Patents

Literature

68results about How to "Quick job change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

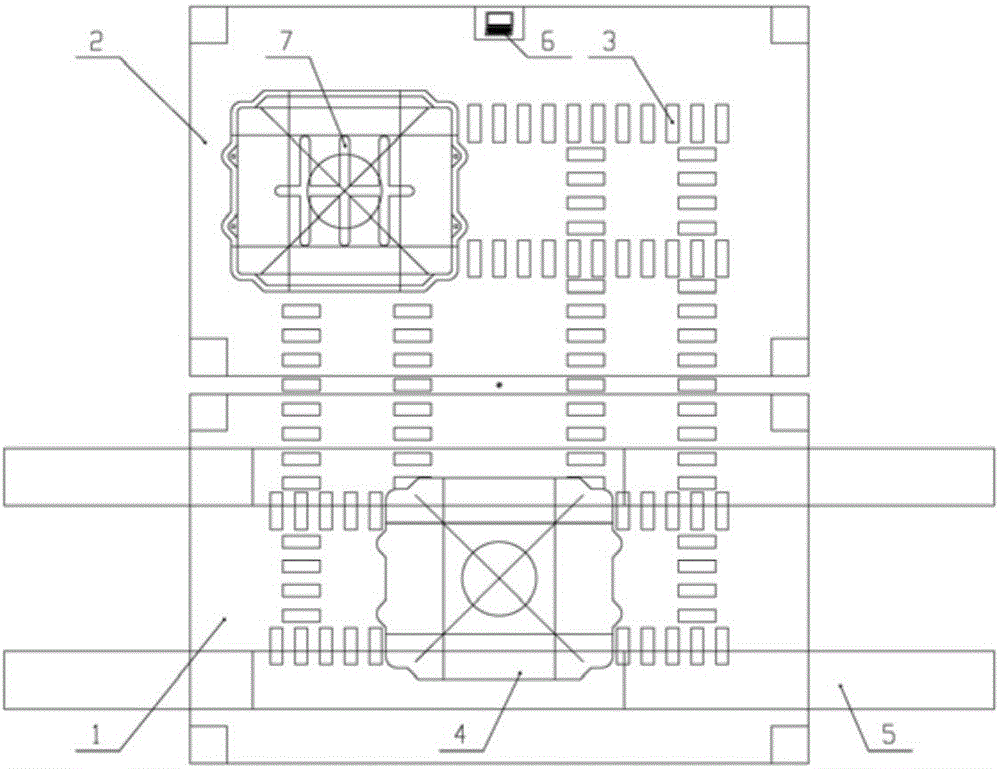

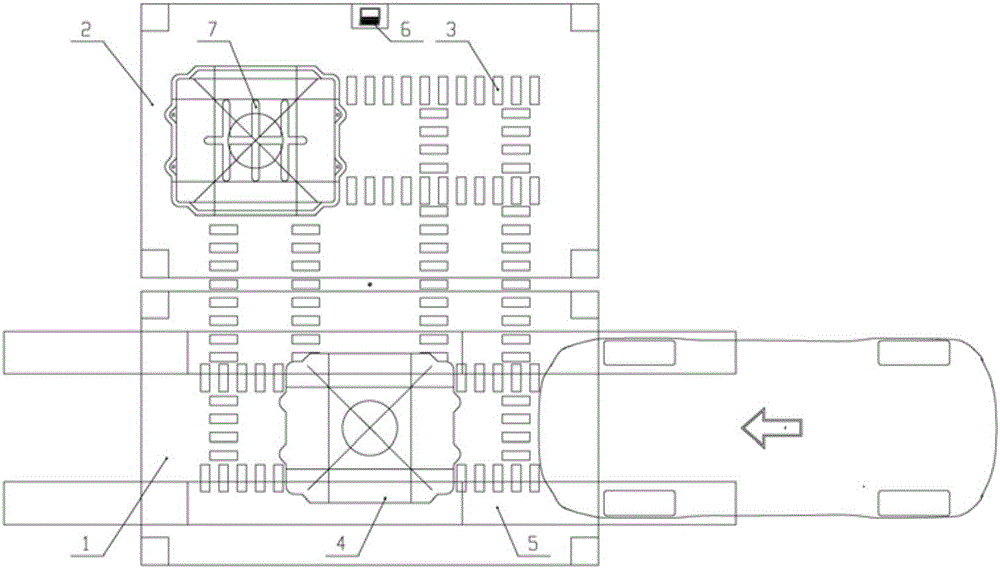

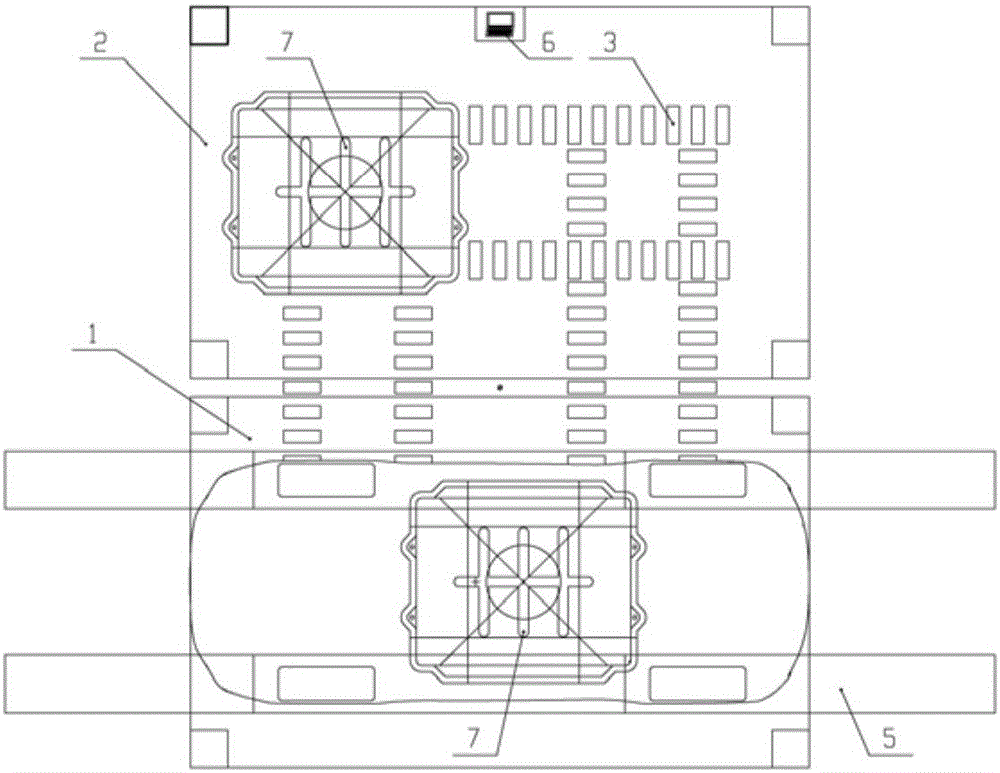

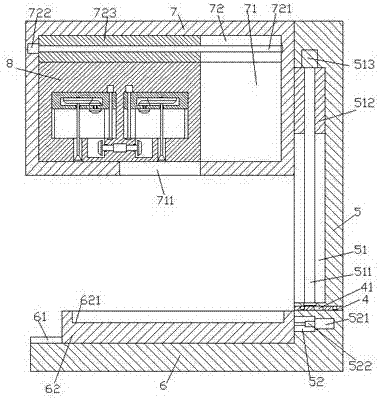

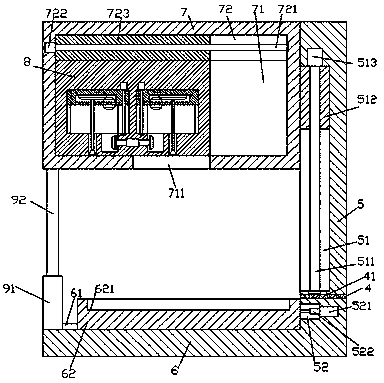

Replacement method of electric vehicle power battery fast replacement system

InactiveCN106218599AQuick changeFast replacementElectric propulsion mountingVehicle servicing/repairingPower batteryElectricity

A replacement method of an electric vehicle power battery fast replacement system includes the steps that firstly, a control system controls a power battery pallet in a charging room to move to a work preparation station in a battery replacement room along a conveying device; secondly, an electric vehicle runs into the battery replacement room along a vehicle track, and the control system controls the position of the power battery pallet to make the power battery pallet move to the work preparation station; thirdly, the control system controls an automatic battery mounting and dismounting mechanism to dismount a to-be-replaced battery under a chassis of the electric vehicle; fourthly, a fully charged power battery is installed under the chassis of the electric vehicle; fifthly, the electric vehicle runs out of the battery replacement room; and sixthly, circulating is conducted. Fast and efficient replacement of power batteries of electric vehicles is achieved, stability and reliability are achieved, replacement efficiency is greatly improved, replacement time is shortened, and fast replacement operation of power batteries of electric vehicles under various working conditions can be achieved.

Owner:LUOYANG MINING MACHINERY ENG DESIGN & RES INST

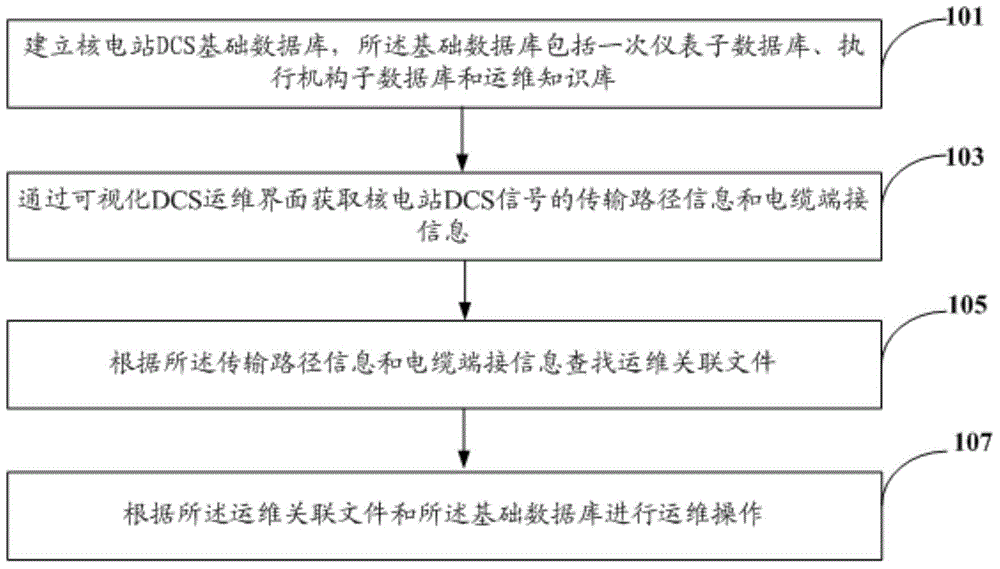

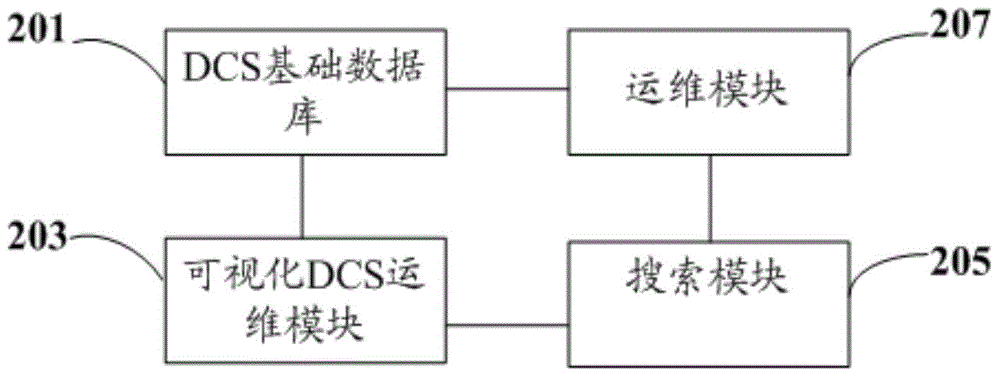

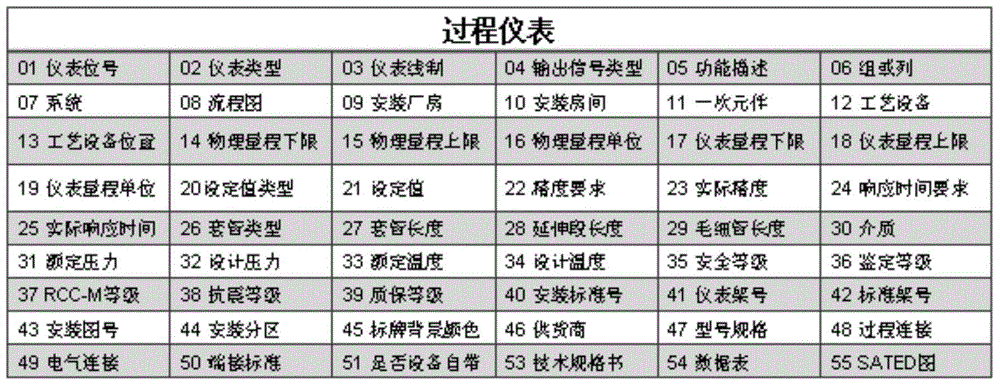

Nuclear power station DCS (digital control system) visual operation and maintenance operating method and system

InactiveCN104571016AQuick job changeEasy to change jobsPower plant safety arrangementNuclear energy generationOperational systemNuclear power

The invention discloses a nuclear power station DCS (digital control system) visual operation and maintenance operating method which comprises the following steps: establishing a nuclear power station DCS basic database which includes a primary instrument subdata base, an actuator subdata base and an operation and maintenance knowledge base; acquiring transmission path information and cable terminating information of nuclear power station DCS signals through a visual DCS operation and maintenance interface; finding an operation and maintenance related file according to the transmission path information and the cable terminating information; performing an operation and maintenance operation according to the operation and maintenance related file and the basic database. The nuclear power station DCS visual operation and maintenance operating method is a nuclear power station DCS visual operation and maintenance operating and processing technology that the operation is accurate and easy, and besides, the invention further discloses a nuclear power station DCS visual operation and maintenance operating system.

Owner:中广核工程有限公司 +1

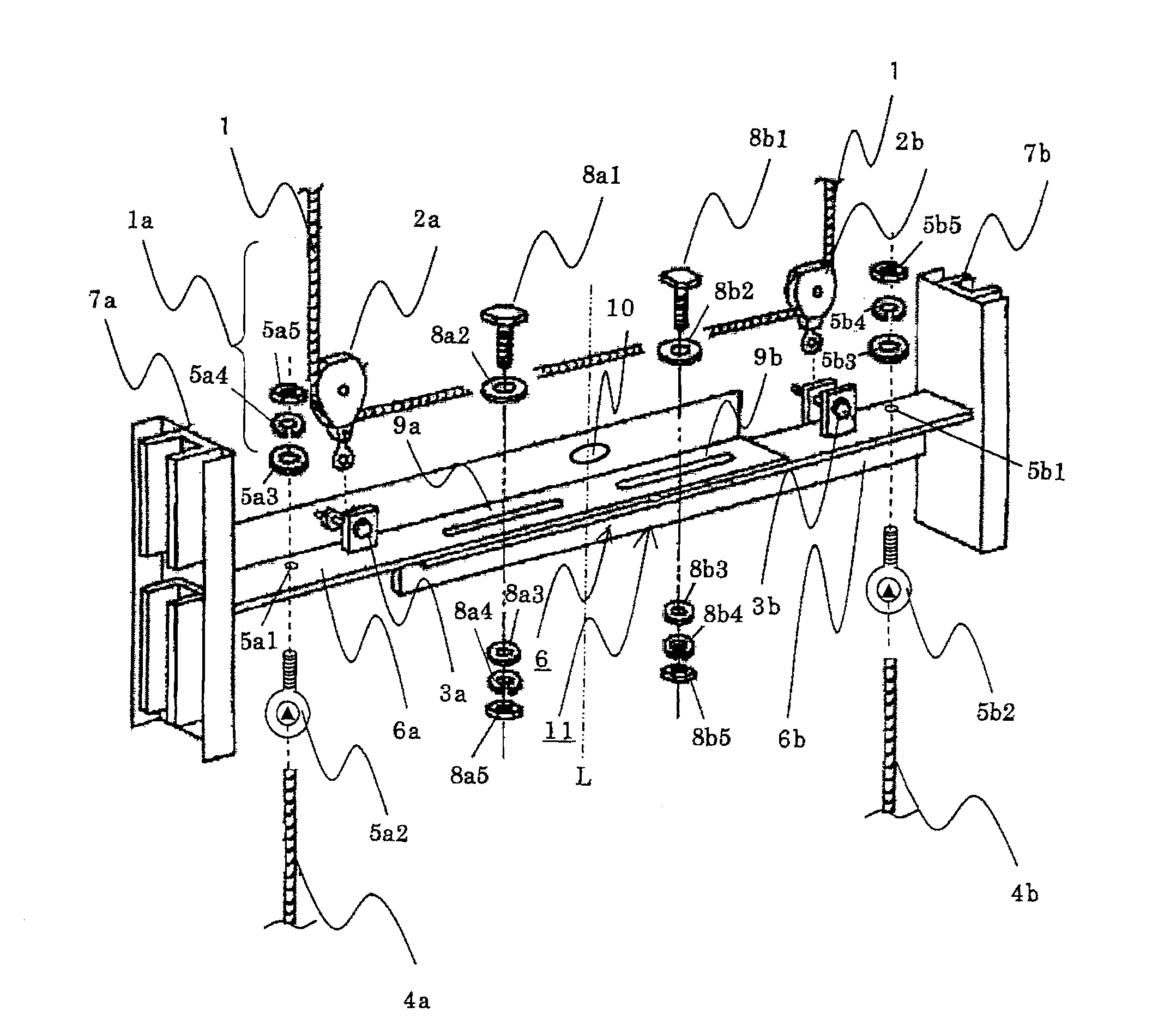

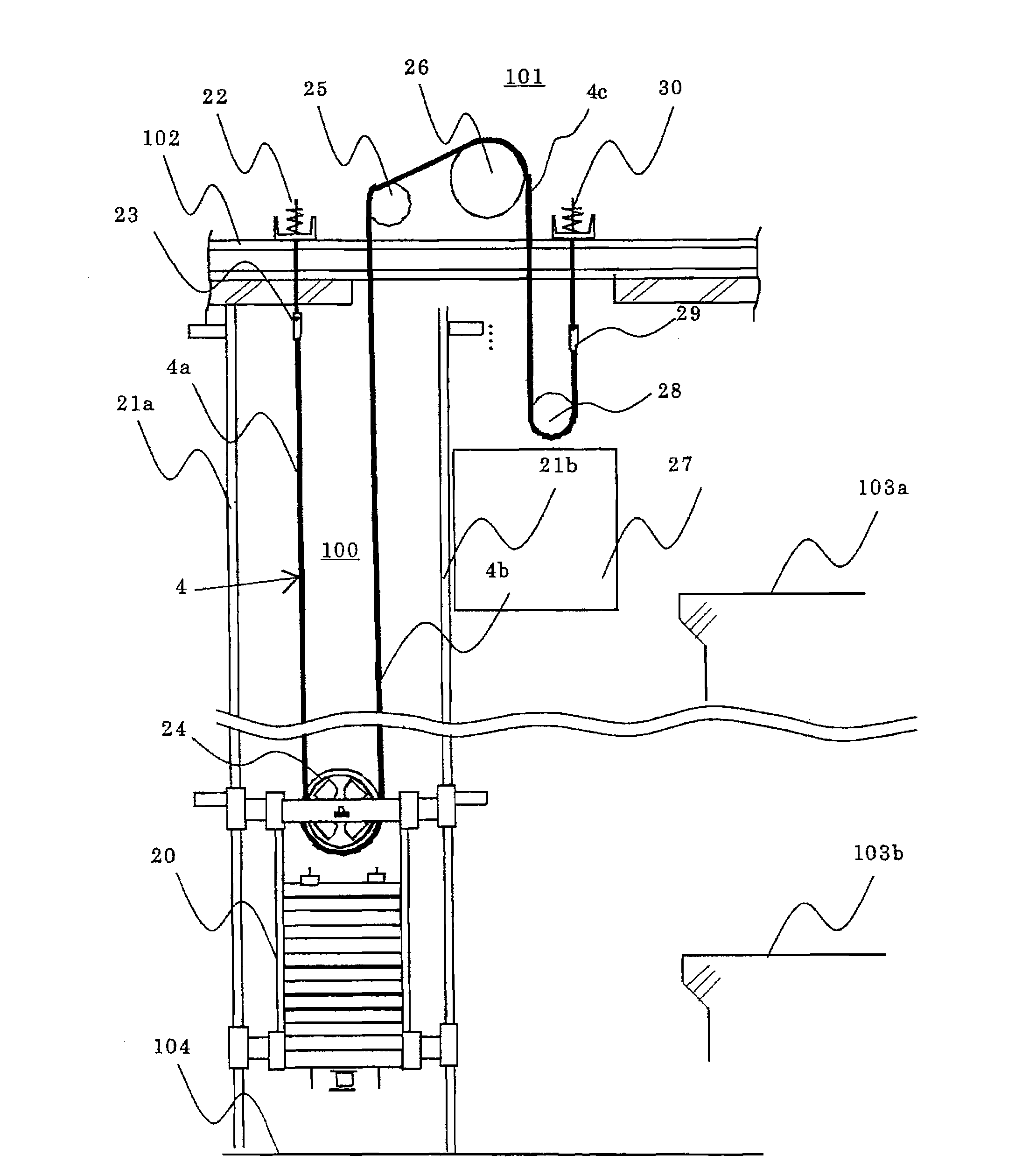

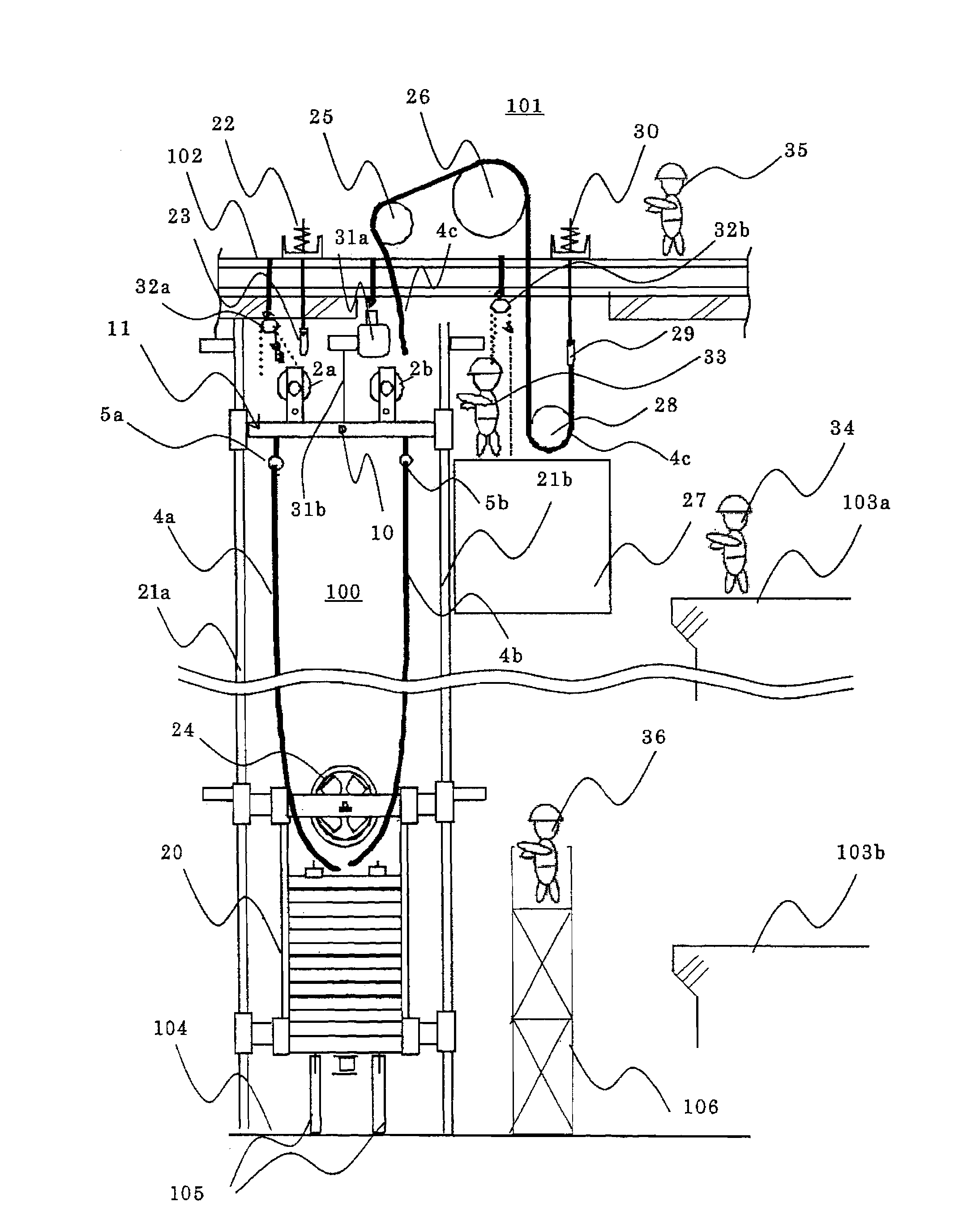

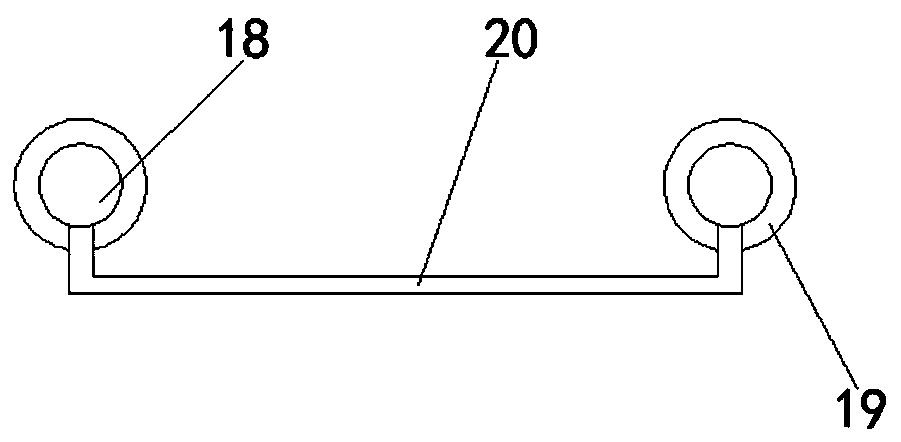

Main wirerope replacing tool of elevator

ActiveCN103224179AReduce the burden onChange jobs quicklyElevatorsMine liftsEngineeringHorizontal diameter

The inveniton provides a main wirerope replacing tool of elevator, which can rapidly carry out the replacing work of main wirerope and reduct cost in the replacing work. The main wirerope replacing tool is applied to elevator and comprises a pair of guide rail (21a, 21b) for guiding a counterbalance (20) which hangs a cage (27) by the main wirerope, and the main wirerope replacing tool of elevator is used for replacing the used main wirerope (4) to a new main wirerope (1). The main wirerope replacing tool of elevator comprises a horizontal bar member (1) provided between the guide rails and arranged above the counterweight, a guiding member (7a, 7b) which is fixedly arranged at double ends of the horizontal bar and slidably installed on the guide rail; a stringing pulley (2a, 2b) which is installed on the horizontal bar memeber when winding the new wirerope; and a wirerope connecting mechanism (5a, 5b) which is provided on the horizontal bar member and connected to the used main wirerope (4a, 4b).

