Large-caliber lower pressure water feeding polythene wire mesh winding pipe and production method and production equipment

A polyethylene and large-diameter technology, applied in the direction of mechanical equipment, pipes, rigid pipes, etc., can solve the problems of heavy welding equipment, inconvenient construction, high production cost, etc., and achieve the effect of less raw material consumption, low production cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

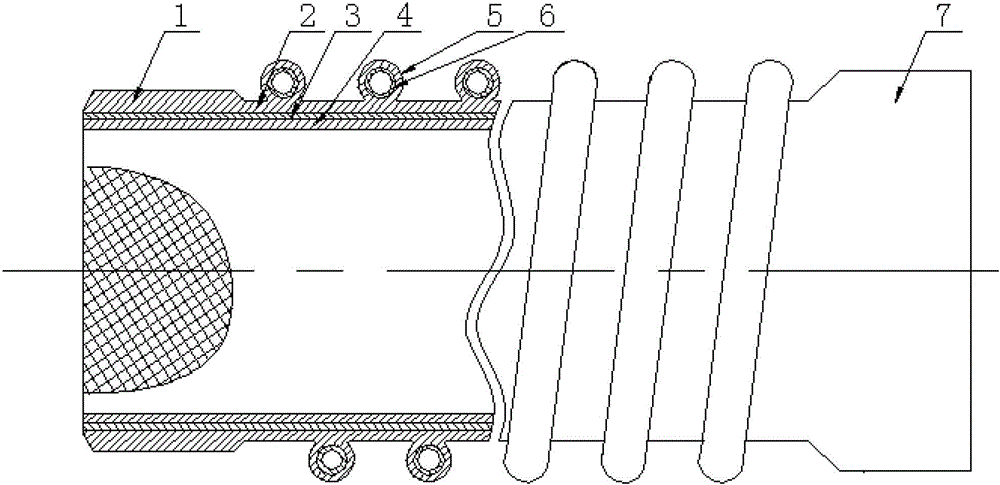

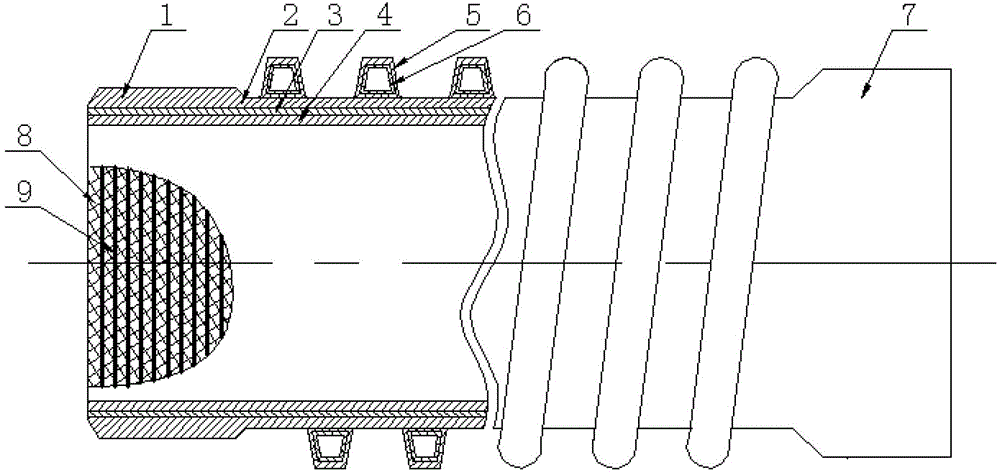

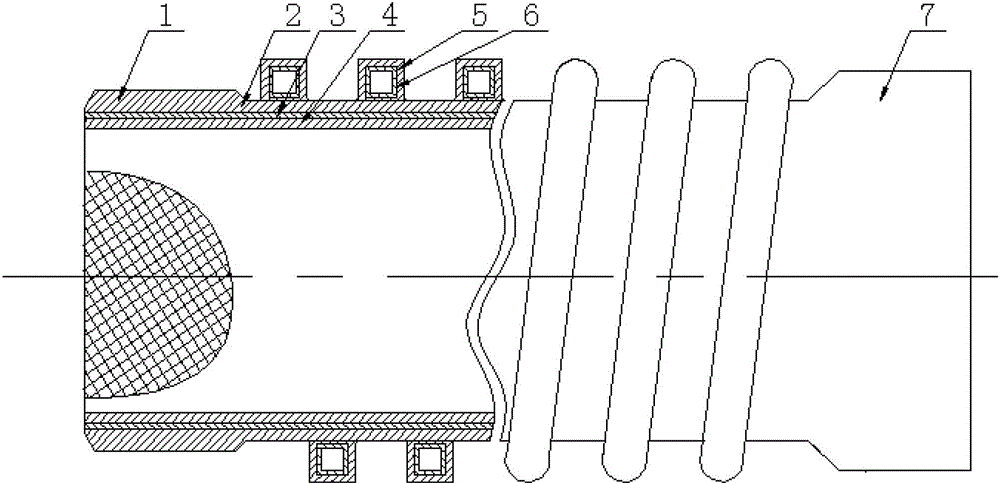

[0033] A large-diameter low-pressure water supply polyethylene wire mesh winding pipe, which is composed of a solid-wall pipe body layer and an outwardly convex reinforced structure layer. The solid-wall pipe body layer is composed of an inner wall layer 4, a reinforcement layer 3 and an outer wall layer 2. The inner wall layer is Sheet polyethylene strips are spirally wound on the surface of the drum mold to form a continuous inner wall layer; the reinforcement layer is a steel wire mesh reinforcement layer 8 formed by a steel wire mesh belt spirally wound outside the inner wall layer; the reinforcement layer also includes a steel wire reinforcement layer 9, which The steel wire reinforcement layer is formed by helically winding multiple str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com