Internal-pressure-resistant fiber weaving, winding and pultrusion composite pipe and preparation method thereof

A technology of fiber braiding and fiber braiding layer, applied in the field of anti-internal pressure fiber braided winding pultrusion composite pipe and its preparation, can solve the problems of increased production pressure, low production efficiency, and low market value, and achieve enhanced anti-internal and external The ability to press, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

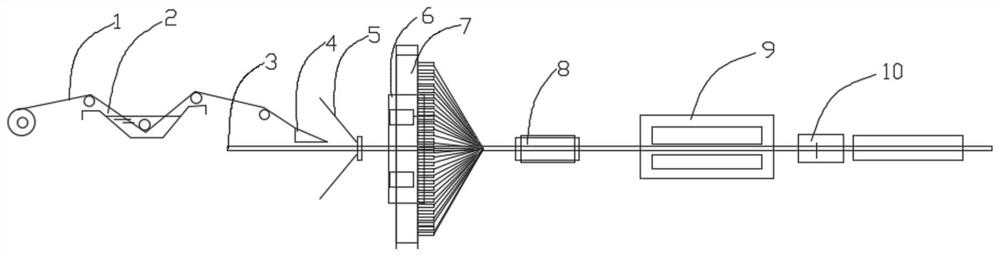

[0032] For details, see figure 1 , a preparation method of anti-internal pressure fiber braided winding pultruded composite pipe, comprising the following steps:

