Rollable heating elements for floors or walls

A heating component, rolling technology, applied in the field of architectural decoration, can solve problems such as complex structure, high energy consumption, uneven indoor temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] (Example 1, heating components for the ground or wall)

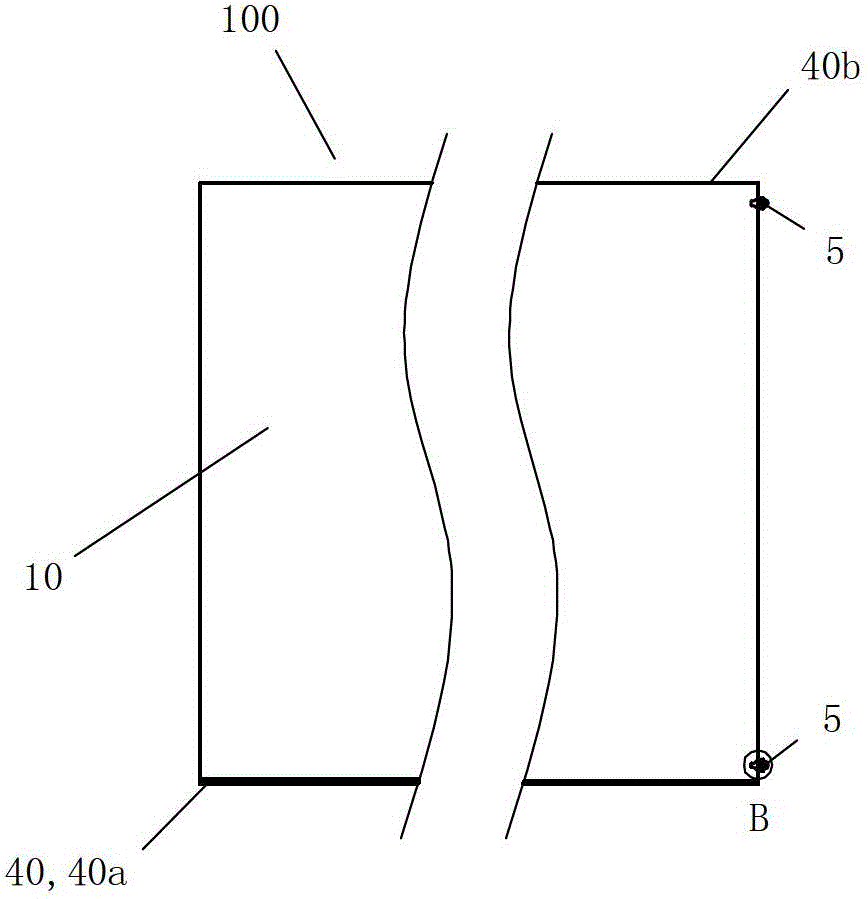

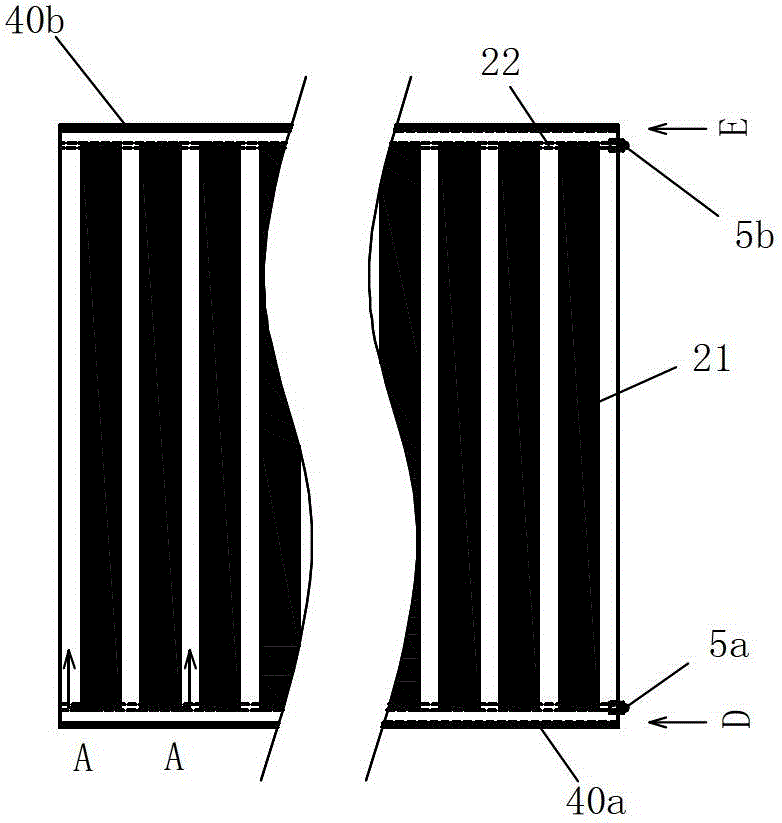

[0092] See figure 1 and image 3 , the heating component 100 of the present invention includes a heating board 10 , a fastener 40 and a socket 5 . The buckle 40 is composed of a front buckle 40 a located at the front of the heating board 10 and a rear buckle 40 b located at the rear of the heating board 10 . The front buckle 40a is the position where the rear buckle 40b of the heating element 100 of the same structure adjacent to the front side is connected and matched with each other; The front buckle parts 40a of the heat generating component 100 of the structure are connected and matched with each other. The socket 5 is