Owner:HITACHI BUILDING SYST CO LTD

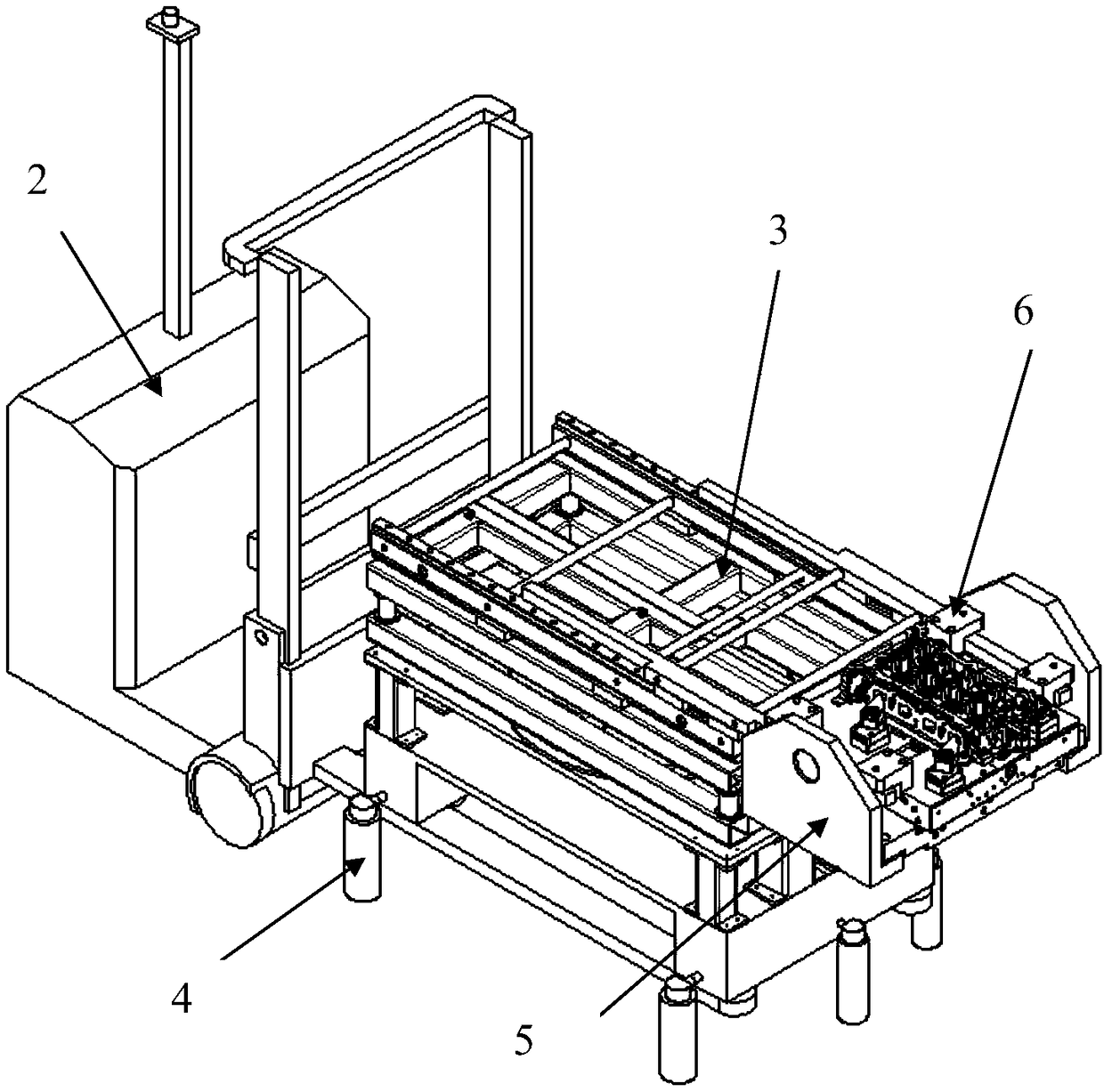

Fully-automatic system for rapidly switching over fixtures

PendingCN108655804AQuick job changeReduce inconvenienceMetal working apparatusEngineeringFully automatic

The invention relates to a fully-automatic system for rapidly switching over fixtures. The fully-automatic system for rapidly switching over the fixtures at least comprises a stereoscopic warehouse for fixture storage, an AGV forklift truck and a rapid replacement device for the fixtures, a location device, and a machine tool workbench connector, wherein the stereoscopic warehouse for fixture storage is used for storing the fixtures needing to be replaced, and outputting the stored fixtures and carrying out secondary location on the output fixtures while receiving a command of needing to replace the fixtures; the rapid replacement device for the fixtures is installed on the AGV forklift truck, and carries the fixtures output by the stereoscopic warehouse for fixture storage to a machine tool window under the cooperation of the AGV forklift truck; the location device is located in front of the machine tool window, and used for locating the rapid replacement device for the fixtures and enabling the rapid replacement device for the fixtures to keep a position suitable for replacing the fixtures, with a machine tool; and the machine tool workbench connector is used for butting with thefixtures needing to be replaced. The fully-automatic system for rapidly switching over the fixtures is capable of accurately and rapidly replacing the fixtures, thereby increasing the working efficiency and the flexibility level of a production line.

Owner:SHANGHAI SMARTSTATE TECH CO LTD

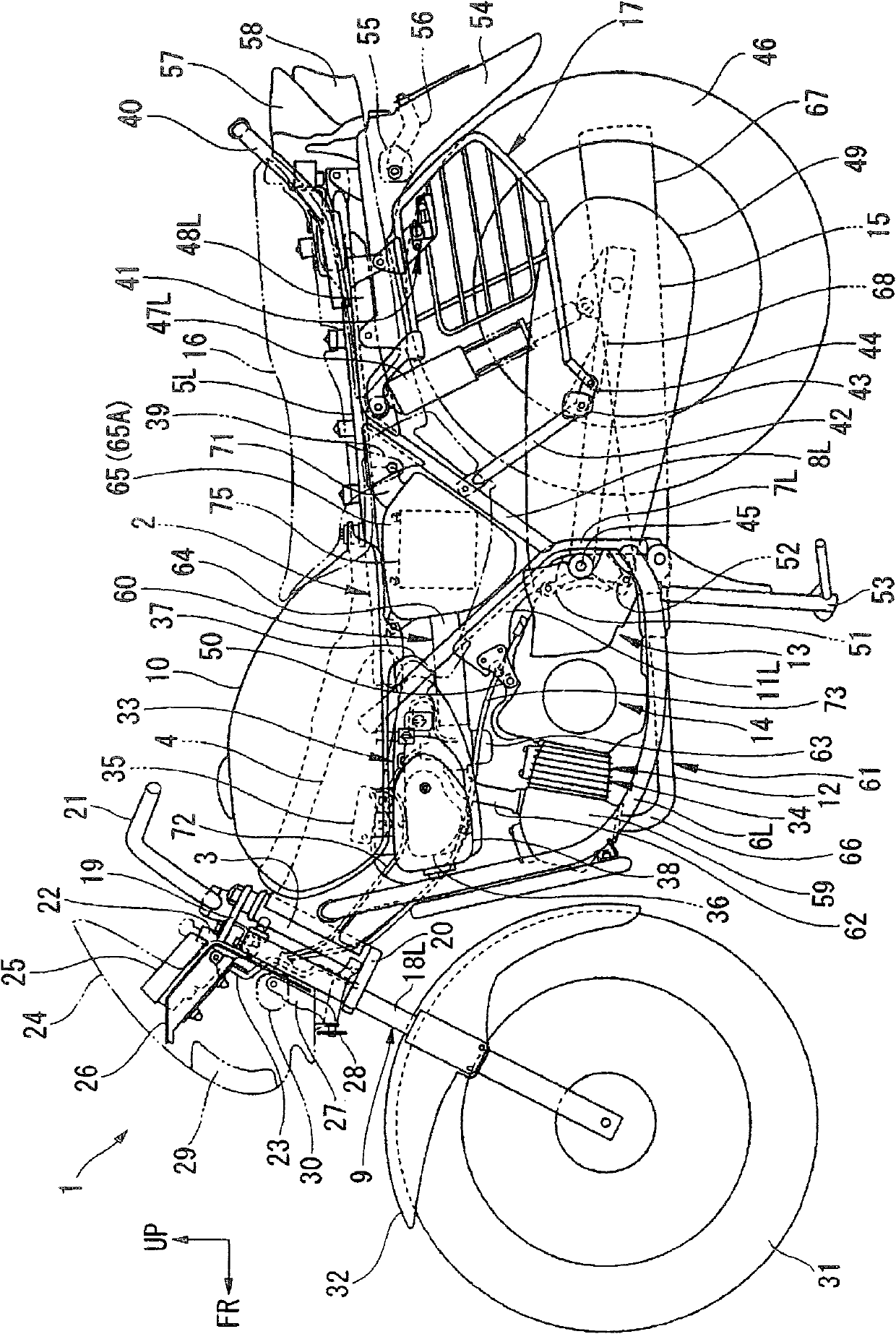

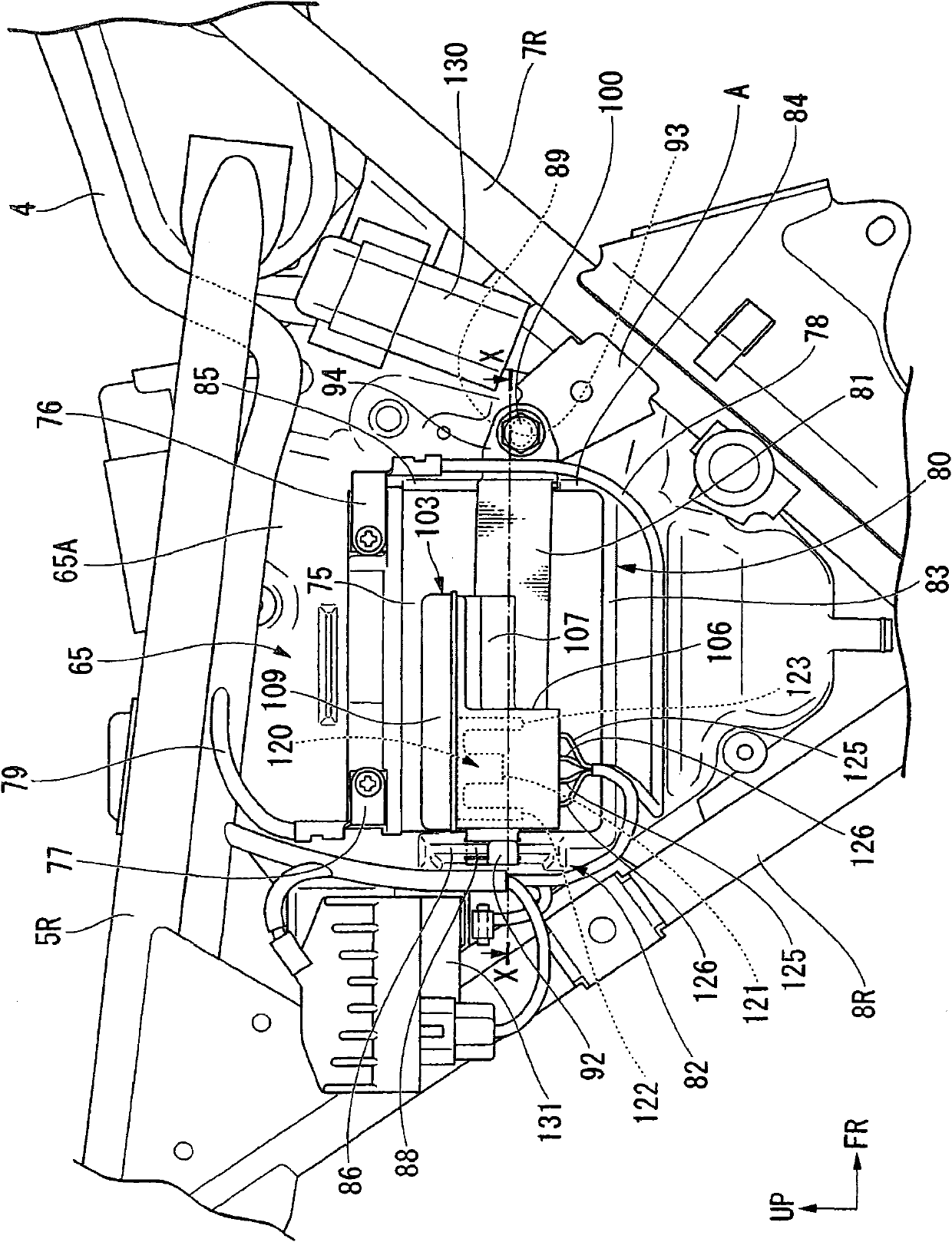

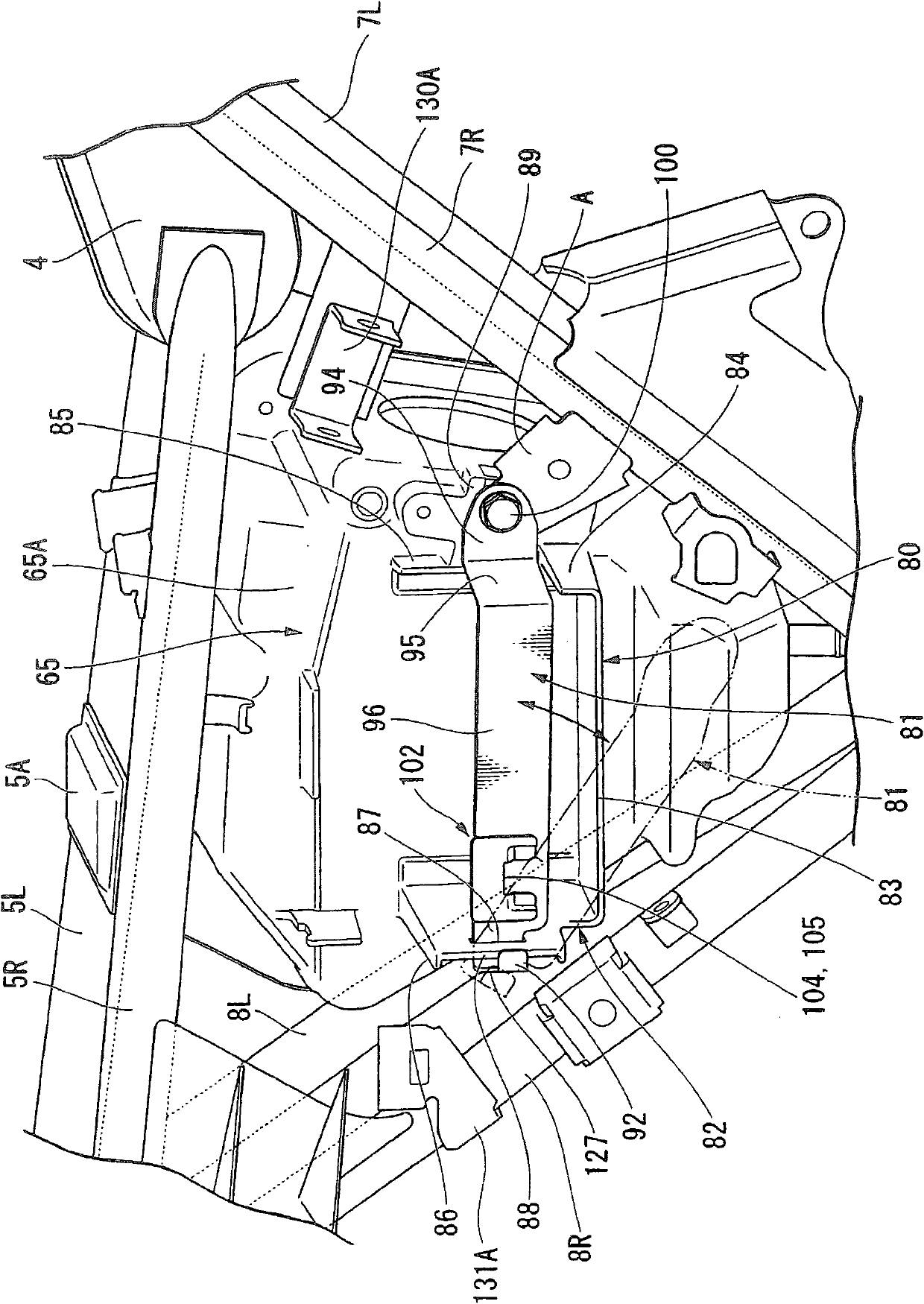

Accumulator fixing structure

ActiveCN102034947AEfficient configurationReduce in quantityElectric propulsion mountingCell component detailsEngineeringMechanical engineering

Owner:HONDA MOTOR CO LTD

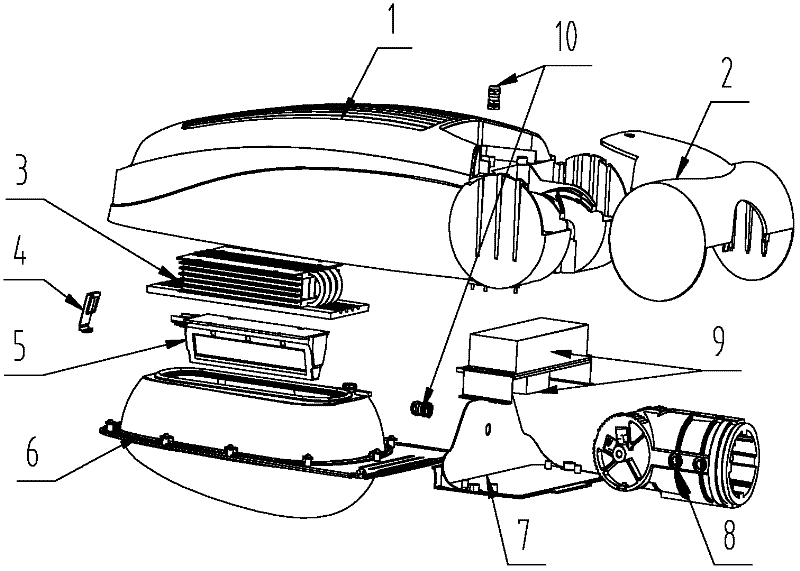

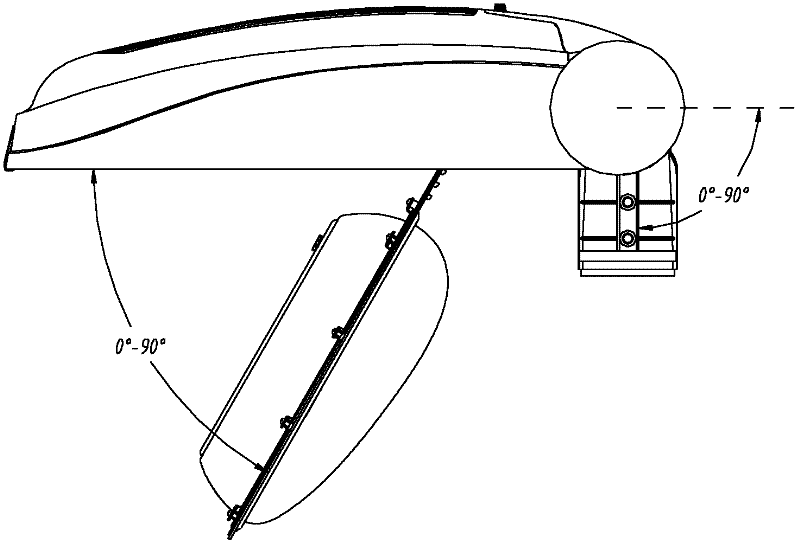

LED split type module lamp

InactiveCN102410478AEasy to implement extended applicationEasy to disassemble and replacePoint-like light sourceElectric circuit arrangementsEngineeringWrench

The invention discloses an LED split type module lamp which comprises a light management module, a light source module, a heat-radiating module and a housing, wherein the housing is provided with a cavity structure with an opened side, the heat-radiating module is arranged in a cavity of the cavity structure, a penetrating structure communicated with outside is arranged on the wall of the cavity,the light source module is fixed with the heat-radiating module, an emergent light side points at the opened side of the cavity, one end of the light management module is connected with the housing through a hinge mechanism and enables the light management module to rotate around the hinge mechanism for covering the opened side so as to cover and buckle the light source module, and the other end of the light management module is fixed with the housing through a wrench buckle. The power drive module, the light source module, the heat-radiating module and the light management module are subjected to split module design, thus the LED split type module lamp is easy to disassemble and replace, and is easy to realize expansion application of a large-power LED split type module lamp.

Owner:BEIJING LAMPEARL PHOTOELECTRIC

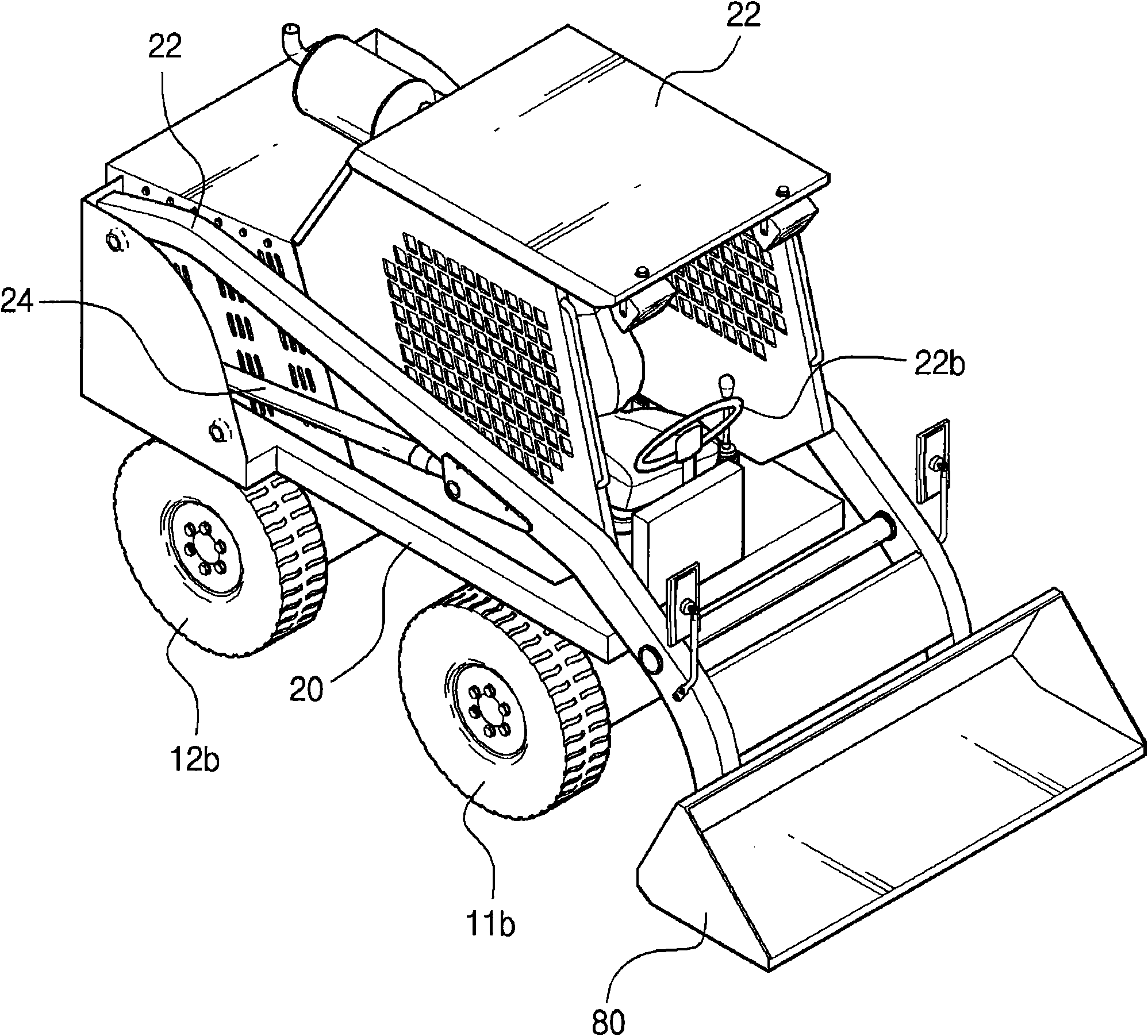

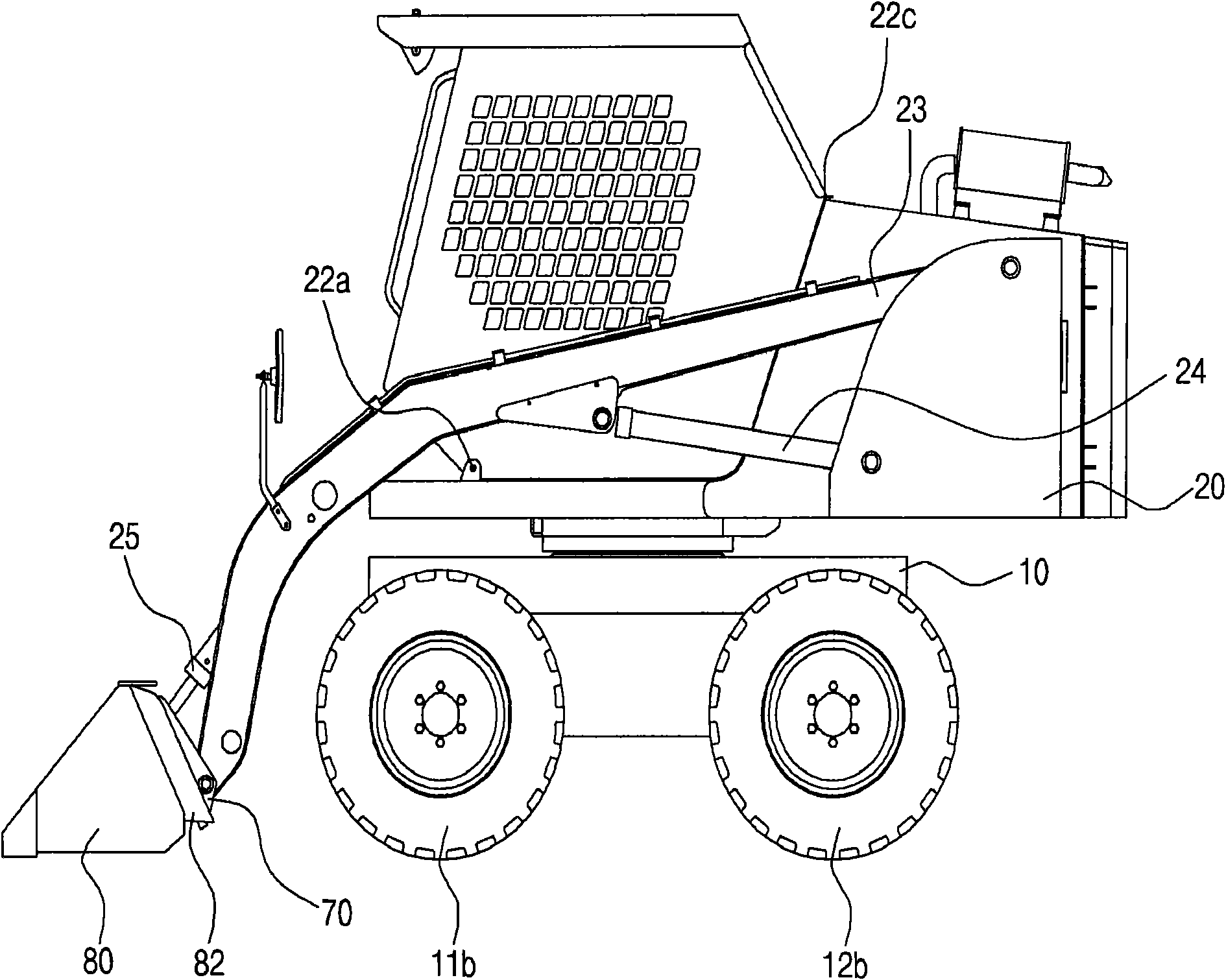

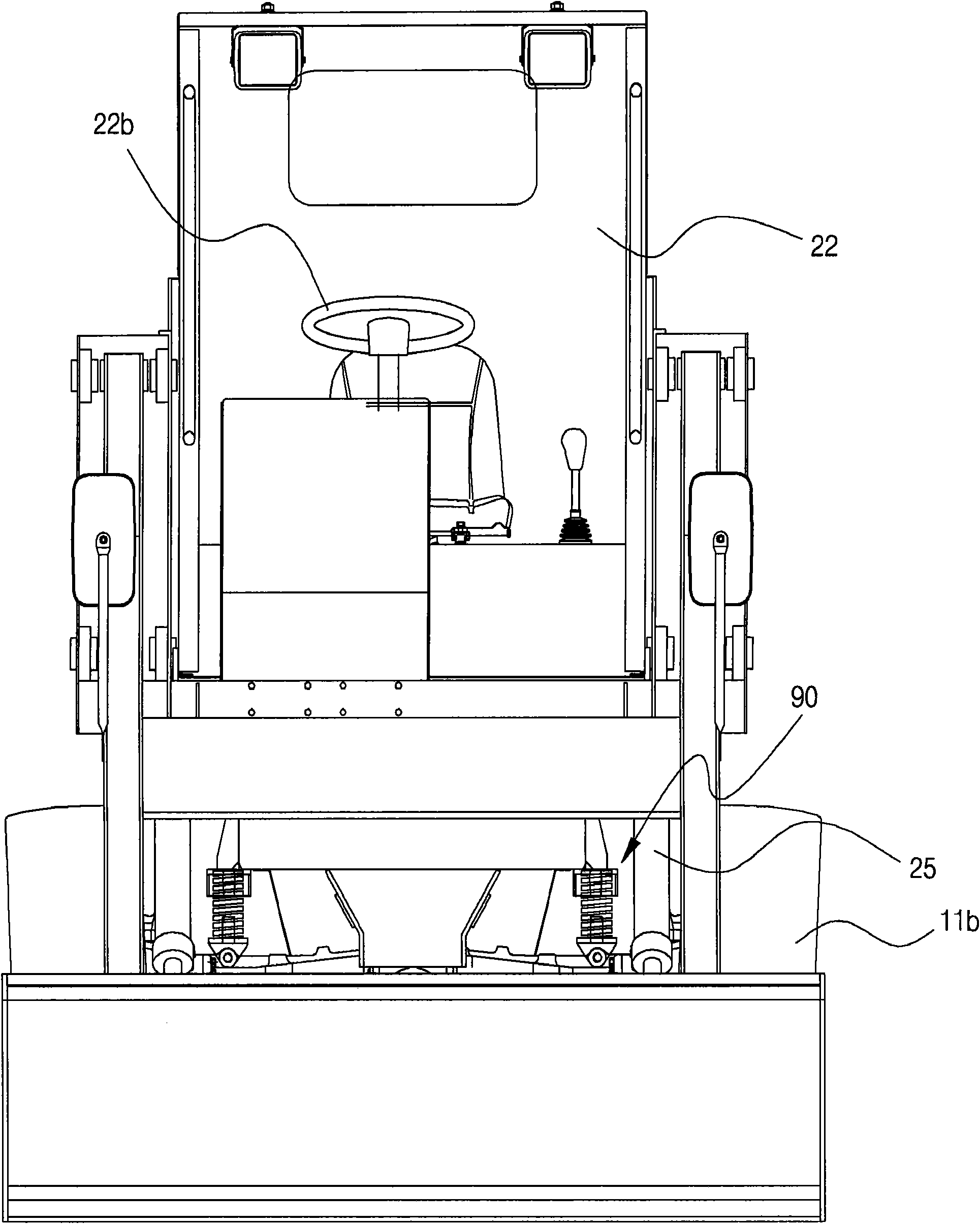

Multi-purpose loader

InactiveCN102061716AQuick job changeSoil lifting machinesMechanical machines/dredgersSteering wheelEngineering

The invention relates to a multi-purpose loader, comprising a lower frame with a front wheel axle box and a rear wheel axle box, an upper frame coupled on the top side of the lower frame and provided with a cab on the top, an upper frame rotating component rotating the upper frame relative to the lower frame, a drive unit driving the front wheels and the rear wheels, a turning unit equipped on the lower frame and rotating the front wheels and the rear wheels according to the rotation of a steering wheel, a linkage unit provided with a linkage body coupled on the two sides of a movable arm equipped on the upper frame and an accessory inserting projecting part formed on the top part of the linkage body, and an accessory provided with an inserting projecting part support groove formed on the upper side of the accessory. Thus the accessory inserting projecting part of the linkage unit is inserted into the accessory in a supporting way.