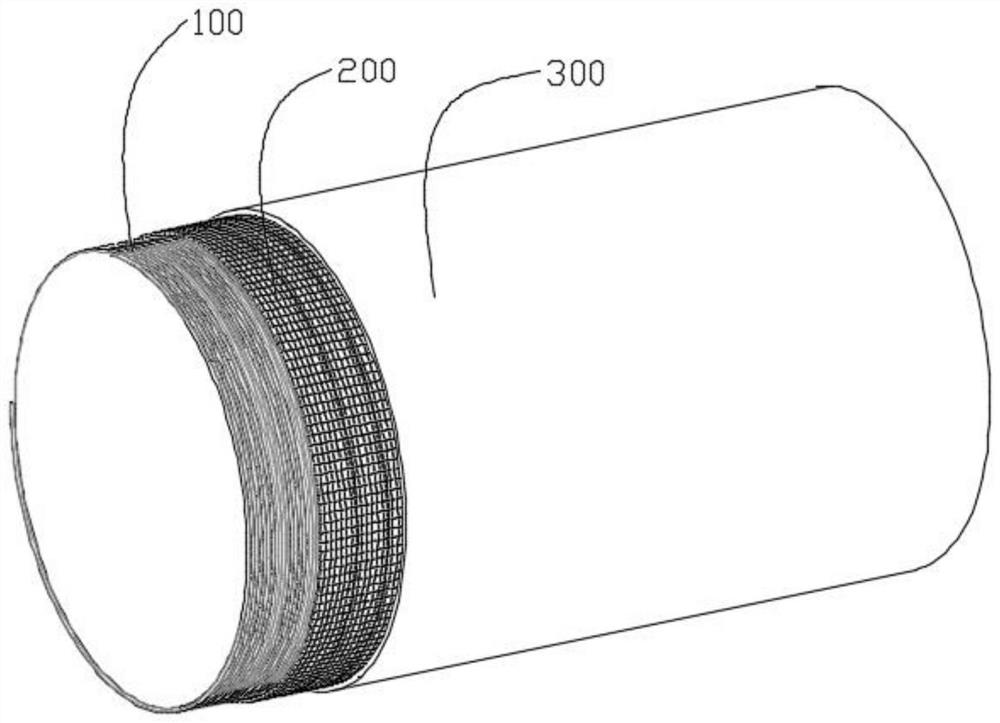

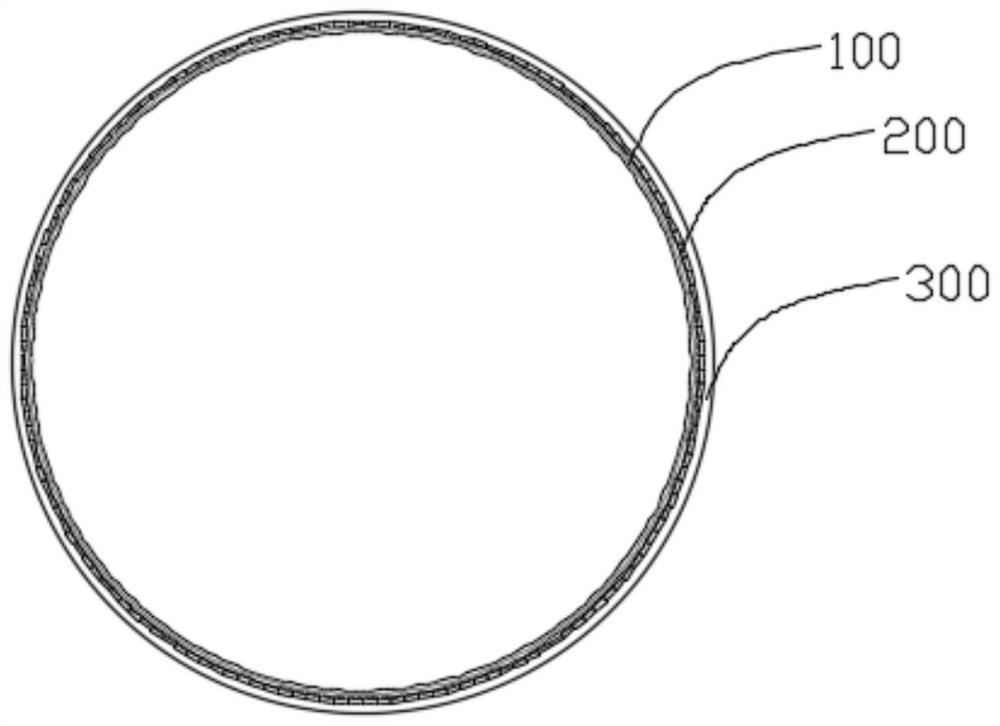

[0033] S1. Inner layer prepreg, the prefabricated impermeable fiber 1 is introduced into the impregnation tank 2, the first thermosetting resin and the impregnation pressure roller in the impregnation tank 2 are then exported to dry and coated on the mandrel 3 through the guide 4 Above, the anti-leakage layer 100 is prepared, wherein the first thermosetting resin is a low-shrinkage polyester resin, and the anti-seepage fiber 1 is glass fiber;

[0034] S2, hoop winding, after the coating of the anti-seepage fiber 1 is completed, a winding machine 6 alternately winds the longitudinal fiber 5 and the hoop fiber on the outer surface of the anti-leakage layer 100 to prepare the hoop winding layer 200;

[0035] S3, weaving the outer layer, the braiding machine 7 weaves the braided fibers on the outer surface of the hoop ...

Embodiment 2

[0041] A method for preparing an internal pressure-resistant fiber braided winding pultrusion composite pipe, comprising the following steps:

[0042] S1. Inner layer prepreg, the prefabricated impermeable fiber 1 is introduced into the impregnation tank 2, the first thermosetting resin and the impregnation pressure roller in the impregnation tank 2 are then exported to dry and coated on the mandrel 3 through the guide 4 Above, the anti-leakage layer 100 is prepared, wherein the first thermosetting resin is polyurethane resin, and the anti-seepage fiber 1 is basalt fiber;

[0043] S2, hoop winding, after the coating of the anti-seepage fiber 1 is completed, two winding machines 6 alternately wind the longitudinal fiber 5 and the hoop fiber on the outer surface of the anti-leakage layer 100 to prepare the hoop winding layer 200;

[0044] S3, weaving the outer layer, the braiding machine 7 weaves the braided fibers on the outer surface of the hoop winding layer 200 to prepare th...

Embodiment 3

[0050] A method for preparing an internal pressure-resistant fiber braided winding pultrusion composite pipe, comprising the following steps:

[0051] S1. Inner layer prepreg, the prefabricated impermeable fiber 1 is introduced into the impregnation tank 2, the first thermosetting resin and the impregnation pressure roller in the impregnation tank 2 are then exported to dry and coated on the mandrel 3 through the guide 4 Above, the anti-leakage layer 100 is prepared, wherein the first thermosetting resin is epoxy resin, and the anti-seepage fiber 1 is carbon fiber;

[0052] S2, hoop winding, after the coating of the anti-seepage fiber 1 is completed, two winding machines 6 alternately wind the longitudinal fiber 5 and the hoop fiber on the outer surface of the anti-leakage layer 100 to prepare the hoop winding layer 200;

[0053] S3, weaving the outer layer, the braiding machine 7 weaves the braided fibers on the outer surface of the hoop winding layer 200 to prepare the hoop ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com