composed of a front socket 5a (right front in this embodiment) and a rear socket 5b (right rear in this embodiment) on the same side as the left and right sides of the heating plate 10 .

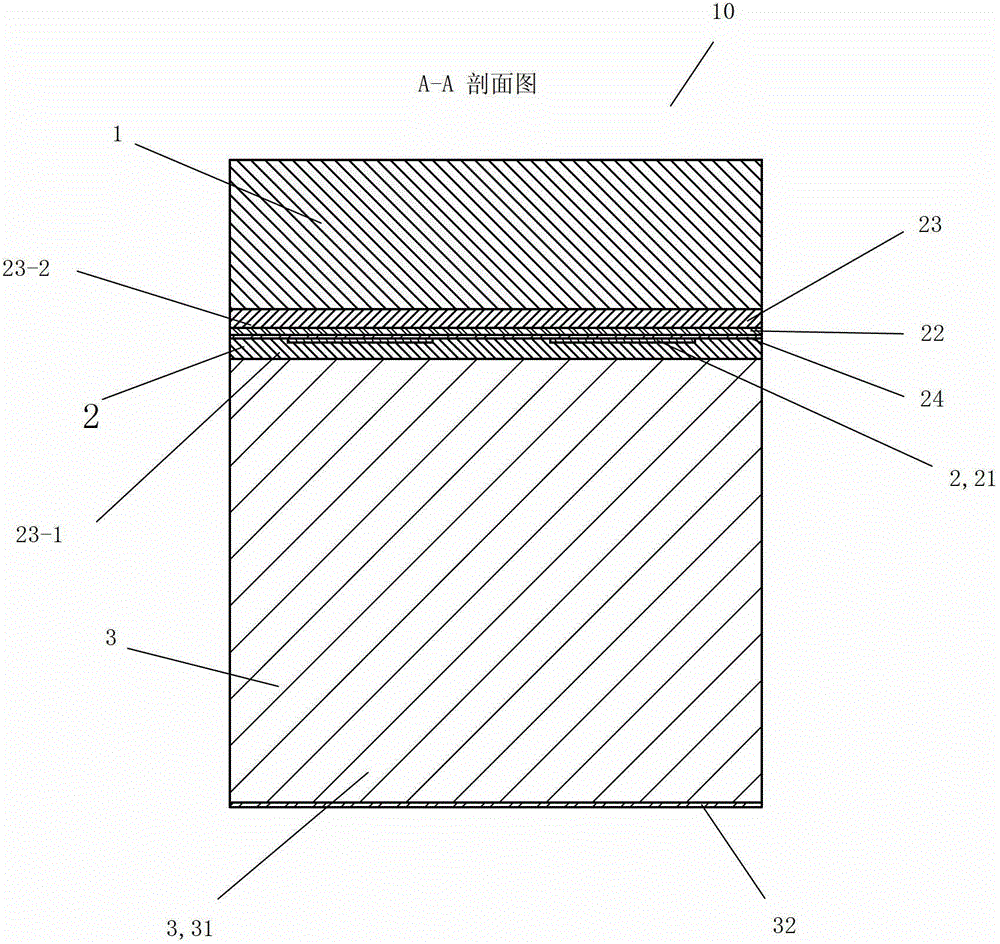

[0093] See Figure 1 to Figure 3 , The heating plate 10 includes a decorative surface layer 1 , a heat...

Embodiment 2

[0131] (Example 2, heating components for the ground or wall)

[0132] See Figure 23 to Figure 26 , The rest of this embodiment is the same as that of Embodiment 1, except that the lower clamping device 54a of the bottom plate 54 of the socket 5 is a bead 54a-2. There are 1 to 4 bead 54a-2 (there are 2 in this embodiment), and the structural shape of each bead 54a-2 is the same. on the triangle.

[0133] The upper clamping device 55b of the pressing plate 55 of the socket 5 is a pressing bar 55b-2. There are 1 to 4 bead 55b-2 (there are 2 in this embodiment), and the structural shape of each bead 55b-2 is the same. Downside down triangle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com