Prefabricated foundation pit slope-protection structure and implementation method

A prefabricated assembly and foundation pit technology, applied in infrastructure engineering, excavation, water supply installations, etc., can solve the problems of waste of resources, inconsistent with the concept of green construction, and the inability to recycle and reuse shotcrete slope protection, so as to improve construction efficiency and improve The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

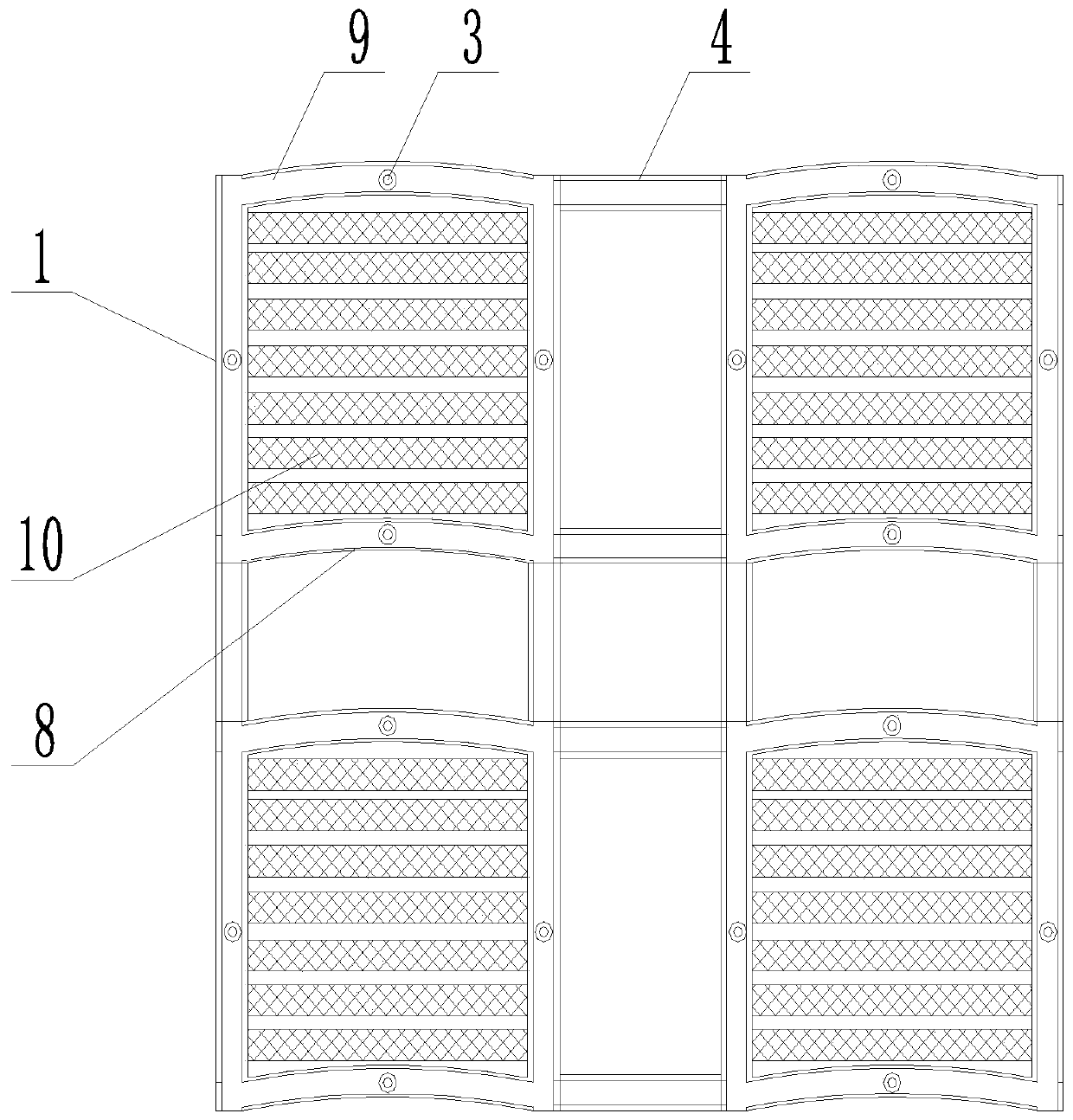

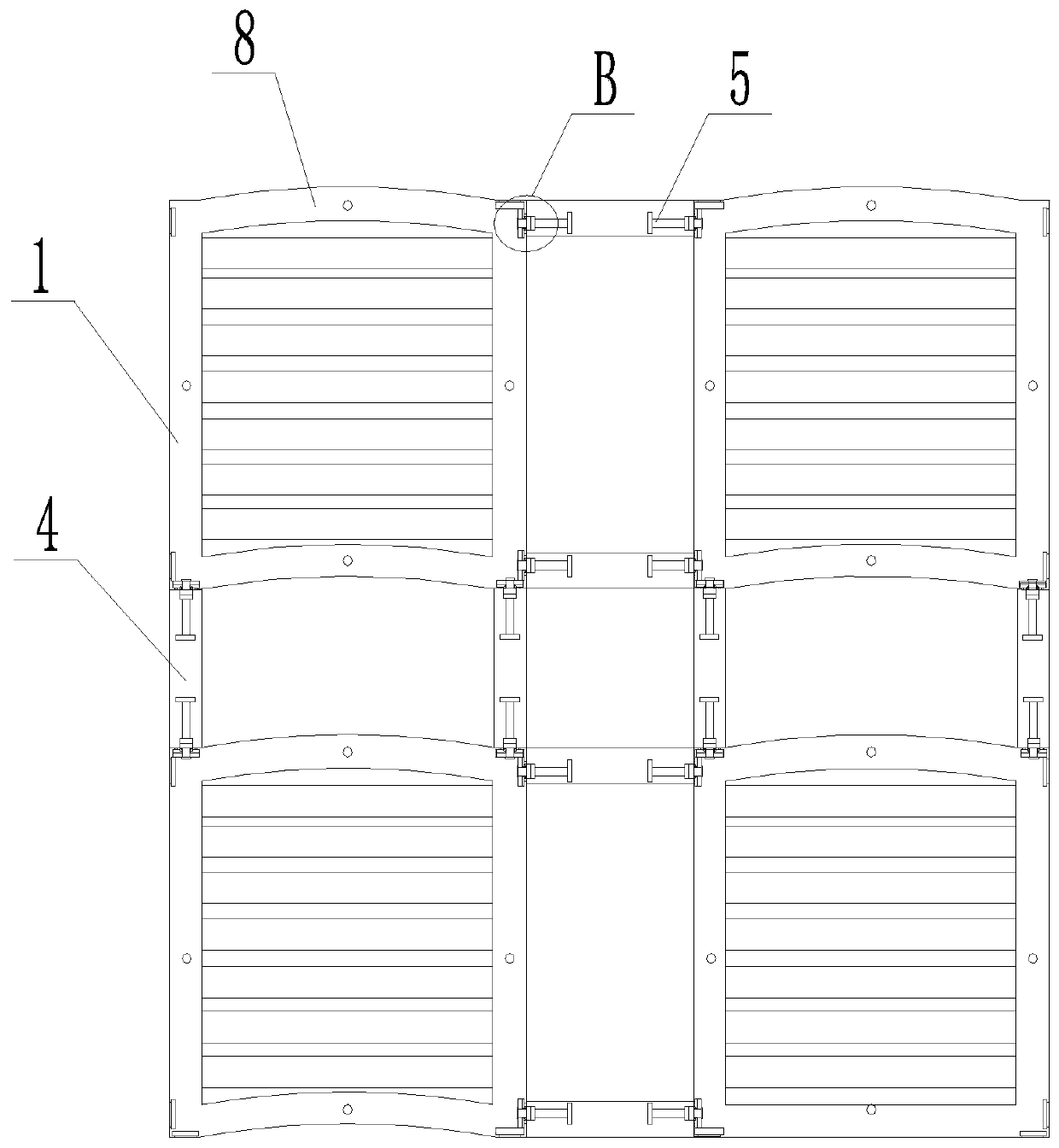

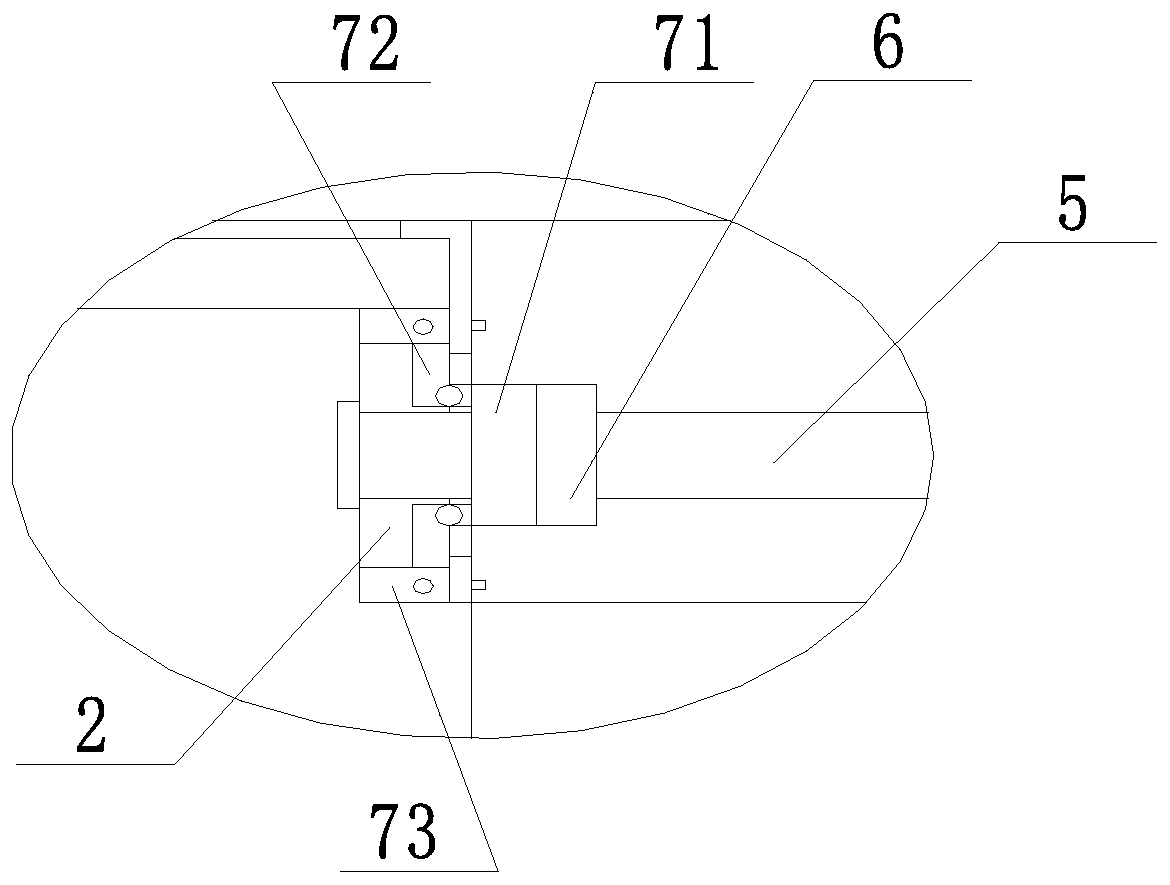

[0032] Such as Figure 1 to Figure 5 As shown, a prefabricated foundation pit slope protection structure includes several support modules 1, each support module 1 is provided with a connecting groove 2, and each support module 1 is provided with a mounting hole, and in the mounting hole A fixing part 3 is installed, and a splicing part 4 is arranged between two adjacent supporting modules 1, and the two ends of the splicing part 4 are attached to the corresponding supporting modules 1 respectively, and the bottom of the splicing part 4 is fixed with a guide seat 5. The guide seat 5 is provided