Arrangement and method for changing endless belt in paper making machine/board machine or polishing machine

A technology for cardboard machines and paper machines, applied in paper machines, grinding/polishing equipment, paper making, etc., can solve the problems of increasing the width of paper machine workshops, hidden safety hazards, and large space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

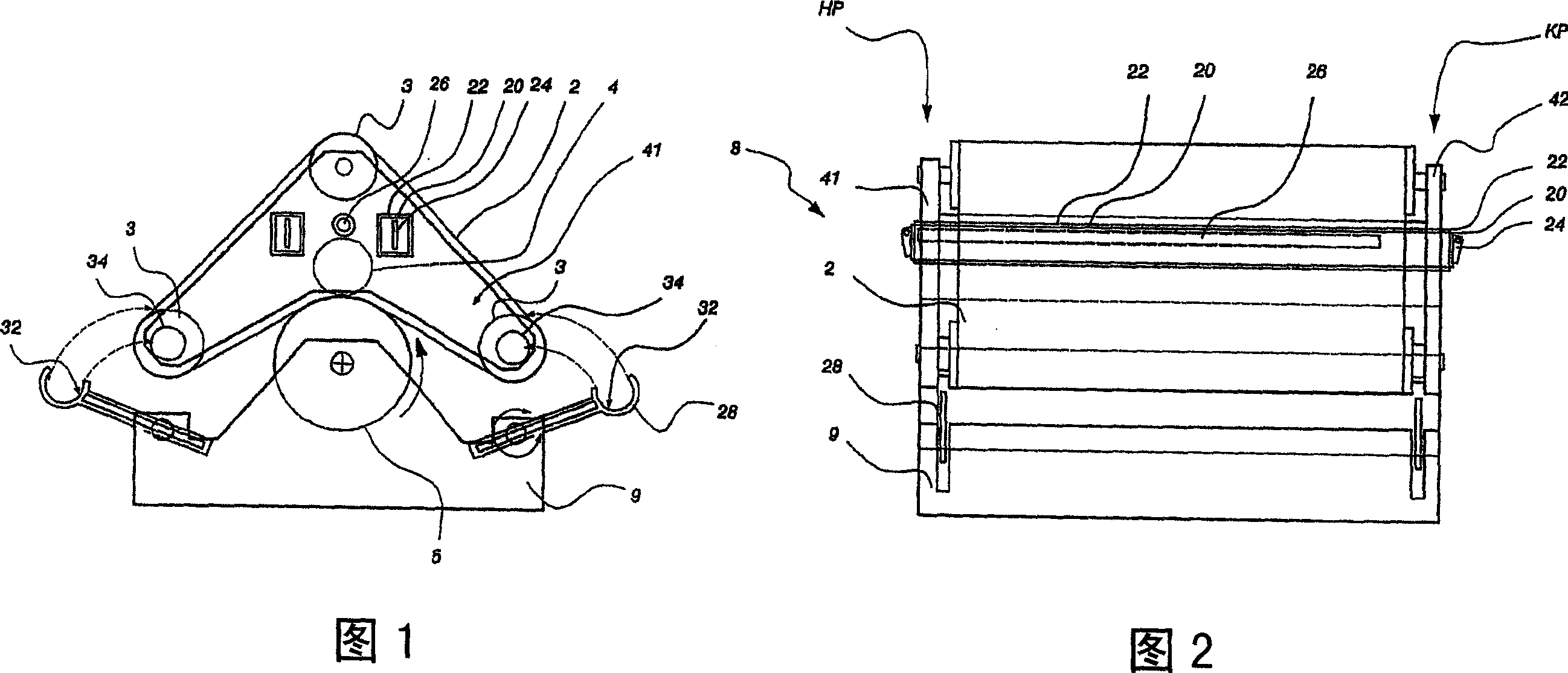

[0020] Figure 1 shows a mechanical structure formed by a closed tire ring. In this case, the belt calender comprises a calender belt 2 running around a main control roller 3 which is used to adjust the pressure of the belt 2 or / and the length of the treatment zone when it 3 At least some of them can be moved. The calender belt 2 follows the ring of the installed roller shaft 5 and travels outside the roller shaft 5 , and then an adjustable calendering area is formed between the belt belt 2 and the roller shaft 5 in the longitudinal direction. The dotted line in the figure shows that the nip roller 4 as a pressing mechanism may press the roller 5 against the belt 2 to form a strong pressure in the calendering zone of the nip area. The roller shaft 4 as the pressing mechanism can be of other shapes or a shrinking and pressing structure with a fixed shape. In addition, this pressing and pressing mechanism can be composed of more continuous parts in the transverse direction of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com