Multifunctional double-wall glass steel pipe and preparation method thereof

A glass fiber reinforced plastic, multi-functional technology, applied in pipeline protection, pipeline system, pipeline protection through thermal insulation, etc., can solve problems such as environmental pollution, and achieve the effect of improving safety performance, internal pressure resistance and external pressure resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

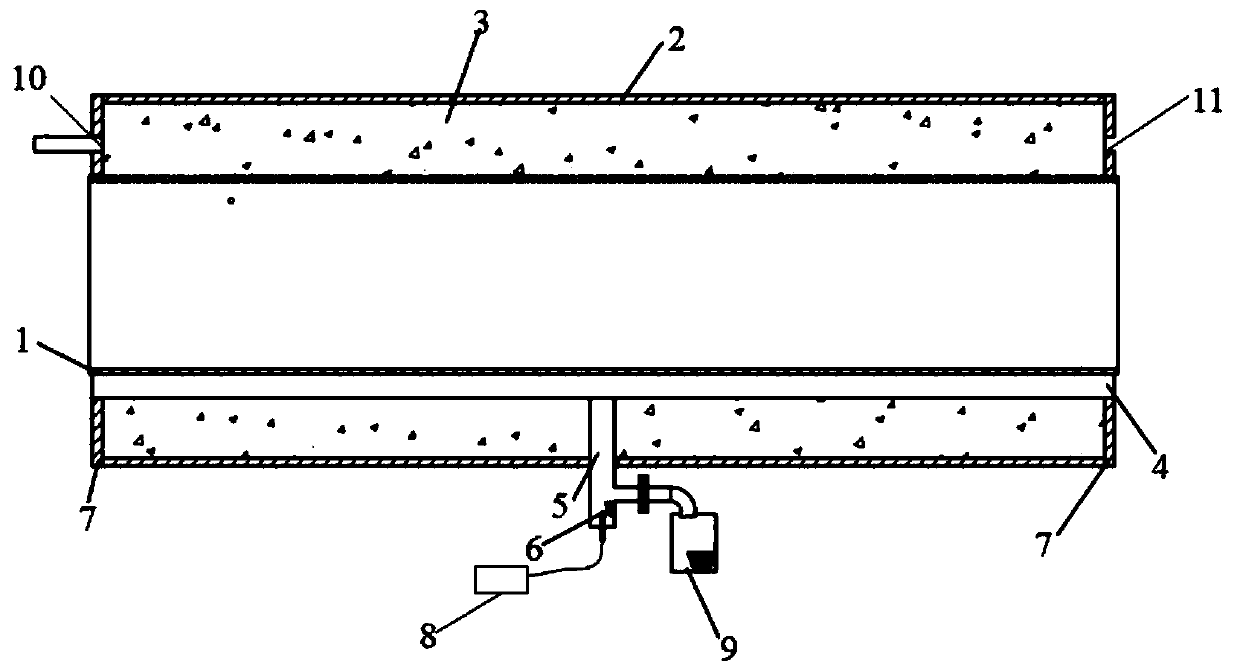

[0030] Such as figure 1 Shown is the structural representation of the multi-functional double-wall FRP pipeline of the present invention, comprising an inner tube 1, an outer tube 2 sleeved outside the inner tube 1, the inner tube 1 and the outer tube 2 are made of glass fiber reinforced plastics, and the inner and outer walls of the inner tube 1 And the inner wall of the outer pipe 2 is provided with an anti-corrosion layer, an insulating layer 3 is arranged between the inner pipe 1 and the outer pipe 2, the insulating layer 3 is made of polyurethane foam, and the two ends of the insulating layer 3 are provided with a fixed sealing plate 7 ; There is a leakage passage 4 along the length direction of the inner pipe 1 between the insulation layer 3 and the inner pipe 1, the leakage passage 4 is located at the lower part of the inner pipe 1, and the leakage passage 4 is closely attached to and communicated with the outer wall of the inner pipe 1 ; The outer tube 2 wall is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com