Owner:HYO CHUN

Cleaning equipment

ActiveCN107159648ARealize automatic controlQuick job changeElectrostatic cleaningEngineeringMechanical engineering

Owner:浙江嘉苑园艺景观有限公司

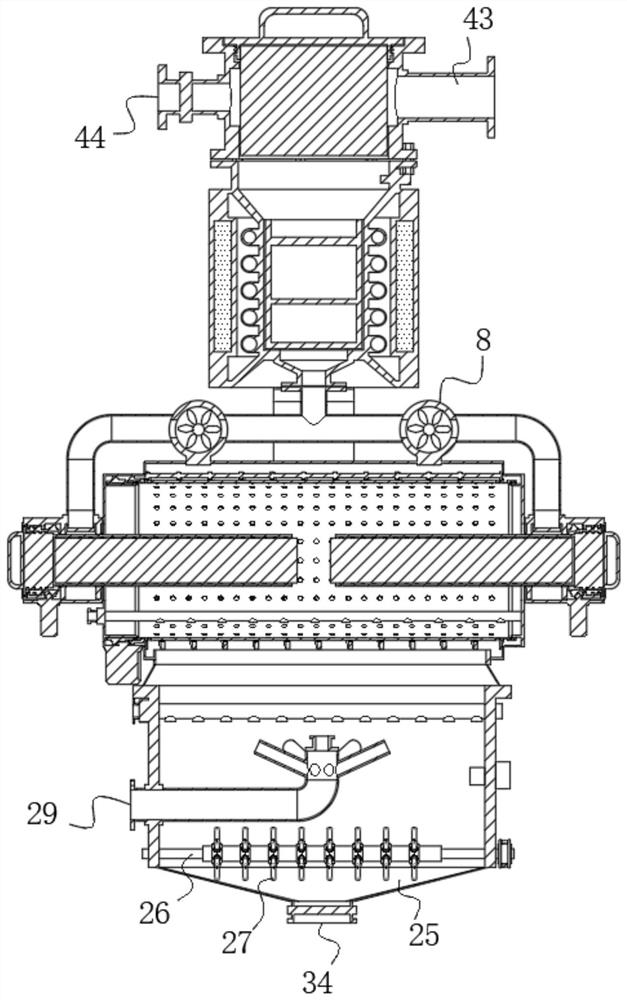

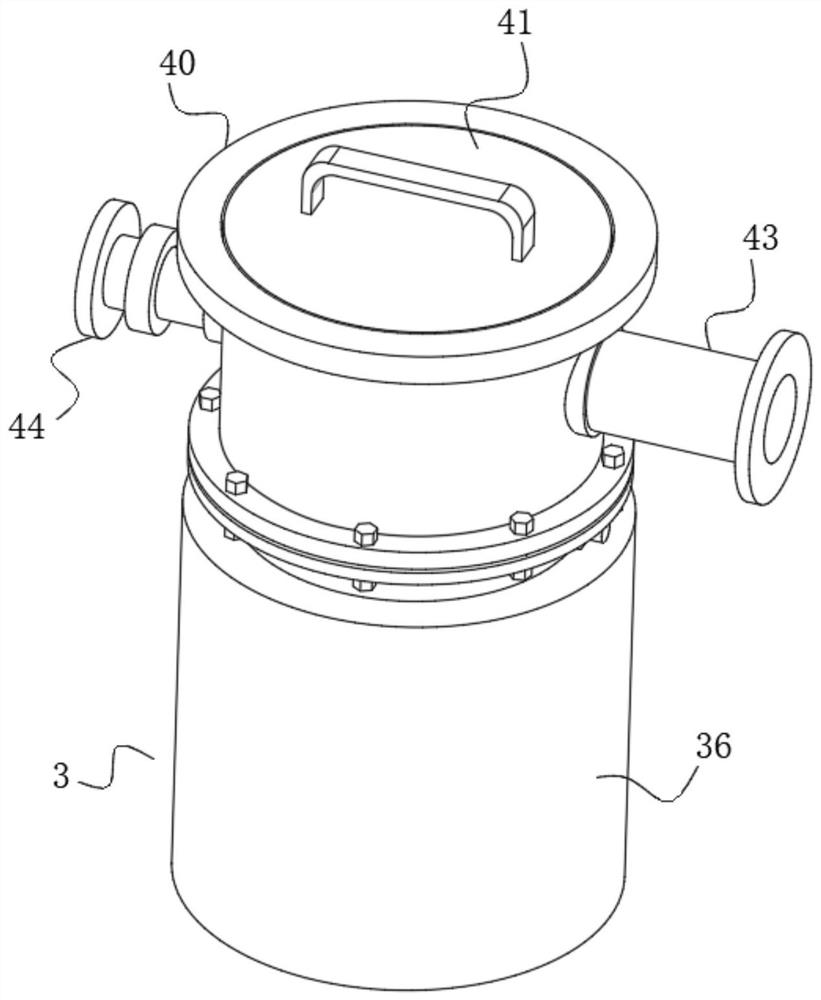

Desulfurization, denitration and dust removal integrated equipment for industrial waste gas

PendingCN113426236AEasy to cleanEasy to useCombination devicesGas treatmentWater storage tankFiltration

The invention relates to desulfurization, denitrification and dust removal integrated equipment for industrial waste gas. The equipment comprises a gas inlet mechanism, a filtering mechanism and a gas exhaust mechanism which are sequentially arranged from bottom to top and communicate with one another, wherein the air inlet mechanism comprises a water storage tank as well as an air inlet device and a spraying device which are arranged in the water storage tank; the filtering mechanism comprises a filtering shell, an air extractor mounted on the filtering shell, and a primary filtering device and a secondary filtering device which are mounted in the filtering shell; the secondary filtering device is mounted in the primary filtering device; the exhaust mechanism is mounted on the filtering mechanism and comprises a catalytic device and a catalytic filtering device which are arranged in sequence. During dust removal, waste gas sequentially passes through the gas inlet device, the spraying device, the primary filtering device and the secondary filtering device for dust removal, then enters the catalytic device for denitration catalysis, is filtered by the catalytic filtering device and then is discharged. The equipment performs spraying dust removal, twice filtration and then the catalytic reaction, and is good in dust removal effect and low in operation cost.

Owner:SUZHOU XIRE ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD +1

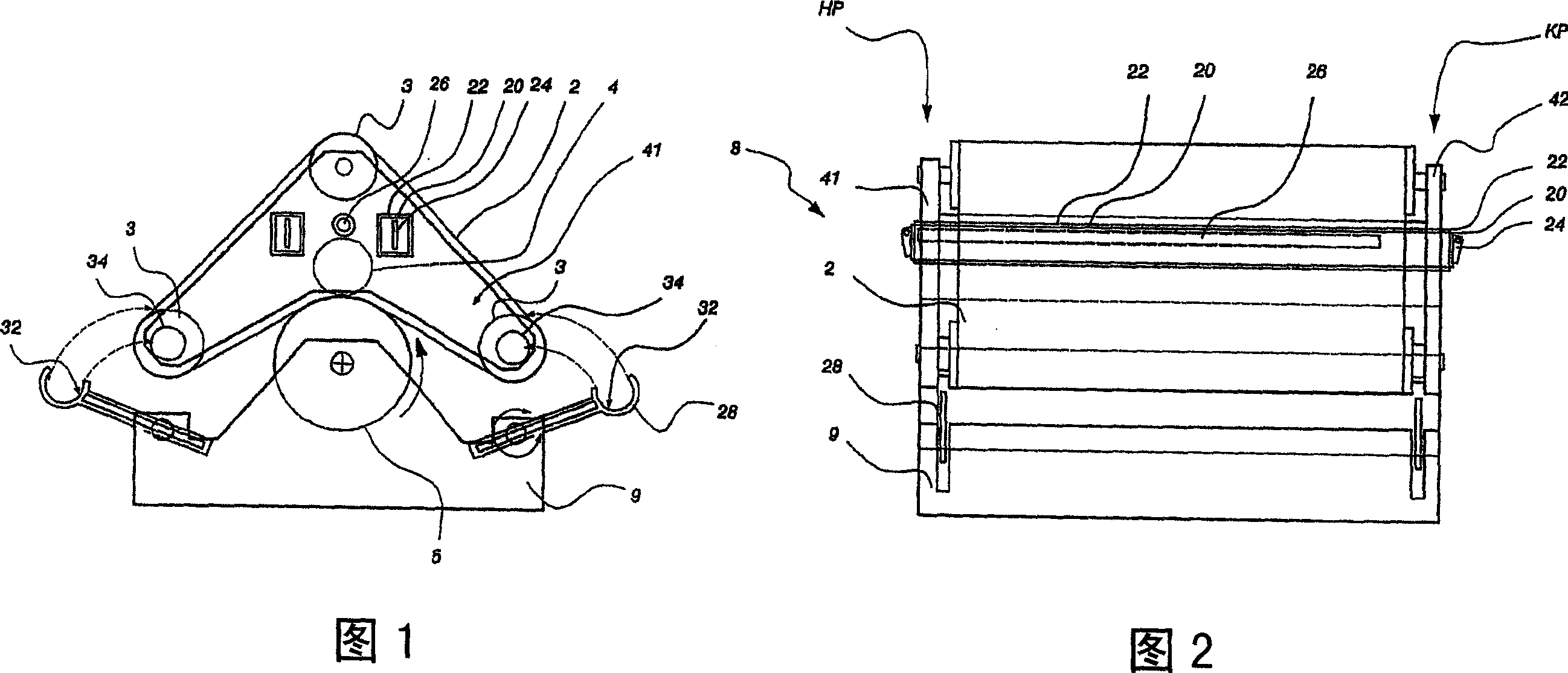

Arrangement and method for changing endless belt in paper making machine/board machine or polishing machine

The present invention relates to a device and a method for exchanging endless tires or corresponding parts in a paper / board machine or polishing machine, which must include at least one ring of the tire. The device includes at least one support mechanism extending transversely across the machine to define a receiving mechanism mounted on the frame mechanism of the machine inside the tire loop. The support mechanism is assembled to the receiving mechanism and can be pulled inward or outward to the desired position to change the tire while the machine is running. The end region of the support means is provided with at least one switching position, the frame means inside the rim of the tire can be moved away from at least one side of said frame means by means of the power conduction of the switching points mounted on the support means, the support means is removed from the receiving device The tire is stretched out to be in the extended state in the transverse direction of the machine and the tire ring is directly or indirectly wrapped around it, and then the tire is removed from the machine or installed on the machine by a corresponding device.

