Production process for continuous fiber reinforced composite pipe

A technology for reinforcing composite materials and continuous fibers, applied in the field of pressure pipes, can solve problems such as pipe safety restrictions, reduce raw material costs, reduce angular tolerances and clearance requirements, and strengthen creep resistance and internal pressure resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

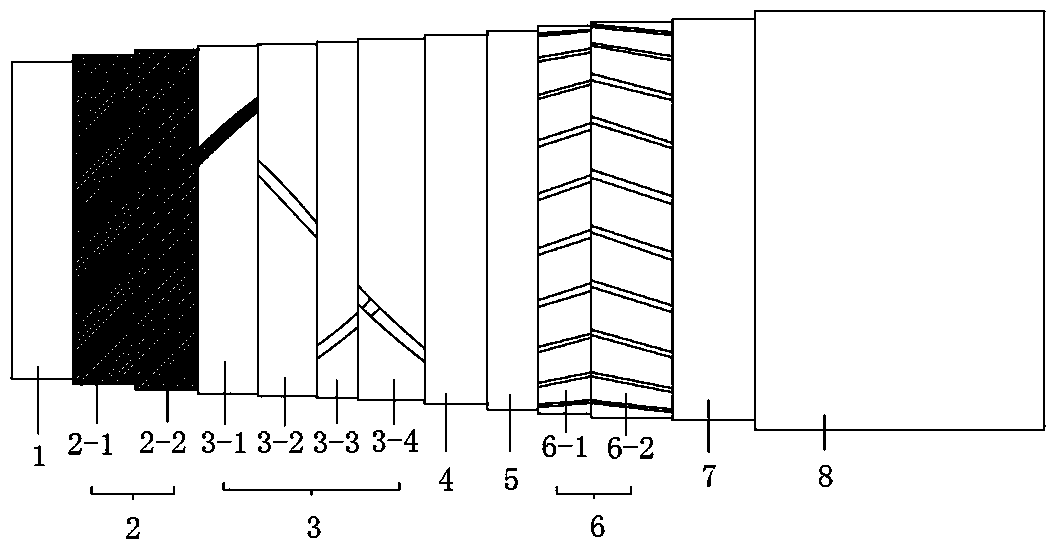

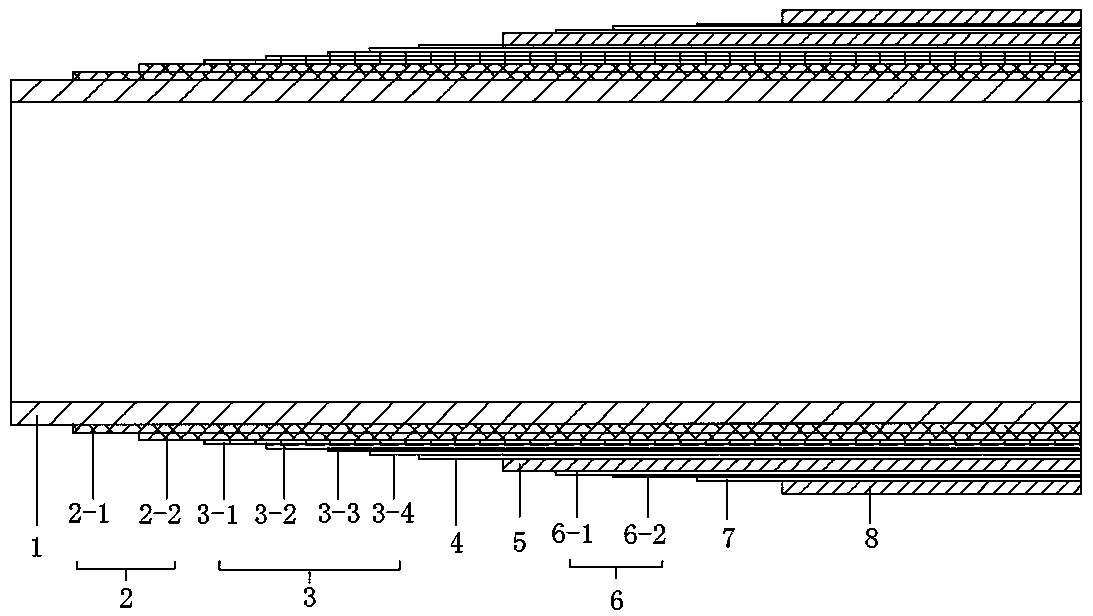

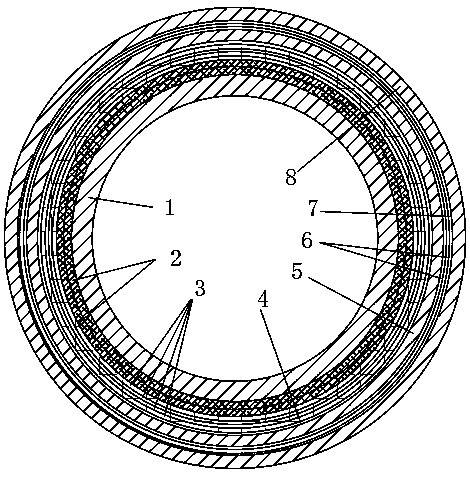

[0036] Example: such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a production process of a continuous fiber reinforced composite pipe, the continuous fiber reinforced composite pipe includes an inner pipe 1, an auxiliary layer 2 wound along the outer surface parallel to the axial direction of the inner pipe, wound on the auxiliary layer Reinforcing layer 3 on the axially outer surface, functional layer 4 wound on the axially outer surface, wear-resistant layer 5 wrapped on the outer surface of the functional layer, axial tensile layer 6 wound on the outer surface of the wear-resistant layer 1. The functional isolation layer 7 wound on the outer surface of the axial tensile layer and the outer protective layer 8 wrapped on the outer surface of the functional layer; the production process steps of the continuous fiber reinforced composite pipe are:

[0037] S1: Inner tube forming: select the material of the inner tube, and then extrude the inner tube through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com