Bilayer separate injection process pipe column device for nonmetal continuous oil pipe

A process pipe string, non-metal technology, applied in drilling pipe, casing, production fluid, etc., can solve the problems of unguaranteed water injection volume, high risk of sticking and blocking in deployment, and large workload of layered water injection well deployment, etc. To achieve the effect of reduced labor intensity of personnel, good work reliability, and small workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

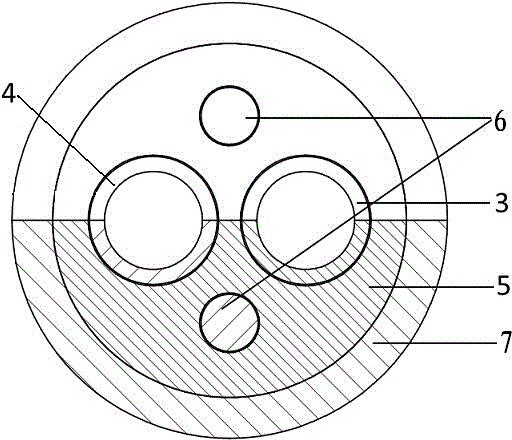

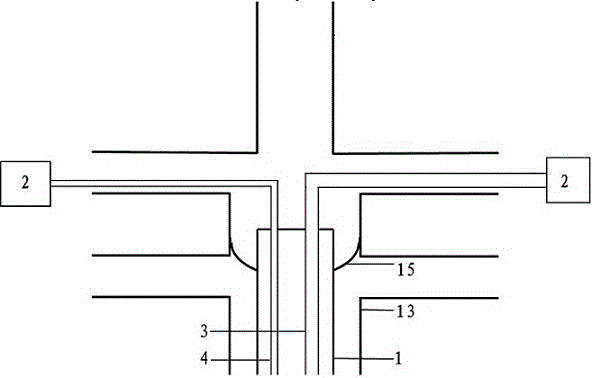

[0025] In order to solve the problems in the prior art that the allocation workload of layered water injection wells is large, the risk of being stuck in allocation is high, and the water injection volume after allocation cannot be guaranteed, this embodiment provides a method such as figure 1 , 2 The non-metallic coiled tubing two-layer separate injection process string device shown includes a non-metallic coiled tubing 1, an injection volume adjustment device 2, a first water injection channel 3 and a Two water injection channels 4, the first water injection channel 3 and the second water injection channel 4 are provided with an injection volume adjustment device 2 at the beginning, and are connected to the injection volume adjustment device 2 through conversion joints. The injection rate regulating device 2 is composed of a wellhead flowmeter and a regulating needle valve. The non-metallic coiled tubing 1, the first water injection channel 3 and the second water injection c...

Embodiment 2

[0029] On the basis of embodiment 1, on-site installation and work process of the present invention are introduced:

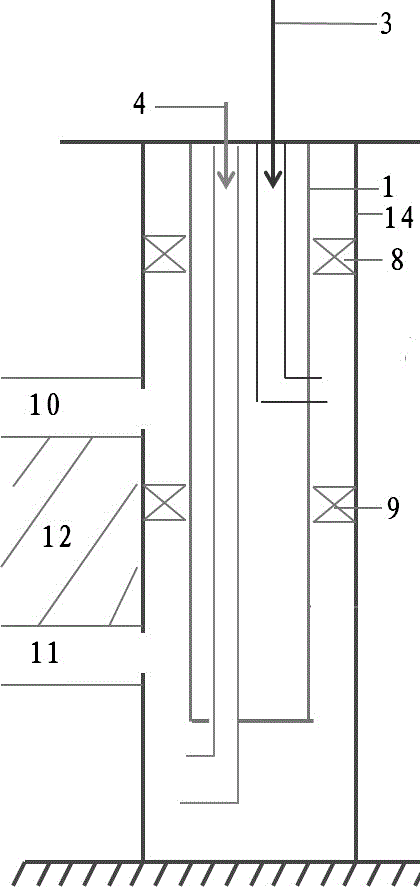

[0030] Such as image 3 As shown, the non-metallic coiled tubing 1 is connected with the tubing hanger 15, the casing protection packer 8, and the reservoir packer 9 through a metal conversion joint, and the first water injection channel 3 and the second water injection channel 4 inside it are connected from The casing protection packer 8 and the interior of the reservoir packer 9 pass through. The non-metallic coiled tubing 1 is in contact with the casing head 13 through the tubing hanger 15 connected thereto, and is pressed against each other by the gravity of the pipe string to form a sealed annular space between the non-metallic coiled tubing 1 and the casing 14 . The first water injection channel 3 and the second water injection channel 4 are connected to the injection volume adjustment and metering device 2 through a conversion joint, and the injection v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com