with an adjusting piece 6 and a connecting piece 7 , and the connecting piece 7 is matched in the connecting groove 2 through the adjusting piece 6 . In the construction process, the support module 1 is first fixed by the fixing part 3, and then the push connecting part 7 is moved into the connection groove 2 by adjusting the adjusting part 6 to realize the connection of the adjacent sup...

Embodiment 2

[0039] Such as Figure 1 to Figure 6 As shown, different from Embodiment 1, the fixing member 3 includes an outer shape unit 31 and an inner shape unit 32 which are all hollow structures, the outer shape unit 31 is provided with a positioning structure and an internal thread, and the inner shape unit 32 is provided with a The thread matches the external thread, and the internal shape unit 32 is provided with an adjustment part 321 for making the positioning structure realize outward expansion. Wherein, the positioning structure includes a fixed ring 311, a positioning rod 312 and a reset member 313 (spring), the fixed ring 311 is fixedly connected on the outer wall of the shape unit 31, and the fixed ring 311 is provided with a guide groove communicating with the outside in the radial direction, and the positioning The rod 312 is moved and installed in the guide groove, one end of the positioning rod 312 extends to the surface of the adjustment part 321, the reset member 313 i...

Embodiment 3

[0042] A method for implementing a prefabricated foundation pit slope protection structure, comprising the following steps:

[0043] S1. Leveling and repairing the slope protection of the foundation pit, and temporarily placing the support module 1 in a predetermined position;

[0044] S2. The support module 1 is fixedly installed in order from bottom to top. When the support module 1 is installed at the bottom of the side wall of the foundation pit, it is fixed and installed on the slope protection of the foundation pit through the fixing part 3. The specific operation is to adjust the inner shape unit 32 to make it move to the inside of the profile unit 31, so that the adjustment part 321 squeezes the positioning rod 312 and extends outward to the outside of the fixing ring 311 and goes into the soil in the slope protection of the foundation pit, and ensures that the bottom of the support module 1 is level ;

[0045] S3, adjust the adjusting part 6 at one end of the splicin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com