Multi-groove and large-powder transformer

A high-power, transformer technology, applied in the field of transformers, can solve the problems of low transformer efficiency and waste of resources, and achieve the effects of improving efficiency, reducing the number of winding layers, and ensuring assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

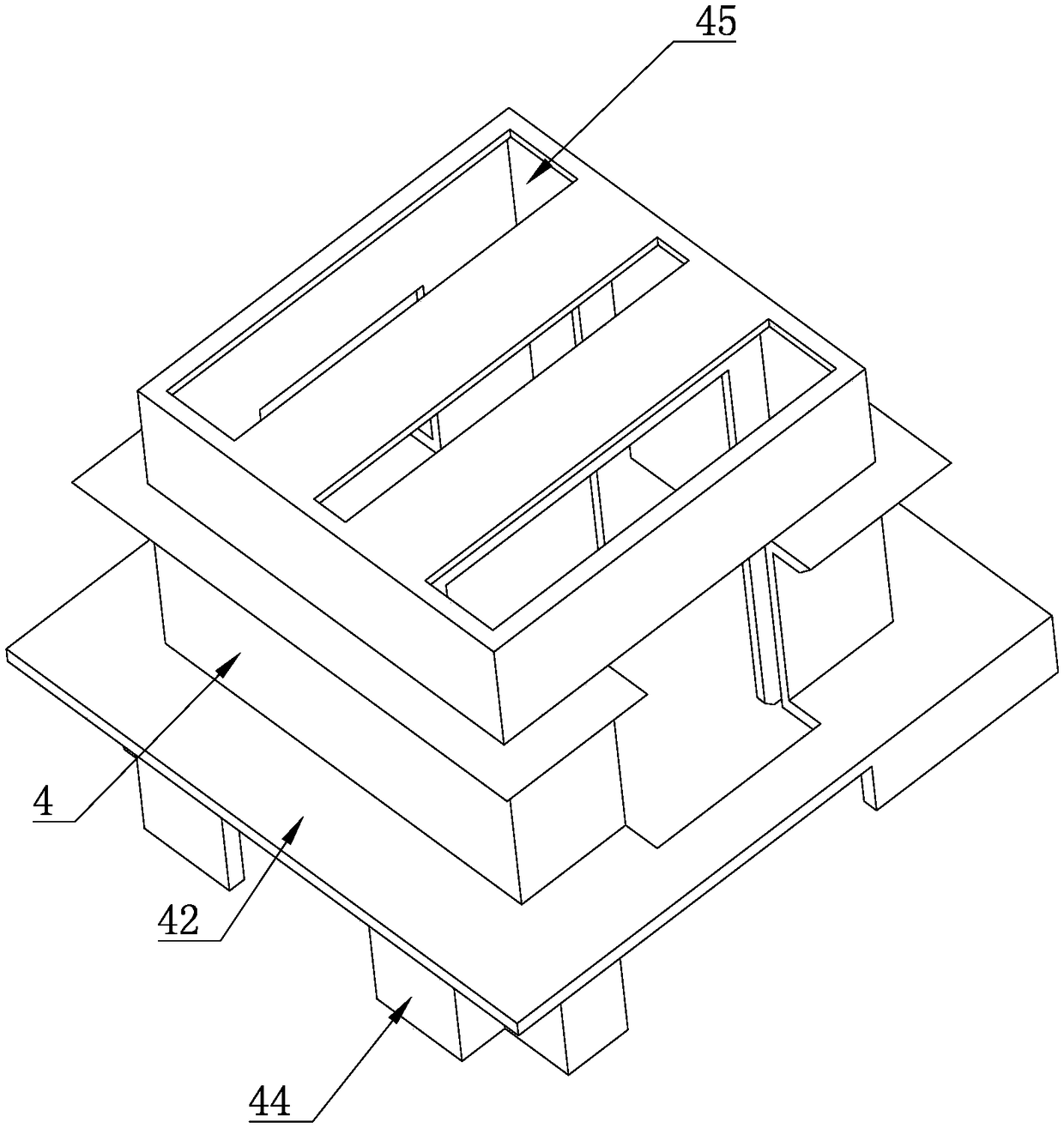

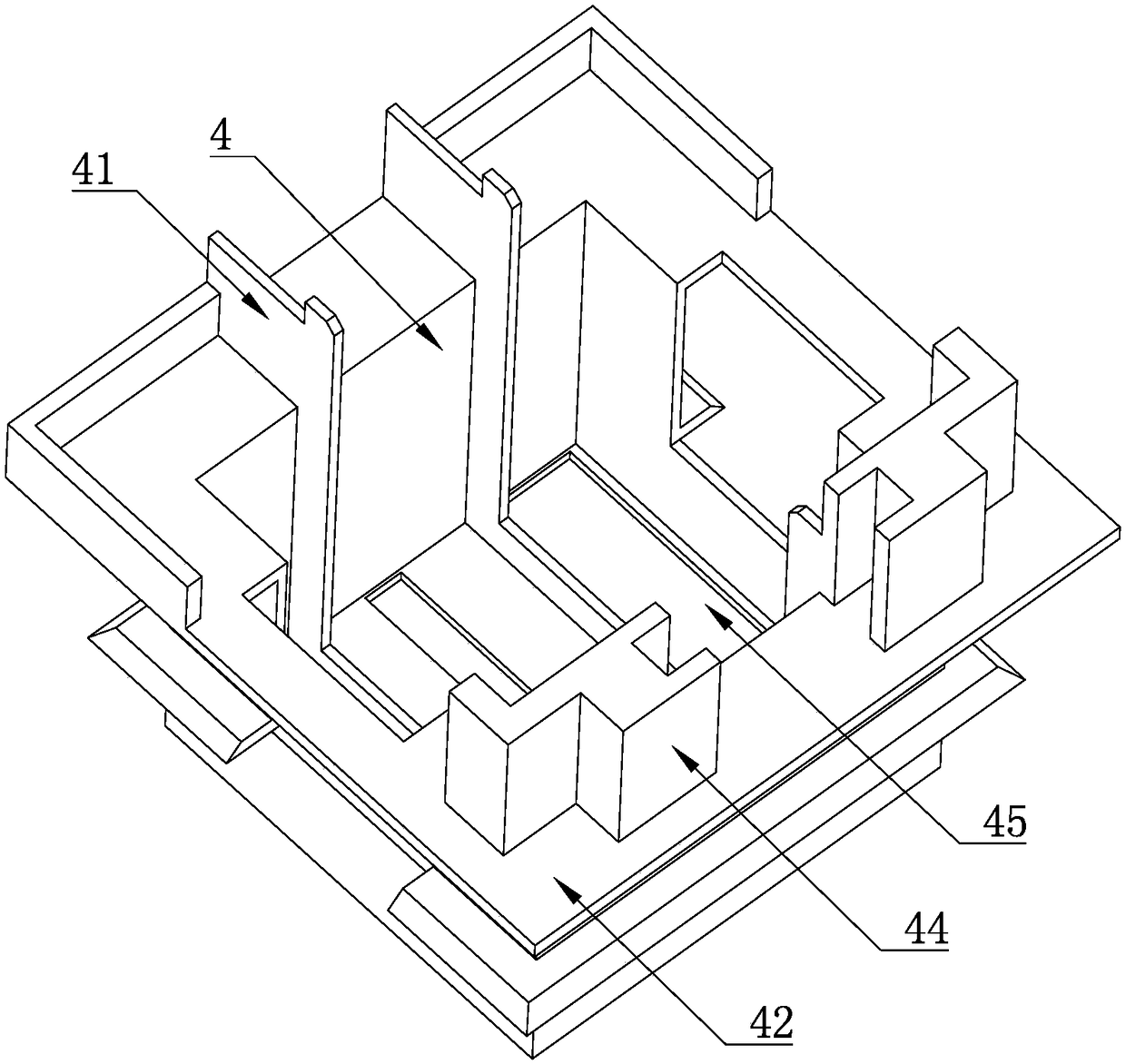

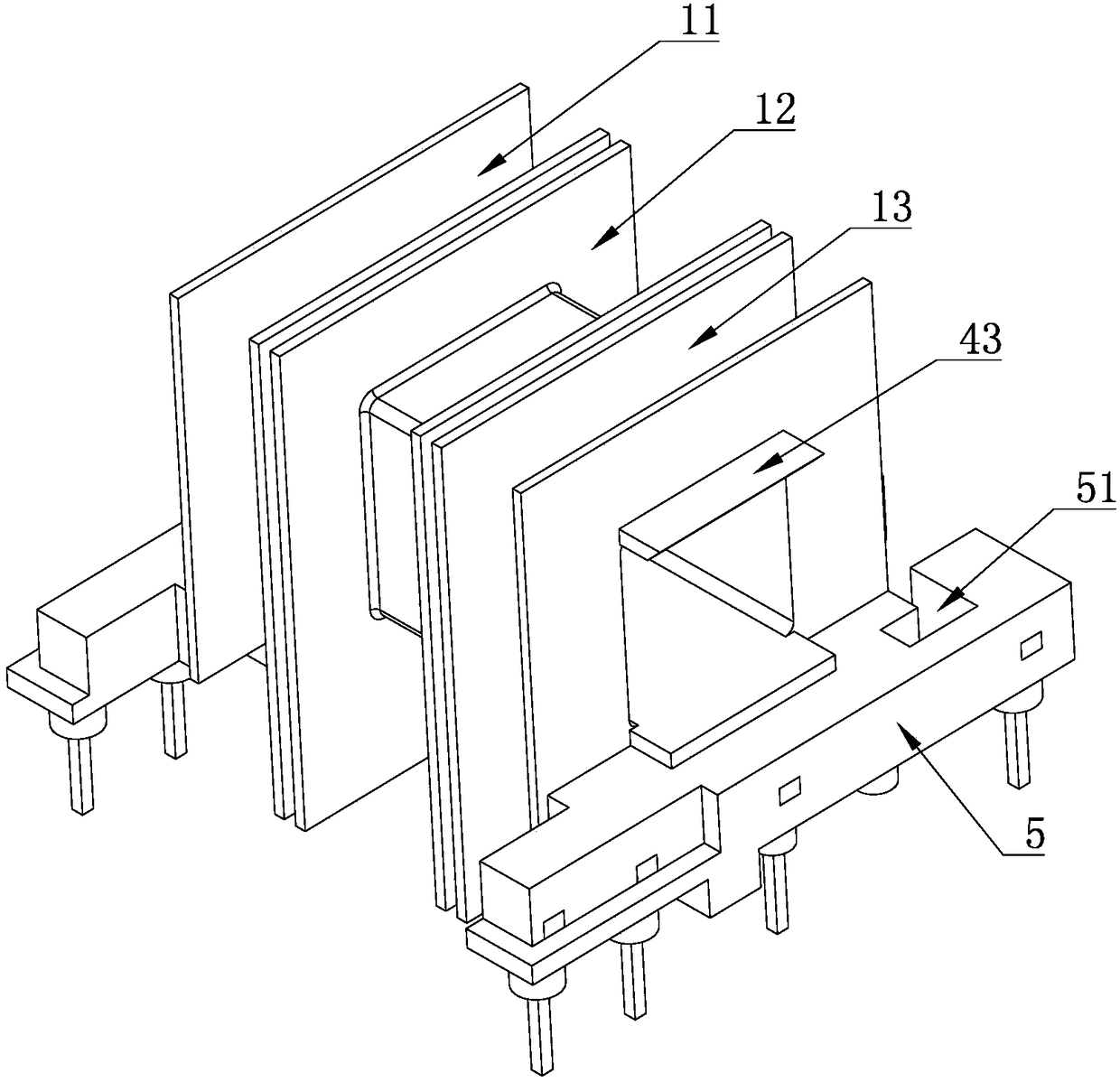

[0025] refer to Figure 1 to Figure 4 The embodiment of a multi-slot high-power transformer of the present invention will be further described.

[0026] A multi-slot high-power transformer, including a skeleton and a magnetic core, the skeleton includes a bobbin 1 sleeved on the magnetic core, and limiting plates 2 arranged at both ends of the bobbin 1, and the bobbin 1 is provided with two A partition plate 3, two partition plates 3 divide the bobbin 1 into the first winding slot 11 and the third winding slot 13 where the first winding is wound and the second winding slot 12 where the second winding is wound , the second winding groove 12 is located between the first winding groove 11 and the second winding groove 12, the skeleton is provided with a shell 4 covering the bobbin 1, and a baffle plate 41 is arranged inside the shell 4, and two separate The partitions 3 are all provided with limiting grooves 31 that are plugged with the baffles 41. When the housing 4 is covered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com