Owner:METSO PAPER INC

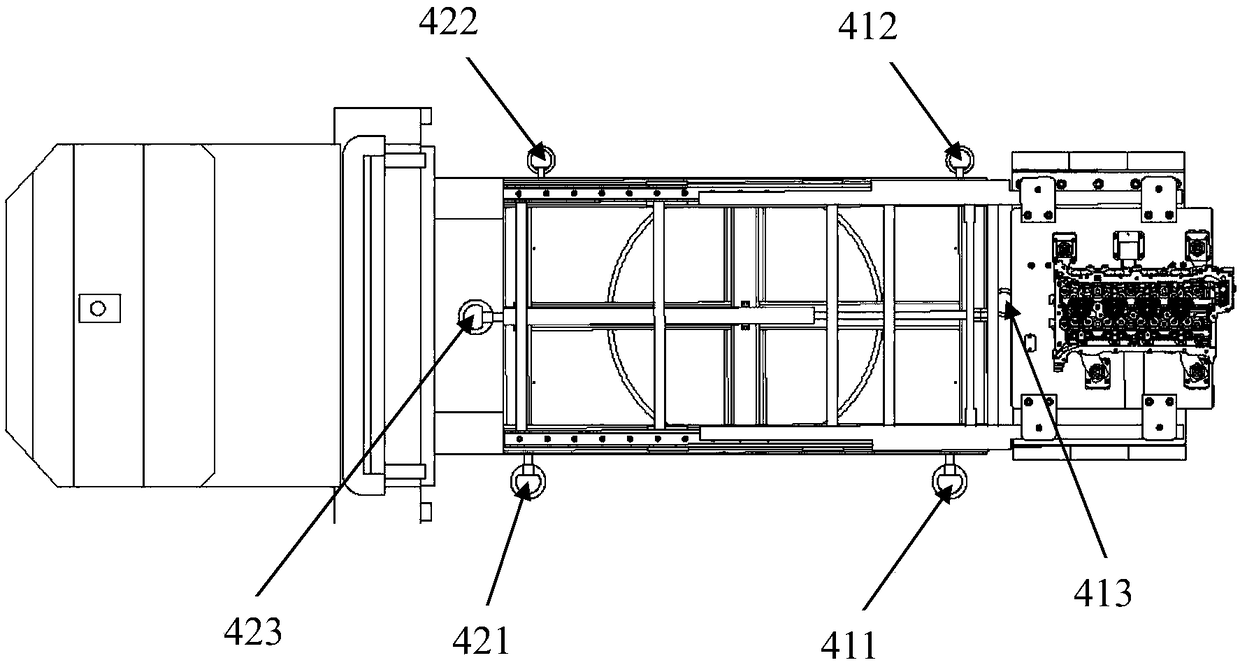

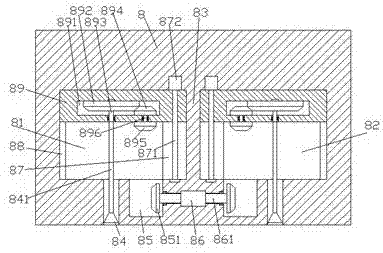

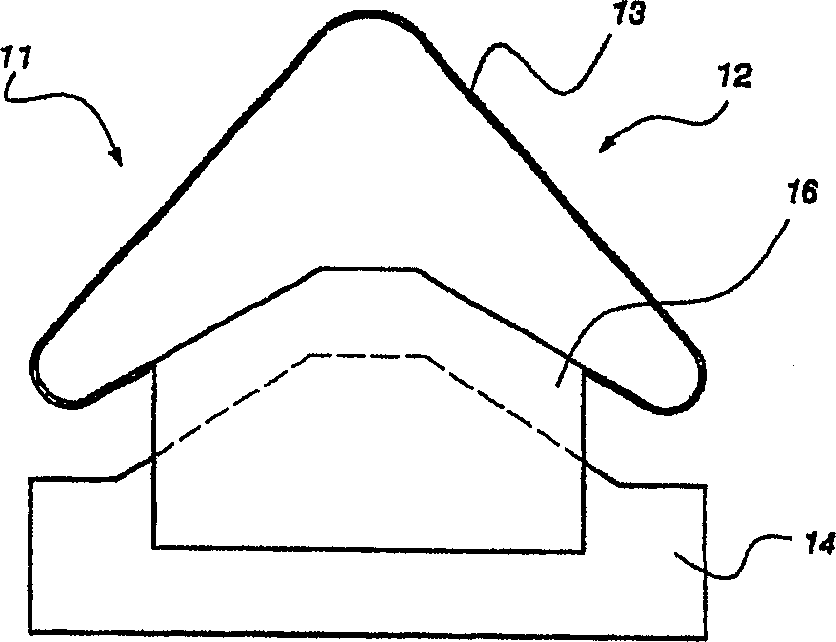

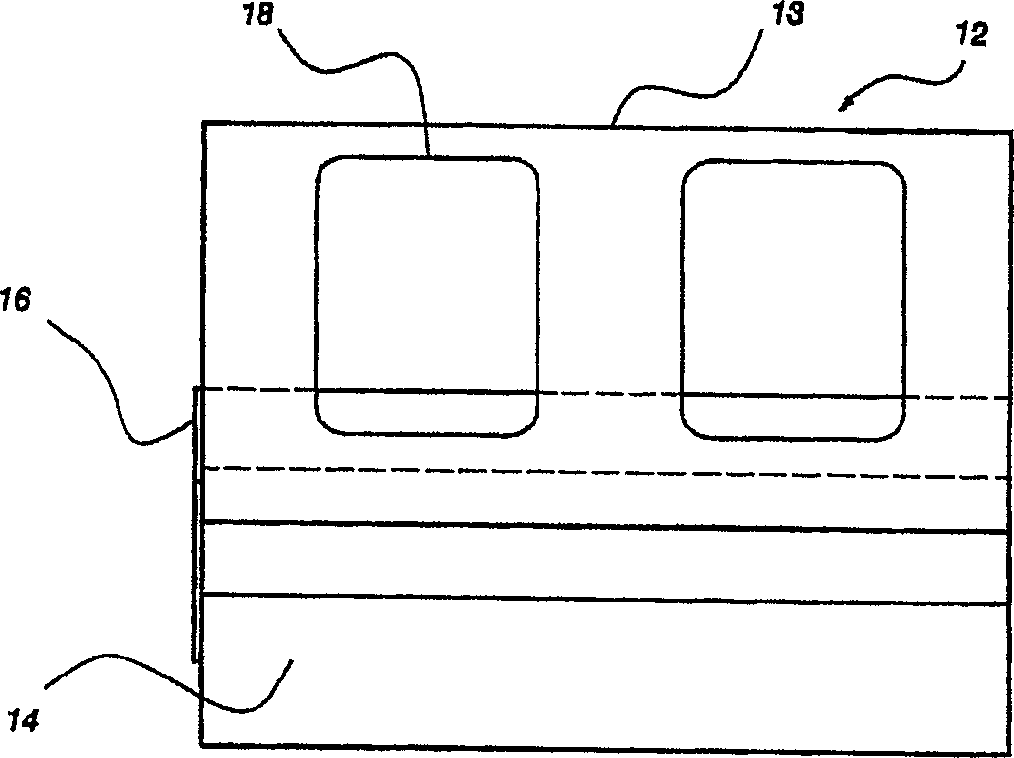

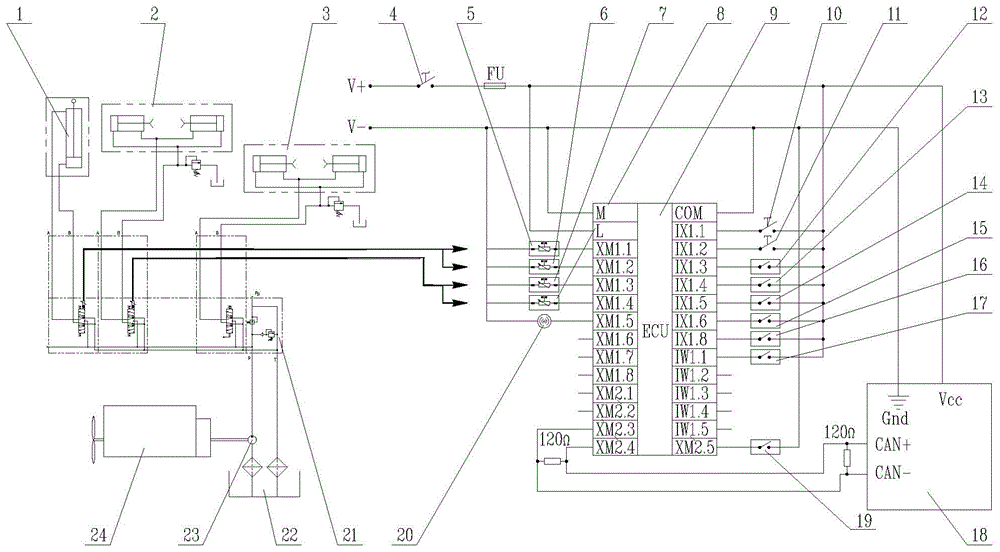

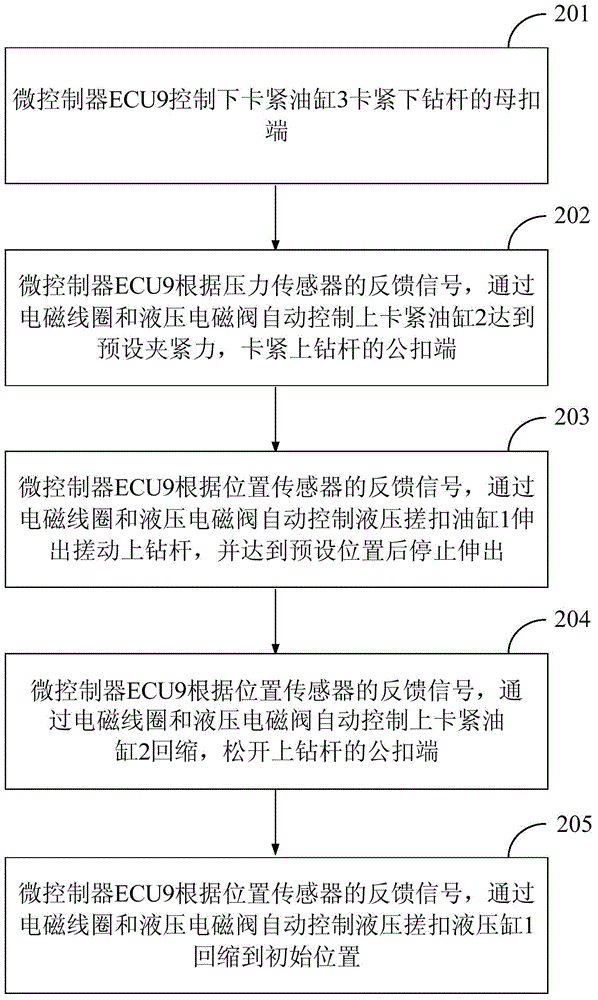

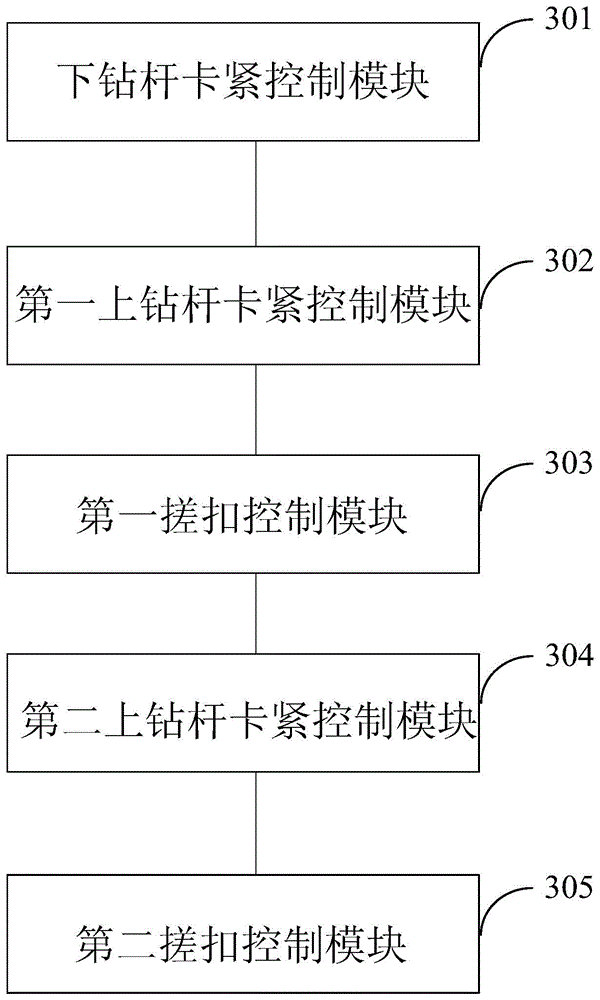

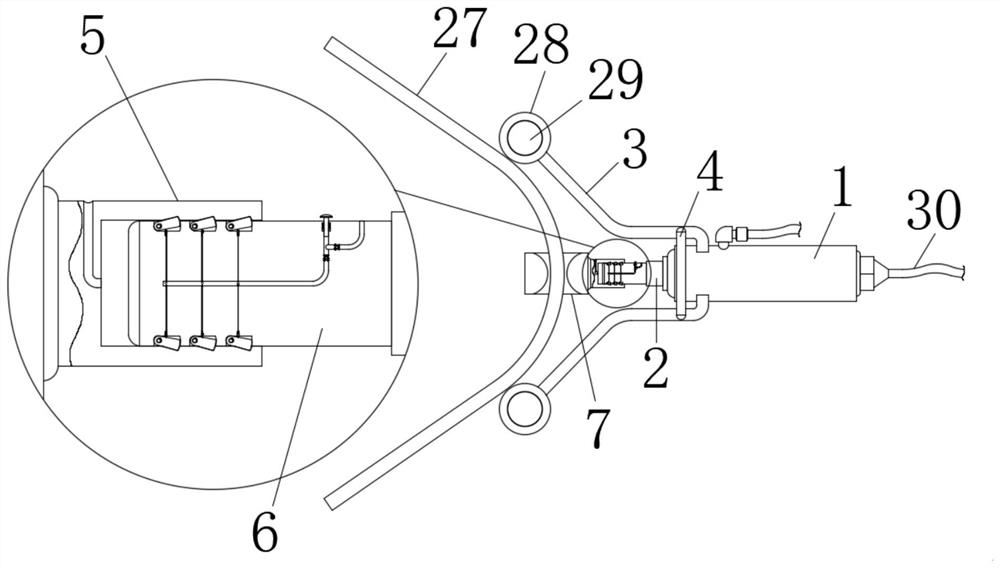

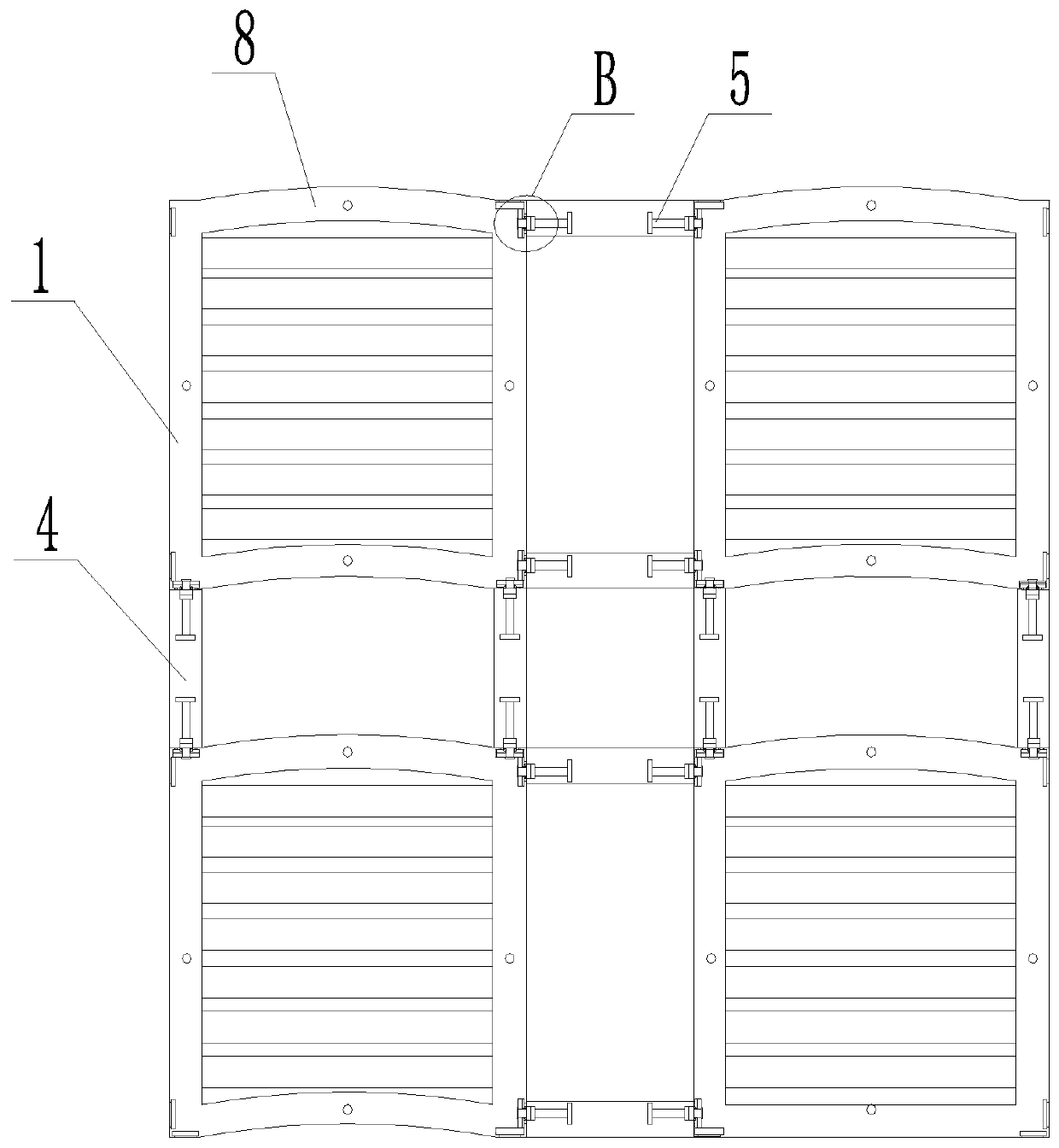

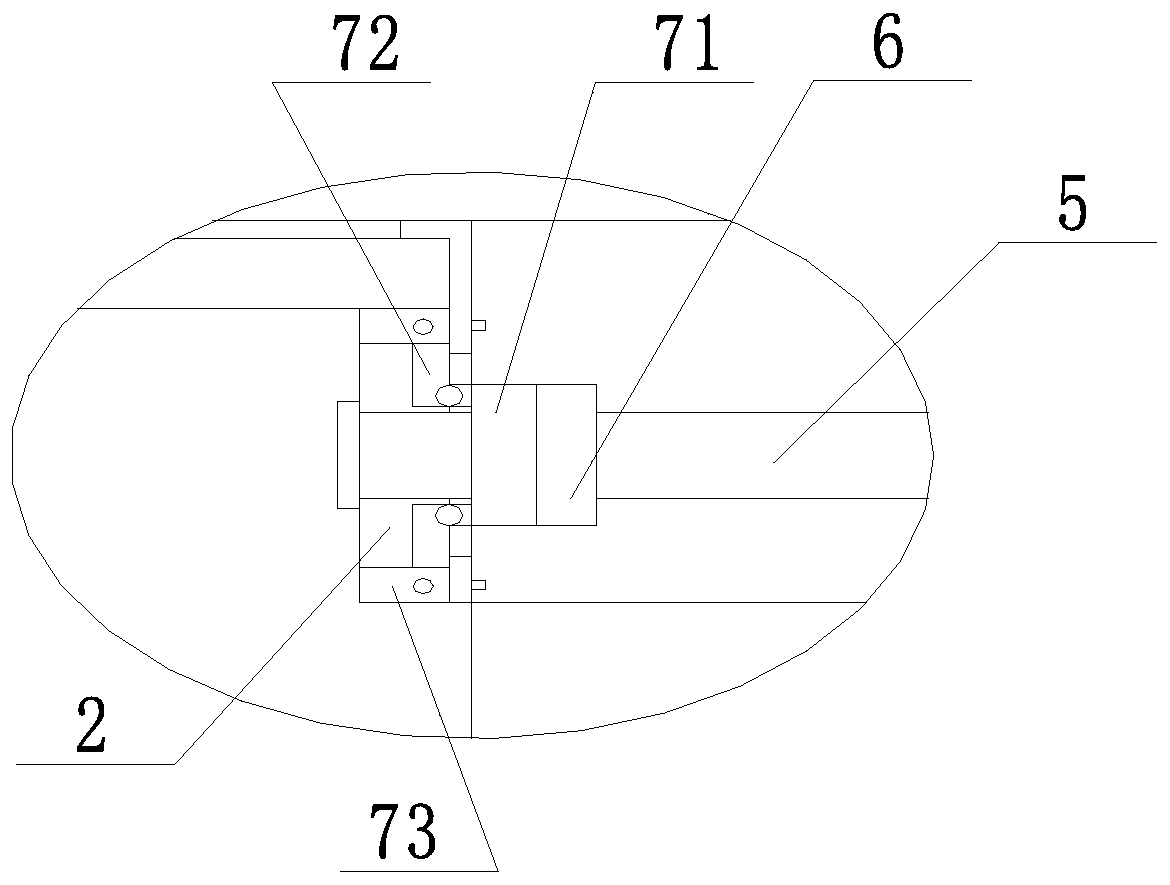

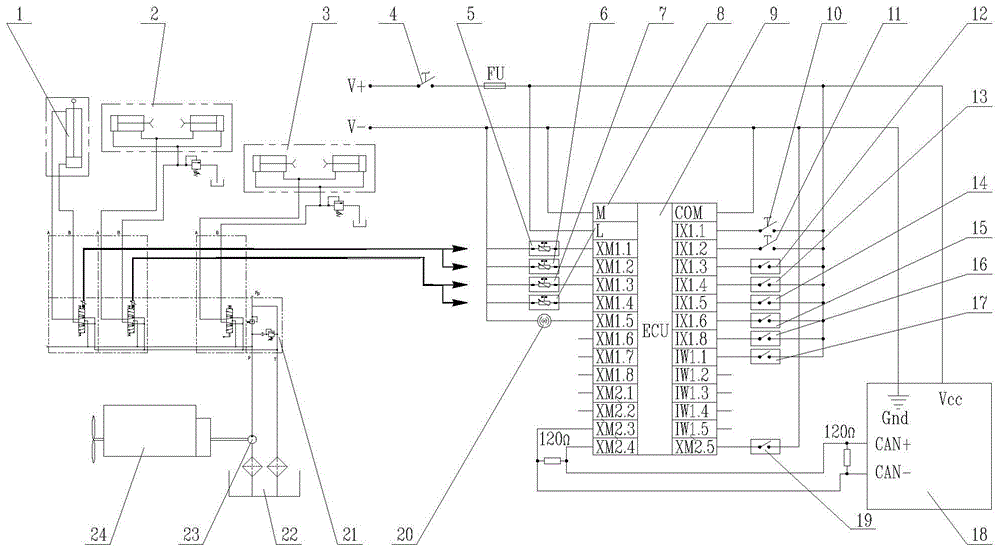

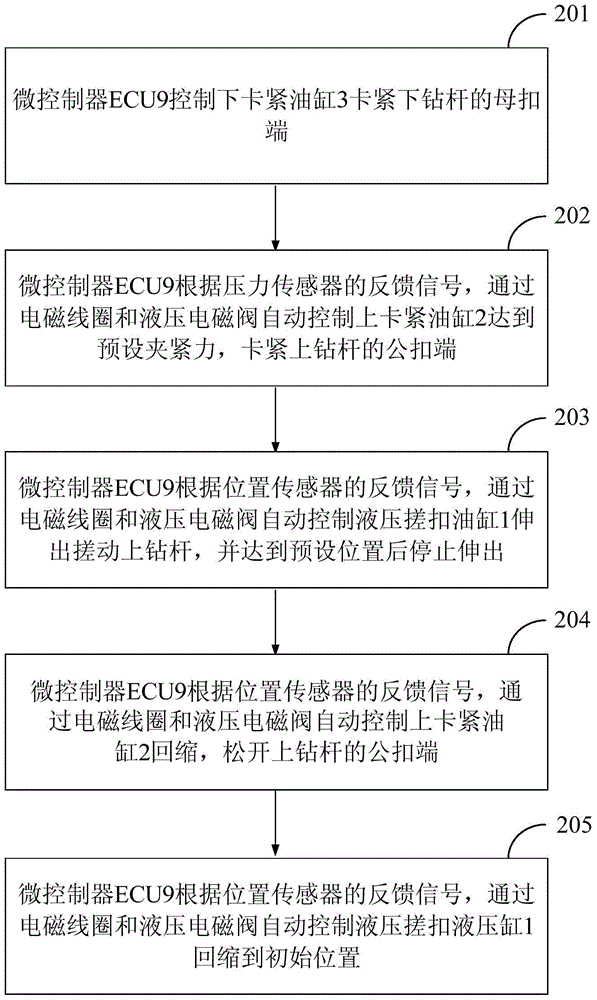

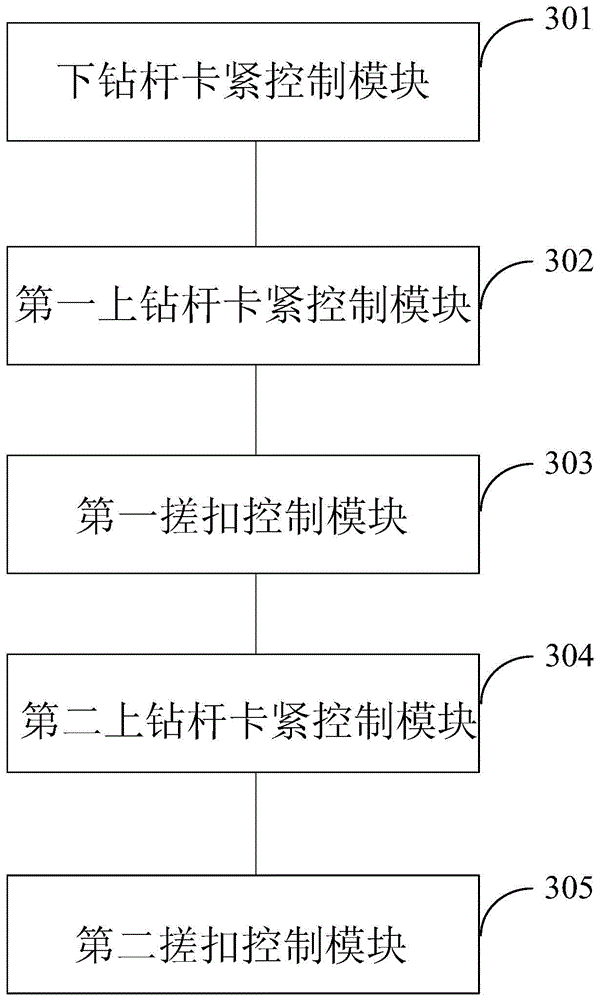

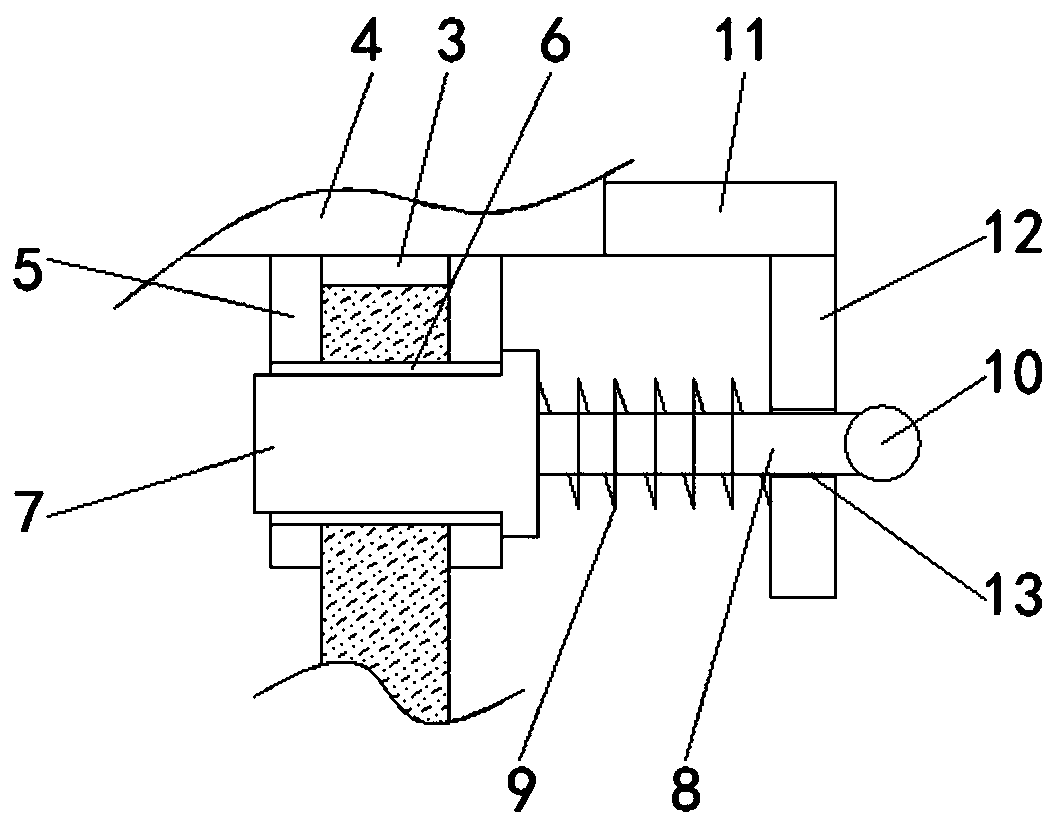

Automatic threaded fastener loosening system of drilling tools, use method thereof and microcontroller

ActiveCN104533320AQuick job changeReduce labor intensityDrilling rodsDrilling casingsMicrocontrollerSolenoid valve

The invention discloses an automatic threaded fastener loosening system of drilling tools, a use method thereof and a microcontroller. The automatic threaded fastener loosening system is used for achieving the effect of automatically switching drilling tools, and comprises a hydraulic solenoid valve, a hydraulic fastener loosening oil cylinder, an upper clamping oil cylinder, a lower clamping oil cylinder, a microcontroller, electromagnetic coils, a pressure sensor and a position sensor. The upper clamping oil cylinder is used for clamping or loosening the male fastener end of an upper drill rod, and the lower clamping oil cylinder is used for clamping or loosening the female fastener end of a lower drill rod. The hydraulic fastener loosening oil cylinder is used for loosening the upper drill rod clamped by the upper clamping oil cylinder. The microcontroller is used for controlling the upper clamping oil cylinder and the hydraulic fastener loosening oil cylinder to stretch and contract according to monitoring of the pressure sensor and the position sensor so as to finish loosening or mounting of connector threaded fasteners of the upper drill rod and the lower drill rod of the drill tools. The automatic threaded fastener loosening system of the drilling tools, the use method thereof and the microcontroller achieve the effect of automatically switching the drilling tools quickly, safely, reliably and conveniently, reduce the labor intensity of the working staff and improve the drilling efficiency.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Rotary disc type switching tool magazine of horizontal combined machining center

PendingCN114871819AEasy to change jobsEasy to adjustPositioning apparatusTotal factory controlGear wheelElectric machinery

The invention provides a horizontal combined machining center rotating disc type switching tool magazine, and relates to the technical field of horizontal machining centers, the horizontal combined machining center rotating disc type switching tool magazine comprises a mounting base, a horizontal machining center body is mounted on the upper surface of the mounting base, and a second mounting box is fixedly mounted on one side of the lower surface of the mounting base; a rotating control mechanism is installed on one side of the interior of the horizontal machining center body, an annular rotating plate is installed on one side of the rotating control mechanism, and a plurality of tool mounting grooves are evenly formed in the surface of the annular rotating plate. Through meshing transmission between a first transmission rack and a second transmission rack on the upper side and the lower side of a second mounting plate and a first transmission gear and a second transmission gear, adjustment work of the position of a cutter on an annular rotating plate is completed under driving of a first driving motor, the control precision is higher, adjustment of the position of the cutter is more accurate, and the working efficiency is improved. And the adjusting process is more stable.

Owner:ZHANGJIAJIE INST OF AERONAUTICAL ENG

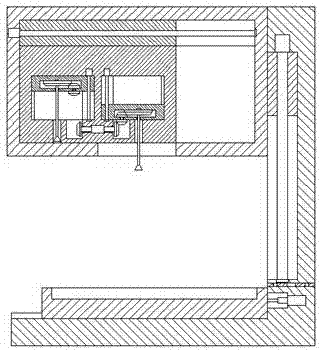

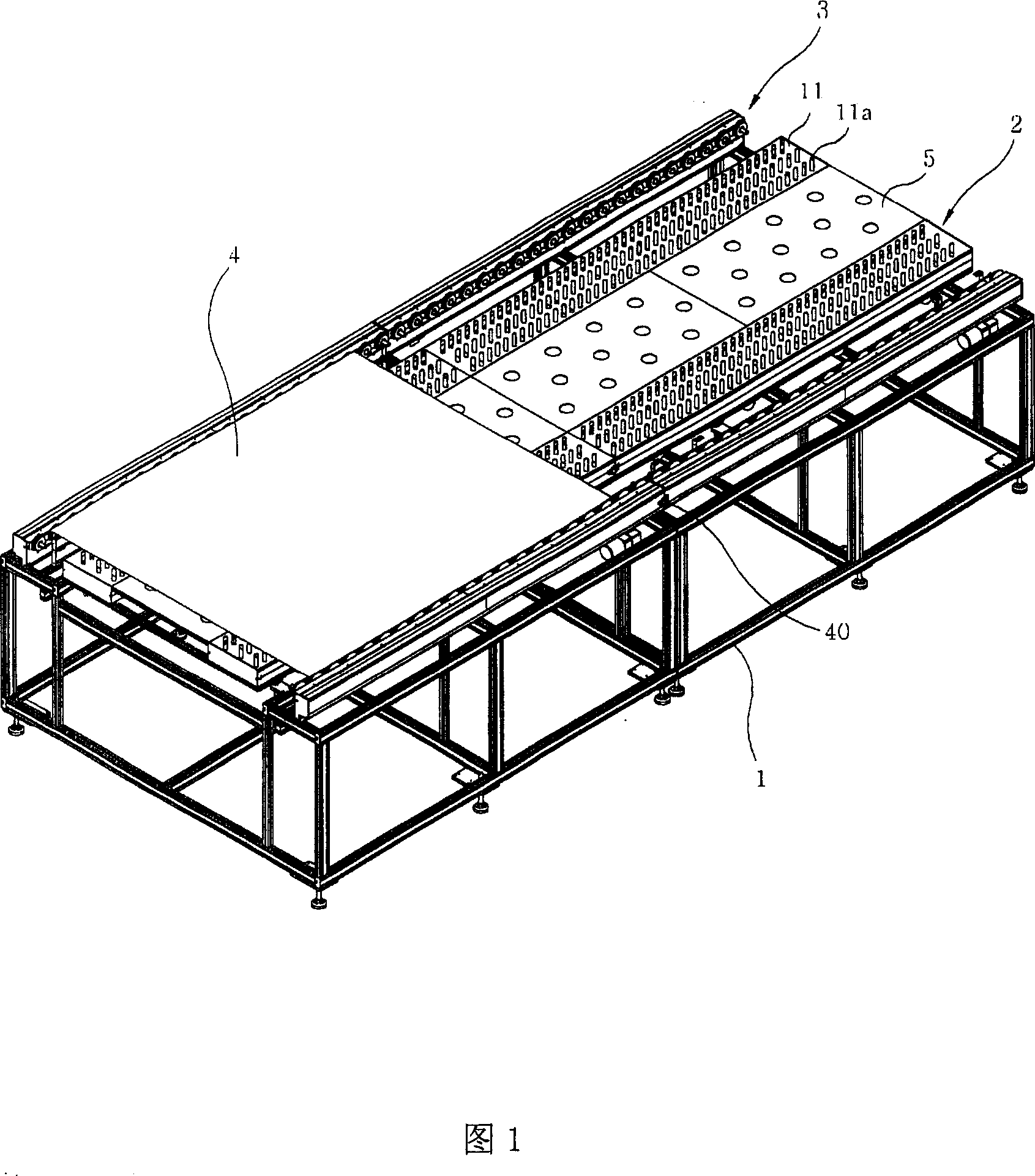

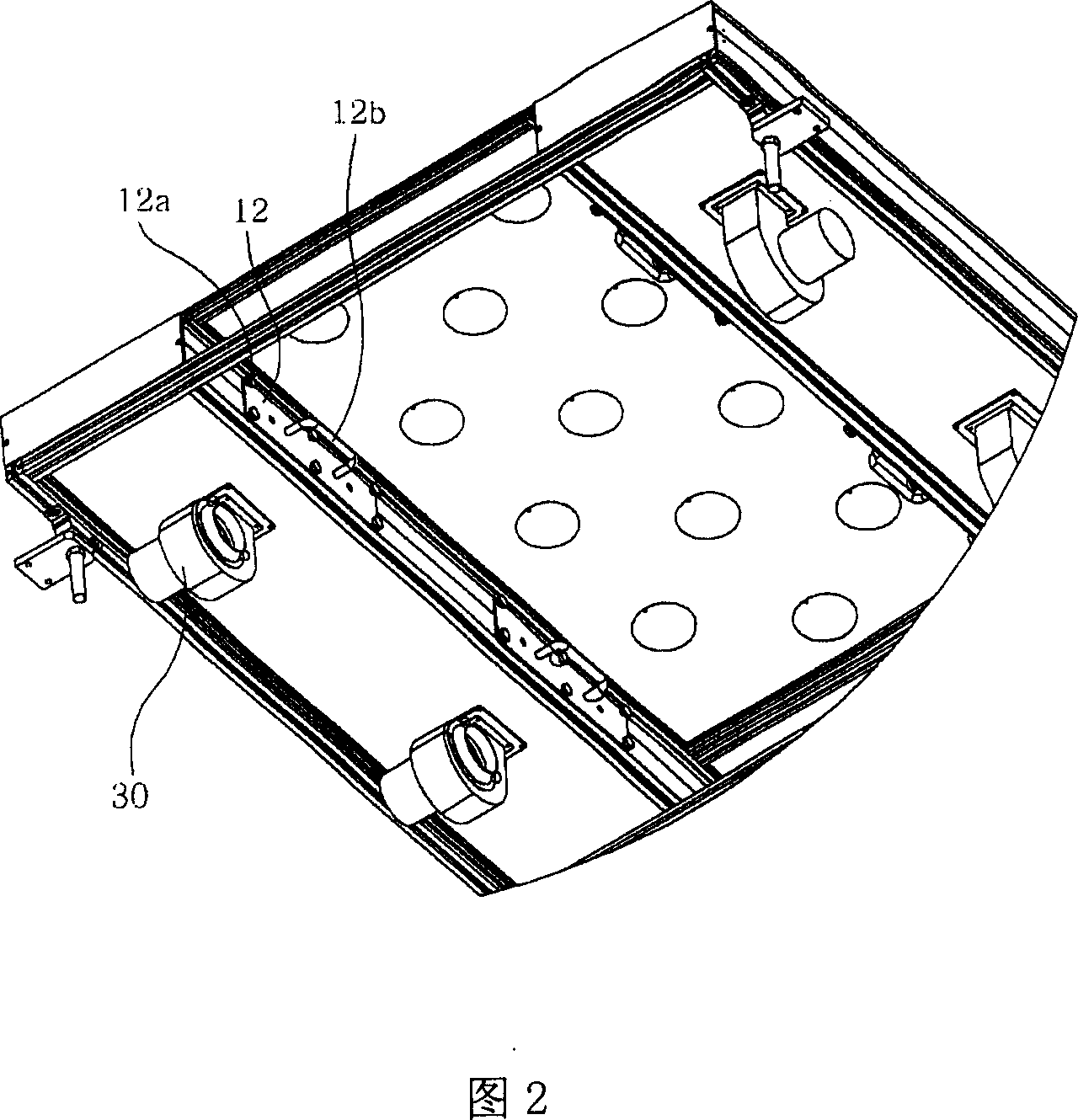

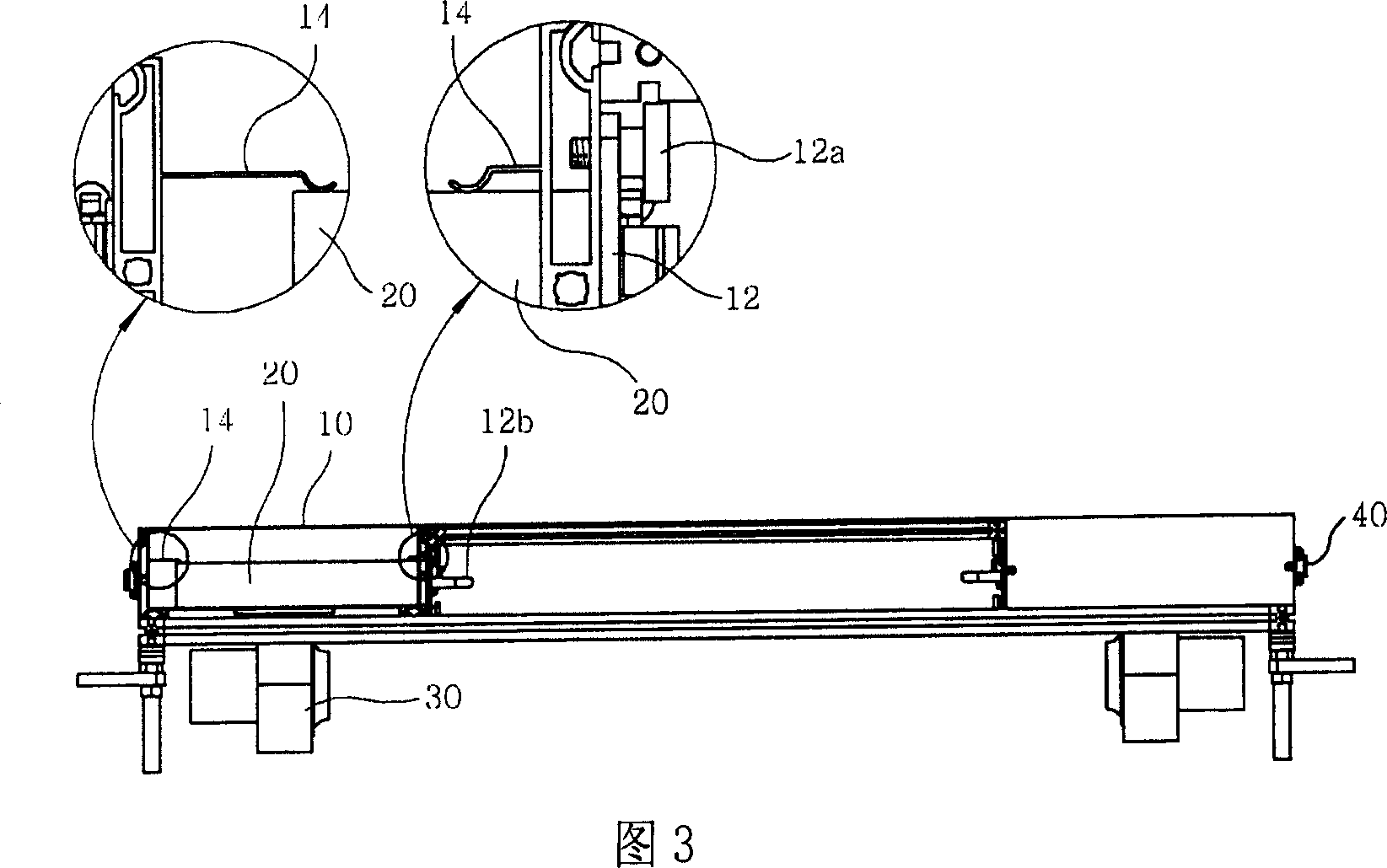

Filter mounting structure of glass panel transferring device

InactiveCN101045501AEasy to set upQuick job changeGlass transportation apparatusCharge manipulationFlat glassAir chamber

The invention provides a filter's setting structure of a glass panel transferring apparatus which can carry out filter's setting and replacing operation simply and quickly. The glass panel transferring apparatus comprises: air flotation equipment (2) with gas chamber (10), filter (20) arranged inside it and exhaust fan (30) arranged on its lower part, the air flotation equipment (2) is installed on the worktable (1); conveyor (3), arranged on both sides of aforementioned air flotation equipment (2) in width direction, transferring the glass panel (4) transferred upon the aforementioned air flotation equipment (2) along the length direction of the set operating line, thereinto, a door (12) is installed at the opening of filter (20) forming a side wall of aforementioned gas chamber (10), on the inside face of said door (12) is installed said filter (20), integrating into one body.

