Integrated ceramic tile easy to lay and production method of integrated ceramic tile easy to lay

A production method and an integrated technology, applied in the field of tiles, can solve the problems of not being able to produce ultra-thin structure composite tiles, not publicly using He Gong's production process, and poor adhesion firmness, etc., to achieve simple structure, not easy to break, and fast production speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

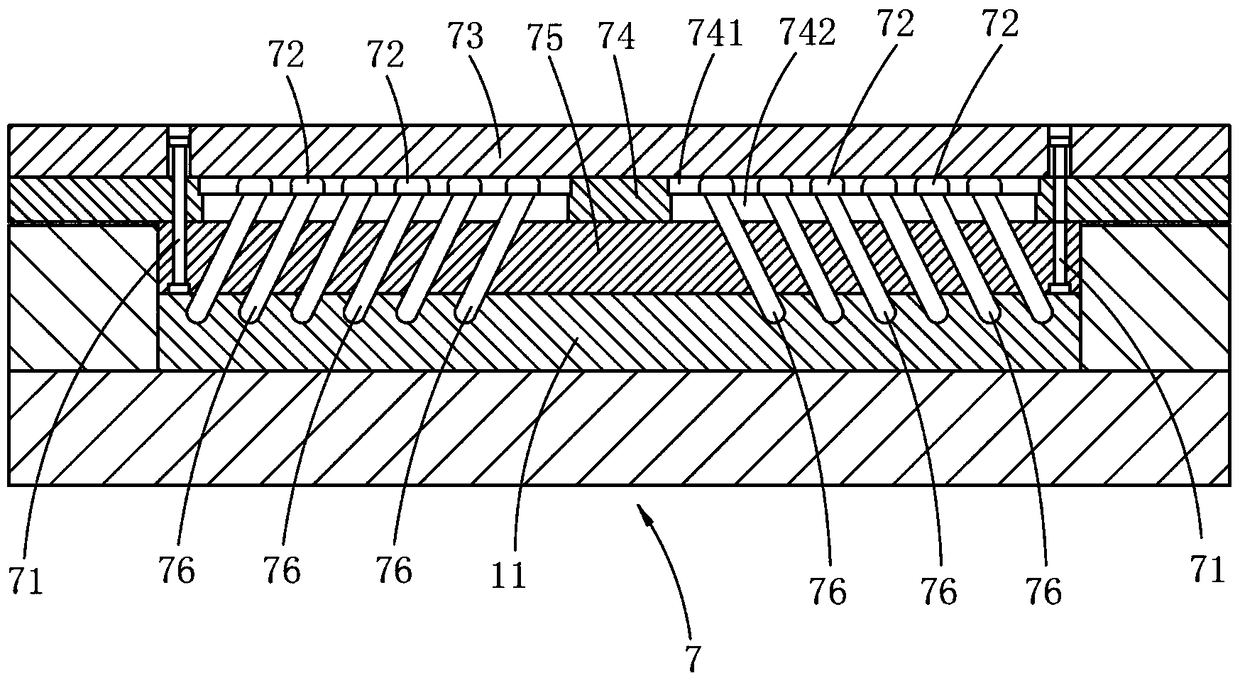

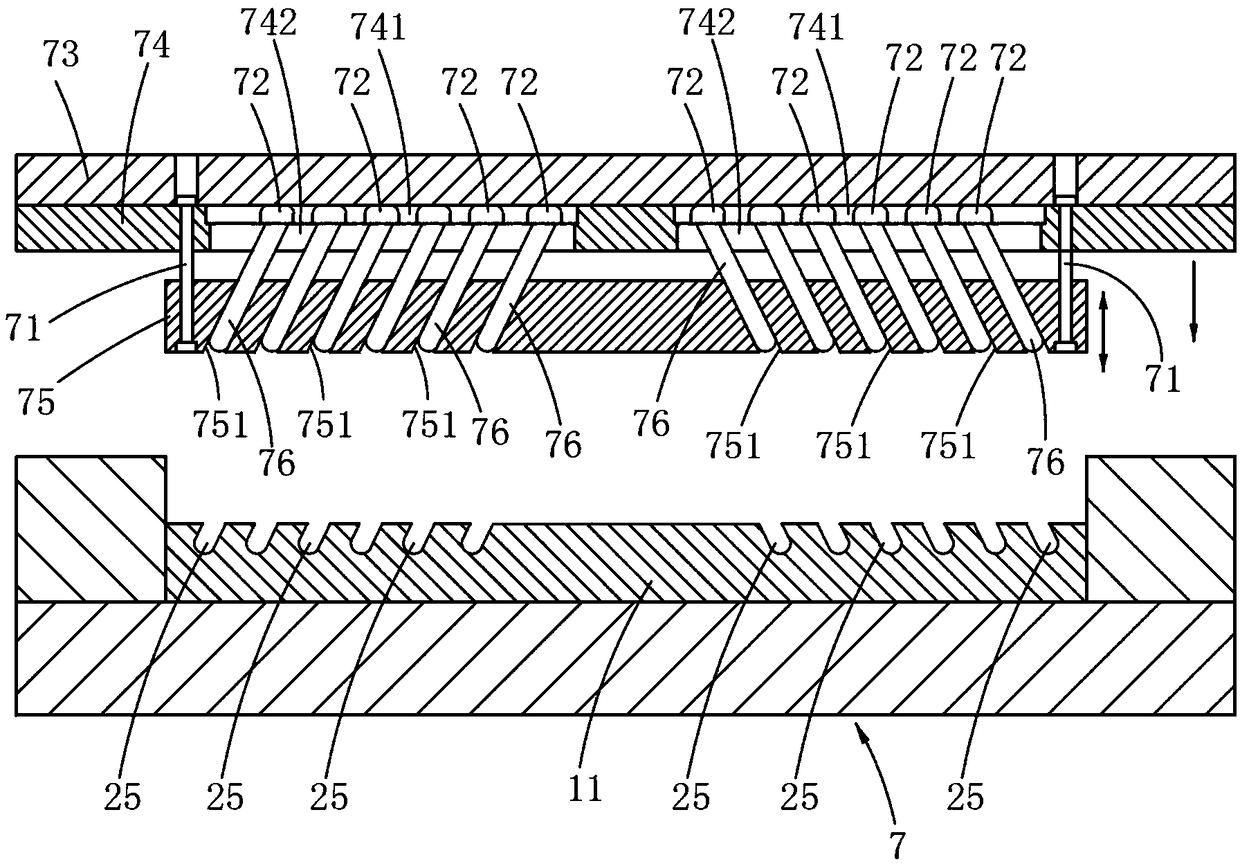

[0079] Production method of integrated easy-to-lay ceramic tiles, Figures 1 to 4 shown, including the following steps,

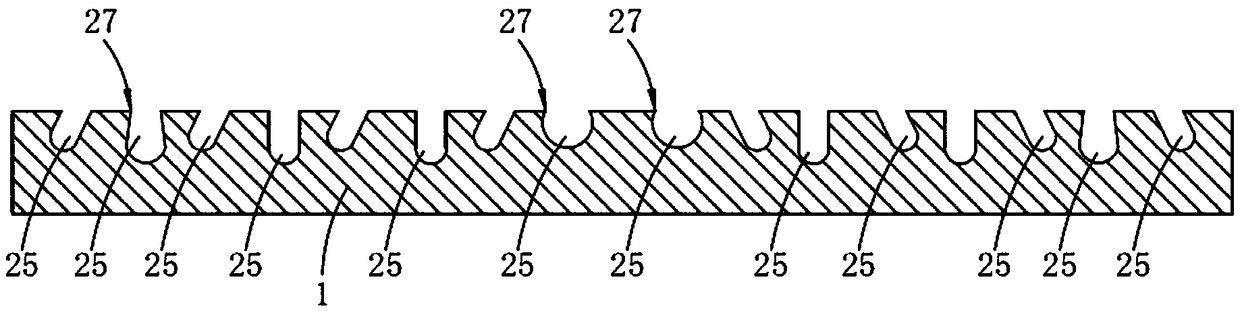

[0080] In the forming step of the ceramic tile main body layer, the ceramic tile main body mud embryo 11 is made first, and a plurality of slot holes 25 with different orientations are formed on the bottom surface of the ceramic tile main body mud embryo 11, and the ceramic tile main body mud embryo 11 is sintered to form the ceramic tile main body layer 1. The bottom surface of the main body layer 1 is formed with a plurality of slots 25, so that the slots 25 have different orientations or the mouth of the slots 25 has a narrowing portion 27 that shrinks; specifically,

[0081] First make the main embryo of the tile,

[0082] Put the ceramic tile main embryo into the sizing chamber of the lower mold of the slot forming mold 7 to carry out extrusion and sizing, and simultaneously pass the slot forming rod 71 installed on the upper mold of the slot forming ...

Embodiment 2

[0103] Production method of integrated easy-to-lay ceramic tiles, Figure 5 As shown, the main steps of this embodiment, the used slot forming die 7 and forming die 8 are respectively the same as those of Embodiment 1, and the similarities will not be repeated here. The difference is that the following steps are included,

