Cleaning equipment

A kind of cleaning equipment and cleaning technology, applied in the field of cleaning, can solve the problems of affecting the cleaning progress, easily damaged equipment, time-consuming and labor-intensive, etc., and achieve the effect of simple structure, convenient operation, and improving the safety of equipment use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

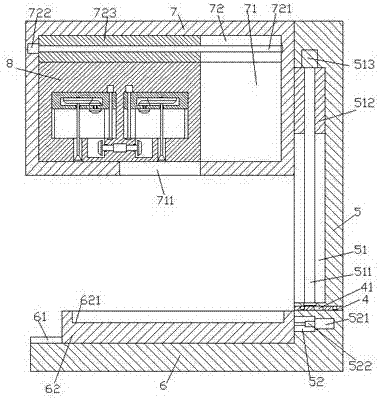

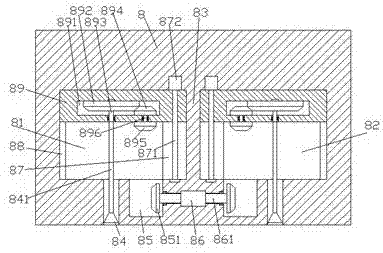

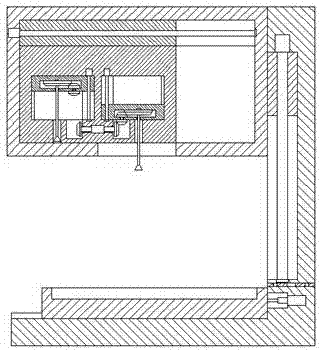

[0023] Such as Figure 1-Figure 6As shown, a cleaning device of the present invention includes a frame composed of a base 6 and a vertical column 5, and a transition device 7 arranged in the frame, and a transition chamber 71 is provided inside the transition device 7. The top wall of the transition chamber 71 extends left and right and is provided with a first sliding groove 72, and the first sliding groove 72 is provided with a first screw rod 721 extending left and right, and the first screw rod 721 is connected with a first sliding groove. Transport block 723, the midpoint of the bottom end surface of the transition device 7 is provided with a top and the transition cavity 71 piercing groove 711, and the transition cavity 71 is provided with a top and the bottom of the first sliding block 723 is fixed. The connected cleaning operation device 8, the left and right sides of the cleaning operation device 8 are oppositely provided with a first sliding chamber 81 and a second s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com