Steel reinforced polyurethane (PE) water supply pipe and connection structure

A technology for connecting structure and water supply pipe, which is applied in the direction of pipe connection arrangement, pipe/pipe joint/pipe fitting, pipe, etc. The deformation is not round, the installation difficulty is reduced, and the effect of saving PE raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

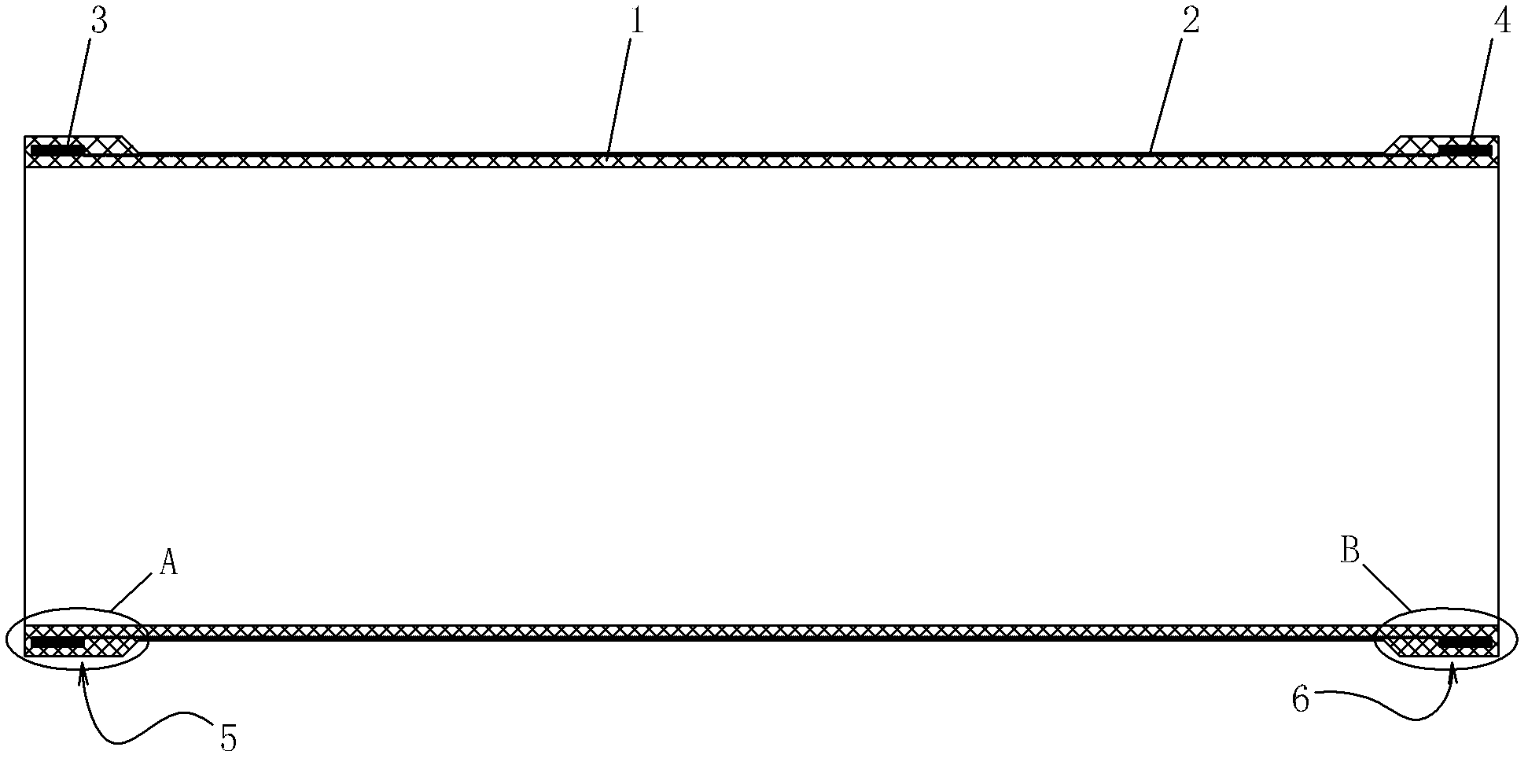

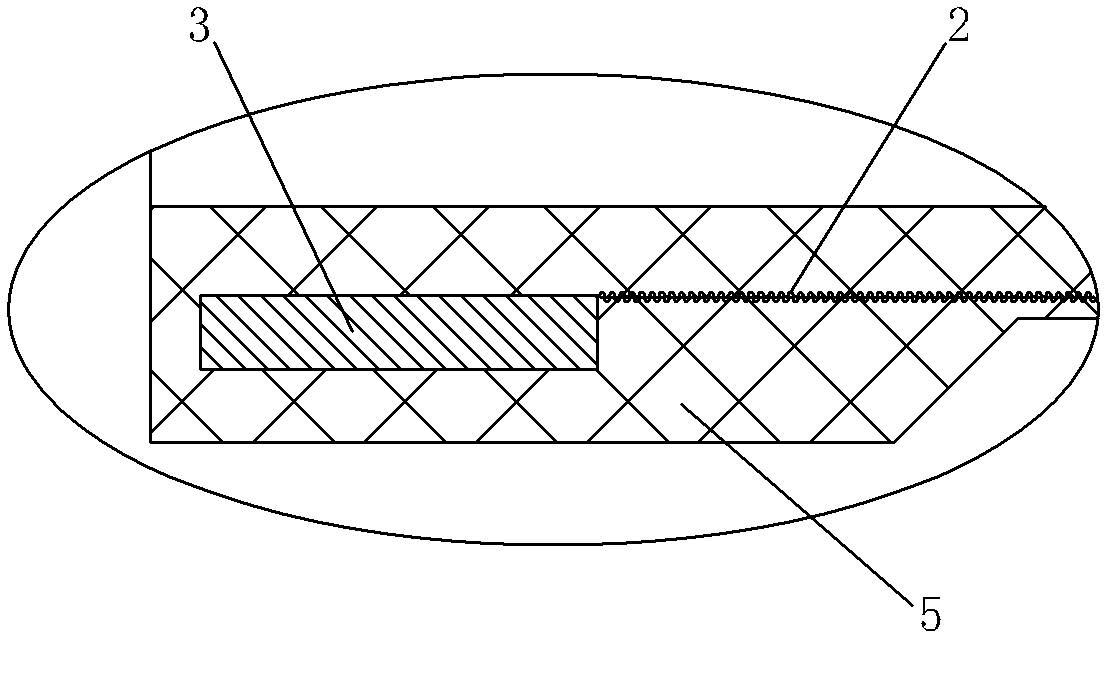

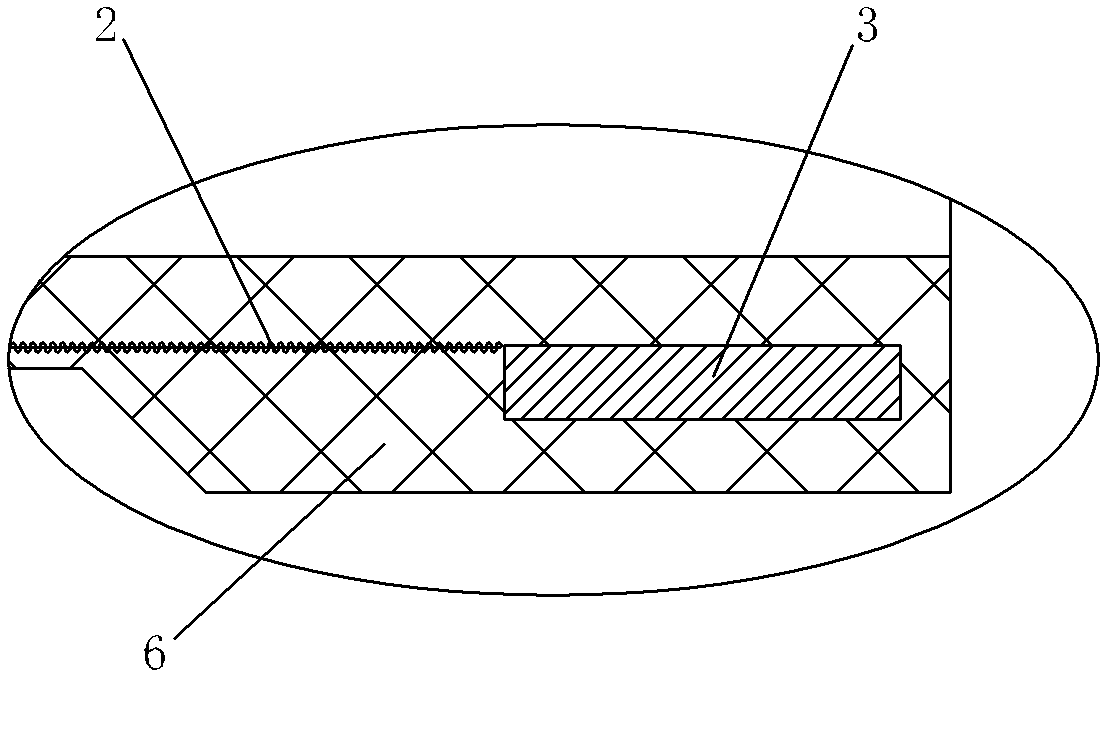

[0016] Such as figure 1 , figure 2 , image 3 In the shown steel reinforced PE water supply pipe, a layer of steel mesh 2 is embedded in the pipe wall 1 of the pipe body. Embedded with steel rings 3,4. The steel rings 3, 4 are fixedly connected with the steel mesh 2 by welding. The steel rings 3, 4 are integrally formed with the pipe body. The steel rings 3 and 4 are shaped steel.

[0017] A steel-reinforced PE water supply pipe connection structure, comprising two water supply pipes as described above, one end interface of the first water supply pipe is welded and fixed to one end interface of the second water supply pipe.

[0018] When the above-mentioned water supply pipe is manufactured, the steel rings are first embedded in both ends of the PE plastic pipe, and the steel mesh steel wire is anchored on the steel ring at one end, and the steel wire is uninterruptedly wound on the PE plastic pipe to form an intermediate layer. The other end is anchored on the steel ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com