Anti-freezing concrete pole with high collision resistance

A technology of concrete and concrete layer, applied in the direction of building type, electrical components, cable installation, etc., can solve the problems affecting the impact strength of concrete poles, cumbersome construction process, poor frost resistance, etc., to achieve all-round performance enhancement, Easy to disassemble and assemble, improve the effect of anti-collision performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

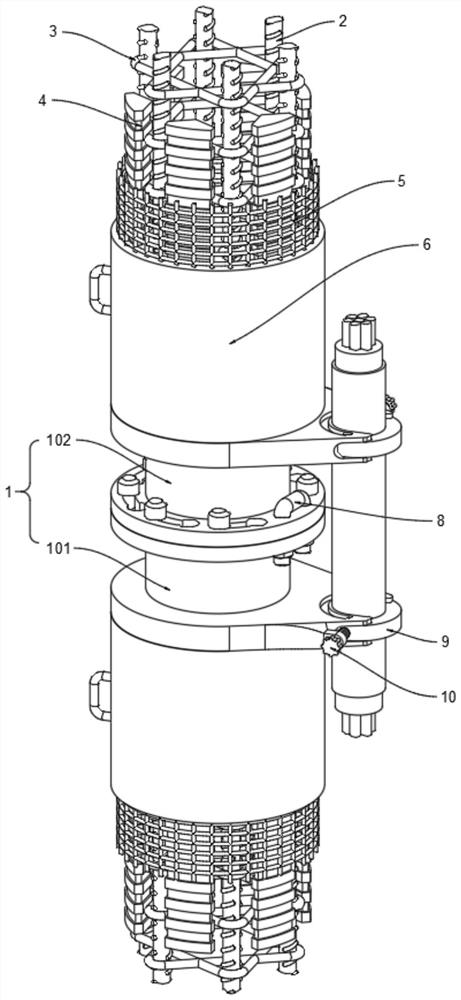

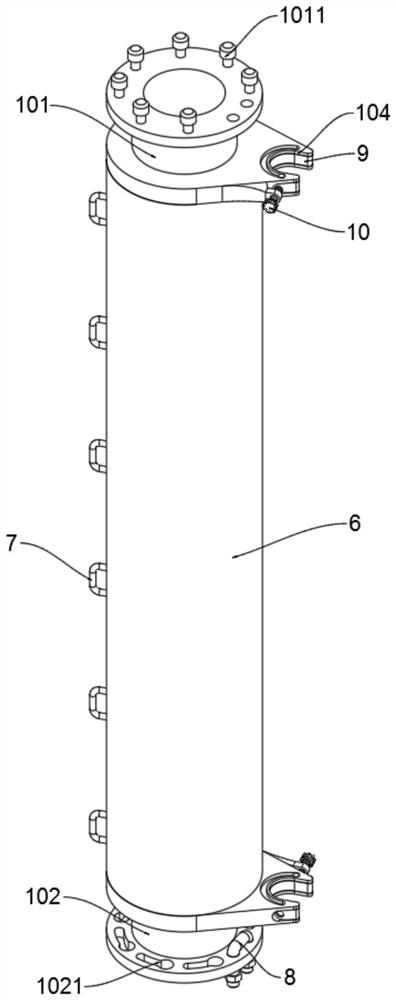

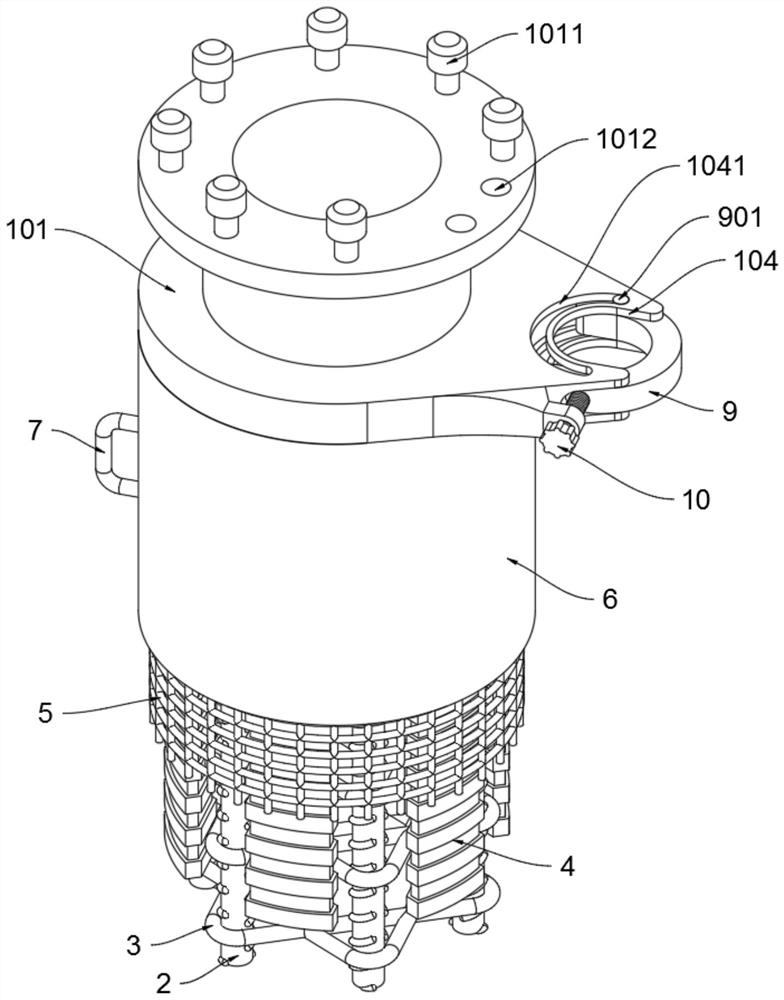

[0036] Please refer to Figure 1 to Figure 9 :

[0037]The present invention proposes a high anti-collision frost-resistant concrete pole, comprising: a connecting piece 1, a steel bar frame 3, a foam strip 4 and a concrete layer 6; Type, and the upper connecting piece 101 is connected to the top of the main steel bar 2, and the lower connecting piece 102 is connected to the bottom end of the main reinforcing bar 2, and the top side of one of the upper connecting pieces 101 is connected to the bottom side of the other lower connecting piece 102; the top of the upper connecting piece 101 There are seven clamping connecting columns 1011 in a circular shape, and seven clamping connecting holes 1021 are provided in a circular shape at the bottom of the lower connecting piece 102. The clamping connecting columns 1011 slide and insert into the clamping connecting holes 1021, and the clamping connecting columns 1011 are connected to the clamping connecting holes 1021. The top side o...

Embodiment 2

[0045] Cable slots 104 are opened at the same position on the outer side of the upper connecting piece 101 and the outer side of the lower connecting piece 102. The upper and lower sides of the cable slot 104 are respectively provided with arc-shaped slide holes 1041. The U-shaped cable lock 9 is rotatably connected to the cable slot 104. Inside, the upper and lower sides of the U-shaped cable lock 9 are respectively provided with sliders 901, and the sliders 901 are slidably connected in the arc-shaped slide hole 1041, and the outer sides of the upper connecting piece 101 and the outer sides of the lower connecting piece 102 are provided with screw holes 105. The bolt 10 is threadedly connected in the screw hole 105, the outer side of the U-shaped cable lock 9 is provided with a limiting groove 902, and the inner end of the manual bolt 10 is inserted into the limiting groove 902;

[0046] Using the above technical scheme, when it is necessary to connect buried cables, the buri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com