A kind of equipment and method for radial stretching of pipe material by differential method

A technology of radial stretching and differential method, applied in the field of pipe stretching, can solve the problems of plastic pipe stress, low tensile strength of plastic pipe, uneven pipe thickness, etc., and achieve toughness and internal pressure resistance Enhanced, easy-to-operate, and simple-to-method effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

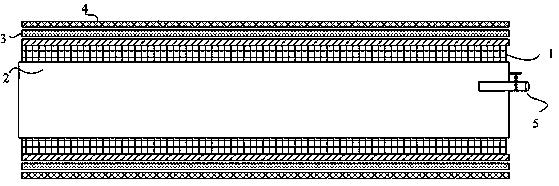

[0018] Example 1, such as figure 1 As shown, this embodiment provides a specific structure of a differential pipe radial stretching device, including the device body, the entire device body is a multi-layer structure, the innermost side of the device body includes a closed cylindrical air bag 2, the air bag 2 The pore size can be enlarged and reduced by inflation and deflation. One end of the airbag 2 is provided with an air nozzle 5 for inflating and deflating the airbag 2. The air nozzle 5 penetrates into the interior of the airbag 2 through a flexible pipe, and an airflow cut-off valve is arranged on the flexible pipe. In order to realize that when the airbag 2 is inflated and expanded, it can generate expansion stress on the tubing located outside the airbag 2, and at the same time, it can protect the airbag 2 and have sufficient hardness. steel1. The bar steel 1 has a strip-shaped structure, and a plurality of bar steel 1 are evenly distributed side by side along the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com