Pneumatic clamping device

A pneumatic clamping and cylinder device technology, which is applied in clamping devices, positioning devices, clamping, etc., can solve problems such as uneven force points of parts, waste of machine tools, and low processing efficiency, so as to improve production efficiency and quality problems , Improve clamping and processing speed, and improve processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

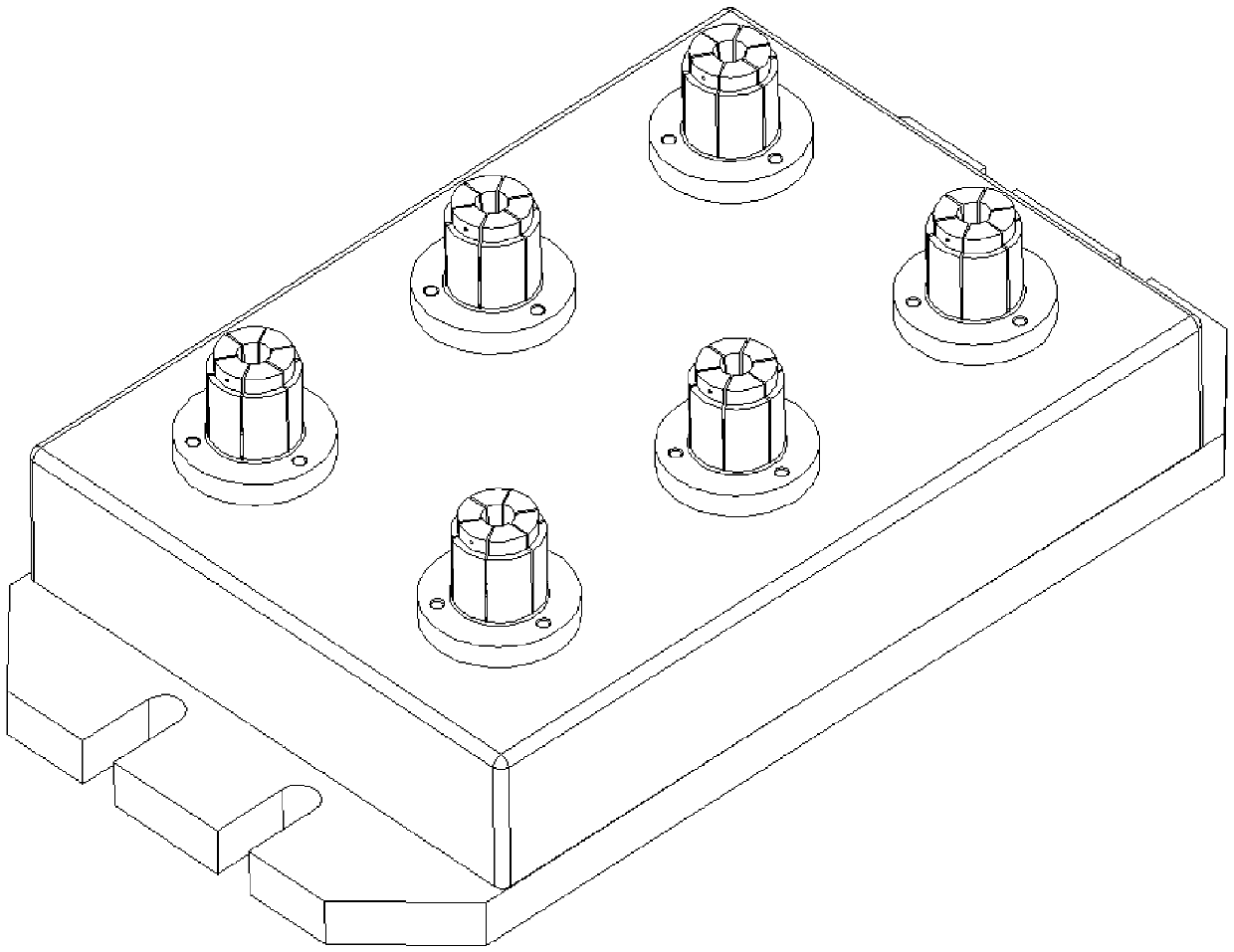

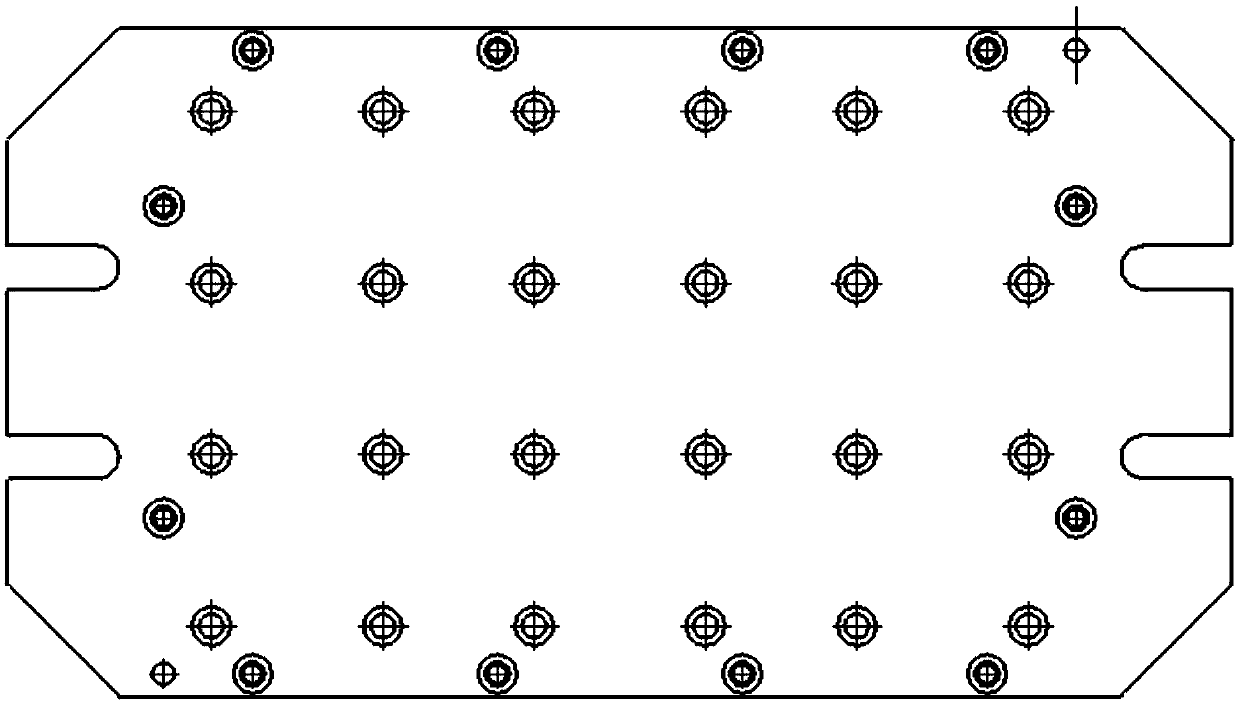

[0026] The pneumatic clamping device is composed as follows: chuck device 1, upper box body 2, cylinder device 3 and lower base plate 4; the number of chuck devices 1 is 4-8 to ensure convenient clamping, parts do not interfere with each other, and do not Affect the tool change without exceeding the stroke. The chuck device 1 is installed on the upper box body 2, and the upper box body 2 is connected to the lower floor 4 upper side, and the chuck device 1 is connected with the cylinder device 3, and the cylinder device 3 is positioned in the upper box body 2 on the base plate 4 upper side.

