PVC (polyvinyl chloride) dual-resistant flexible pipe

A polyvinyl chloride, soft polyvinyl chloride technology, applied in the direction of hoses, pipes, pipes/pipe joints/pipe fittings, etc., can solve the problem of separation of the skeleton layer and the plastic layer, and achieve creep and thermal expansion and contraction coefficients Small size, good compatibility, enhanced antistatic and flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

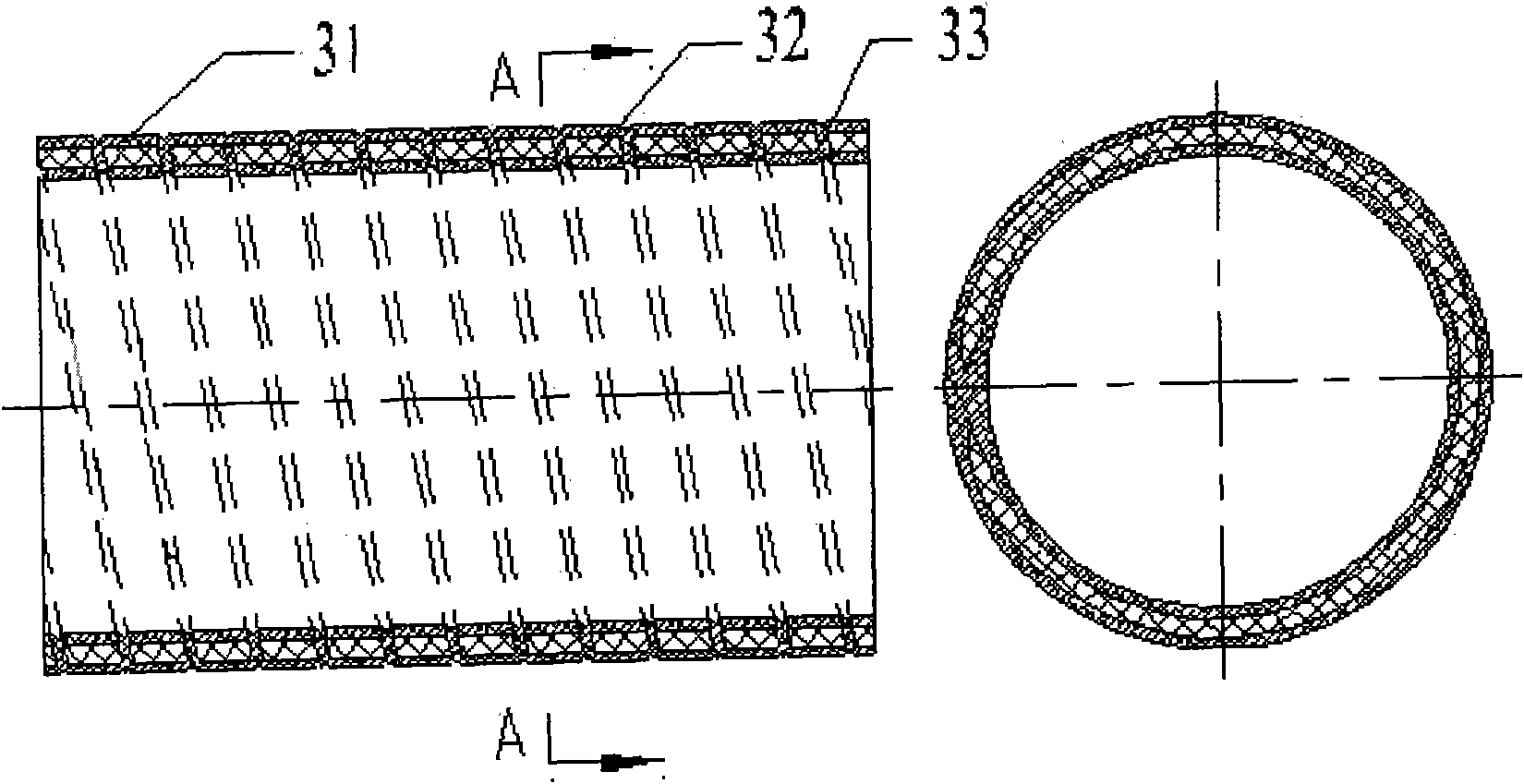

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0020] The structure of a polyvinyl chloride double-resistant hose of the present invention is as follows: image 3 As shown, the hose includes soft PVC and a skeleton layer embedded in the soft PVC, the skeleton layer is composed of unplasticized PVC hard strips, and adjacent unplasticized PVC hard strips are formed by soft PVC strips. quality PVC separated. The soft PVC contains carbon black, graphite or an organic antistatic agent, and an organic flame retardant or an inorganic flame retardant.

[0021] This embodiment uses unplasticized PVC hard strips as the skeleton layer, fully utilizes the high tensile strength and high elastic modulus of hard PVC, and can be use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com