Owner:TAE SUNG ENG

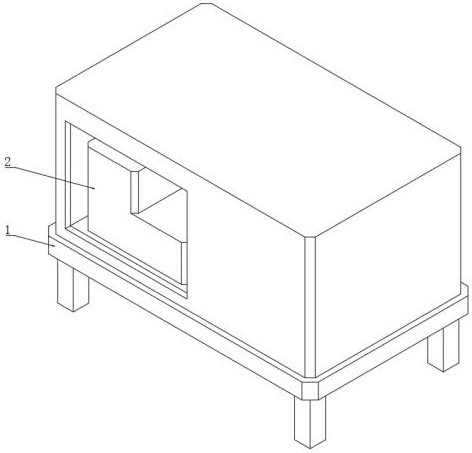

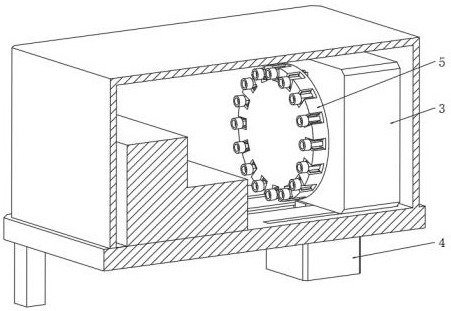

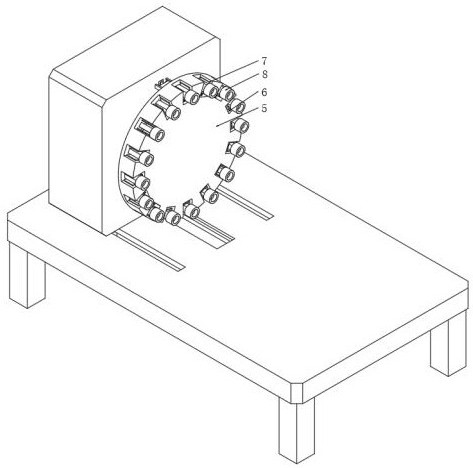

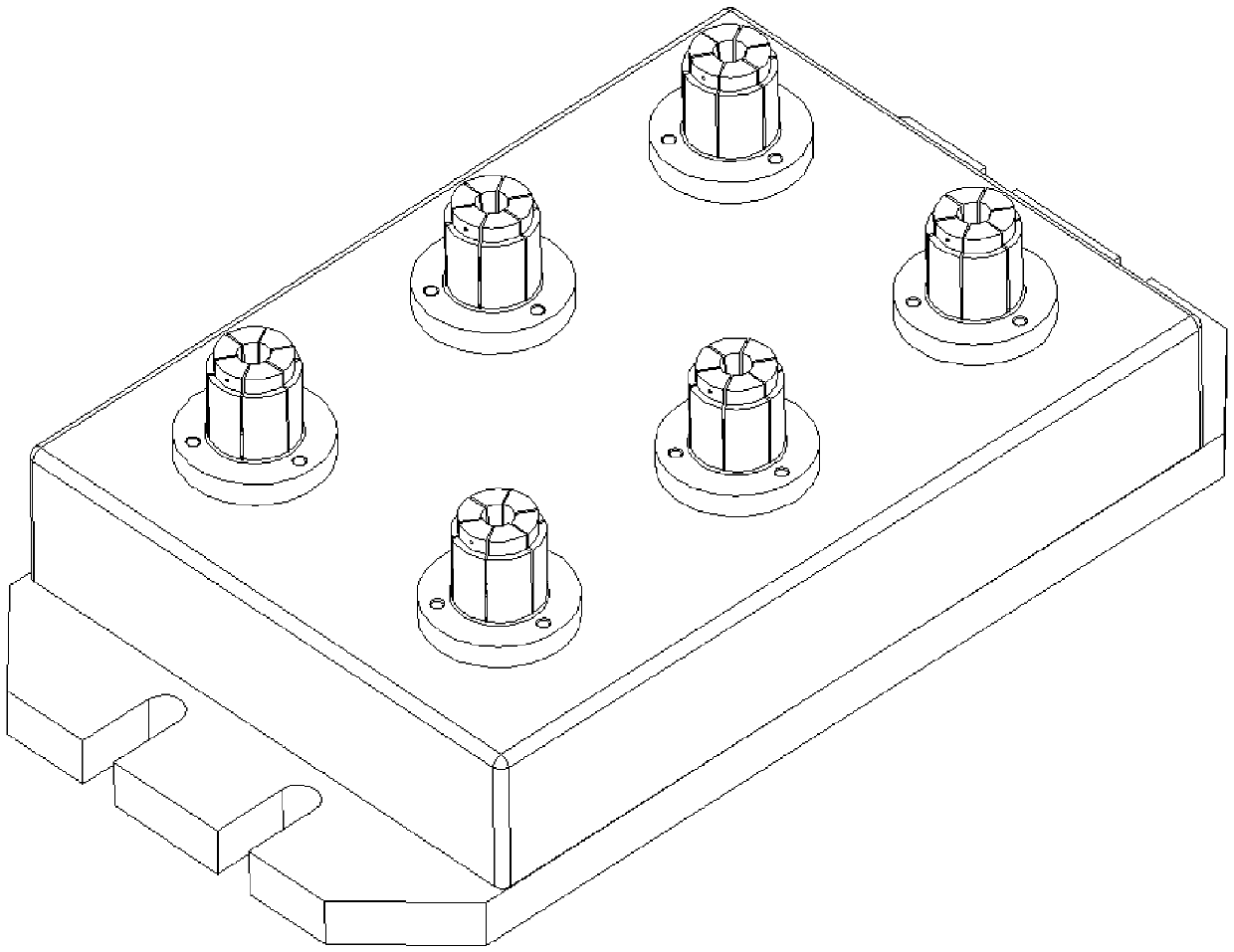

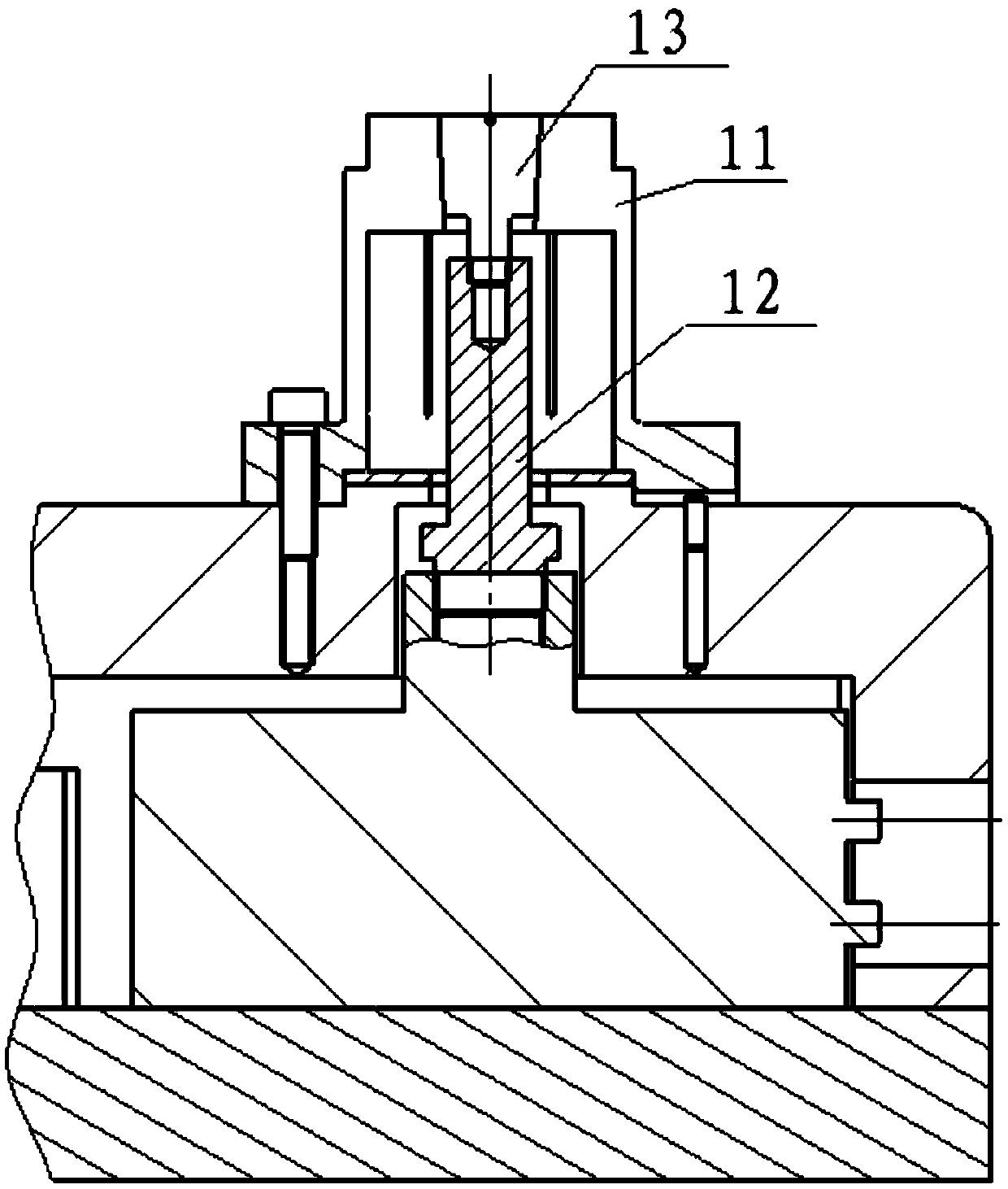

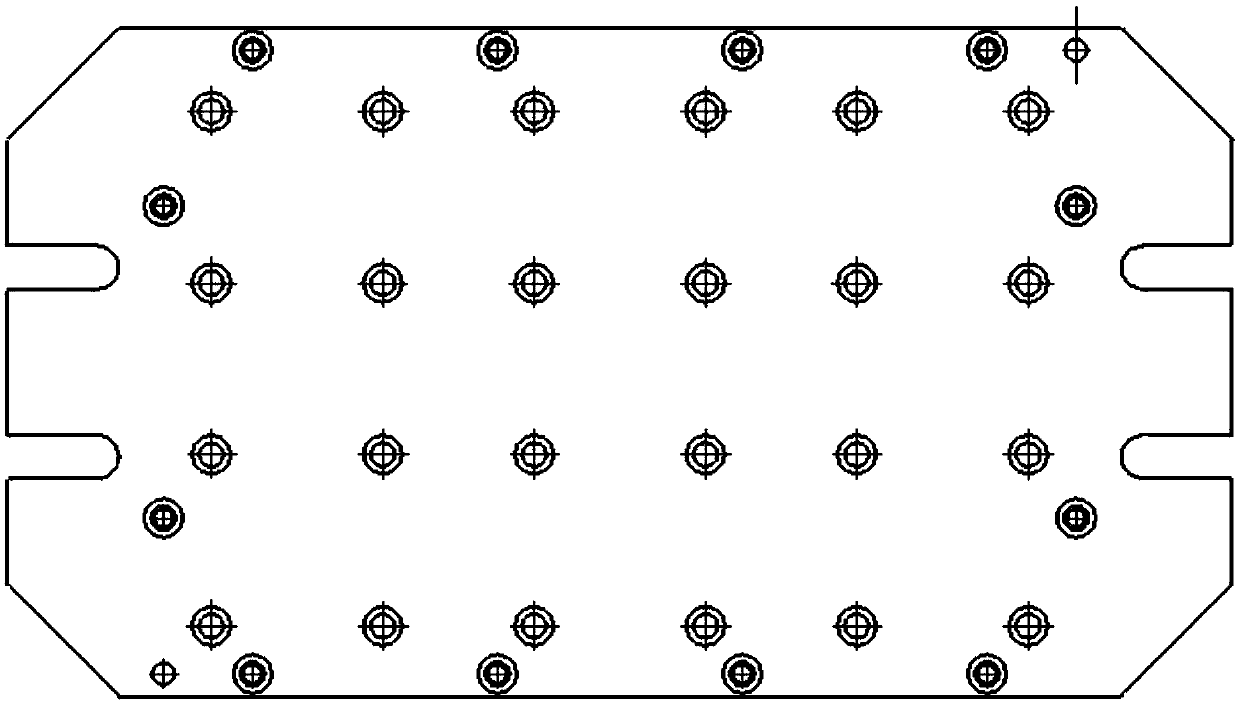

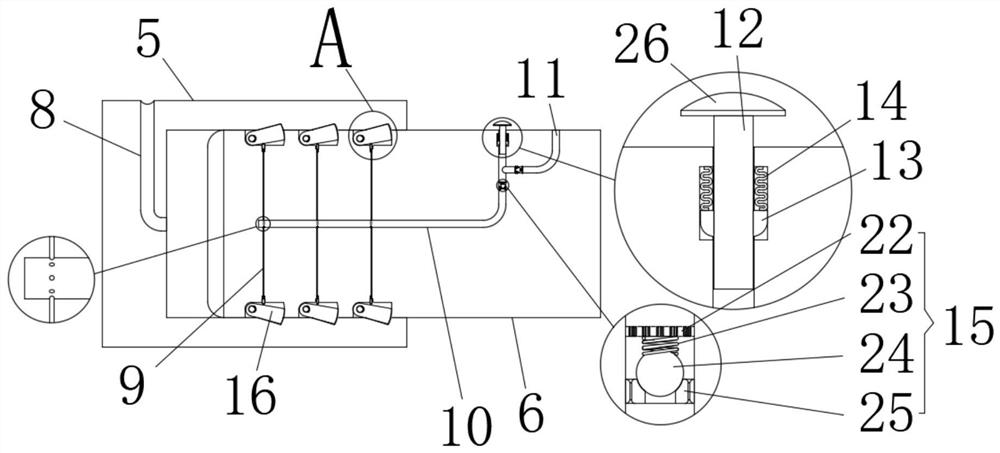

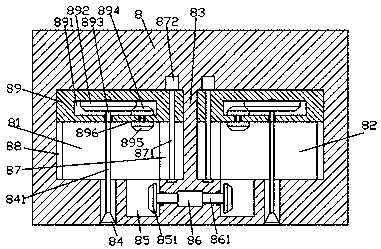

Pneumatic clamping device

InactiveCN105500077AAchieving simple requirementsSolve bottlenecksWork clamping meansPositioning apparatusNumerical controlEngineering

The invention discloses a pneumatic clamping device which is composed of chuck devices (1), an upper box (2), a cylinder device (3) and a lower bottom plate (4). The number of the chuck devices (1) is 4-8, the chuck devices (1) are installed on the upper box (2), the upper box (2) is connected with the upper side of the lower bottom plate (4), the chuck devices (1) are connected with the cylinder device (3), and the cylinder device (3) is located in the upper box (2) on the upper side of the lower bottom plate (4). The pneumatic clamping device is designed into a multi-clamping-position pneumatic clamping device, and space of a worktable of a numerical control machining center is used to the largest extent to clamp more parts and achieve one-by-one machining. Clamping is achieved at 4-8 points, electric control and pneumatic control are combined, clamping and machining speed is effectively increased, and accordingly machining efficiency is improved. Work efficiency of the numerical control machining center is improved, quick replacement is achieved, part production quality is improved, and labor intensity of workers is reduced.

Owner:沈阳兴华航空电器有限责任公司

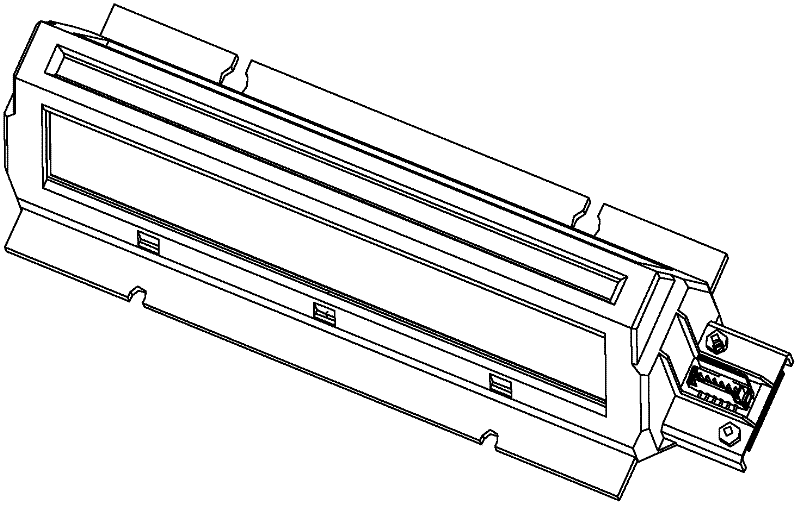

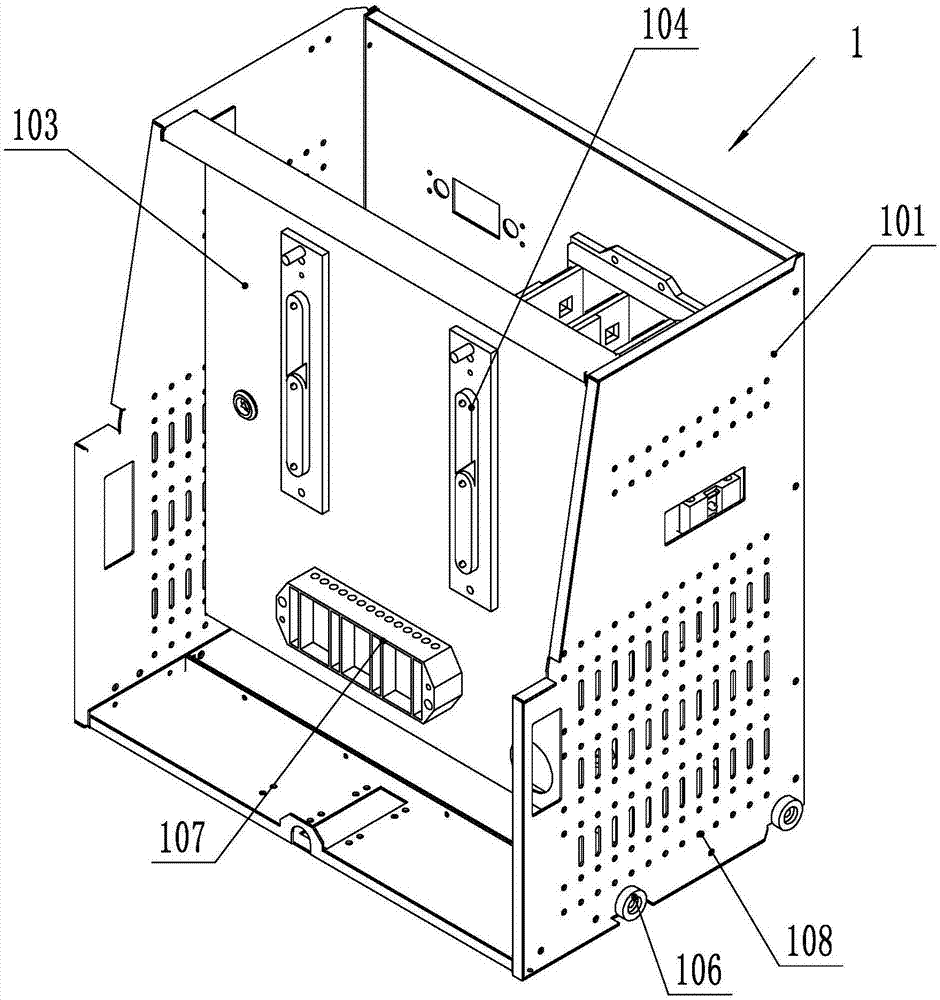

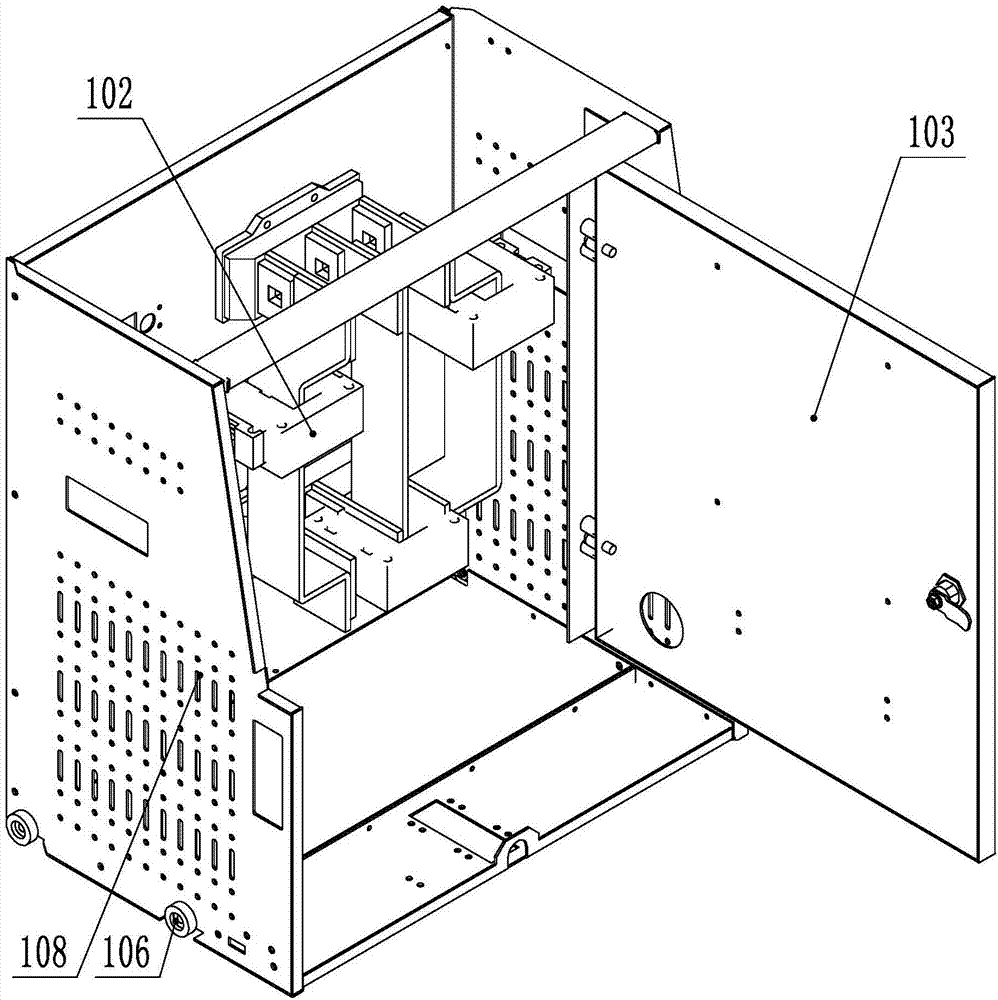

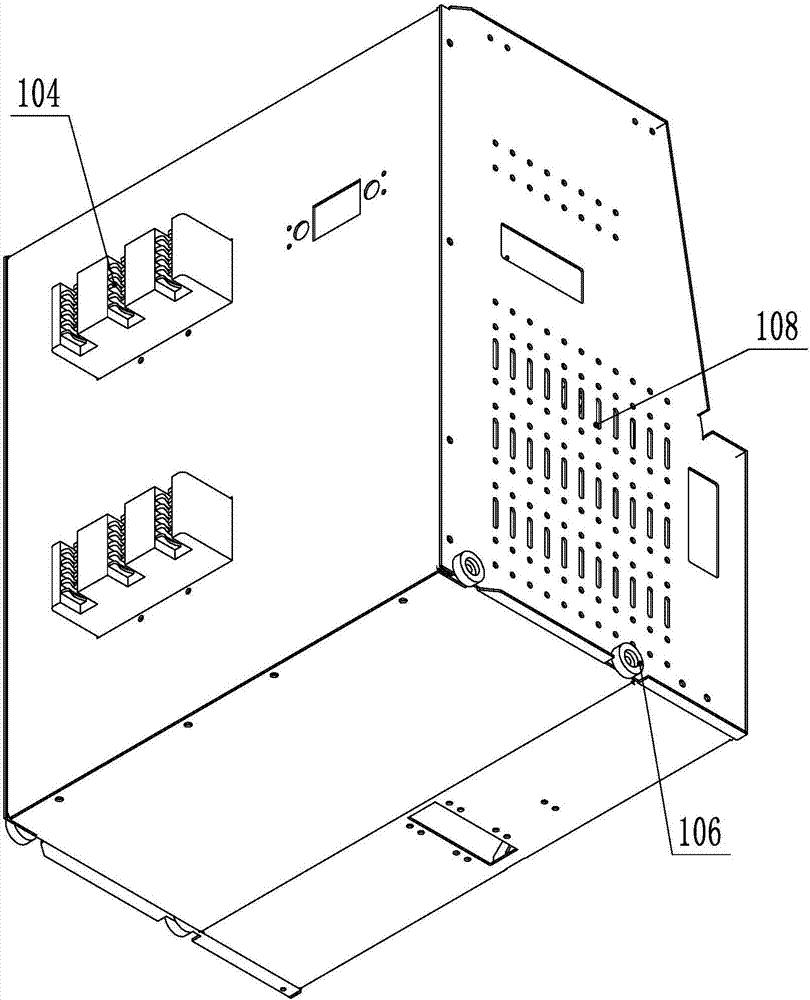

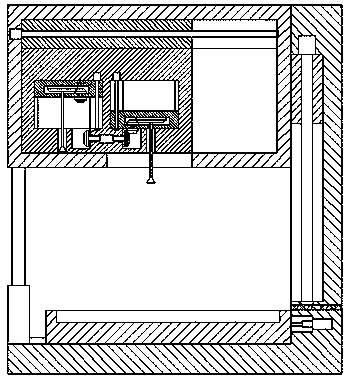

Drawer type metering module device, power distribution cabinet and maintenance method

PendingCN107404075ASave time at workReduce power outage lossSubstation/switching arrangement detailsSwitchgearInductorCopper

The invention relates to a drawer type metering module device, a power distribution cabinet and a maintenance method and belongs to the power distribution field. According to the prior art, high-voltage-side power supply and low-voltage side metering power distribution equipment of 400kVA or below includes a GGD cabinet, a GCK cabinet, a JP cabinet and so on, and metering devices are all on-site fixed type devices, and as a result, the problems of long maintenance time, high complicity and error-proneness will be brought about. The invention aims to solve the above problems. The drawer type metering module device comprises a shell, a mutual inductor arranged in the shell and a meter; a partition plate is arranged in the shell and divides the shell into an inner cavity and an outer cavity; the mutual inductor is arranged in the inner cavity; the meter is arranged in the outer cavity; and the back surface of the shell is provided with a copper bar connecting seat which is in plugging connection with a primary side copper bar. With the drawer type metering module device provided by the technical schemes of the invention adopted, on-site working time can be saved. The plugging-connection module device can be assembled in an office or in a warehouse before the plugging-connection module device is installed, and therefore, power failure loss can be decreased, operation is convenient and safe. The plugging-connection module device can act as a disconnecting switch.

Owner:张胜达

Portable hydraulic steel bar bender

The invention relates to the technical field of steel bar benders, in particular to a portable hydraulic steel bar bender. The portable hydraulic steel bar bender comprises a hydraulic cylinder, a hydraulic shaft, supporting plates and a lifting handle, wherein the hydraulic shaft is arranged in the hydraulic cylinder, one end of the hydraulic shaft protrudes out of the hydraulic cylinder, the twosymmetrically-distributed supporting plates are fixedly connected to the hydraulic cylinder, one sides of the supporting plates are fixedly connected with the n-shaped bent-rod-shaped lifting handle,one ends of the supporting plates are fixedly connected with sleeves, the sleeves are movably sleeved with inner shafts, one end of the hydraulic shaft is provided with an outer barrel, an inner column is connected between the hydraulic shaft and the outer barrel, and one end of the inner column is fixedly connected with the hydraulic shaft. According to the structural design, quick replacement work of connecting pieces of different types and sizes is achieved, air flow in the inner column can be caused to flow only by pressing the handle, then a clamping block is controlled, the connecting state between the outer barrel and the inner column is controlled, the function is stable and powerful, and the whole bending machine can meet the machining requirements of reinforcing steel bars of different types.

