High-strength fiber pultrusion pipeline

A high-strength fiber and pipe technology, applied in the direction of layered products, chemical instruments and methods, glass/slag layered products, etc., can solve the problems of slow production speed, high production cost and low production efficiency of fiber braided and pultruded pipes problems, achieve high production efficiency, ensure performance, and increase production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

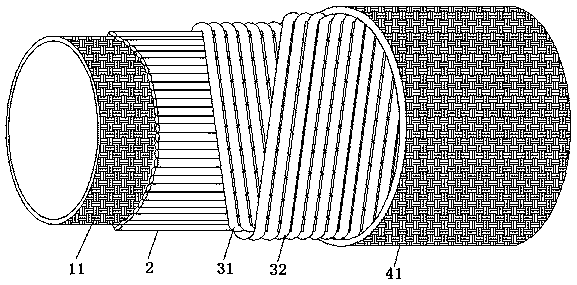

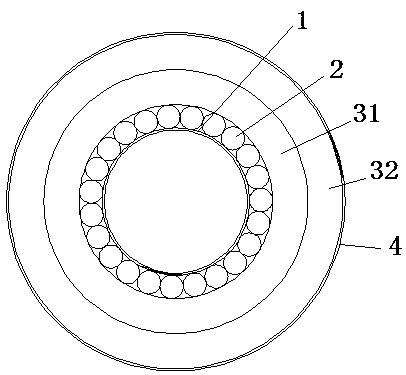

[0033] Such as Figure 1-2 As shown, a high-strength fiber pultruded pipe is composed of fibers impregnated with a thermosetting matrix; it includes an integral fiber layer 1 with a ring-shaped cross section. In this embodiment, the integral fiber layer 1 is warp and weft glass fiber cloth 11 A plurality of radially distributed fiber filaments 2 are arranged around the outer side of the warp and weft fiberglass cloth 11; the radially distributed fiber filaments 2 are evenly distributed and cover the outer side of the warp and weft fiberglass cloth 11. The outer sides of the radial fiber filaments 2 are respectively provided with wrapping layers, and in the wrapping layers, in any section of 8 mm taken along the radial direction, the number of glass fibers wrapped therein is more than one and a half turns. The outer side of the winding layer is provided with a reinforcing layer 4, and the reinforcing layer of this embodiment adopts the warp and latitude glass fiber cloth 41 wra...

Embodiment 2

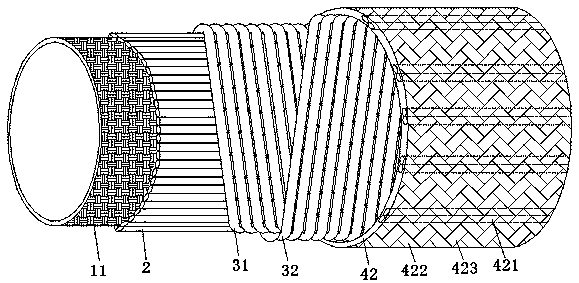

[0038] Such as Figure 3-4 As shown, a high-strength fiber pultrusion pipe is composed of fibers impregnated with a thermosetting matrix; it includes an integral fiber layer 1 with a ring-shaped cross section. In this embodiment, the integral fiber layer 1 is a weft glass fiber cloth 11, Overlapping seams are arranged at the junctions of the warp and weft fiberglass cloths 11, and the width of the seams is more than one-tenth of the perimeter of the pultruded pipe. A plurality of radially distributed fiber filaments 2 are arranged around the outer side of the warp and weft fiberglass cloth 11; the radially distributed fiber filaments 2 are evenly distributed and cover the outer side of the warp and weft fiberglass cloth 11. The outer sides of the radial fiber filaments 2 are respectively provided with wrapping layers, and in the wrapping layers, in any section of 8 mm taken along the radial direction, the number of glass fibers wrapped therein is more than one and a half turns...

Embodiment 3

[0043] Such as Figure 5-6 As shown, a high-strength fiber pultrusion pipe is composed of fibers impregnated with a thermosetting matrix; it includes a fiber integral layer 1 with a ring-shaped cross section. In this embodiment, the fiber integral layer 1 adopts a braided fiber inner layer 12, The braided fiber inner layer 12 includes glass fibers E121 and glass fibers F122 woven in the radial direction. A plurality of radially distributed fiber filaments 2 are arranged around the outer side of the braided fiber inner layer 12 ; the radially distributed fiber filaments 2 are evenly distributed and cover the outer side of the braided fiber inner layer 12 . The outer sides of the radial fiber filaments 2 are respectively provided with wrapping layers, and in the wrapping layers, in any section of 8 mm taken along the radial direction, the number of glass fibers wrapped therein is more than one and a half turns. The outer side of the wrapping layer is provided with a reinforcing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com