Construction method of bridge seamless type expansion joint

A construction method and technology of expansion joints, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of bridge head jumping, cumbersome installation and positioning, small displacement, etc., and achieve comfortable and stable driving, good waterproof performance, and elastic recovery force strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

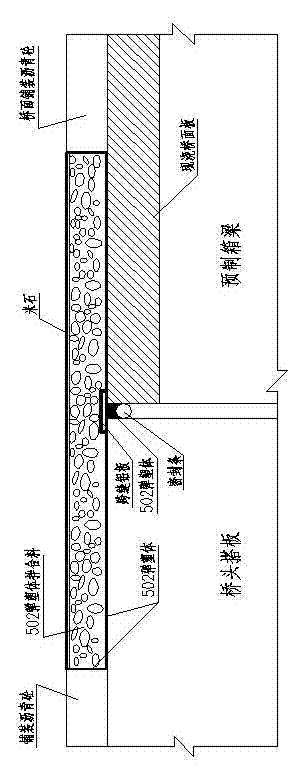

[0025] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

[0026] A construction method for bridge seamless expansion joints, the specific steps are as follows:

[0027] A. Remove the sundries and dust in the notch of the expansion joint, rinse and dry the notch with a heater;

[0028] B. Apply a layer of 502 elastic-plastic body melted at 160°C on the bottom and edge of the tank as a primer, and let it dry for 10-20 minutes;

[0029] C. Embed a sealing strip in the gap of the expansion joint, pour 502 elastic-plastic body melted at 160°C and fill the gap;

[0030] D. Place the aluminum plate across the seam and press it in the center;

[0031] E. Then coat a layer of 502 elastic-plastic body melted at 160°C on the bottom and edge of the tank, with a thickness of 1-2mm;

[0032] F, the granite stone material is screened, cleaned and dried, and the selected particle size is 5-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com