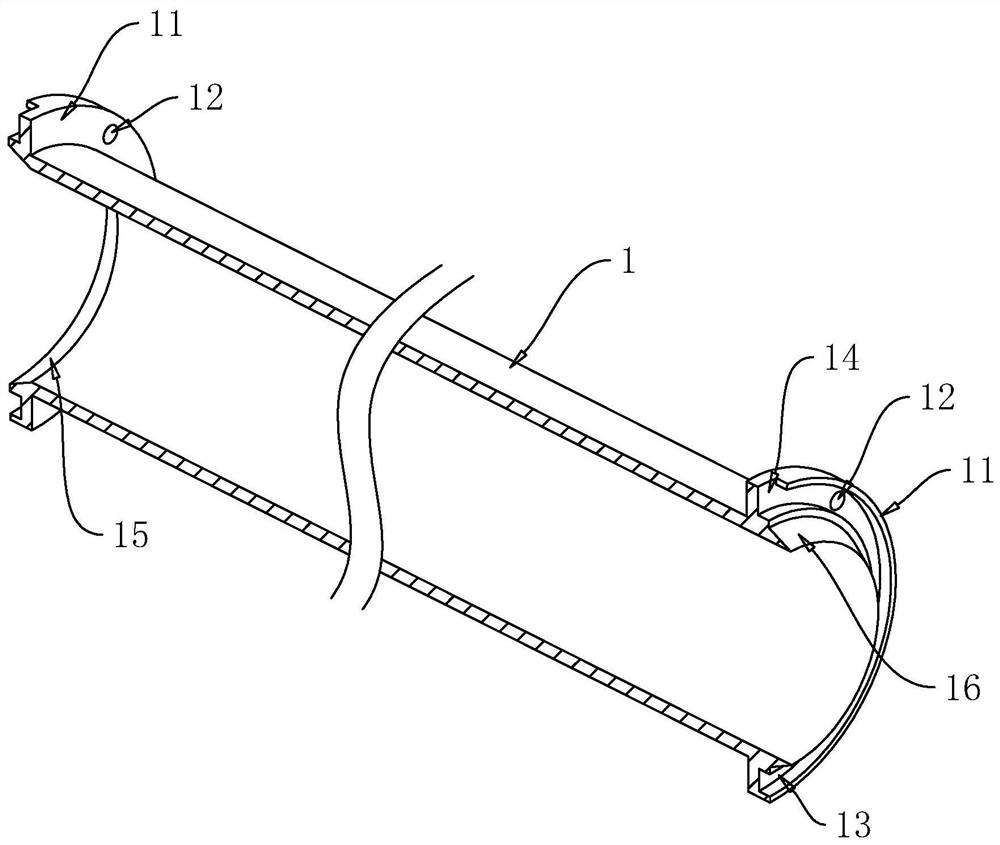

[0047] refer to figure 2 , S2 Prefabrication of straight pipeline 1, prefabricated straight pipeline 1 according to the construction line, both ends of straight pipeline 1 are integrally formed with fastening ring 11, and the fastening ring 11 is evenly opened with the axis of fastening ring 11 as the axis A plurality of fastening holes 12, the ends of the two fastening rings 11 away from each other are all centered on the axis of the fastening ring 11 to be provided with a ring groove 13, and the ring groove 13 communicates with the fastening holes 12, and the mutual connection of the fastening rings 11 A notch g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com