Owner:台州市黄岩博远车业有限公司

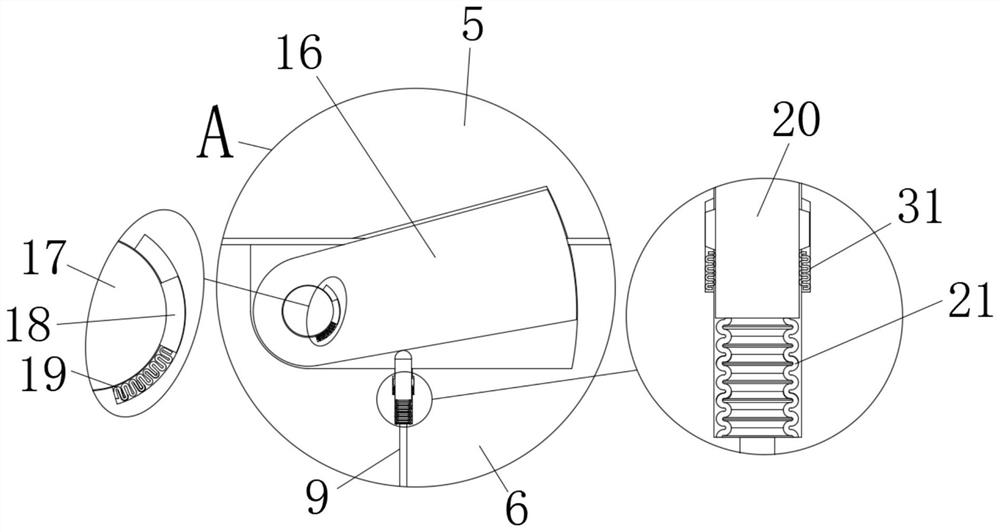

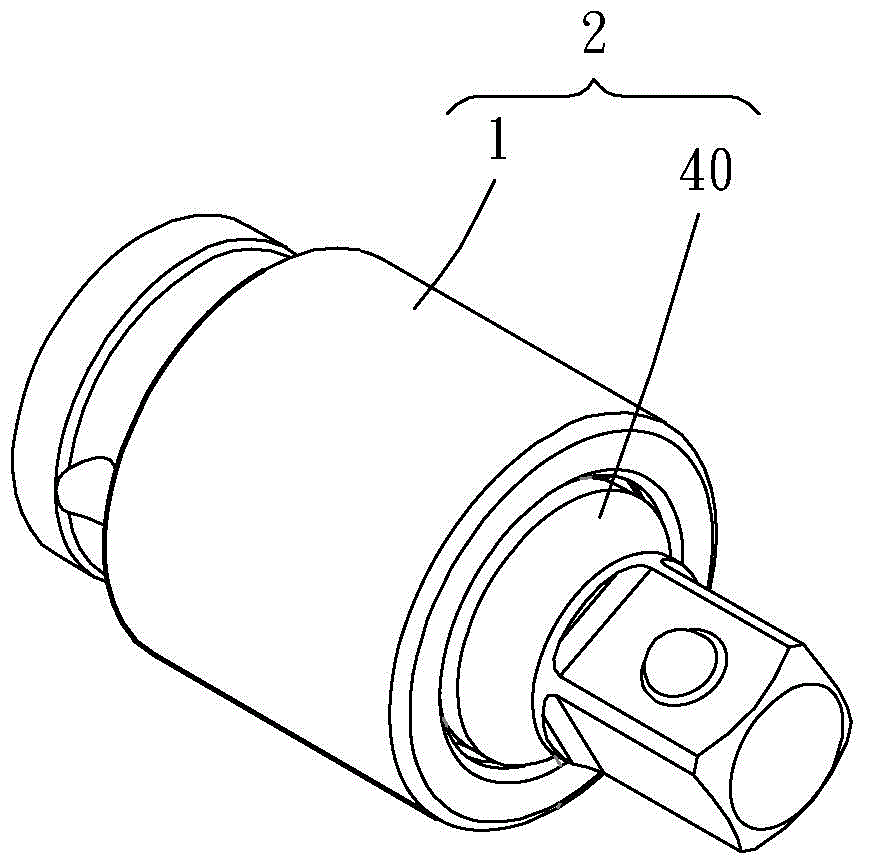

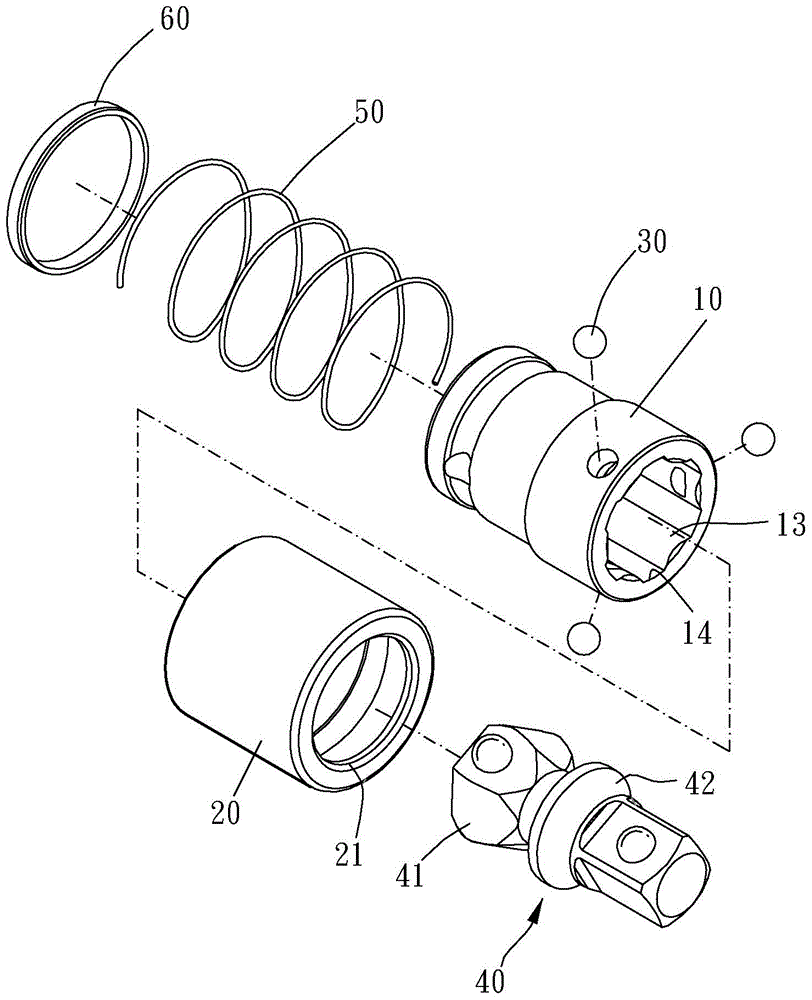

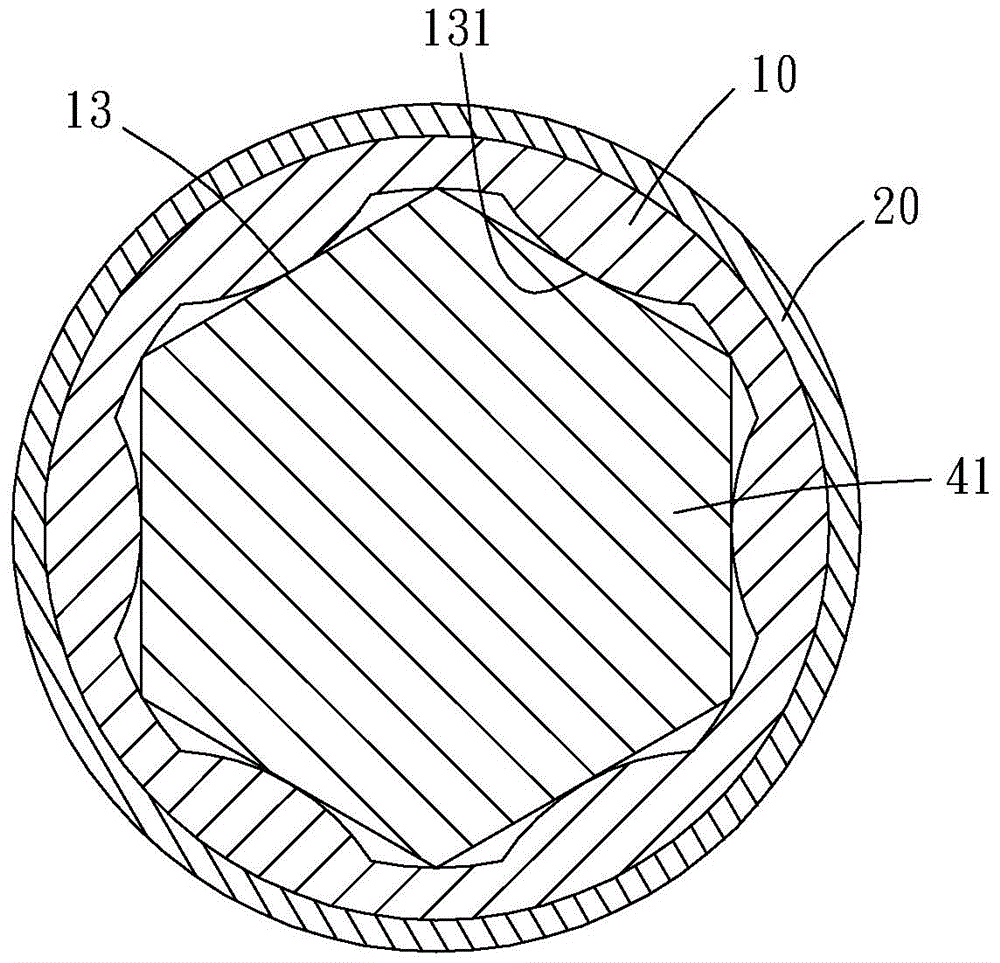

Tool having replaceable driving head and set thereof

ActiveCN105437165AQuick job changeSolve the problem of locked cardPortable power-driven toolsMetal-working hand toolsEngineeringMechanical engineering

The invention discloses a tool having a replaceable driving head and a set thereof. The set comprises a joint, a sheath and at least one limiting part. The joint is provided with an accommodating groove and a driving end, both of which are opposite to each other. Multiple protruding ribs extending axially and multiple grooves located among the protruding ribs are arranged on the inner wall of the accommodating groove. A groove of the accommodating groove is used for inserting connection of multi-angle spherical heads. The sheath can be connected outside the joint in the manner of mutually limiting an axial sliding sleeve group. The inner wall of the sheath is provided with a recess and a projection and can slide at the first position and the second position relative to the joint.Limiting parts are provided with protruding ribs which selectively protrude of the accommodating grooves.When the sheath is located at the first position, the projection abuts against the limiting parts and protrudes out of the accommodating grooves while the limiting parts are used for clamping and limiting the multi-angle spherical heads into the accommodating grooves. When the sheath is located at the second position, the recess is opposite to the limiting parts while the limiting parts can go in and out of the recess and the multi-angle spherical heads can be drawn out of the accommodating grooves.The tool having the replaceable driving head and the set thereof have following beneficial effects: the driving head can be rapidly replaced; the tool is simple in structure and convenient in manufacture and assembly; friction is decreased; and working efficiency is increased.

Owner:YUAN HSING IND

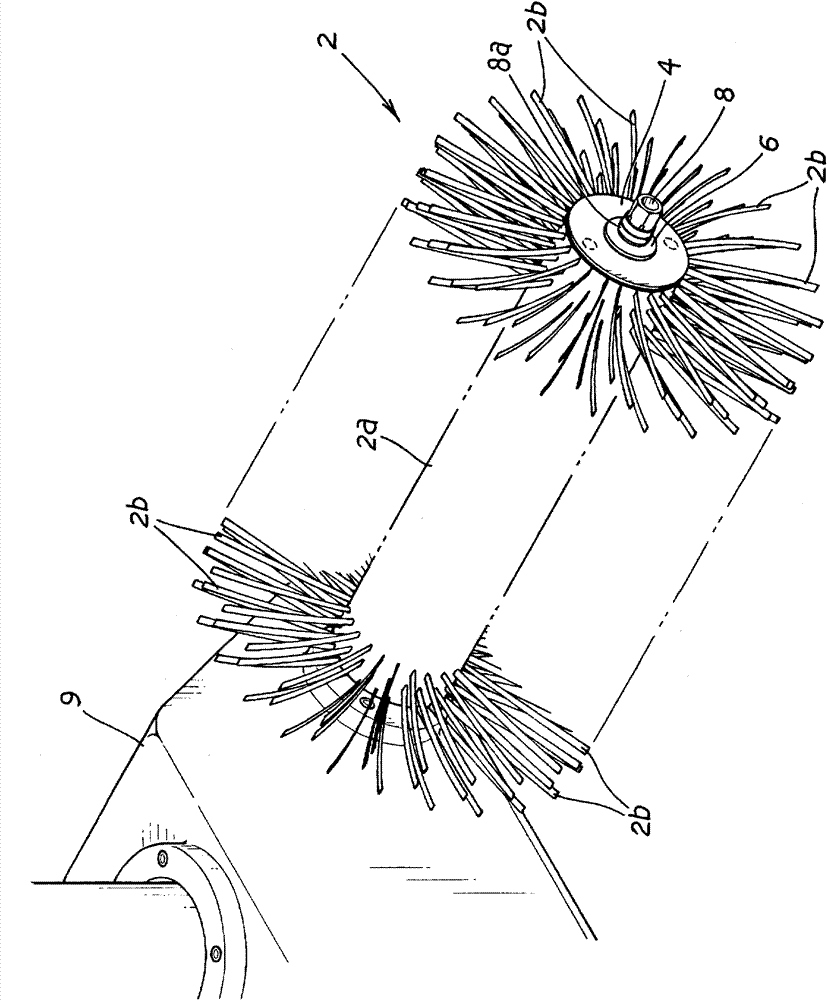

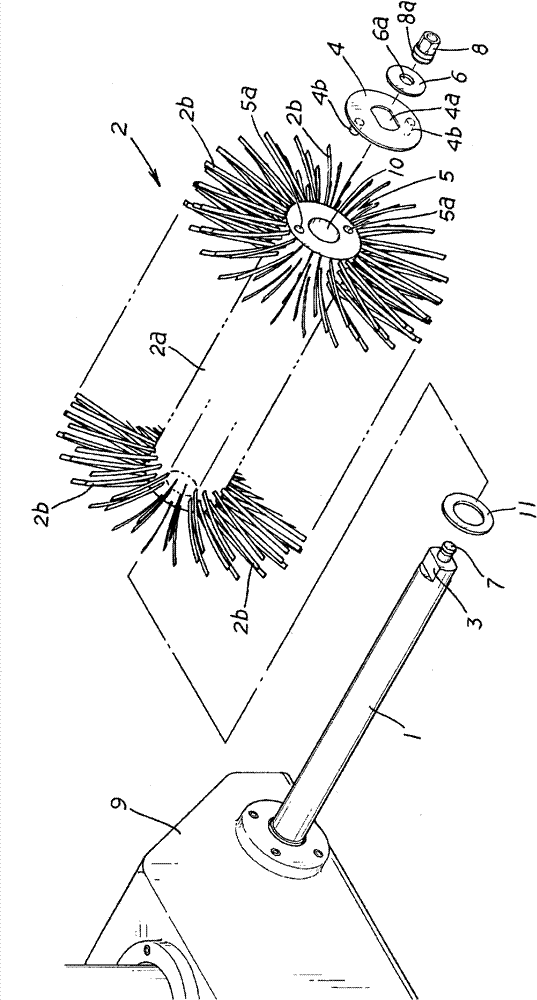

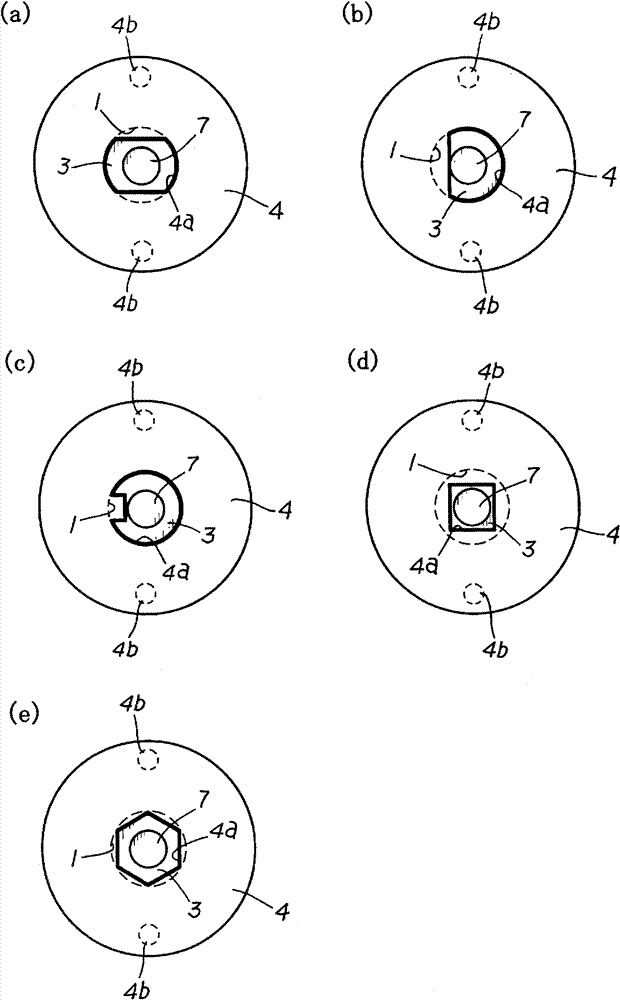

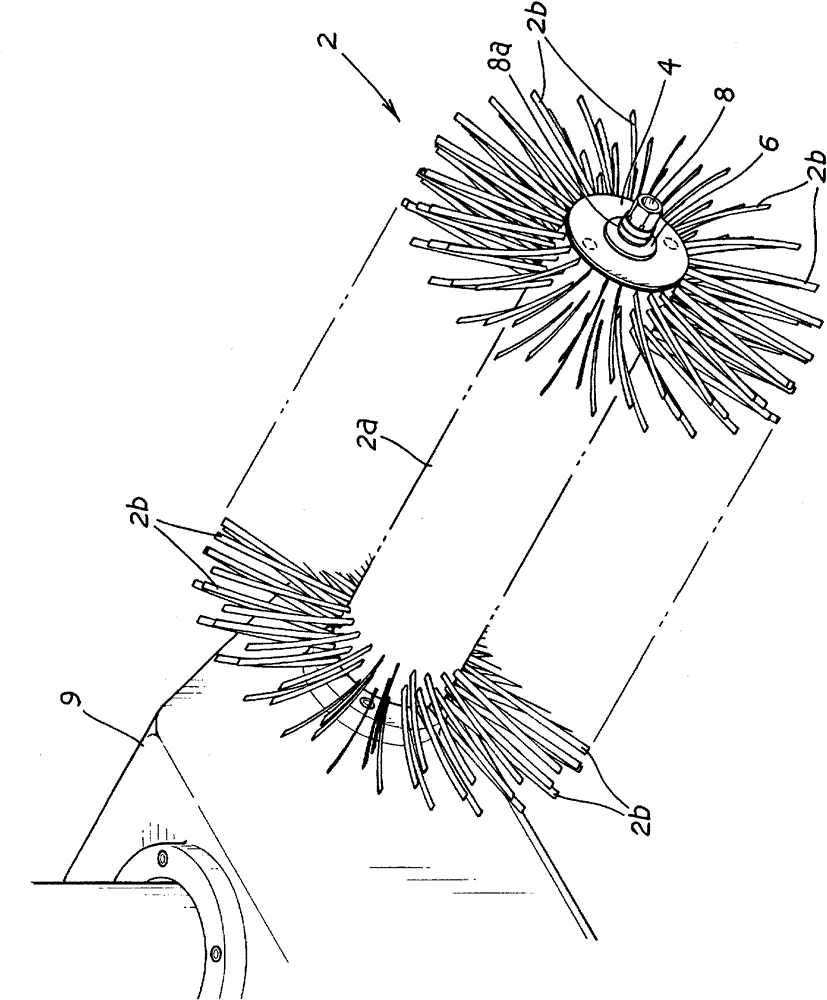

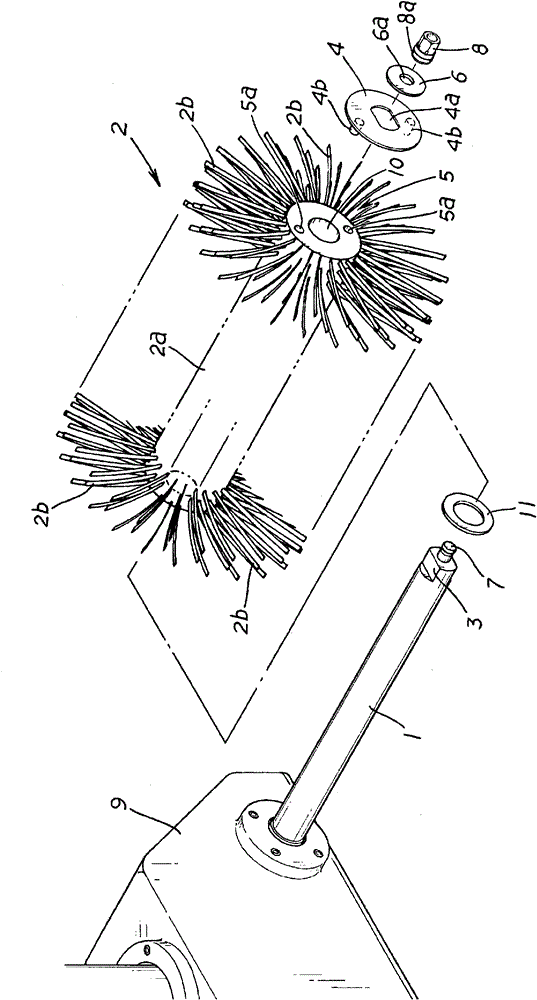

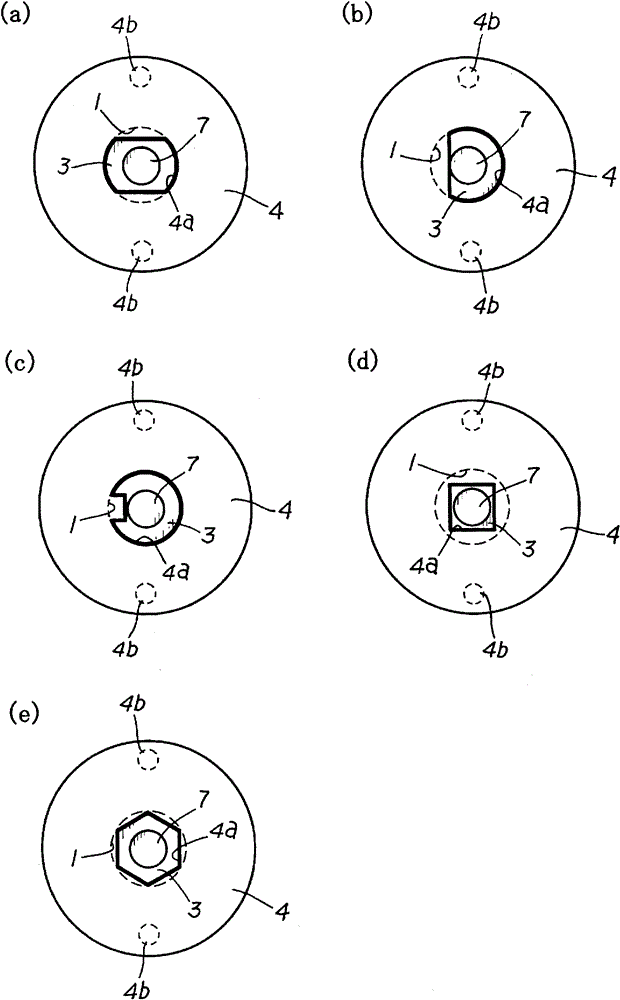

Grinding device

ActiveCN102814726AEasy to disassemblePracticalGrinding wheel securing apparatusLapping machinesEngineeringMechanical engineering

The present invention provides a grinding device, which can arrange a rotating grinding body in a state of rotating together with a rotating shaft by a very simple structure, and can conduct the replacement operation for the rotating grinding body easily. The rotating shaft (1) is provided with a rotating stop part (3). The rotating stop part (3) is provided with a rotating stop embedding part (4) which is embedded in the rotating stop part. The end of the rotating grinding body (2) is provided with a grinding body side embedding part (5) which is embedded with the rotating stop embedding part. The rotating grinding body and the rotating stop embedding part are disposed on the rotating shaft to embed with the rotating stop part and embed with the rotating stop embedding part and the grinding body side embedding part. The rotating stop embedding part stops rotating relative to the rotating shaft, and the grinding body side embedding part is disposed on the end of the rotating grinding body. Thus the rotating grinding body stops rotating relative to the rotating shaft. A locking body (6) is disposed on the end of the rotating shaft in a manner of free assembling. The locking body can prevent the rotating grinding body from dropping from the rotating shaft. So the rotating grinding body is arranged in a manner of free assembling.

Owner:S T LINK

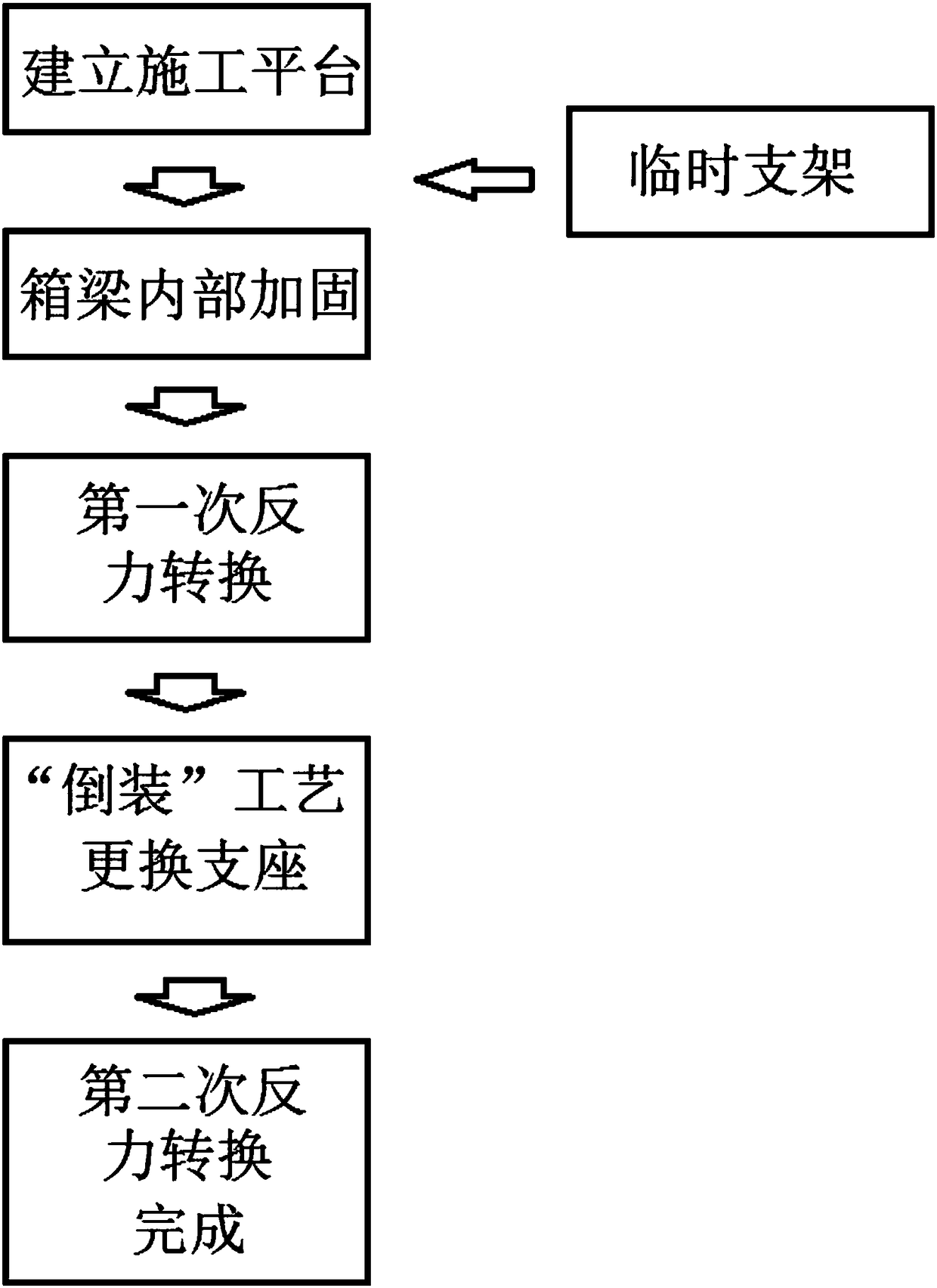

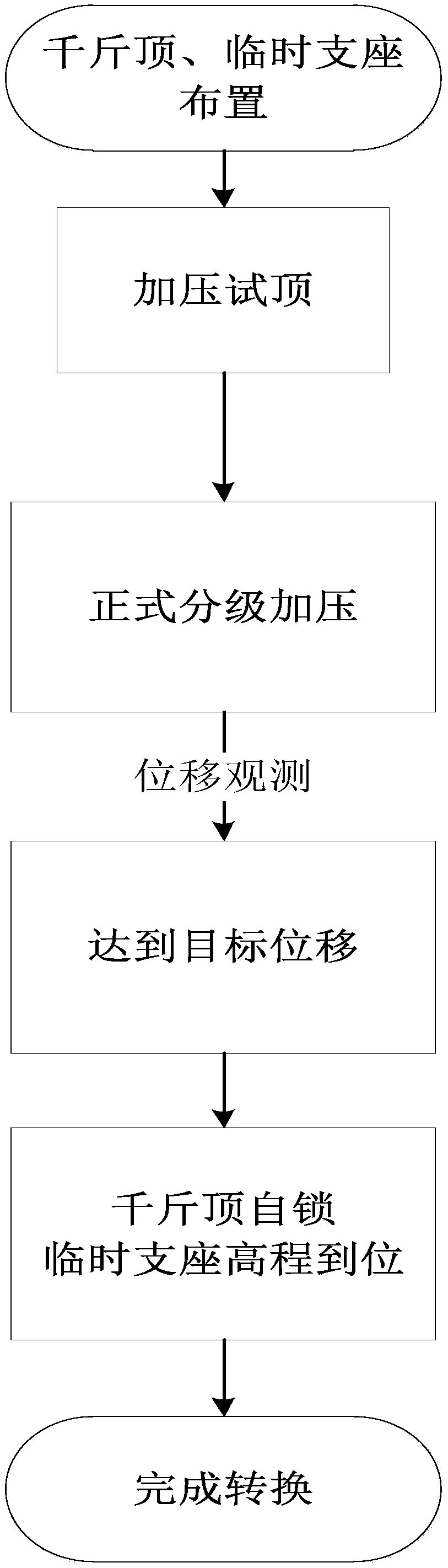

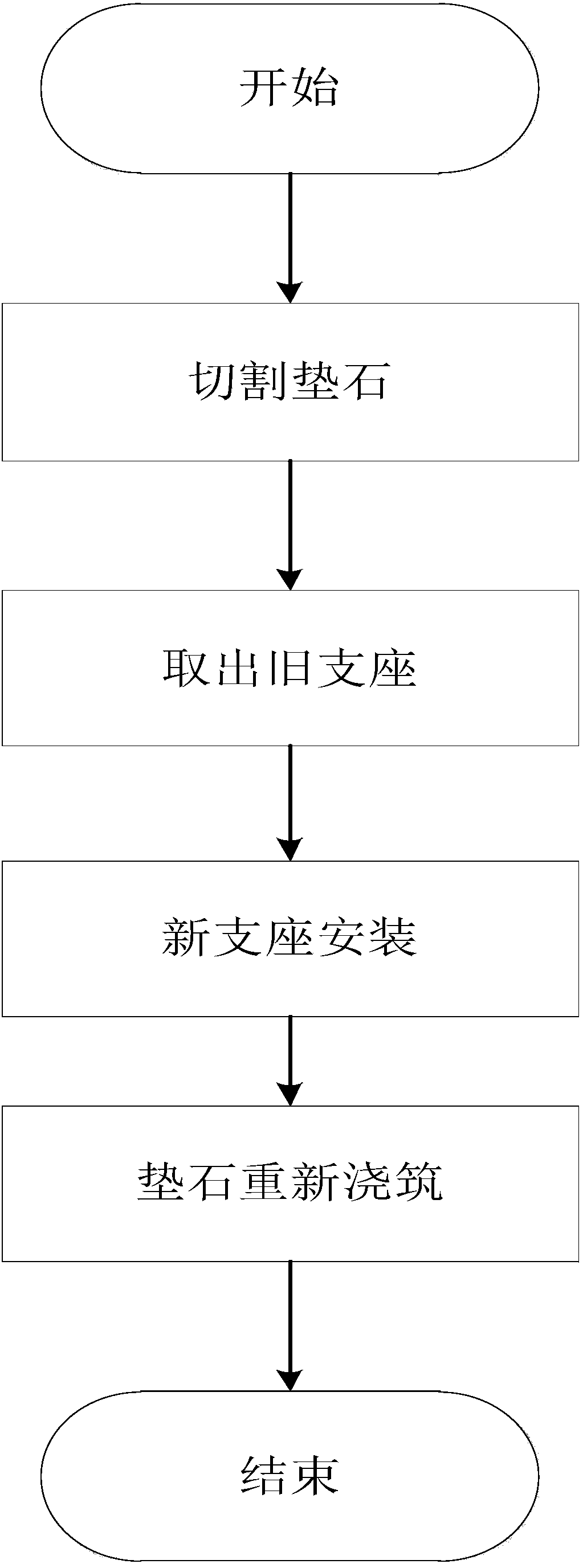

Construction process for replacement of large-tonnage bridge support

ActiveCN108442260ASolve the problem of replacement constructionEfficient job replacementBridge structural detailsBridge erection/assemblyEngineeringVertical displacement

The invention relates to the field of building construction, in particular to a construction process for replacement of a large-tonnage bridge support. The process comprises the steps that firstly, manholes of diaphragm plates in box girders are temporarily and locally reinforced, a temporary support is arranged, jacks are placed, counter-force replacement is completed when no vertical displacement of fulcrums of girder bodies is achieved, and the temporary support and an old support are subjected to joint load carrying; and then a method of reverse construction is adopted, a padstone of the old support is cut and removed, a new support is installed, the temporary support is released, the counter-force replacement of the new support and the old support is completed, and thus the replacement work of all old supports is completed. The construction process for the replacement of the large-tonnage bridge support is mainly applied to the replacement construction process of the large-tonnageold supports, the old support replacement project is efficiently completed by two times of counter-force replacement, and good real effect is achieved.