[0104] The forming steps of the ceramic tile main layer are the same as those in Embodiment 1.

[0105] The in-mold molding step is the same as that of Embodiment 1.

[0106] The in-mold secondary molding step is to at least integrally form the elastic balance cushion layer 5, the mute cushion layer 4 or the plastic sheet layer 6 on the bottom surface of the plastic substrate layer 2 through the in-mold secondary molding process; the ceramic tile main layer 1 is made of porcelain Tile base material made of quality or stone; the mute cushion layer 4 is made of PVC mute cushion layer 4, EVA mute cushion layer 4 or IXPE mute cushion layer 4, and the bottom su...

Embodiment 3

[0121] An in-mold one-piece easy-to-pave ceramic tile, Figures 6 to 8 As shown, including the ceramic tile main layer 11, a plastic substrate layer 22 is integrally formed on the bottom surface of the ceramic tile main layer 11 through an in-mold molding process. The ceramic tile main layer 11 is made of porcelain or stone. The plastic substrate Layer 22 is a substrate layer formed by selecting natural rubber, synthetic rubber, plastic, stone-plastic composite material or wood-plastic composite material.

[0122] The edge of the plastic substrate layer 22 is directly formed with the groove and tenon structure 2121 during the in-mold molding process. The tenon-and-groove structure 2121 selects a card groove or a tenon that is clamped up and down, and two adjacent one-piece easy-to-pave ceramic tiles are spliced or clamped up and down through the tenon-and-groove structure 2121, so as to realize rapid laying and one-piece easy-to-pave ceramic tiles.

[0123] The sides of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com