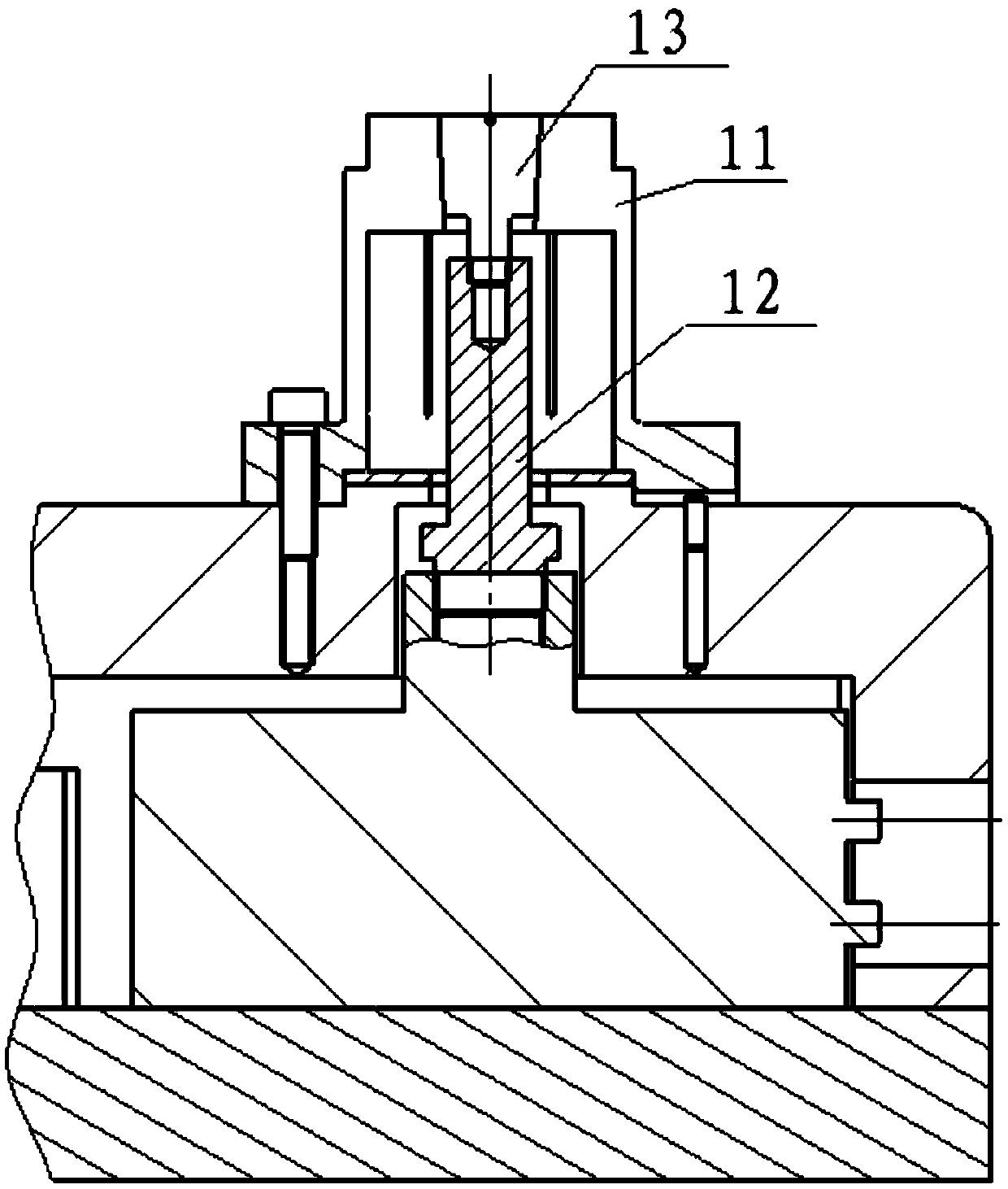

[0027] Described chuck device 1 is constituted as follows: circlip 11, piston rod 12, cone 13, described circlip 11 is installed on the upper box body 2, and circlip 11 is connected with cylinder device 3 by piston rod 12 and cone 13 . Circlip 11 is an expansion circlip, and mandrel and jacket are no longer used to save material. Design circlips of different sizes, and each part correspo...

Embodiment 2

[0037] The pneumatic clamping device is composed as follows: chuck device 1, upper box body 2, cylinder device 3 and lower base plate 4; the number of chuck devices 1 is 6 to ensure convenient clamping, parts do not interfere with each other, and do not affect replacement. Knife, not beyond the stroke. The chuck device 1 is installed on the upper box body 2, and the upper box body 2 is connected to the lower floor 4 upper side, and the chuck device 1 is connected with the cylinder device 3, and the cylinder device 3 is positioned in the upper box body 2 on the base plate 4 upper side.

[0038] Described chuck device 1 is constituted as follows: circlip 11, piston rod 12, cone 13, described circlip 11 is installed on the upper box body 2, and circlip 11 is connected with cylinder device 3 by piston rod 12 and cone 13 . Circlip 11 is an expansion circlip, and mandrel and jacket are no longer used to save material. Design circlips of different sizes, and each part corresponds t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com