Owner:ROAD & BRIDGE INT +3

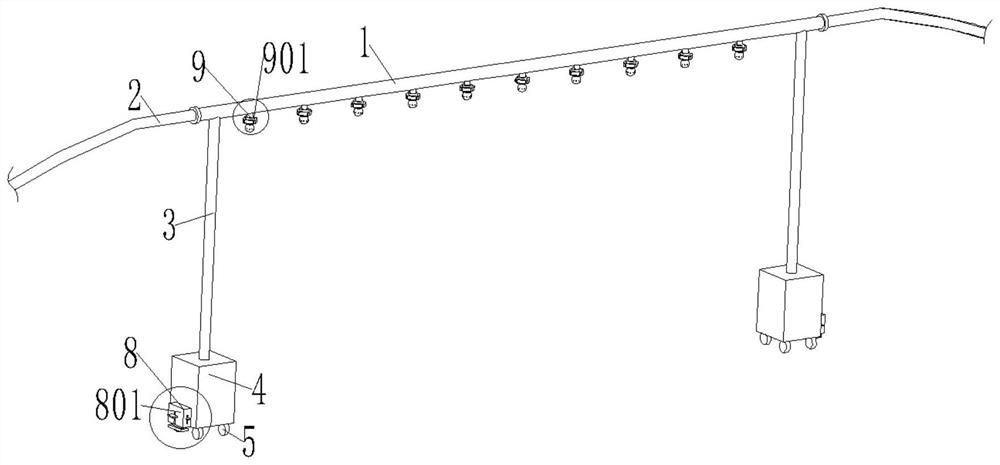

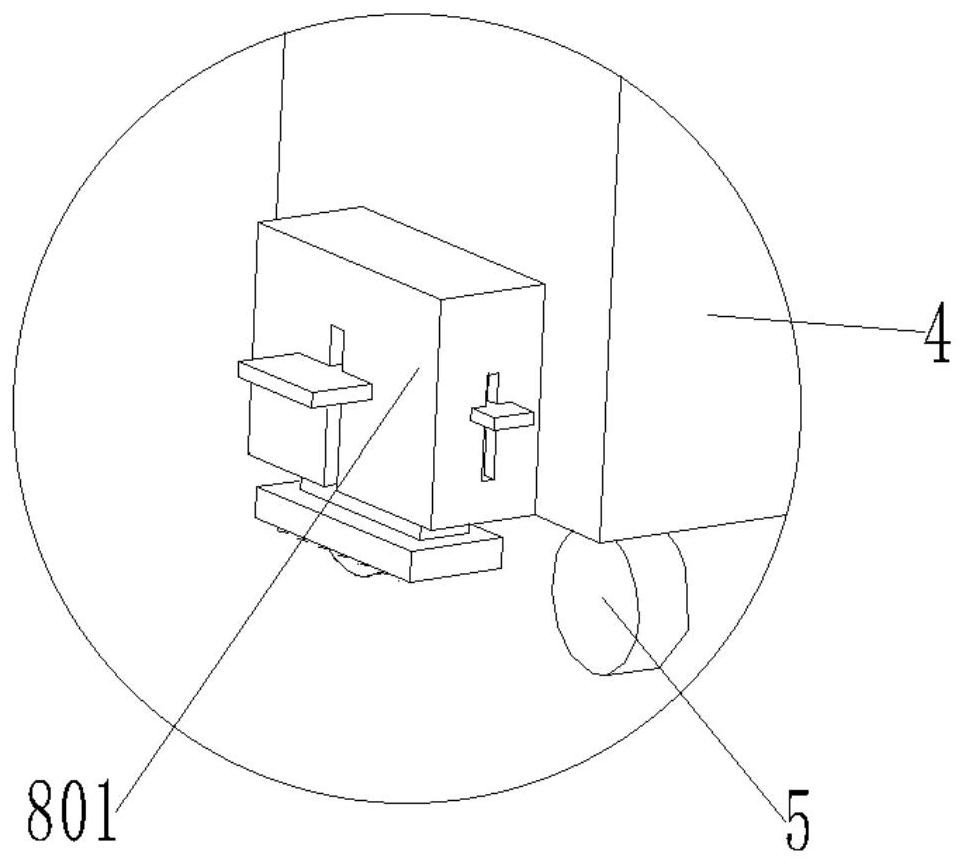

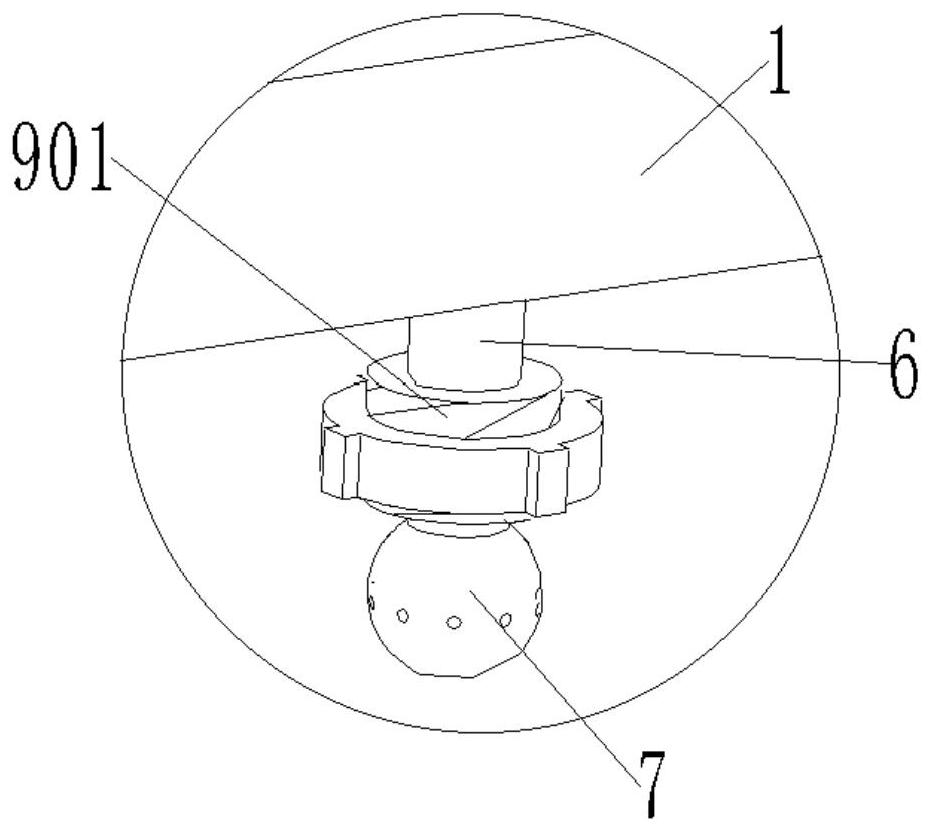

Suspended spraying system

InactiveCN113499874AEasy to moveImplementation processUsing liquid separation agentLiquid spraying apparatusThermodynamicsEngineering

The invention discloses a suspended spraying system. The suspended spraying system comprises a main water spraying pipe, water conveying hoses, water spraying branch pipes, spray heads and a positioning device, wherein the water conveying hoses are symmetrically arranged at two ends of the main water spraying pipe. According to the suspended spraying system designed by the invention, firstly, the movement of the spraying device can be realized through the arrangement of a supporting cube and rolling wheels, the use flexibility of the spraying device is improved, and the spraying working efficiency is further improved; through the arrangement of the positioning device, the position can be well positioned for working, and the stability of the spraying work is ensured; in addition, through the arrangement of a locking structure, the spray heads can be rapidly replaced; and when the spray heads are blocked or damaged and need to be replaced, the spray heads can be rapidly dismounted and mounted, normal spraying work is ensured; and the working efficiency of spraying and dust falling is further improved.

Owner:CHINA CONSTR EIGHTH ENG DIV

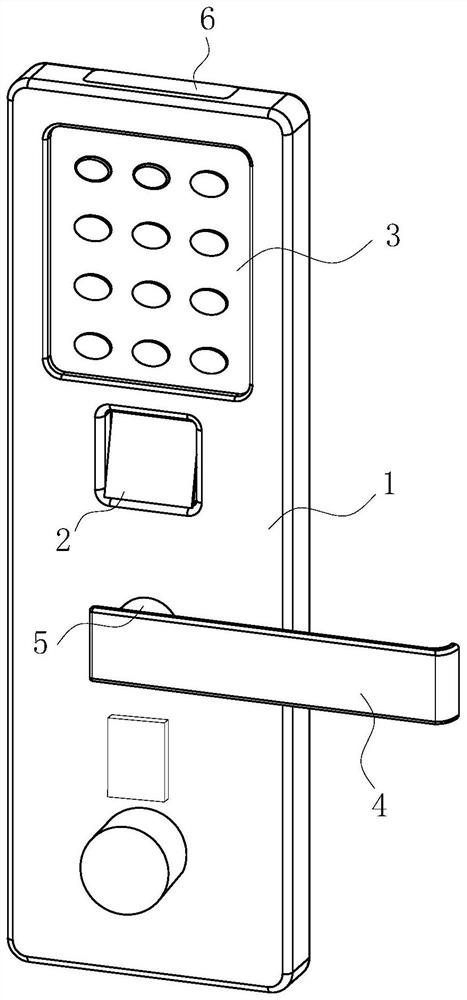

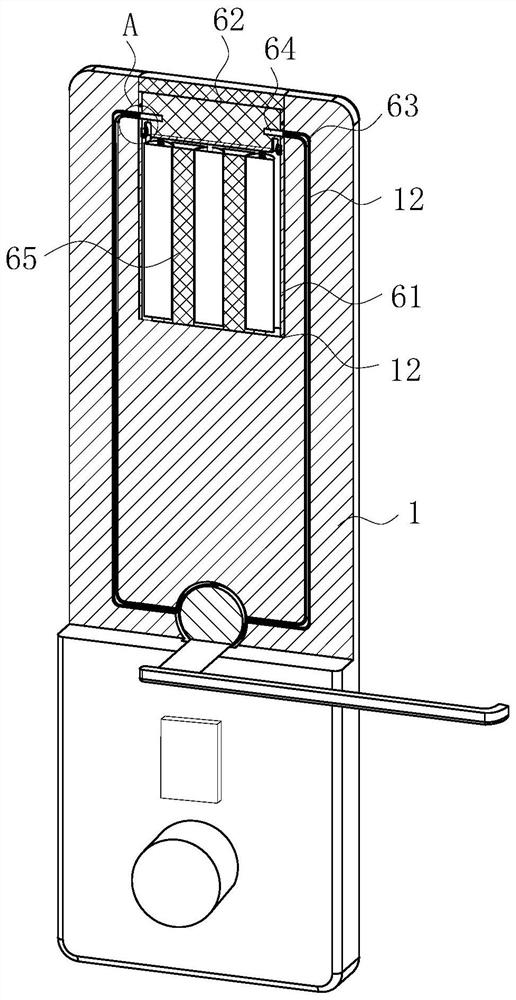

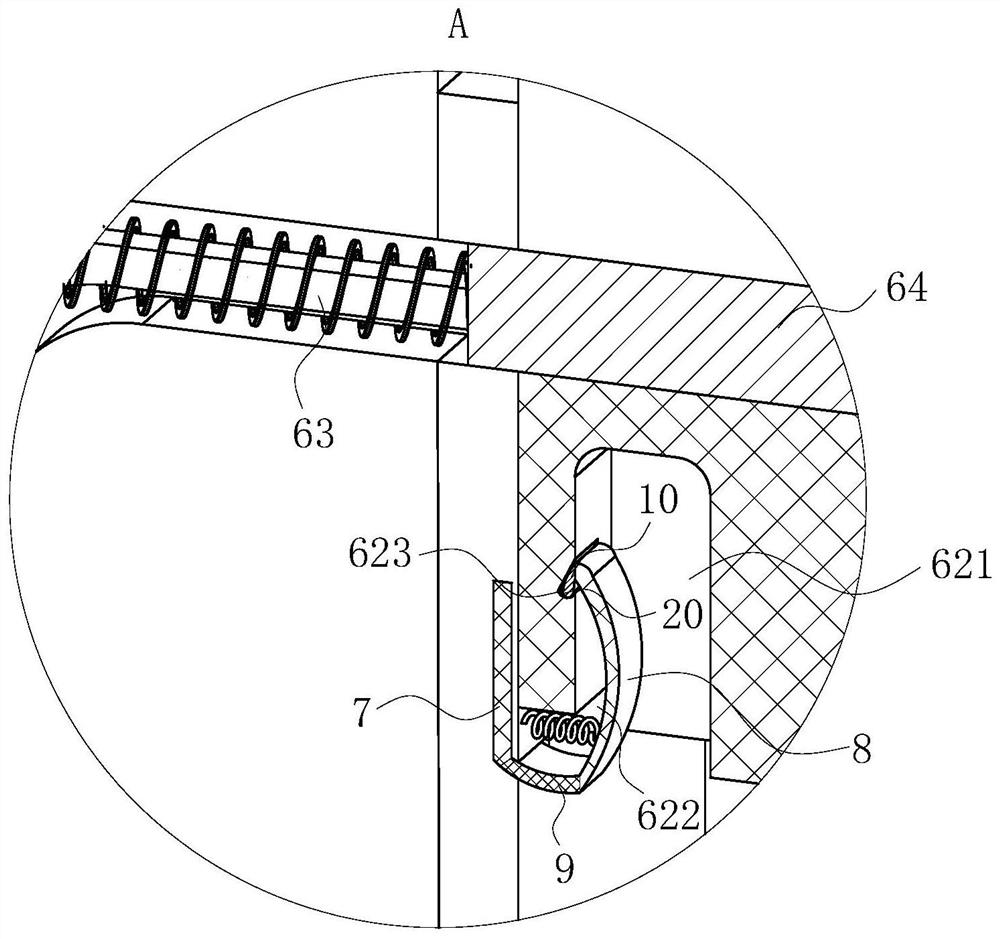

Intelligent household door lock

PendingCN111809970AEasy to openEasy to replaceNon-mechanical controlsLock casingsEngineeringStructural engineering

The invention belongs to the technical field of door locks, and particularly relates to an intelligent household door lock. The intelligent household door lock comprises an outer box body, an outer handle is arranged outside the outer box body, and a rotating shaft is rotationally arranged on the outer box body; the outer end part of the rotating shaft is connected with the outer handle; a mounting cavity is formed in the upper end of the outer box body; a battery box is fixedly arranged in the mounting cavity, and a mounting inserting cover is inserted into the top end of the battery box; pulling grooves are formed in the outer box body, one end of each of the pulling grooves communicates with the outer wall of the rotating shaft, and the other ends of the pulling grooves communicate withthe outer wall of the battery box; sliding inserting grooves are formed in the two side walls of the battery box and the two side walls of the mounting inserting cover; pulling ropes are arranged inthe symmetrically-formed pulling grooves, and one end of each of the symmetrically-arranged pulling ropes is connected to the upper end face and the lower end face of the rotating shaft correspondingly; and the other ends of the pulling ropes are connected with mounting clamping heads, and the mounting clamping heads are slidably inserted into the sliding inserting grooves. According to the intelligent household door lock, the safety use of the intelligent household door lock is improved, and meanwhile, a battery of the intelligent household door lock is more convenient and faster to replace.

Owner:孔瑞扬

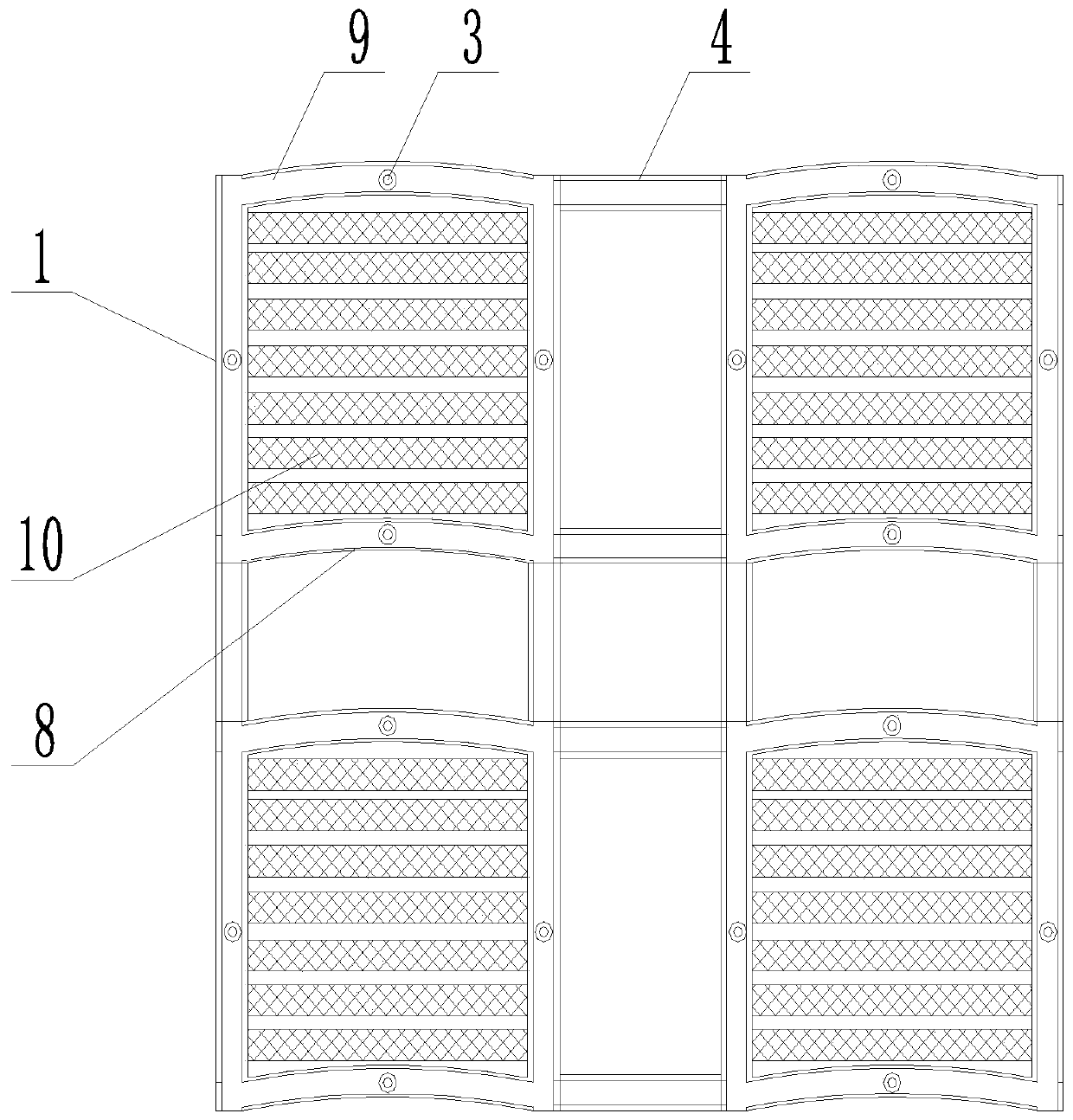

Prefabricated foundation pit slope-protection structure and implementation method

ActiveCN111236243AImprove construction efficiencyGuaranteed connection strengthExcavationsSewer pipelinesArchitectural engineeringStructural engineering

The invention discloses a prefabricated foundation pit slope-protection structure and an implementation method, and belongs to the technical field of construction for foundation pit support. The prefabricated foundation pit slope-protection structure comprises a plurality of support modules. Connecting grooves are formed in each support module, and mounting holes are also formed in each support module. Fixing pieces are mounted in the mounting holes. A splicing piece is arranged between every two adjacent support module, and the two ends of each splicing piece are separately attached to the corresponding support modules. Guide bases are fixedly arranged at the bottoms of the splicing pieces. Adjustment pieces and connecting pieces are arranged on the guide bases. The connecting pieces canbe arranged in the connecting grooves in a matched mode through the adjustment pieces, so that the construction efficiency is improved, and the overall connection strength can be guaranteed; and evenif a certain part is broken in the subsequent stage, only a single component needs to be replaced for repair, and repeated utilization of the prefabricated foundation pit slope-protection structure isrealized.

Owner:CHINA MCC17 GRP

Automatic rubbing system of drilling rig and its application method, microcontroller

ActiveCN104533320BQuick job changeReduce labor intensityDrilling rodsDrilling casingsMicrocontrollerSolenoid valve

The invention discloses an automatic threaded fastener loosening system of drilling tools, a use method thereof and a microcontroller. The automatic threaded fastener loosening system is used for achieving the effect of automatically switching drilling tools, and comprises a hydraulic solenoid valve, a hydraulic fastener loosening oil cylinder, an upper clamping oil cylinder, a lower clamping oil cylinder, a microcontroller, electromagnetic coils, a pressure sensor and a position sensor. The upper clamping oil cylinder is used for clamping or loosening the male fastener end of an upper drill rod, and the lower clamping oil cylinder is used for clamping or loosening the female fastener end of a lower drill rod. The hydraulic fastener loosening oil cylinder is used for loosening the upper drill rod clamped by the upper clamping oil cylinder. The microcontroller is used for controlling the upper clamping oil cylinder and the hydraulic fastener loosening oil cylinder to stretch and contract according to monitoring of the pressure sensor and the position sensor so as to finish loosening or mounting of connector threaded fasteners of the upper drill rod and the lower drill rod of the drill tools. The automatic threaded fastener loosening system of the drilling tools, the use method thereof and the microcontroller achieve the effect of automatically switching the drilling tools quickly, safely, reliably and conveniently, reduce the labor intensity of the working staff and improve the drilling efficiency.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

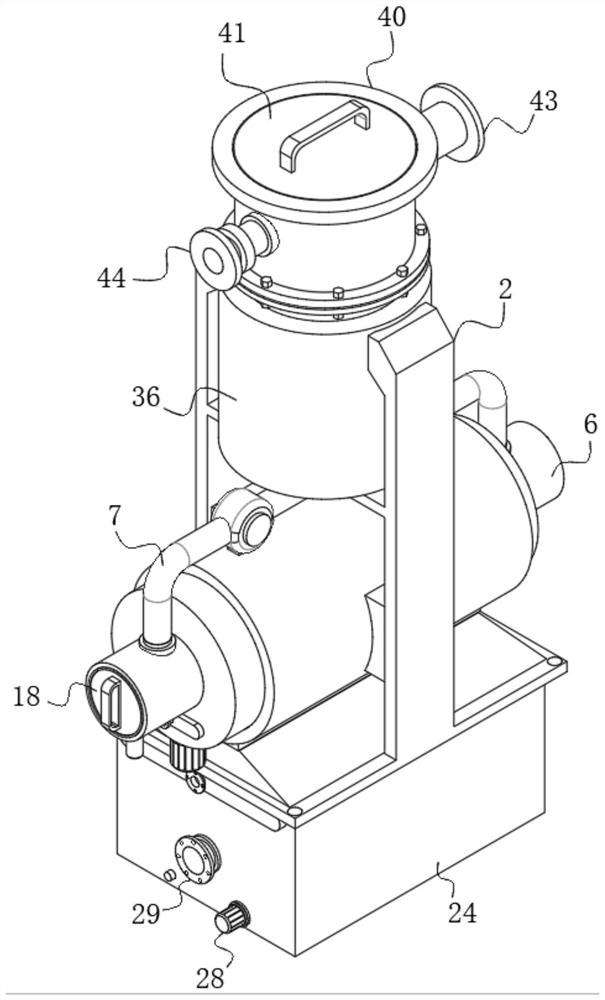

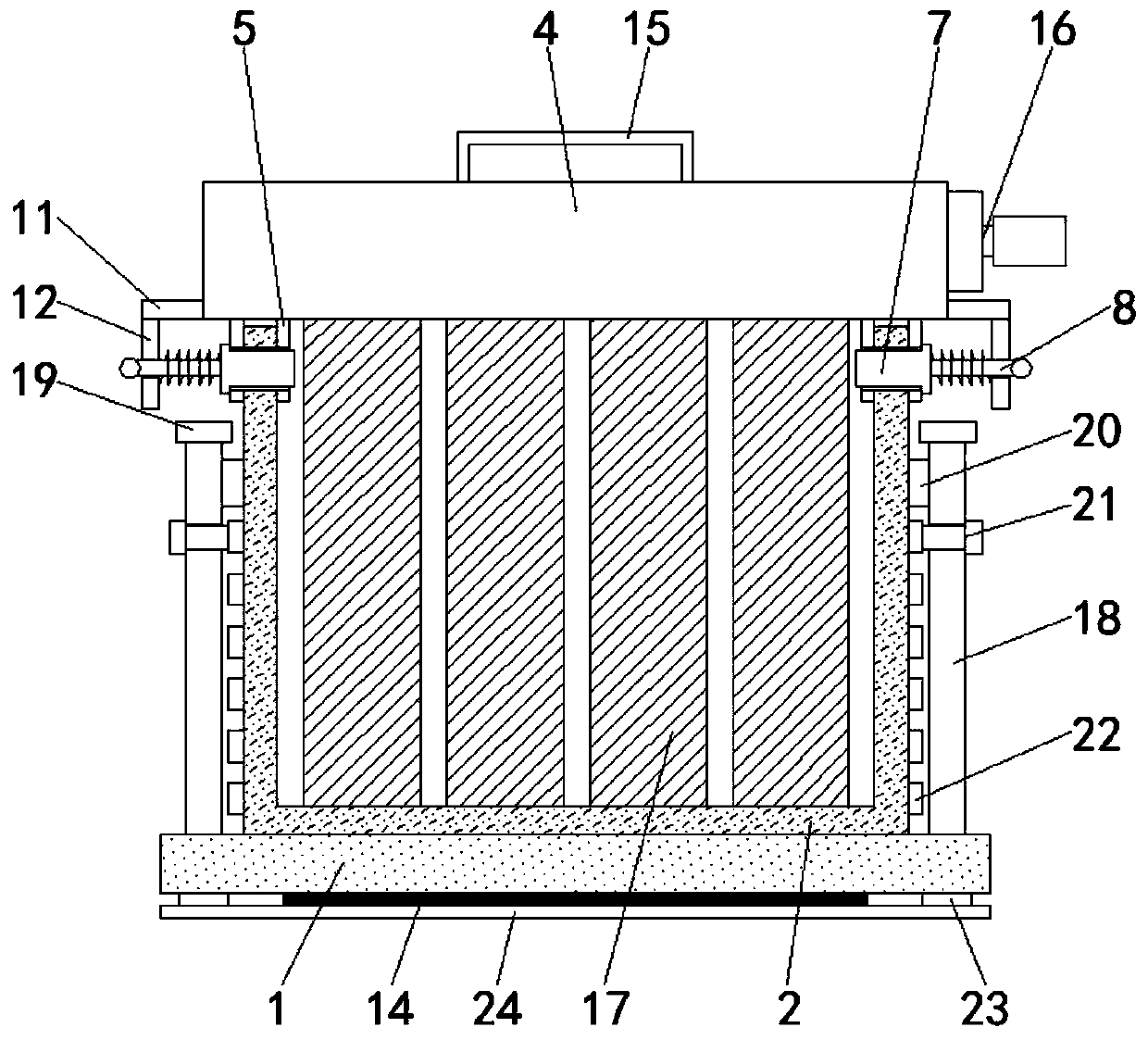

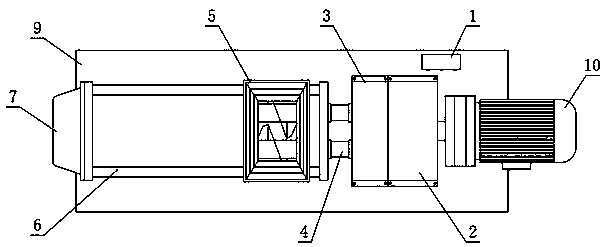

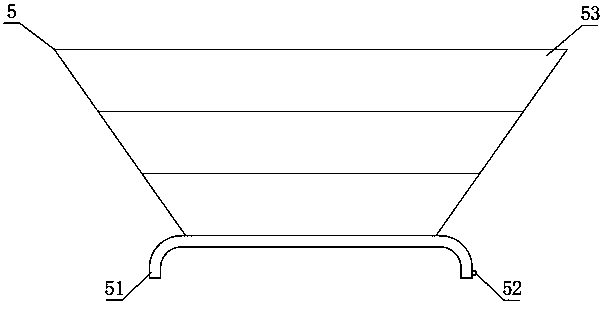

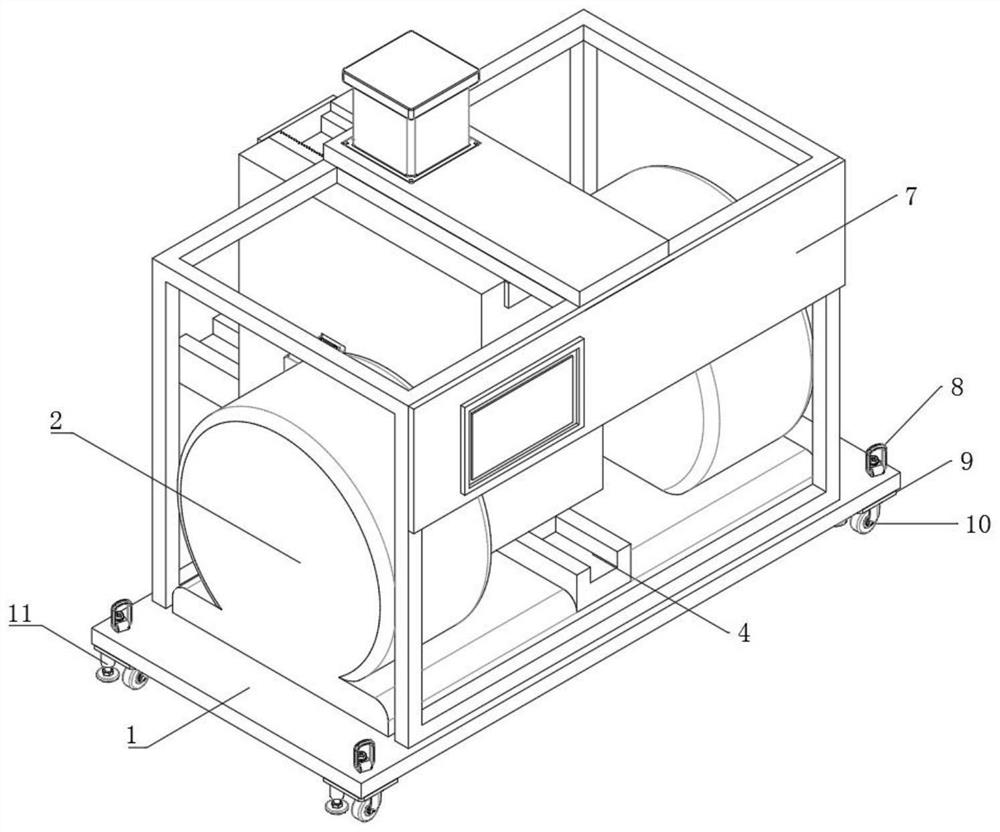

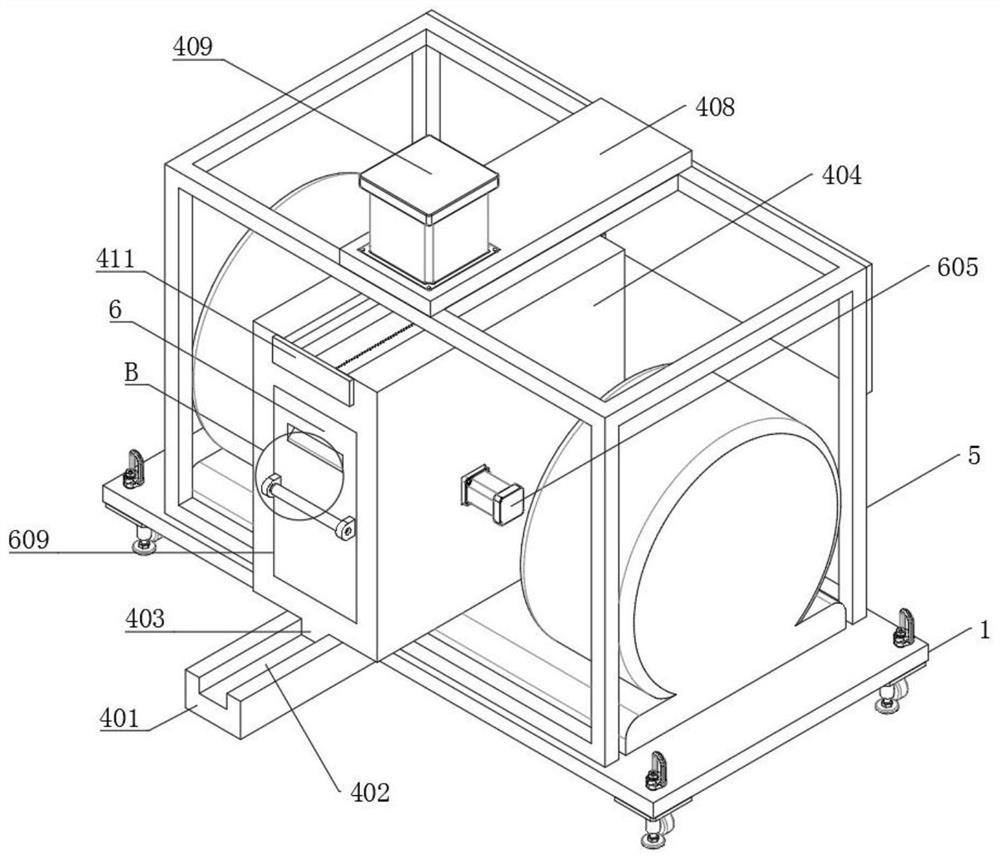

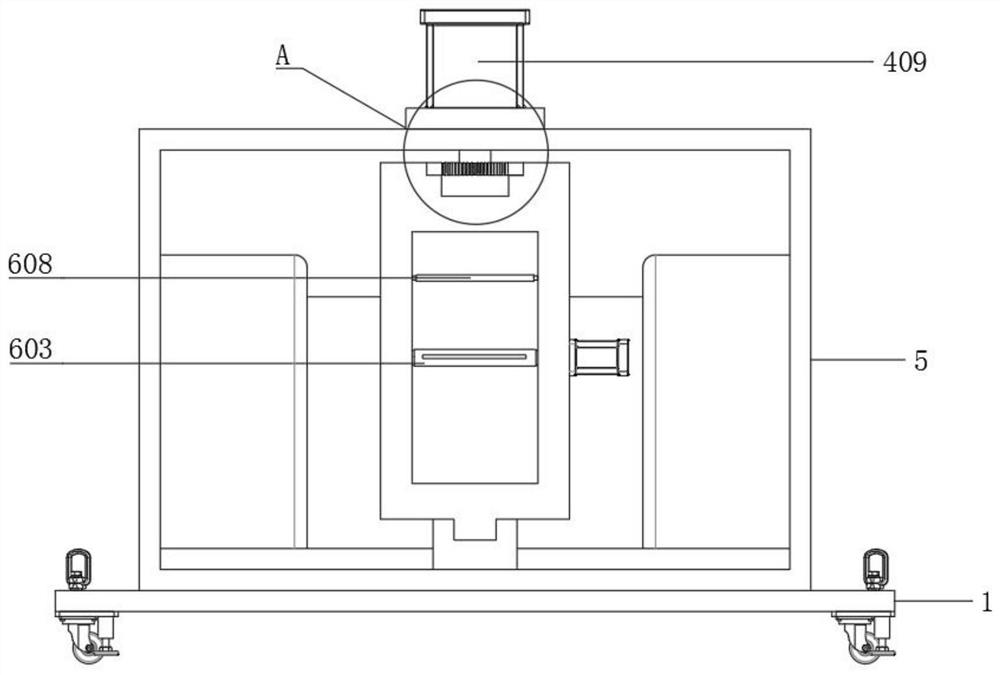

Small flat bag-type dust collector for dust suppression material guide tank system

InactiveCN110075627APrevent leakageEasy to change jobsDispersed particle filtrationLower limitBaghouse

The invention relates to the technical field of bag-type dust collectors, and discloses a small flat bag-type dust collector for a dust suppression material guide tank system. The small flat bag-typedust collector for the dust suppression material guide tank system comprises a mounting base, a box body, a sealing block, a cover body, a clamping plate, a sealing sleeve, an insertion block, a movable rod, a return spring, a pulling block, a connecting block, a fixing block, a movable groove, a cushion block, a handle, a driving mechanism, a bag body, an adjusting column, an upper limiting block, a connecting plate, a threaded column, an internal threaded block, a lower limiting block and a bottom plate. The box body is fixedly connected to the top of the mounting base, and the top of the box body is in contact with the sealing block; the top of the sealing block is fixedly connected with the cover body; the bottom of the cover body is fixedly connected with the clamping plate; the sealing sleeve is movably connected with the sealing block, and is movably connected with the clamping plate; the insertion block is inserted in the sealing sleeve; and the top of the cover body is fixedlyconnected with the handle. The small flat bag-type dust collector for the dust suppression material guide tank system is convenient to use.

Owner:武汉正源输送工程有限公司

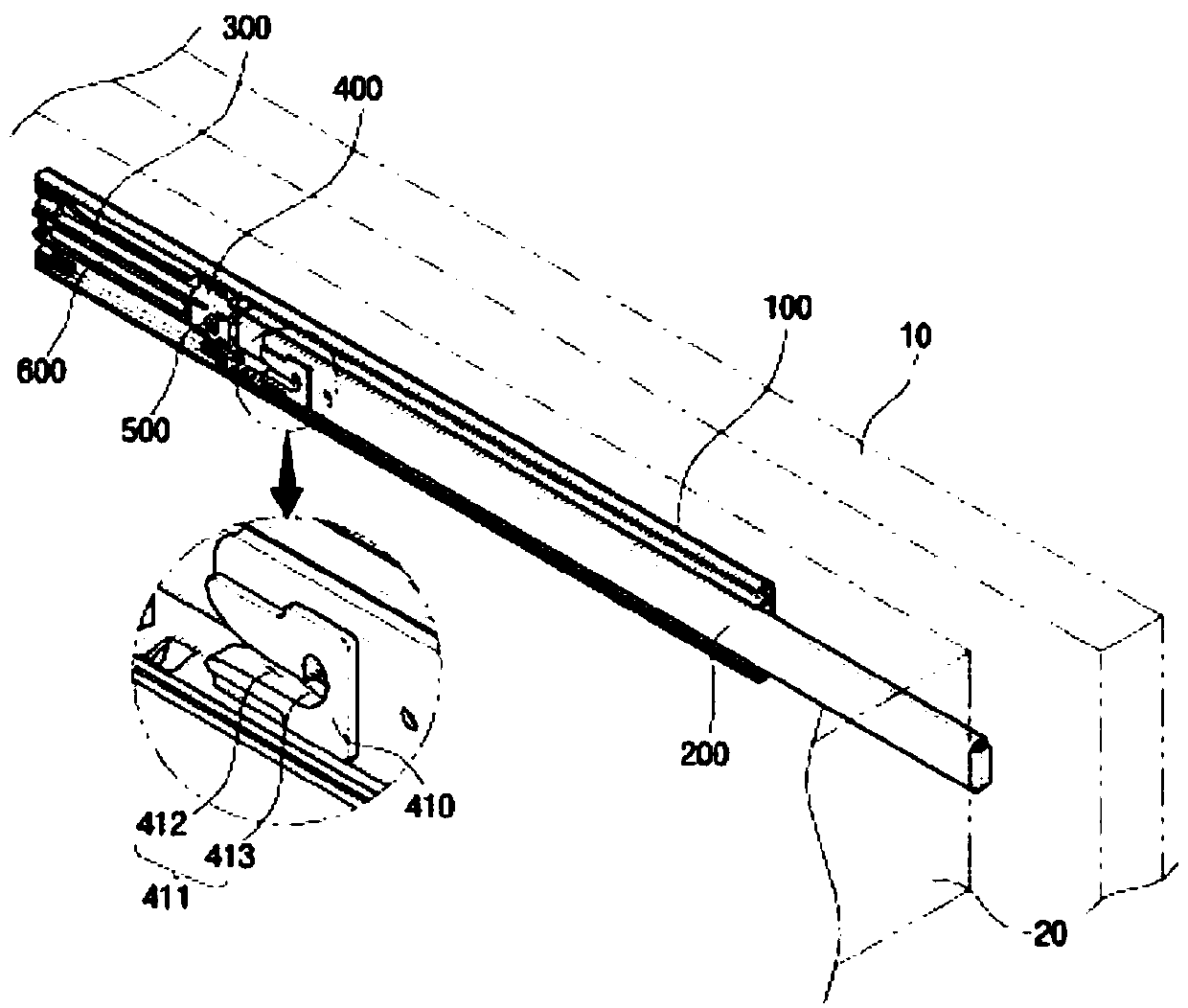

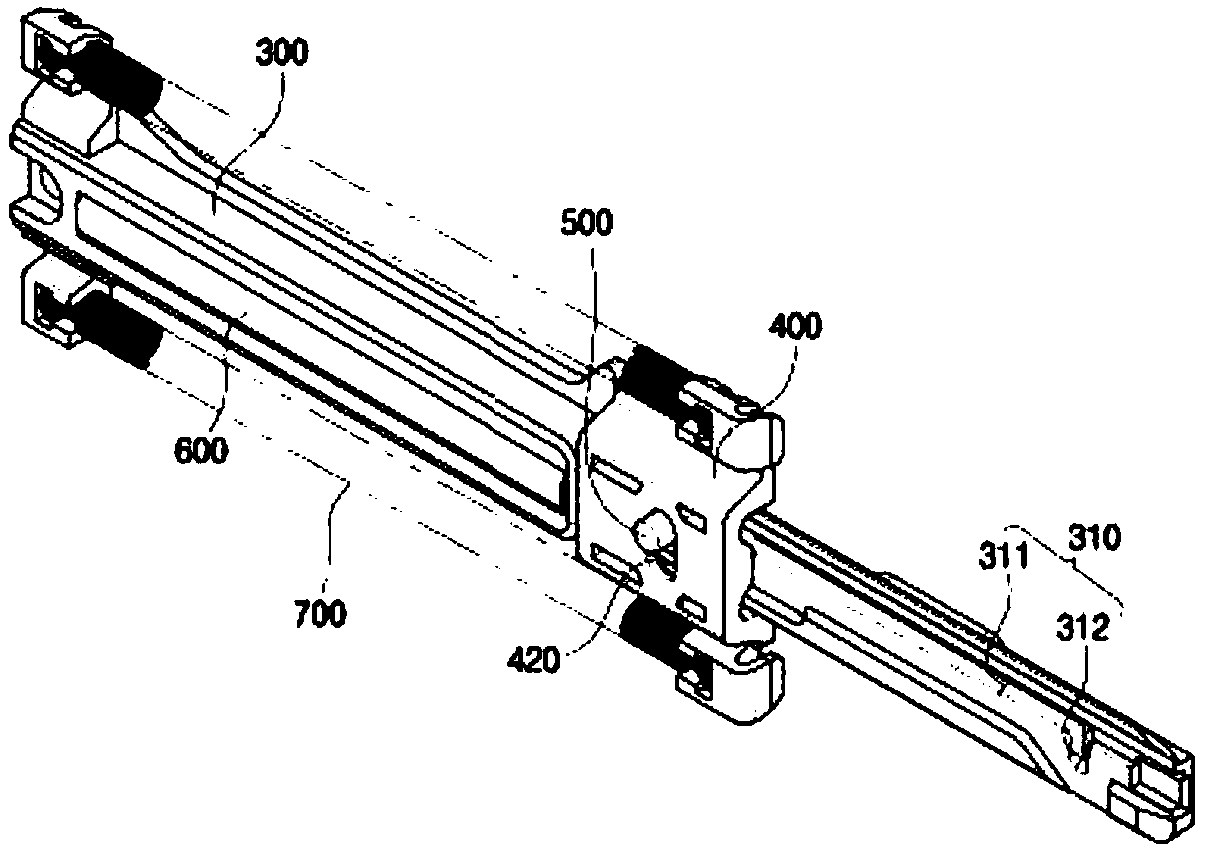

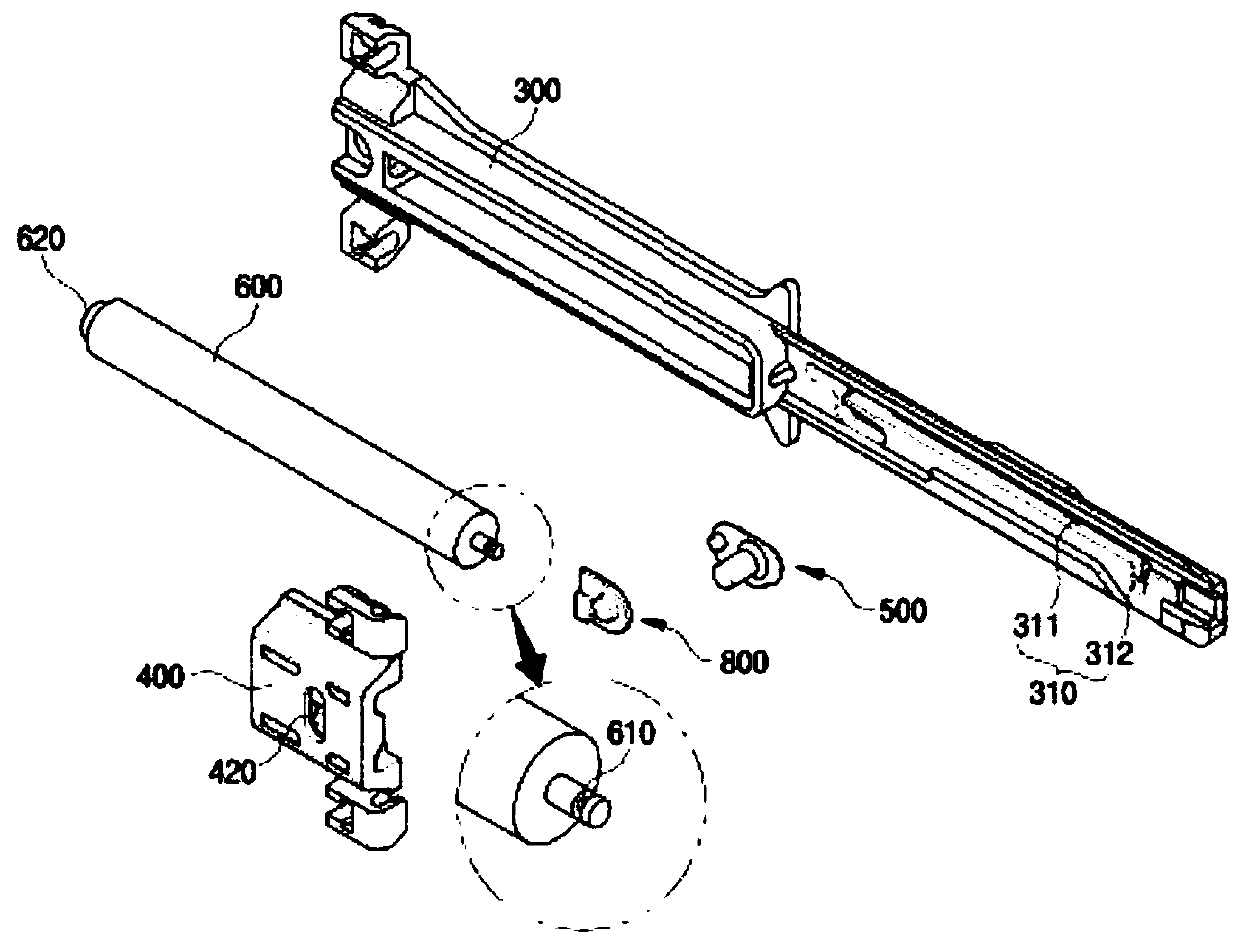

Slide device

ActiveCN107847047AIncreased durabilityCombination structure is simpleLinear bearingsDrawersMechanical engineering

Disclosed is a slide device. The slide device of the present invention comprises: a body which is provided at one side end region of a fixed rail and has a guide path; a slider which is coupled to thebody and is selectively slidably movable along the lengthwise direction of the body during the slidable movement of a transfer rail; a transfer pin which is coupled to the slider so as to be movablesimultaneously at the time of the movement of the slider and is movable along the guide path; and a damper which is provided on the body and of which the rod end part is provided so as to be connectedwith the transfer pin. The present invention employs a structure in which the rod end part of the damper is separably coupled to a sub transfer pin without being directly coupled to the slider, and thereby can maximally prevent occurrence of a problem wherein the durability of the slider degrades during long-term reciprocating movement.

Owner:SEGHERS CO LTD

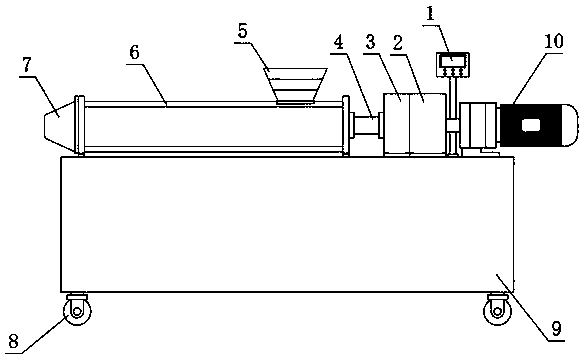

Co-rotating twin-screw extruder for PP material processing and using method

The invention discloses a co-rotating twin-screw extruder for PP material processing and a using method. The co-rotating twin-screw extruder comprises a fixed table and a filter, rolling wheels are arranged at the four corners of the lower end of the fixed table, a rotating motor is arranged at the upper right end of the fixed table, a control box device is arranged at the rear side of the upper right end of the fixed table, due to the fact that a magnet feeding groove device is installed, the magnet feeding groove device is fixedly connected with a charging barrel in an adsorption mode through an electromagnet, when the magnet feeding groove device is damaged, a power source is cut off through a wiring terminal, a worker can disassemble the magnet feeding groove device rapidly, and therefore replacement work can be carried out rapidly; and due to the fact that a stretching feeding groove is stretchable, the stretchable feeding groove is used for stretching work, the feeding storage space can be expanded, then the worker has no need repeatedly pouring materials, the replacement efficiency is improved, and the operation time is saved.

Owner:SUZHOU WEIRUICHENG NEW MATERIAL

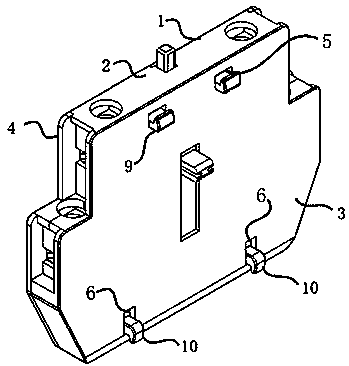

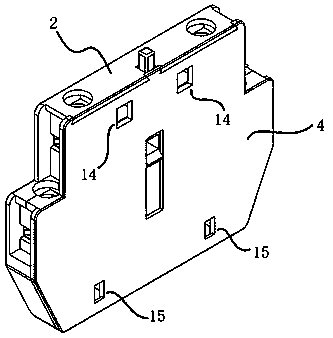

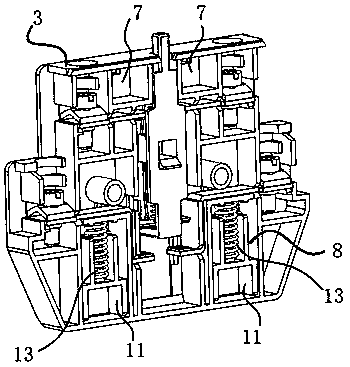

Auxiliary contact unit hung on alternating current contactor

PendingCN110047704AEasy to assemble and disassembleQuick job changeElectromagnetic relay detailsContactorEngineering

The invention discloses an auxiliary contact unit hung on an alternating current contactor. The auxiliary contact unit comprises a shell of the auxiliary contact unit, two upper through holes and twolower through holes are symmetrically formed in the outer wall of the shell bottom of the shell, upper cavities and lower cavities which are respectively matched with the upper through holes and the lower through holes are formed in the inner wall of the shell, an upper buckle is arranged in the upper cavity, a hook at the front end of the upper buckle extends out of the upper through hole and thedirection of the hook is upward; a lower buckle is arranged in the lower cavity, a hook at the front end of the lower buckle extends out of the lower through hole, and the direction of the hook is downward; upper hanging holes opposite to the upper through holes and lower hanging holes opposite to the lower through holes are formed in the side wall, which is connected with the auxiliary contact unit, of the alternating current contactor. According to the auxiliary contact unit in the invention, an upper hanging buckle and a lower hanging buckle which extend out of the shell are arranged on one side of the shell bottom, the auxiliary contact unit is hung on the side wall of the alternating current contactor through the lower hanging buckle and the upper hanging buckle, the auxiliary contact unit can be conveniently disassembled and assembled, quick replacement operation of the auxiliary contact unit can be realized in a narrow area, and time and labor are saved.

Owner:NO 13 ELECTRICAL APPLIANCES

Convenient cleaning equipment

InactiveCN107694969ARealize automatic controlEasy job changeElectrostatic cleaningCleaning using toolsEngineering

Owner:广州凯柔进出口贸易有限公司

Multi-stage sounding device of marine hydrological winch

PendingCN113879999AHigh measurement accuracyAccurate size adjustmentPortable liftingElectric machineryElectrical and Electronics engineering

The invention discloses a multi-stage sounding device of a marine hydrological winch. The multi-stage sounding device of the marine hydrological winch comprises a winch bottom plate, a winch body is mounted at the top of the winch bottom plate, a driving fixing mounting groove is formed in the top of the winch body, a driving mechanism is connected to the inner wall of the driving fixing mounting groove, a driving detector is mounted in the driving mechanism, a detection mounting groove is formed in one end face of a driving detection seat, mounted bearings are mounted on the two sides of the detection mounting groove, a detection driving fixing shaft is connected to the inner walls of each mounted bearing, a motor mounting groove is formed in one side of the driving detection seat, a second driving motor is mounted on the inner wall of the motor mounting groove, and a movable connector is fixed at the output end of the second driving motor. According to the multi-stage sounding device of the marine hydrological winch, the second driving motor is controlled to rotate through an operation panel, the detection driving fixing shaft is driven to rotate between the two mounted bearings through the movable connector, and accurate size adjustment of the diving length of a detection piece required by detection is facilitated.

Owner:董英伟

grinding device

ActiveCN102814726BEasy to disassemblePracticalGrinding wheel securing apparatusLapping machinesRotational axisEngineering

The present invention provides a grinding device, which can arrange a rotating grinding body in a state of rotating together with a rotating shaft by a very simple structure, and can conduct the replacement operation for the rotating grinding body easily. The rotating shaft (1) is provided with a rotating stop part (3). The rotating stop part (3) is provided with a rotating stop embedding part (4) which is embedded in the rotating stop part. The end of the rotating grinding body (2) is provided with a grinding body side embedding part (5) which is embedded with the rotating stop embedding part. The rotating grinding body and the rotating stop embedding part are disposed on the rotating shaft to embed with the rotating stop part and embed with the rotating stop embedding part and the grinding body side embedding part. The rotating stop embedding part stops rotating relative to the rotating shaft, and the grinding body side embedding part is disposed on the end of the rotating grinding body. Thus the rotating grinding body stops rotating relative to the rotating shaft. A locking body (6) is disposed on the end of the rotating shaft in a manner of free assembling. The locking body can prevent the rotating grinding body from dropping from the rotating shaft. So the rotating grinding body is arranged in a manner of free assembling.

Owner:S T LINK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com